LED Mounter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439883 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

LED Mounter Market Size

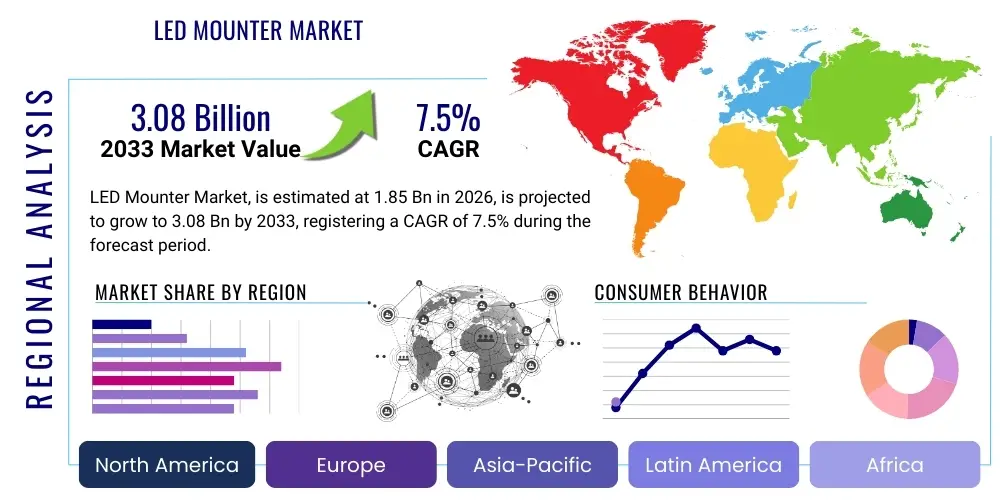

The LED Mounter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.08 Billion by the end of the forecast period in 2033. This growth trajectory is underpinned by the escalating global demand for advanced LED technologies across diverse applications, alongside continuous innovations in manufacturing automation and precision engineering. The increasing penetration of LEDs in lighting, display, and automotive sectors significantly contributes to this expansion, requiring sophisticated placement solutions capable of handling high volumes and intricate component designs.

LED Mounter Market introduction

The LED Mounter Market encompasses the sophisticated machinery essential for the precise placement of Light Emitting Diodes (LEDs) and other surface-mount components onto printed circuit boards (PCBs) during the manufacturing process. These high-precision, automated pick-and-place machines are fundamental to Surface Mount Technology (SMT) lines, designed specifically to handle the delicate and often miniaturized nature of LEDs with extreme accuracy and speed. Key applications span a vast array of industries including general illumination, automotive lighting, large-format displays, consumer electronics, and specialized industrial equipment, where reliable and efficient LED integration is paramount.

The primary benefit of advanced LED mounters lies in their ability to significantly enhance production efficiency, ensure consistent product quality, and enable the manufacturing of increasingly complex LED modules. They facilitate the high-volume assembly required by global markets while minimizing defects through advanced vision systems and robotic control. Driving factors for this market's expansion include the widespread global adoption of energy-efficient LED lighting solutions, the burgeoning demand for high-resolution LED displays across various consumer and commercial applications, and the relentless trend towards miniaturization in electronic devices. Furthermore, the integration of smart technologies and automation within manufacturing facilities continues to propel the demand for more intelligent and flexible LED mounter systems capable of adapting to diverse production requirements and intricate designs.

LED Mounter Market Executive Summary

The LED Mounter Market is currently experiencing robust growth, driven by dynamic business trends centered on automation and precision manufacturing. Key business trends indicate a strong shift towards intelligent automation solutions, integrating advanced robotics, real-time data analytics, and machine learning to optimize placement accuracy and throughput while reducing operational costs. Manufacturers are increasingly focused on developing highly flexible and scalable mounters that can adapt to rapid changes in product designs and production volumes, particularly with the rise of custom LED solutions and diverse component sizes, from standard SMD LEDs to emerging MicroLEDs and MiniLEDs. The industry is also witnessing an emphasis on sustainable manufacturing practices, influencing the design of more energy-efficient and material-optimized mounter systems, aligning with global environmental objectives and corporate social responsibility initiatives. Furthermore, the push for Industry 4.0 integration is transforming production lines into interconnected smart factories, where LED mounters play a critical role in data exchange and predictive maintenance cycles, thereby maximizing uptime and overall equipment effectiveness.

Regional trends highlight Asia Pacific as the undisputed powerhouse for LED mounter consumption and production, primarily due to the concentration of major electronics manufacturing hubs in countries like China, South Korea, Japan, and Taiwan. This region continues to dominate through substantial investments in advanced manufacturing infrastructure and a vast network of OEM and EMS providers. Europe and North America also exhibit significant growth, primarily driven by demand for high-end automotive lighting, specialized industrial applications, and advanced display technologies, alongside a strong focus on research and development for next-generation LED assembly processes. These regions are characterized by a preference for mounters incorporating cutting-edge vision systems, sophisticated software, and robust after-sales support. Emerging markets in Latin America, the Middle East, and Africa are showing nascent but accelerating demand, spurred by industrialization, urbanization, and increasing local production capabilities for consumer electronics and basic LED lighting, presenting new opportunities for market expansion and localized technological adoption strategies.

Segment trends within the LED Mounter Market showcase particular strength in high-speed mounters and multi-functional mounters, reflecting the industry's dual need for rapid, efficient mass production and versatile handling of diverse component types and sizes. High-speed mounters cater to the enormous volumes required for general LED lighting and consumer electronics, prioritizing throughput and accuracy at scale. Multi-functional mounters, on the other hand, offer greater flexibility, capable of placing a wider range of components including irregularly shaped LEDs, larger drivers, and passive components, making them ideal for specialized applications like automotive modules and complex display backlighting where precision and versatility are paramount. The increasing complexity of LED packages, including Chip-on-Board (COB) and Flip-Chip technologies, is also driving demand for specialized mounters with advanced bonding capabilities and highly precise placement mechanisms. Moreover, the evolution towards MicroLED and MiniLED technologies necessitates ultra-high precision and placement speed, pushing the boundaries of existing mounter capabilities and spurring innovation in fine-pitch assembly and micro-component handling, thus influencing the development of future market segments.

AI Impact Analysis on LED Mounter Market

Users frequently inquire about how Artificial Intelligence (AI) will revolutionize the LED Mounter Market, focusing on aspects such as enhancing precision, optimizing operational efficiency, facilitating predictive maintenance, and automating quality control processes. Key concerns revolve around the integration challenges, data security, and the potential impact on workforce skills, while expectations center on significantly improved throughput, reduced waste, and the ability to handle increasingly complex and miniaturized LED components with unprecedented accuracy. The discourse often highlights AI's role in driving smart manufacturing initiatives, enabling real-time decision-making, and fostering a more adaptive and resilient production environment.

- AI-driven vision systems significantly enhance placement accuracy and defect detection for even the smallest LED components, surpassing human capabilities in speed and consistency.

- Predictive maintenance algorithms powered by AI analyze real-time operational data from mounters to forecast potential equipment failures, dramatically reducing downtime and extending machine lifespan.

- Machine learning optimizes production parameters, such as nozzle pressure, placement speed, and component feeder rates, leading to higher yield, reduced material waste, and improved overall equipment effectiveness (OEE).

- Automated optical inspection (AOI) systems integrated with AI can identify microscopic defects and misalignments in LED arrays with greater precision and speed than traditional methods, ensuring superior product quality.

- AI-enabled scheduling and resource allocation systems can dynamically adjust production plans based on real-time demand, material availability, and machine performance, optimizing throughput and reducing lead times.

- Generative AI tools could potentially assist in designing optimal placement patterns and assembly sequences for new LED module layouts, shortening product development cycles.

DRO & Impact Forces Of LED Mounter Market

The LED Mounter Market is profoundly shaped by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating global adoption of energy-efficient LED lighting across residential, commercial, and industrial sectors, alongside the burgeoning demand for sophisticated LED displays in consumer electronics, automotive applications, and signage. The continuous miniaturization of electronic components necessitates highly precise and efficient placement machinery, further bolstering market growth. However, this growth is partially restrained by the significant initial capital investment required for advanced LED mounters, which can be prohibitive for smaller manufacturers. The rapid pace of technological advancements also presents a challenge, as equipment can quickly become technologically obsolete, requiring ongoing investment in upgrades or new machines. Furthermore, the scarcity of highly skilled operators and maintenance technicians capable of handling these complex systems poses a significant operational hurdle.

Opportunities for market expansion are abundant, particularly with the emergence of next-generation LED technologies such as MicroLED and MiniLED, which demand even greater precision and novel assembly techniques, opening avenues for innovation in mounter design. The pervasive trend towards Industry 4.0 and smart factory integration creates opportunities for mounters equipped with advanced IoT capabilities, AI-driven optimization, and seamless connectivity within a larger manufacturing ecosystem. Additionally, the growing demand for customizable and highly specialized LED solutions across various niche markets, including medical devices and advanced sensor technology, provides fertile ground for manufacturers offering flexible and adaptable mounter platforms. The expansion into developing economies, spurred by increasing urbanization and industrialization, also presents new markets for both advanced and cost-effective LED mounter solutions. Impact forces, such as global economic stability, trade policies, and environmental regulations promoting energy efficiency, significantly influence market dynamics. Technological breakthroughs in robotics, machine vision, and material science continually reshape the competitive landscape, while geopolitical shifts and supply chain vulnerabilities necessitate robust and adaptable manufacturing strategies from market participants. Ultimately, the market's trajectory will be determined by its capacity to innovate in response to evolving technological demands and to overcome economic and operational challenges.

Segmentation Analysis

The LED Mounter Market is comprehensively segmented to provide a detailed understanding of its diverse landscape and to identify key areas of growth and opportunity. These segmentations typically categorize the market based on the type of mounter, its application across various industries, the end-user profile, and the level of automation offered. This granular analysis allows stakeholders to discern specific market dynamics, competitive intensities, and technological requirements pertinent to each segment, thereby aiding in strategic planning and product development. Understanding these distinct segments is crucial for manufacturers to tailor their offerings, for investors to identify promising ventures, and for end-users to select optimal equipment that aligns with their specific production needs and operational scales.

- By Type:

- High-Speed Mounters: Designed for rapid placement of small and medium-sized components, prioritizing throughput.

- Multi-functional Mounters: Offer versatility in handling a wide range of component sizes and types, including odd-shaped LEDs and larger packages.

- Chip Mounters: Specialized for very small chip-scale components, often with higher precision and lower placement forces.

- By Application:

- General Lighting: Production of LED bulbs, tubes, panels, and fixtures for residential, commercial, and industrial uses.

- Backlighting: Manufacturing of LED modules for LCD TVs, monitors, and other display devices.

- Automotive Lighting: Assembly of LED headlamps, taillights, interior lights, and dashboard displays for vehicles.

- LED Displays: Production of large-format LED screens for signage, billboards, and video walls.

- Consumer Electronics: Integration of LEDs into smartphones, tablets, wearables, and home appliances.

- Other Applications: Includes medical devices, industrial sensors, and specialized optical systems.

- By End-User:

- Original Equipment Manufacturers (OEMs): Companies that design and manufacture their own LED products.

- Electronics Manufacturing Services (EMS) Providers: Contract manufacturers that provide assembly services for multiple clients.

- By Automation Level:

- Fully Automatic Mounters: Requiring minimal human intervention, these systems offer high throughput and consistent quality.

- Semi-Automatic Mounters: Combining automated processes with manual loading or setup, suitable for lower volume or specialized production.

Value Chain Analysis For LED Mounter Market

The value chain for the LED Mounter Market is an intricate ecosystem involving multiple stages, from raw material suppliers to the final end-users of LED assembly. Upstream activities include the provision of highly specialized components and sub-systems necessary for mounter manufacturing. This encompasses suppliers of precision robotics, advanced vision systems like CCD cameras and 3D inspection modules, sophisticated motion control systems, highly durable nozzles and feeders, and the development of specialized software for programming, optimization, and fault detection. These upstream providers are critical in determining the performance, accuracy, and reliability of the final LED mounter equipment, constantly pushing the boundaries of technological innovation to meet evolving industry demands for speed and precision.

Midstream in the value chain are the LED mounter manufacturers themselves, who integrate these advanced components into complete, functional machines. They focus on engineering, assembly, quality control, and testing of the mounters, often developing proprietary technologies for enhanced performance and user experience. Downstream activities involve the distribution, sales, installation, and after-sales service of these sophisticated machines to end-users. The distribution channel typically involves a mix of direct sales forces for large enterprise clients and a network of specialized distributors or system integrators who provide local support, customization, and integration services. Direct sales allow manufacturers to maintain close relationships with key customers, providing tailored solutions and immediate feedback for product development. Indirect channels, through distributors, expand market reach, especially in geographically diverse or emerging markets, offering local expertise and support crucial for complex industrial machinery. Both channels play a vital role in ensuring that the advanced capabilities of LED mounters are effectively delivered and maintained throughout their operational lifecycle within various manufacturing environments globally.

LED Mounter Market Potential Customers

The potential customers for LED mounters represent a broad spectrum of industries deeply invested in the production and integration of LED technology. These end-users are primarily manufacturers who require high-precision, efficient, and reliable machinery to assemble their LED-based products. A significant segment comprises LED lighting manufacturers, ranging from large-scale enterprises producing millions of bulbs and fixtures to specialized companies creating bespoke architectural or industrial lighting solutions. Their demand is driven by the global transition to energy-efficient illumination and the constant evolution of lighting design. Similarly, manufacturers of LED display panels, for applications spanning from consumer electronics like televisions and smartphones to large commercial billboards and digital signage, form a crucial customer base, requiring mounters capable of ultra-fine pitch placement for high-resolution displays.

Beyond traditional lighting and display, the automotive industry stands as a burgeoning customer segment. Automotive electronics suppliers and car manufacturers increasingly integrate LEDs into headlamps, taillights, interior lighting, and sophisticated dashboard displays, demanding mounters that meet stringent reliability and quality standards. The broader consumer electronics sector, including producers of wearables, home appliances, and computing devices, also represents a substantial market for LED mounters as LEDs become ubiquitous in status indicators, backlights, and aesthetic elements. Furthermore, electronics manufacturing services (EMS) providers and original design manufacturers (ODM) constitute a significant portion of the customer base, as they serve multiple clients across various industries, necessitating versatile and robust LED mounters capable of handling diverse production requirements. These customers prioritize equipment that offers high throughput, exceptional accuracy, flexibility for multiple product lines, and strong after-sales support to maintain continuous and efficient operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.08 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fuji Corporation, ASM Pacific Technology Ltd. (ASMPT), Mycronic AB, Yamaha Motor Co., Ltd., Panasonic Corporation, JUKI Corporation, Kulicke & Soffa Industries, Inc., Hanwha Precision Machinery Co., Ltd., Universal Instruments Corporation, Nordson Corporation, PVA TePla AG, Saki Corporation, Viscom AG, Koh Young Technology Inc., MIRTEC Co., Ltd., Yestech, Test Research, Inc. (TRI), CyberOptics Corporation, DEK, BTU International |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

LED Mounter Market Key Technology Landscape

The LED Mounter Market is characterized by a rapidly evolving technological landscape, driven by the continuous demand for increased precision, speed, and efficiency in LED assembly processes. At the core of these advanced machines are sophisticated vision systems, typically employing high-resolution CCD cameras and advanced 3D inspection technology, which enable precise component recognition, alignment, and defect detection before and after placement. These vision systems are critical for handling the increasingly miniaturized and complex LED packages. Robotic arms, often operating with multiple gantries, provide the high-speed, multi-axis movement necessary for rapid pick-and-place operations, while precision feeders ensure accurate and reliable component delivery from tape-and-reel or tray formats to the placement head. These mechanical innovations are complemented by cutting-edge software solutions that manage everything from programming and optimization of placement routines to real-time process monitoring and data analytics.

Further technological advancements include the integration of artificial intelligence (AI) and machine learning (ML) algorithms, which are revolutionizing mounter capabilities by enabling predictive maintenance, self-optimization of placement parameters, and enhanced automated optical inspection (AOI). Laser alignment systems offer unparalleled accuracy for fine-pitch component placement, particularly crucial for MicroLED and MiniLED applications. Advanced nozzle designs, often made from specialized materials, are continuously being developed to handle a wider array of component sizes and shapes with minimal risk of damage. Furthermore, the adoption of Industry 4.0 principles is driving the incorporation of IoT connectivity, allowing mounters to communicate seamlessly within a smart factory ecosystem for improved overall equipment effectiveness (OEE) and integrated production planning. Thermal management features, critical for certain types of LED assembly, are also seeing innovation to ensure component integrity during the placement and reflow processes. These combined technological thrusts are not only enhancing the current generation of LED mounters but are also paving the way for future systems capable of assembling even more advanced and integrated LED solutions with unprecedented levels of precision and automation.

Regional Highlights

- Asia Pacific (APAC): This region dominates the LED Mounter Market, driven by its extensive electronics manufacturing industry, particularly in countries like China, South Korea, Japan, and Taiwan. APAC benefits from robust government support for manufacturing, a vast supply chain ecosystem, and a massive domestic market for LED-based products. The continuous investment in smart factory initiatives and advanced production technologies further solidifies its position as both the largest producer and consumer of LED mounters globally.

- North America: Characterized by significant investments in research and development, North America is a key region for innovation in LED mounter technology. Demand is driven by specialized applications in automotive lighting, high-end display technologies, and aerospace, requiring mounters with high precision and flexibility. The region also emphasizes automation and integration with Industry 4.0 principles, focusing on efficiency and quality control.

- Europe: Europe represents a mature market with a strong focus on high-quality, energy-efficient LED solutions for automotive, industrial, and architectural lighting. Countries like Germany, France, and the UK are prominent, driven by stringent quality standards and a demand for advanced, flexible mounter systems capable of handling diverse production needs. The region also exhibits a growing interest in sustainable manufacturing and automation technologies.

- Latin America: This region is an emerging market for LED mounters, experiencing growth fueled by increasing industrialization, urbanization, and a rising demand for consumer electronics. Countries such as Brazil and Mexico are leading the adoption, as local manufacturing capabilities expand. The market here is price-sensitive but increasingly seeking efficient and reliable automation solutions to enhance competitiveness.

- Middle East and Africa (MEA): The MEA region is witnessing gradual but steady growth, primarily driven by infrastructure development projects, increasing adoption of LED lighting in smart city initiatives, and diversification of manufacturing sectors away from traditional industries. Demand for LED mounters is concentrated in countries like the UAE, Saudi Arabia, and South Africa, as they invest in modernizing their industrial base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the LED Mounter Market.- Fuji Corporation

- ASM Pacific Technology Ltd. (ASMPT)

- Mycronic AB

- Yamaha Motor Co., Ltd.

- Panasonic Corporation

- JUKI Corporation

- Kulicke & Soffa Industries, Inc.

- Hanwha Precision Machinery Co., Ltd.

- Universal Instruments Corporation

- Nordson Corporation

- PVA TePla AG

- Saki Corporation

- Viscom AG

- Koh Young Technology Inc.

- MIRTEC Co., Ltd.

- Yestech

- Test Research, Inc. (TRI)

- CyberOptics Corporation

- DEK (part of ASM Pacific Technology Ltd.)

- BTU International (part of Amtech Group)

Frequently Asked Questions

Analyze common user questions about the LED Mounter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an LED mounter and why is it crucial for manufacturing?

An LED mounter is a high-precision robotic machine used in Surface Mount Technology (SMT) to accurately pick and place Light Emitting Diodes (LEDs) and other electronic components onto printed circuit boards (PCBs). It is crucial because it ensures the high-speed, accurate, and consistent assembly required for mass production of LED-based products, driving efficiency and quality in modern electronics manufacturing.

What are the primary applications driving the demand for LED mounters?

The primary applications driving demand include general LED lighting (bulbs, panels), backlighting for displays (TVs, monitors), automotive lighting (headlamps, interior lights), large-format LED displays (billboards, signage), and consumer electronics (smartphones, wearables). The widespread adoption of LEDs across these sectors necessitates advanced mounter technology.

How is Artificial Intelligence (AI) transforming the LED Mounter Market?

AI is transforming the market by enhancing vision systems for superior placement accuracy and defect detection, enabling predictive maintenance for reduced downtime, optimizing production parameters for higher yield, and automating quality control processes. This leads to increased efficiency, improved product quality, and more intelligent, self-optimizing manufacturing lines.

What are the key growth drivers and restraints impacting the LED Mounter Market?

Key growth drivers include the increasing global adoption of energy-efficient LED lighting, the proliferation of LED displays, and the continuous miniaturization of electronic components. Restraints often involve the high initial capital investment for advanced machinery, the rapid pace of technological obsolescence, and the shortage of skilled technical personnel required to operate and maintain these complex systems.

Which regions are leading in LED mounter adoption and technological innovation?

The Asia Pacific region, particularly China, South Korea, and Japan, leads significantly in LED mounter adoption due to its extensive electronics manufacturing base and supply chain. North America and Europe are key regions for technological innovation and high-precision applications, focusing on advanced R&D and integrating Industry 4.0 principles into their manufacturing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager