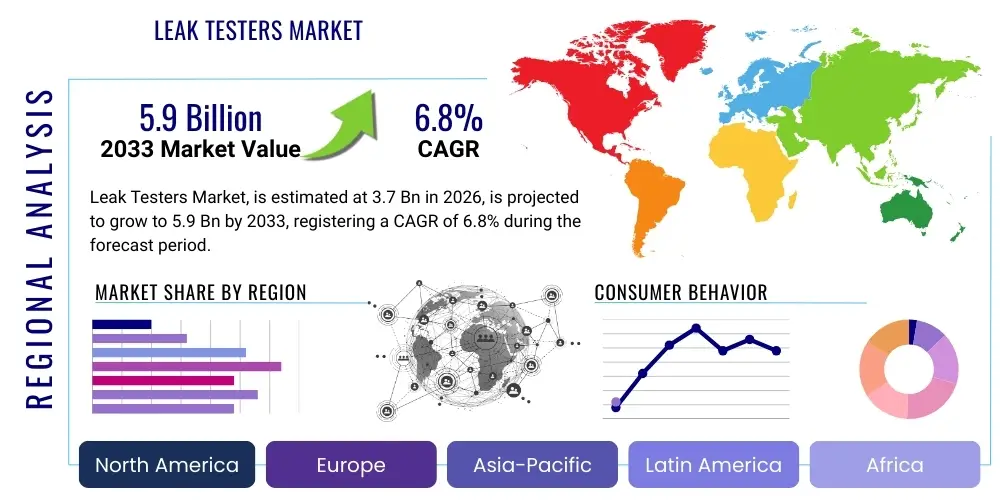

Leak Testers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440685 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Leak Testers Market Size

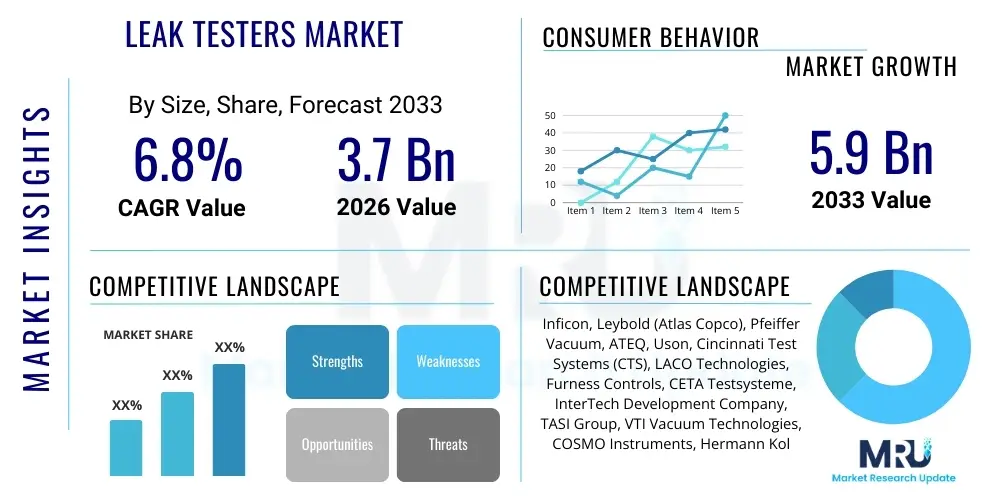

The Leak Testers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.7 billion in 2026 and is projected to reach USD 5.9 billion by the end of the forecast period in 2033.

Leak Testers Market introduction

The Leak Testers Market encompasses a diverse range of instruments and systems designed to detect and quantify the escape of gases or liquids from sealed components, assemblies, or systems. These sophisticated devices are critical for ensuring product quality, operational safety, and adherence to stringent regulatory standards across a multitude of industries. From the smallest medical implants to large industrial pipelines, preventing leaks is paramount to avoiding costly failures, environmental damage, and safety hazards, making leak testers indispensable tools in modern manufacturing and maintenance. The fundamental principle behind these testers involves creating a pressure differential or using tracer gases to identify breaches in containment, leveraging various physical phenomena to provide precise and repeatable measurements.

Products within this market range from manual bubble immersion tests and simple pressure decay units to highly automated mass spectrometer-based systems and advanced ultrasonic detectors. Each type of leak tester is optimized for specific applications based on sensitivity requirements, throughput demands, and the nature of the product being tested. Major applications span critical sectors such as automotive manufacturing for fuel systems and airbags, medical device production for sterile packaging and drug delivery systems, HVAC-R for refrigerant containment, aerospace for structural integrity, and industrial manufacturing for a vast array of components from valves to consumer electronics. The increasing complexity of modern products and the demand for enhanced reliability necessitate increasingly sophisticated and precise leak detection solutions.

The benefits derived from employing advanced leak testing solutions are substantial, including significant improvements in product quality and reliability, enhanced operational safety, and compliance with national and international standards. Furthermore, effective leak testing contributes to reduced warranty claims, lower production costs by minimizing rework and scrap, and improved environmental stewardship by preventing the escape of harmful substances. Key driving factors propelling this market forward include the ever-tightening regulatory landscape mandating zero-defect production, the relentless pursuit of quality excellence in competitive industries, the burgeoning demand for automation in manufacturing processes to boost efficiency, and the continuous expansion of end-user industries such as electric vehicles, advanced medical devices, and sophisticated consumer electronics, all of which require meticulous leak integrity verification.

Leak Testers Market Executive Summary

The Leak Testers Market is currently experiencing robust growth, driven by an confluence of evolving business trends, significant regional expansion, and dynamic segment shifts. A prominent business trend is the accelerating adoption of automation and integration with Industry 4.0 paradigms, leading to smart, connected leak testing systems that offer enhanced precision, speed, and data analytics capabilities. Manufacturers are increasingly seeking solutions that can seamlessly integrate into automated production lines, provide real-time monitoring, and offer predictive maintenance insights. Furthermore, the push towards non-destructive testing (NDT) methodologies is gaining traction, minimizing material waste and ensuring product integrity without compromising components, which is a critical consideration in high-value manufacturing sectors. The miniaturization of components across industries, particularly in electronics and medical devices, also necessitates more sensitive and specialized leak testing equipment, driving innovation in detector technology.

Regional trends indicate that the Asia Pacific (APAC) region is emerging as the fastest-growing market for leak testers, primarily fueled by rapid industrialization, the proliferation of manufacturing hubs, and increasing investments in automotive, electronics, and medical device production in countries like China, India, Japan, and South Korea. This growth is further supported by the rising emphasis on quality control and the adoption of international manufacturing standards. North America and Europe, while more mature markets, continue to demonstrate steady growth, propelled by stringent regulatory frameworks, high demand for advanced and highly accurate leak testing solutions, and continuous technological advancements in aerospace, automotive, and healthcare sectors. These regions are often at the forefront of adopting innovative technologies such as AI-driven analysis and advanced robotics in leak detection systems.

From a segmentation perspective, the market is witnessing significant shifts. The automatic leak testers segment is projected to experience the highest growth rate, reflecting the industry's pervasive move towards fully automated manufacturing processes to achieve higher throughput and reduced human error. Among the various technologies, mass spectrometer leak detectors are expected to maintain a leading position due to their unparalleled sensitivity and accuracy, particularly for demanding applications in aerospace and semiconductor manufacturing. However, pressure decay and vacuum decay methods remain widely used for their cost-effectiveness and versatility in various industrial settings. The automotive and medical device industries consistently represent the largest end-user segments, with increasing regulatory pressures and the criticality of leak-free components driving sustained demand. Furthermore, the demand for after-sales services, including calibration, maintenance, and training, is also growing, indicating a shift towards comprehensive solution offerings by market players.

AI Impact Analysis on Leak Testers Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Leak Testers Market predominantly revolve around themes of enhanced precision, automation capabilities, predictive maintenance, and data analysis. Users are keen to understand how AI can reduce human error in the testing process, improve the accuracy and speed of leak detection, and ultimately contribute to higher quality control standards. There is a strong interest in AI's potential to interpret complex sensor data, identify subtle leak patterns that might be missed by traditional methods, and learn from historical data to optimize testing parameters. Furthermore, the integration of AI with existing leak testing infrastructure, the costs associated with implementing AI solutions, and the necessary skill sets for operating these advanced systems are recurring concerns among industry professionals. Expectations include AI leading to more efficient, reliable, and cost-effective leak testing operations.

AI's transformative potential in the leak testers market extends beyond mere automation; it promises a paradigm shift in how leaks are detected, analyzed, and mitigated. By leveraging machine learning algorithms, leak testing systems can process vast amounts of data from various sensors—pressure, flow, acoustic, thermal, and visual—to identify anomalies and patterns indicative of leaks with unprecedented accuracy. This capability allows for the detection of micro-leaks or intermittent leaks that are challenging for conventional systems, ensuring a higher standard of product integrity. AI can also adapt to variations in testing conditions or product specifications, providing a more robust and flexible testing environment. The ability to perform real-time diagnostics and even self-correct minor operational issues further enhances the reliability and uptime of leak testing equipment.

The strategic deployment of AI in leak detection facilitates a move from reactive problem-solving to proactive quality assurance. Predictive analytics, powered by AI, can forecast potential equipment malfunctions or performance degradation, enabling preventative maintenance before costly failures occur. This not only minimizes downtime but also extends the lifespan of expensive testing equipment. Moreover, AI-driven data analysis tools can correlate leak test results with upstream manufacturing processes, identifying root causes of defects and enabling continuous process improvement. This holistic approach to quality control, from initial design to final inspection, is crucial for industries striving for zero-defect manufacturing. The integration of AI also supports the development of more intuitive user interfaces, simplifying complex operations and reducing the need for extensive operator training, thereby making advanced leak testing more accessible to a broader range of manufacturers.

- Enhanced accuracy and sensitivity in detecting micro-leaks through pattern recognition.

- Predictive maintenance capabilities for leak testing equipment, reducing downtime.

- Real-time data analysis and interpretation for immediate feedback and process optimization.

- Automated decision-making and self-calibration for improved efficiency and reduced human intervention.

- Root cause analysis of leaks by correlating test data with production parameters.

- Optimization of testing parameters and protocols based on learned historical data.

- Integration with broader Industry 4.0 ecosystems for seamless data flow and control.

- Reduction in false positives and negatives, leading to more reliable quality assurance.

DRO & Impact Forces Of Leak Testers Market

The Leak Testers Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and various impact forces that collectively shape its trajectory. Key drivers include the escalating global demand for high-quality, defect-free products across industries, stringent regulatory mandates regarding safety and environmental protection, and the increasing adoption of automation in manufacturing processes aimed at improving efficiency and reducing labor costs. The rapid expansion of industries such as electric vehicles, advanced medical devices, and consumer electronics, all of which require meticulous leak integrity verification, further propels market growth. Continuous technological advancements, leading to more sensitive, faster, and integrated leak testing solutions, also serve as a significant catalyst, enabling manufacturers to meet evolving quality standards and production demands.

Despite these powerful drivers, the market faces several notable restraints. The high initial capital investment required for advanced leak testing equipment, particularly for automated and high-precision systems like mass spectrometers, can be a significant barrier for small and medium-sized enterprises (SMEs). The complexity associated with operating and maintaining sophisticated leak testing systems often necessitates specialized technical expertise, leading to a shortage of skilled labor capable of maximizing equipment potential. Furthermore, the market's fragmentation, with numerous players offering a variety of technologies, can sometimes lead to confusion for end-users in selecting the most appropriate solution, potentially slowing adoption rates. The ongoing need for calibration and regular maintenance to ensure accuracy also adds to the total cost of ownership, presenting another challenge for widespread implementation.

Opportunities for growth are abundant, particularly in emerging markets where industrialization is accelerating and quality standards are progressively tightening, creating new demand for leak testing solutions. The increasing trend towards customization and specialized solutions tailored to unique product geometries and material properties offers manufacturers a competitive edge. Integration with cutting-edge technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and advanced robotics presents avenues for developing intelligent, predictive, and fully autonomous leak testing systems. Furthermore, the burgeoning growth in advanced manufacturing sectors, such as additive manufacturing (3D printing), which often produces parts with intricate internal geometries requiring specialized leak detection, opens up entirely new application areas. The expansion of after-sales services, including comprehensive training, technical support, and calibration services, also represents a significant opportunity for market players to build stronger customer relationships and recurring revenue streams.

Segmentation Analysis

The Leak Testers Market is meticulously segmented across various parameters to provide a comprehensive understanding of its structure and dynamics. These segmentations allow for a granular analysis of market trends, identifying areas of growth and specific demands from different industries and applications. Understanding these segments is crucial for market players to develop targeted strategies, innovate effectively, and cater to the diverse needs of end-users. The market is typically analyzed by factors such as technology type, automation level, end-user industry, and component, each revealing distinct market behaviors and growth opportunities. This detailed breakdown ensures that market participants can strategically position their products and services to address specific niche requirements while also capitalizing on broader industry trends.

- By Technology

- Mass Spectrometer Leak Detectors

- Pressure Decay Leak Testers

- Vacuum Decay Leak Testers

- Bubble Leak Testers

- Ultrasonic Leak Detectors

- Tracer Gas Leak Detectors (Helium, Hydrogen)

- Thermal Conductivity Leak Detectors

- Electrical Conductivity Leak Detectors

- By Automation Level

- Manual Leak Testers

- Semi-Automatic Leak Testers

- Automatic Leak Testers

- By End-User Industry

- Automotive

- Medical & Pharmaceutical

- HVAC & Refrigeration

- Industrial Manufacturing

- Packaging

- Aerospace & Defense

- Electronics & Semiconductor

- Oil & Gas

- Research & Development

- By Component

- Systems/Equipment

- Services (Maintenance, Calibration, Installation, Training)

- By Application

- Component Testing

- System Testing

- Package Testing

Value Chain Analysis For Leak Testers Market

The value chain for the Leak Testers Market is a complex ecosystem involving multiple stages, from raw material sourcing to final deployment and after-sales support, each contributing significantly to the overall value proposition. Upstream analysis reveals a critical dependency on suppliers of high-precision components such as sensors, vacuum pumps, valves, electronic control units, and specialized materials like high-grade stainless steel for chambers. These suppliers form the foundational layer, providing the core elements that determine the accuracy, reliability, and longevity of leak testing equipment. Innovation at this stage, particularly in sensor technology and pump efficiency, directly impacts the performance capabilities of the final product. Manufacturers often engage in strategic partnerships with these component suppliers to ensure quality, supply chain stability, and access to the latest technological advancements, thereby optimizing the initial stages of production and maintaining a competitive edge in a demanding market.

Further along the value chain, the manufacturing and assembly of leak testing systems involve integrating these diverse components into functional units. This stage includes sophisticated engineering, software development for control and data analysis, and rigorous quality control processes to ensure the testers meet specified performance criteria and regulatory standards. Once manufactured, these systems reach the downstream segment through various distribution channels. System integrators play a crucial role, particularly for complex, custom-built automated solutions, as they combine leak testers with other manufacturing equipment to create complete production lines. Service providers, offering installation, calibration, maintenance, and training, are also vital, ensuring the optimal operation and longevity of the equipment throughout its lifecycle. This downstream support is increasingly valued by end-users seeking comprehensive solutions and minimal downtime.

Distribution channels in the Leak Testers Market are varied, encompassing both direct and indirect approaches. Direct sales are common for large-scale enterprises or specialized applications where manufacturers engage directly with end-users to provide tailored solutions, often involving extensive consultation, customization, and long-term support contracts. This approach allows for closer customer relationships and a deeper understanding of specific client needs. Indirect channels involve a network of distributors, resellers, and regional agents who serve smaller businesses, penetrate diverse geographical markets, and provide localized sales and support. Online platforms are also gaining traction, especially for standard product lines and replacement parts, offering convenience and broader reach. The effectiveness of these distribution strategies is paramount for market penetration, customer acquisition, and ensuring prompt delivery and reliable post-sales assistance, all of which contribute to the overall perceived value and market position of a leak tester manufacturer.

Leak Testers Market Potential Customers

Potential customers for leak testing equipment span a vast and diverse range of industries, all united by the critical need to ensure product integrity, operational safety, and compliance with stringent quality and environmental standards. At the forefront are manufacturers in the automotive sector, which rely heavily on leak testers for components such as fuel tanks, engines, transmissions, airbags, and increasingly, battery packs for electric vehicles. The integrity of these components is non-negotiable for vehicle safety and performance. Similarly, the medical and pharmaceutical industries are significant consumers, requiring ultra-precise leak detection for sterile packaging, drug delivery systems, catheters, syringes, and implantable devices where even a microscopic leak can have life-threatening consequences or compromise drug efficacy. These sectors demand the highest levels of accuracy and validation, often driving innovation in leak testing technology.

Beyond automotive and medical, the HVAC and refrigeration industry is a substantial end-user, utilizing leak testers to prevent the escape of refrigerants from air conditioning units, heat pumps, and chillers, which is crucial for energy efficiency and environmental protection dueating to strict F-gas regulations. Industrial manufacturing, a broad category, encompasses a multitude of applications from testing valves, pumps, and pipe fittings in process industries to ensuring the integrity of consumer electronics, white goods, and power tools. Packaging companies also form a key customer segment, using leak testers to verify the seal integrity of food, beverage, and other consumer product packaging, which directly impacts shelf life, quality, and consumer safety. The aerospace and defense sector requires exceptionally robust and sensitive leak testing for aircraft components, hydraulic systems, fuel lines, and space vehicle modules, where reliability is paramount.

Furthermore, the electronics and semiconductor industry relies on advanced leak testing to protect sensitive components from moisture and contaminants, ensuring the longevity and performance of integrated circuits and electronic assemblies. Research and development institutions across various scientific and engineering disciplines also utilize leak testers for experimental setups, vacuum systems, and material characterization. The oil and gas sector employs specialized leak detection for pipelines, storage tanks, and drilling equipment to prevent hazardous leaks and minimize environmental impact. Essentially, any industry where containment of gases or liquids is essential, or where the ingress of external elements can compromise product performance, represents a potential customer for leak testing solutions. The increasing complexity of modern products, coupled with rising consumer expectations for quality and safety, continues to expand the base of potential buyers for this critical technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.7 billion |

| Market Forecast in 2033 | USD 5.9 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Inficon, Leybold (Atlas Copco), Pfeiffer Vacuum, ATEQ, Uson, Cincinnati Test Systems (CTS), LACO Technologies, Furness Controls, CETA Testsysteme, InterTech Development Company, TASI Group, VTI Vacuum Technologies, COSMO Instruments, Hermann Kolb GmbH, Team Corporation, Anritsu Industrial Solutions, Nolek, Sika AG, MOCON, Qualitek. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Leak Testers Market Key Technology Landscape

The Leak Testers Market is characterized by a dynamic and evolving technology landscape, continuously driven by the demand for higher sensitivity, faster testing cycles, and greater automation. One of the most advanced technologies is mass spectrometry, particularly helium mass spectrometry, which offers unparalleled sensitivity for detecting extremely small leaks (down to 10^-12 mbar l/s). This method is widely used in critical applications such as semiconductor manufacturing, aerospace components, and ultra-high vacuum systems where even minute leaks are unacceptable. Tracer gas methods, employing helium or hydrogen, are gaining traction due to their accuracy and environmental friendliness, with hydrogen being particularly appealing for non-toxic and cost-effective detection in automotive and industrial settings. These technologies often integrate sophisticated vacuum systems, high-speed pumps, and precise gas handling units to achieve their remarkable detection capabilities.

Complementing these high-end solutions are more conventional yet highly effective techniques like pressure decay and vacuum decay testing. These methods operate on the principle of measuring pressure changes within a sealed component over a specific period. While generally less sensitive than mass spectrometry, they are highly versatile, cost-effective, and suitable for a wide range of industrial applications, including automotive parts, medical devices, and packaging. Advancements in sensor technology, digital signal processing, and control algorithms have significantly enhanced the precision and reliability of these decay-based testers, allowing them to detect smaller leaks and provide more repeatable results. Many modern pressure and vacuum decay systems incorporate advanced software for data logging, statistical process control, and easy integration into factory automation systems, enhancing their utility in high-volume production environments.

Beyond these primary methods, other technologies continue to hold significant relevance and are undergoing continuous innovation. Ultrasonic leak detectors, for instance, identify leaks by sensing the ultrasonic sound waves generated by escaping gas, making them ideal for quick identification of larger leaks in pressurized systems like air lines and pipelines, particularly in noisy industrial environments. Bubble testing, a traditional method, remains valuable for its simplicity and visual verification, often used for quality checks on sealed packages or components submerged in water. Emerging technologies and advancements focus on non-destructive testing (NDT) with enhanced capabilities, such as thermal imaging for temperature-differential leaks, electrical conductivity for membrane integrity, and even optical methods for micro-leak detection. The overarching trend is towards integrating these diverse technologies with IoT connectivity, artificial intelligence for data analysis and predictive maintenance, and robotic automation to create smart, fully autonomous leak testing stations that can adapt to varying production requirements and deliver comprehensive quality assurance.

Regional Highlights

North America stands as a significant market for leak testers, driven by robust manufacturing sectors, stringent regulatory frameworks, and a strong emphasis on quality control and safety standards. The region, particularly the United States and Canada, boasts a mature industrial landscape with a high concentration of automotive, aerospace, medical device, and electronics manufacturers. These industries are early adopters of advanced leak testing technologies, investing heavily in automated and high-precision systems to meet rigorous product quality specifications and regulatory compliance. The demand for sophisticated leak detection solutions is further fueled by continuous innovation in these sectors, such as the growth of electric vehicle manufacturing and the development of next-generation medical implants, both requiring meticulous leak integrity verification. Furthermore, a strong research and development ecosystem fosters technological advancements, keeping North America at the forefront of leak tester innovation.

The regulatory environment in North America, with bodies like the EPA and FDA, enforces strict standards for emissions, product safety, and sterile packaging, creating a consistent demand for reliable leak testing. This regulatory pressure encourages manufacturers to upgrade their existing equipment and invest in newer, more sensitive technologies to avoid costly recalls, penalties, and reputational damage. The presence of leading global leak tester manufacturers and their extensive distribution networks also contributes to the market's strength in the region. Additionally, the increasing trend towards industrial automation and the adoption of Industry 4.0 principles across various manufacturing processes are propelling the demand for integrated, smart leak testing solutions that can seamlessly communicate with broader production systems, offering real-time data and predictive maintenance capabilities. This focus on efficiency and data-driven decision-making further cements North America's position as a key market.

Europe represents another critical market for leak testers, characterized by a highly advanced industrial base, stringent environmental regulations, and a strong focus on high-value manufacturing across sectors like automotive, medical, and aerospace. Countries such as Germany, Italy, France, and the UK are global leaders in precision engineering and high-quality production, necessitating advanced leak detection solutions. The European Union's comprehensive directives, including those related to F-gas regulations for refrigerants and various CE marking requirements for product safety, create a strong imperative for manufacturers to implement robust leak testing protocols. This regulatory landscape not only drives demand but also encourages innovation in environmentally friendly and highly efficient leak detection technologies, such as those utilizing hydrogen as a tracer gas.

The automotive industry in Europe, particularly with the transition towards electric vehicles and hydrogen fuel cell technology, is a primary driver for the leak testers market. The complex battery systems, cooling circuits, and fuel cells in these new vehicles require extremely precise and reliable leak testing. Similarly, Europe's strong medical device manufacturing sector, known for its high standards and innovation, demands the most sensitive leak detection for critical devices and sterile packaging. The emphasis on automation and integrated manufacturing solutions is also prominent in Europe, with companies actively seeking leak testing systems that can be seamlessly incorporated into automated production lines, contributing to higher throughput and reduced human error. The region also benefits from a well-established network of specialized engineering firms and research institutions that contribute to ongoing technological advancements in leak detection.

Asia Pacific (APAC) is projected to be the fastest-growing market for leak testers, propelled by rapid industrialization, massive investments in manufacturing, and increasing adoption of advanced quality control measures across its diverse economies. Countries like China, India, Japan, South Korea, and Southeast Asian nations are transforming into global manufacturing hubs for automotive components, consumer electronics, medical devices, and industrial machinery. This expansive manufacturing base generates immense demand for leak testing equipment to ensure product quality and meet international export standards. The sheer volume of production in these countries necessitates high-speed, automated leak testing solutions that can keep pace with rapid production cycles while maintaining precision and reliability.

The rising middle class and increasing disposable incomes across APAC are driving demand for higher quality consumer goods, pushing local manufacturers to elevate their production standards, including implementing more rigorous leak detection. Furthermore, foreign direct investment in manufacturing facilities within the region often brings with it the adoption of international best practices and advanced technologies, including sophisticated leak testers. Governments in several APAC countries are also enacting stricter environmental regulations and product safety standards, further stimulating the market for compliant leak testing solutions. While cost-effectiveness remains a consideration, there is a growing appreciation for the long-term benefits of investing in accurate and efficient leak detection, such as reduced waste, fewer warranty claims, and enhanced brand reputation, collectively positioning APAC as a powerhouse for market expansion.

Latin America represents an emerging market for leak testers, driven by ongoing industrialization, infrastructure development, and increasing foreign investment in various manufacturing sectors. Countries such as Brazil, Mexico, and Argentina are witnessing growth in automotive production, appliance manufacturing, and food and beverage processing, all of which require reliable leak detection. The demand for leak testing solutions is primarily influenced by the need to ensure product quality for both domestic consumption and export, as well as by the adoption of international manufacturing standards. While the market is not as mature as North America or Europe, there is a steady trajectory of growth as local industries modernize their production lines and prioritize quality assurance, particularly in sectors that have significant export potential.

The market in Latin America is characterized by a growing awareness among manufacturers about the importance of leak testing to prevent costly defects and enhance operational safety. Investment in new manufacturing facilities and the expansion of existing ones contribute to the rising demand for leak testing equipment. Challenges include economic volatility in some countries and the initial cost barrier for advanced systems, which often leads to a preference for more cost-effective and versatile solutions like pressure decay testers. However, as the region's industrial base continues to evolve and integrate into global supply chains, the demand for more sophisticated and automated leak detection systems is expected to accelerate. Furthermore, regulatory alignment with international quality and safety standards is gradually strengthening, providing additional impetus for market growth.

Middle East and Africa (MEA) is another developing market for leak testers, experiencing growth primarily due to significant investments in infrastructure, oil and gas, and manufacturing diversification initiatives. The oil and gas sector in the Middle East, with its extensive network of pipelines, storage facilities, and processing plants, generates substantial demand for specialized leak detection solutions to ensure operational safety, prevent environmental contamination, and comply with stringent industry regulations. Countries like Saudi Arabia, UAE, and Qatar are continuously investing in modernizing their energy infrastructure, driving the need for reliable leak testing equipment. In Africa, industrialization efforts, particularly in sectors like automotive assembly, food processing, and consumer goods manufacturing in countries like South Africa and Nigeria, are gradually expanding the customer base for leak testers.

The region's growth is also influenced by increasing urbanization and a rising focus on building quality infrastructure, including HVAC systems and water distribution networks, which require leak-free components. While the market is still in its nascent stages compared to other regions, the emphasis on industrial safety and environmental protection is growing, albeit at varying paces across different countries. Challenges include a relatively smaller manufacturing base outside of specific sectors and the dependence on imported technologies and expertise. However, as governments continue to pursue economic diversification strategies and attract foreign investment into manufacturing, the demand for leak testing solutions is anticipated to increase, particularly for versatile and robust systems that can operate effectively in challenging industrial environments. The need for efficient resource management and adherence to international quality benchmarks will further stimulate market development in MEA.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Leak Testers Market.- Inficon

- Leybold (Atlas Copco)

- Pfeiffer Vacuum

- ATEQ

- Uson

- Cincinnati Test Systems (CTS)

- LACO Technologies

- Furness Controls

- CETA Testsysteme

- InterTech Development Company

- TASI Group

- VTI Vacuum Technologies

- COSMO Instruments

- Hermann Kolb GmbH

- Team Corporation

- Anritsu Industrial Solutions

- Nolek

- Sika AG

- MOCON

- Qualitek

Frequently Asked Questions

What is a leak tester and why is it important?

A leak tester is an instrument or system used to detect and quantify the escape of gases or liquids from a sealed component or system. It is critical for ensuring product quality, operational safety, environmental protection, and compliance with industry regulations across diverse manufacturing sectors. Without effective leak testing, products could fail prematurely, pose safety risks, or lead to significant financial losses and environmental damage.

What are the primary types of leak testing technologies?

The primary types of leak testing technologies include mass spectrometer leak detectors (e.g., helium leak testing for high sensitivity), pressure decay and vacuum decay testers (measuring pressure changes in a sealed component), bubble leak testers (visual detection in water), and ultrasonic leak detectors (sensing sound waves from escaping gas). Tracer gas methods, using helium or hydrogen, are also prominent for their accuracy and versatility.

Which industries extensively use leak testers?

Leak testers are extensively used across a wide array of industries, including automotive (fuel systems, airbags, EV batteries), medical and pharmaceutical (sterile packaging, drug delivery devices), HVAC and refrigeration (refrigerant containment), aerospace and defense (aircraft components, hydraulic systems), industrial manufacturing (valves, pumps, electronics), and packaging (food, beverage, consumer goods). Any industry requiring sealed components or systems for safety, quality, or performance relies on leak testing.

How is Artificial Intelligence (AI) impacting the Leak Testers Market?

AI is significantly impacting the Leak Testers Market by enhancing accuracy, automating processes, and improving data analysis. AI-driven systems can detect micro-leaks more precisely by identifying subtle patterns in sensor data, offer predictive maintenance for equipment, and optimize testing parameters in real-time. This leads to reduced human error, increased efficiency, and a more proactive approach to quality control, integrating seamlessly with Industry 4.0 initiatives for smarter manufacturing.

What are the key drivers and restraints for the Leak Testers Market?

Key drivers include stringent regulatory compliance, increasing demand for high-quality and defect-free products, the growing adoption of automation in manufacturing, and expansion in end-user industries like electric vehicles and advanced medical devices. Restraints often involve the high initial investment cost of advanced systems, the complexity requiring specialized skills, and market fragmentation which can make technology selection challenging for some enterprises.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Leak Testers Market Size Report By Type (Portable Leak Tester, Compact Leak Tester, Stationary Leak Tester), By Application (Industrial, Automotive, Medical, HVAC/R, Laboratories, Energy), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Leak Testers Market Statistics 2025 Analysis By Application (Industrial, Automotive, Medical, HVAC/R, Laboratories, Energy), By Type (Portable Leak Tester, Compact Leak Tester, Stationary Leak Tester), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager