Lens Edger System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440584 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Lens Edger System Market Size

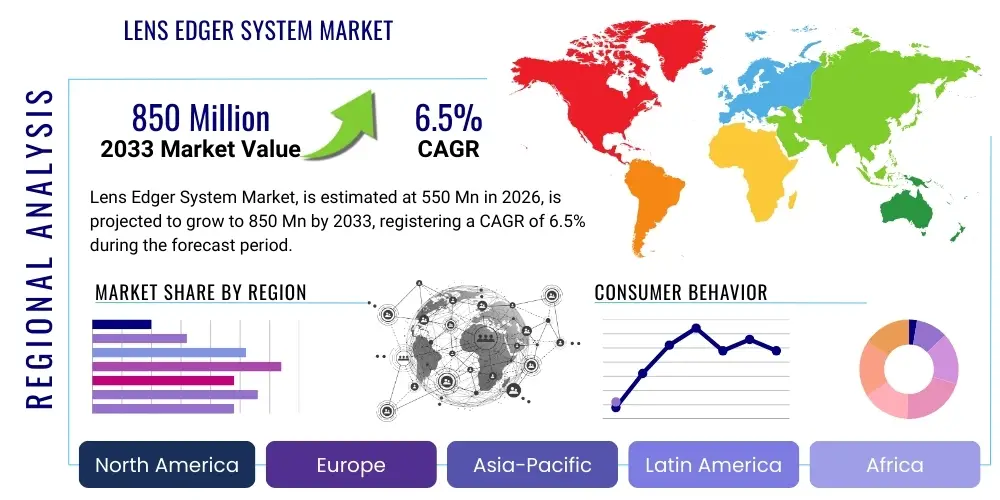

The Lens Edger System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 850 Million by the end of the forecast period in 2033.

Lens Edger System Market introduction

A lens edger system stands as a cornerstone technology within the ophthalmic industry, serving the critical function of precisely shaping, grinding, and finishing spectacle lenses to integrate flawlessly into diverse eyewear frames. These advanced machines are indispensable for optometrists, opticians, and optical laboratories, enabling them to transform raw lens blanks into custom-fitted lenses that meet exact prescription specifications and aesthetic requirements. The operational scope of modern lens edgers extends beyond simple cutting, encompassing sophisticated tasks such as intricate beveling for full-rim frames, grooving for rimless designs, drilling for specialized mountings, and highly precise polishing to achieve an impeccable edge finish. This evolution from manual to fully automated, digitally controlled systems reflects the industry's continuous pursuit of accuracy, efficiency, and the ability to process an ever-widening array of lens materials, from standard plastics to high-index, polycarbonate, and Trivex lenses, each demanding specific processing parameters.

The global market for lens edger systems is propelled by several robust macroeconomic and technological drivers. Foremost among these is the escalating prevalence of vision correction needs worldwide, significantly driven by an aging global population that is increasingly susceptible to conditions such as presbyopia, cataracts, and glaucoma. This demographic shift inherently leads to a sustained demand for multifocal, progressive, and specialized corrective lenses, necessitating advanced edging capabilities. Furthermore, rising disposable incomes in emerging economies contribute to increased spending on premium and designer eyewear, which often requires highly precise and customizable lens finishing. Technological innovations, including the advent of sophisticated 3D edging, seamless integration with practice management software, and the incorporation of artificial intelligence for enhanced automation and quality control, are pivotal in fostering market expansion. These innovations allow optical professionals to offer faster turnaround times, superior product quality, and a broader range of customized eyewear solutions, cementing the indispensable role of lens edger systems in the contemporary optical ecosystem and supporting the industry's shift towards digital fabrication and personalized patient care.

Lens Edger System Market Executive Summary

The Lens Edger System market is undergoing a significant transformation, characterized by an accelerated pace of technological integration and an evolving competitive landscape. Key business trends highlight a decisive pivot towards fully automated and networked edging solutions, which are designed to reduce human error, optimize throughput, and significantly enhance the precision required for complex lens designs such, as freeform and progressive lenses. There is a growing emphasis among manufacturers to develop user-friendly interfaces, incorporate remote diagnostic capabilities, and ensure seamless connectivity with various practice management and enterprise resource planning (ERP) systems. This focus on digital integration and operational efficiency is critical for optical laboratories and retail chains striving to maintain high service standards and cost-effectiveness in a rapidly changing consumer market. The strategic partnerships between edger manufacturers and lens material providers are also becoming more prevalent, aimed at developing integrated solutions that optimize the processing of new and specialized lens substrates, further enhancing market dynamism.

From a regional perspective, the market presents a varied growth outlook. North America and Europe, despite being mature markets, continue to represent substantial revenue bases, primarily driven by the consistent need for equipment upgrades, high consumer expectations for advanced eyewear, and robust healthcare infrastructure supporting comprehensive eye care. These regions are early adopters of innovative technologies, including AI-driven edgers and fully automated laboratory setups. Conversely, the Asia Pacific (APAC) region is projected to experience the most vigorous growth over the forecast period. This surge is attributed to a confluence of factors, including rapid urbanization, increasing per capita disposable income, a burgeoning middle class, and significant investments in expanding healthcare and optical retail networks. Within market segments, automatic lens edgers are expected to maintain their dominance, driven by their inherent advantages in precision, speed, and capability to handle a diverse range of lens materials and complex geometries. The demand for 3D edging technology is also on a steep upward trajectory, reflecting the growing consumer preference for customized and aesthetically integrated eyewear solutions that traditional 2D edgers cannot adequately address.

AI Impact Analysis on Lens Edger System Market

The advent of Artificial Intelligence (AI) is ushering in a transformative era for the Lens Edger System market, addressing long-standing user demands for unprecedented precision, operational efficiency, and enhanced predictive capabilities. Users are increasingly seeking AI-driven solutions that can autonomously analyze intricate lens parameters, frame geometries, and patient-specific data to optimize the edging process, thereby minimizing material waste and ensuring a perfect fit with minimal manual intervention. The integration of machine learning algorithms is anticipated to significantly reduce the learning curve for technicians, while simultaneously elevating the consistency and quality of finished lenses, particularly for complex prescriptions and advanced lens designs. Expectations are high for AI to not only automate routine tasks but also to unlock new dimensions of personalization in eyewear manufacturing, making custom lens production more accessible and error-proof, ultimately leading to superior visual outcomes and enhanced patient satisfaction.

A significant area of user interest and concern revolves around the potential for AI to introduce predictive maintenance capabilities, which could revolutionize equipment management by forecasting potential failures before they occur, thereby maximizing uptime and extending the operational lifespan of expensive edger systems. Furthermore, users are exploring how AI-powered vision systems can perform real-time quality control checks, instantly detecting minute imperfections or deviations from specifications that human inspection might miss, thus ensuring an exceptionally high standard of product delivery. While concerns about the initial investment cost and the necessity for robust cybersecurity measures for data protection are valid, the overwhelming consensus points towards AI as a pivotal technology that will not only streamline current workflows but also fundamentally redefine the capabilities of lens edger systems. The market is keenly watching for AI solutions that offer seamless integration with existing digital ophthalmic ecosystems, providing comprehensive data analytics for continuous process improvement and facilitating a more interconnected and intelligent optical laboratory environment.

- Enhanced Precision and Accuracy: AI algorithms, leveraging advanced computer vision and machine learning, can analyze complex lens data, frame geometries, and material properties in real-time to optimize grinding paths and bevel placement, significantly reducing measurement errors and ensuring a flawless fit and finish.

- Predictive Maintenance and Optimized Uptime: AI systems continuously monitor the operational parameters of lens edgers, identifying subtle patterns indicative of wear or potential component failure. This enables proactive maintenance scheduling, minimizes unexpected downtime, and extends the lifespan of the equipment, thereby reducing long-term operational costs.

- Automated Quality Control and Defect Detection: AI-powered imaging systems can perform instant, high-resolution scans of edged lenses, automatically detecting microscopic defects, scratches, or deviations from specified dimensions with a consistency and speed impossible for human inspectors, ensuring superior product quality.

- Personalized Lens Design and Customization: By processing vast amounts of patient data, frame styles, and optical preferences, AI can intelligently recommend and execute highly customized lens designs, including intricate bevels and drilling patterns, catering to individual aesthetic and functional requirements beyond standard options.

- Material Optimization and Waste Reduction: AI algorithms can optimize cutting strategies to maximize the use of expensive lens blanks, minimizing material wastage during the edging process. This leads to significant cost savings for optical laboratories and contributes to more sustainable manufacturing practices.

- Streamlined Workflow Integration and Efficiency: AI-driven edgers can seamlessly communicate with other digital laboratory equipment, practice management software, and remote ordering platforms. This creates a fully integrated and automated workflow, reducing manual data entry, improving throughput, and accelerating order fulfillment.

- Operator Assistance and Training: AI can provide intelligent guidance and troubleshooting support to technicians, offering real-time feedback and step-by-step instructions. This simplifies operator training, enhances operational consistency, and enables staff to quickly adapt to new machine functionalities and complex lens types.

DRO & Impact Forces Of Lens Edger System Market

The Lens Edger System market is shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, which collectively constitute the overarching impact forces influencing its growth trajectory. A primary driver is the accelerating global prevalence of various vision impairments, notably presbyopia, myopia, and astigmatism, which are exacerbated by an increasingly aging global population and lifestyle changes involving prolonged screen time. This demographic trend directly translates into a sustained and expanding demand for corrective eyewear, thereby necessitating more efficient and precise lens edging solutions. Concurrently, rapid technological advancements, including the widespread adoption of 3D edging, sophisticated CAD/CAM integration, and the incorporation of artificial intelligence, are significantly pushing the market forward by offering unparalleled accuracy, enhanced automation, and the capacity to process an ever-broader spectrum of complex lens materials and designs. The growing consumer demand for personalized, aesthetically pleasing, and high-performance eyewear also serves as a strong impetus, driving the need for edgers capable of highly customized finishing.

Despite these powerful drivers, the market faces several notable restraints. The substantial initial capital investment required for acquiring advanced automatic lens edger systems poses a significant barrier to entry and upgrade, particularly for smaller independent optical practices and laboratories in emerging markets. This investment extends beyond the machinery itself to include associated software licenses, specialized operator training, and ongoing maintenance costs, which can deter adoption. Furthermore, the increasing complexity of modern edger systems necessitates a highly skilled workforce for both operation and maintenance; a shortage of such qualified technicians can impede efficient workflow and the full utilization of technological capabilities. The intensifying competition from online eyewear retailers, which often offer more standardized and cost-effective lens solutions without the immediate need for in-house custom edging, also presents a competitive pressure. These factors necessitate continuous innovation from manufacturers and strategic differentiation to emphasize the unique value proposition of precision-edged, customized lenses.

Opportunities within the Lens Edger System market are substantial and diverse. The burgeoning optical markets in developing regions, particularly across Asia Pacific and Latin America, present vast untapped potential as economic growth and increasing healthcare awareness drive demand for modern eye care services and quality eyewear. Moreover, the growing trend towards customization and personalization in consumer goods extends to eyewear, creating a strong opportunity for edgers that can deliver unique lens shapes, specialized bevels, and intricate finishes tailored to individual preferences and frame designs. The ongoing integration of smart technologies, such as IoT for remote monitoring and diagnostics, and AI for predictive analytics, offers avenues for enhancing operational efficiency, reducing maintenance costs, and improving overall laboratory throughput. Furthermore, the development of eco-friendly edging processes and materials presents an opportunity for manufacturers to align with global sustainability trends and appeal to environmentally conscious consumers, further broadening market appeal and fostering long-term growth.

Segmentation Analysis

The Lens Edger System market is comprehensively segmented to provide a detailed understanding of its varied operational landscapes and distinct technological applications. This granular segmentation facilitates a precise analysis of market trends, consumer preferences, and technological adoption rates across different categories, offering invaluable insights for strategic decision-making. By dissecting the market along dimensions such as product type, operational modality, end-user base, and underlying technology, stakeholders can identify specific niches, assess competitive dynamics, and project future growth trajectories with greater accuracy. Each segment represents unique characteristics, catering to different scales of operation, budget constraints, and technical requirements within the expansive ophthalmic industry, thereby contributing to a holistic view of market composition and potential areas for innovation and expansion.

- By Product Type:

- Automatic Lens Edgers: These systems offer high-volume processing with minimal human intervention, ideal for large optical labs and busy retail chains due to their speed, precision, and consistency.

- Semi-Automatic Lens Edgers: Providing a balance between automation and manual control, these are suitable for medium-sized optical shops seeking efficiency gains without the full investment of automatic systems, allowing for some manual adjustments.

- Manual Lens Edgers: Characterized by operator-intensive processes, these are typically found in smaller practices or for specialized repair work where volume is low and a high degree of manual control over the grinding process is desired.

- By Modality:

- Bench-top Systems: Compact and space-saving, these edgers are designed to fit on a countertop, making them suitable for smaller optical shops and clinics with limited space.

- Stand-alone Systems: Larger and more robust, these edgers are typically floor-standing units, offering higher processing capacities and more advanced features, ideal for large-scale ophthalmic laboratories.

- By End-User:

- Optical Shops & Retail Chains: The primary end-users, requiring edgers that can handle a diverse range of prescriptions and provide quick turnaround times for customer satisfaction.

- Ophthalmic Clinics & Hospitals: Utilize edgers for in-house lens processing, often for specialized medical needs, ensuring timely provision of corrective eyewear to patients.

- Large Ophthalmic Laboratories: Centralized facilities that process high volumes of lenses for multiple retail outlets, demanding fully automated, high-throughput, and networked edging solutions.

- Research & Academic Institutions: Employ edger systems for experimental purposes, material testing, and training future optical professionals, valuing versatility and precision for scientific applications.

- By Technology:

- 2D Edgers: Traditional systems that process lenses based on two-dimensional frame outlines, suitable for standard lens shapes.

- 3D Edgers: Advanced systems capable of processing lenses with complex curvatures and precise bevels to perfectly match three-dimensional frame designs, crucial for modern, aesthetic eyewear.

- CAD/CAM Integrated Systems: Edgers that seamlessly link with Computer-Aided Design and Manufacturing software, enabling digital design of lens shapes and automated, high-precision manufacturing processes.

Value Chain Analysis For Lens Edger System Market

The value chain for the Lens Edger System market commences with robust upstream activities, involving a complex network of raw material suppliers and component manufacturers. This foundational stage is critical for ensuring the quality, reliability, and technological sophistication of the final product. Key inputs include high-grade metals and alloys for machine chassis and moving parts, specialized abrasive materials (such as diamond wheels) essential for lens grinding, advanced electronic components for control boards and integrated sensors, and precision optics for measurement systems. Furthermore, a significant upstream contribution comes from software developers who create the intricate algorithms, user interfaces, and connectivity solutions that power modern, automated edger systems, integrating CAD/CAM functionalities and diagnostic capabilities. Strong supplier relationships and rigorous quality control at this stage are paramount to prevent defects and ensure the performance standards expected by the ophthalmic industry.

Moving through the midstream, the value chain encompasses the sophisticated processes of manufacturing, assembly, and quality assurance. Manufacturers of lens edger systems integrate the various components, from mechanical structures to electronic systems and software, to produce the final, fully functional machines. This often involves highly specialized engineering and assembly lines to ensure precision, durability, and compliance with stringent industry standards. Post-production, these systems undergo rigorous testing and calibration to guarantee their accuracy and reliability before reaching the market. The downstream segment of the value chain is focused on market penetration, distribution, and critical post-sales support. This includes establishing effective distribution channels, which can range from direct sales forces for large ophthalmic laboratories and chains to specialized medical equipment distributors who provide local market access, technical expertise, and support for independent optical practices. The efficiency of these channels is crucial for timely delivery and installation.

Crucially, the downstream segment also encompasses comprehensive after-sales services, which are a cornerstone of customer satisfaction and long-term market presence. These services typically include machine installation, intensive operator training, ongoing technical support, preventative maintenance, and the supply of spare parts. The quality and responsiveness of these services significantly impact customer loyalty and can be a strong differentiator in a competitive market. Direct distribution channels allow manufacturers to maintain closer relationships with end-users, facilitating direct feedback and faster response times for technical issues, which can be critical for complex machinery. Indirect channels, through distributors, offer broader market reach, especially in geographically dispersed or emerging markets, leveraging the distributor's local knowledge and infrastructure. Both direct and indirect models are essential for a comprehensive market strategy, ensuring that lens edger systems are efficiently delivered, expertly supported, and continuously maintained throughout their operational lifecycle.

Lens Edger System Market Potential Customers

The potential customer base for Lens Edger Systems is highly diversified, reflecting the broad spectrum of entities involved in vision care and eyewear manufacturing, each with unique operational needs and investment capacities. At the forefront are independent optical shops and small-to-medium sized optometry practices. These businesses typically require versatile, user-friendly edgers that can handle a moderate volume of lens processing, offering both basic and advanced functions to cater to their local clientele, often prioritizing ease of use, compact design, and reliable after-sales support to minimize downtime. The ability to quickly produce customized lenses enhances their competitive edge against larger retail chains and online competitors, fostering strong customer relationships.

A significant segment of potential customers includes large optical retail chains and franchise operations. These entities demand high-throughput, fully automatic, and often networked edger systems capable of processing vast numbers of lenses daily across multiple locations. Their priorities typically revolve around maximizing efficiency, ensuring consistent quality across all branches, and seamless integration with centralized inventory management and ordering systems. For these high-volume operations, factors such as speed, minimal manual intervention, and robust connectivity for data exchange are paramount, alongside long-term reliability and scalability of the equipment. Investment in such advanced systems is often driven by a strategic imperative to reduce per-unit processing costs and accelerate order fulfillment.

Furthermore, ophthalmic clinics and hospitals with in-house optical laboratories represent another vital customer segment. These medical facilities often require edgers capable of handling specialized and therapeutic lenses for complex patient cases, including custom prosthetics, high-power prescriptions, or lenses for pediatric patients. For these settings, precision, reliability, and compliance with stringent healthcare regulations are non-negotiable. Finally, large-scale ophthalmic laboratories, which serve as central manufacturing hubs for numerous optical outlets and direct-to-consumer businesses, constitute a premium customer group. These labs demand industrial-grade, highly automated, and often robotic edger systems integrated into a comprehensive digital surfacing and finishing line. Their primary focus is on achieving maximum throughput, advanced material handling capabilities, sophisticated quality control features, and seamless data flow across the entire production process to optimize efficiency and maintain competitive pricing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 850 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Essilor Instruments, NIDEK CO., LTD., Topcon Corporation, MEI S.R.L., Fuji Giken Co., Ltd., WECO Vision Technology GmbH, Takubomatic Co., Ltd., Huvitz Corp, Satisloh AG, Briot International (Luneau Technology Group), A&R Optical Co., Inc., Visslo, Indo Lens Private Limited, OptiGroup, Gerber Coburn, DIA Optical Co., Ltd., Nakanishi Inc., Santinelli International, Visionix (part of Luneau Technology Group), OptoTech Optikmaschinen GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lens Edger System Market Key Technology Landscape

The Lens Edger System market is distinguished by a dynamic and continuously advancing technology landscape, where innovation is paramount to meeting the evolving demands for precision, efficiency, and versatility in ophthalmic lens processing. A foundational element of this landscape is the widespread adoption and sophistication of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) integration. This technology allows for the digital creation of complex lens shapes and frame geometries, which are then translated into precise machine instructions for the edger, ensuring unparalleled accuracy and consistency in the manufacturing process. CAD/CAM systems are critical for processing modern freeform lenses, intricate bevel designs, and complex drilling patterns required for fashion-forward and highly customized eyewear, effectively bridging the gap between digital design and physical fabrication with minimal human error and maximum reproducibility.

Further enhancing the technological capabilities are advanced optical measurement systems, including 3D scanning and sophisticated tracing technologies. These systems accurately capture the three-dimensional contours of both lenses and frames, providing critical data points that inform the edging process, ensuring a perfect fit and seamless integration of the lens into the chosen frame. This precision in measurement significantly reduces the likelihood of fitting errors and subsequent remakes, thereby saving time, materials, and improving customer satisfaction. Moreover, the increasing integration of artificial intelligence (AI) and machine learning (ML) algorithms is revolutionizing the edger market by enabling predictive analytics for maintenance, real-time quality control checks, and optimizing grinding parameters based on lens material and design complexity. AI-powered systems can learn from vast datasets to anticipate potential issues and fine-tune operations autonomously, leading to greater efficiency and consistent output quality.

The current technology landscape also emphasizes enhanced automation and connectivity through the Internet of Things (IoT). Fully automated lens loading and unloading mechanisms, often complemented by robotic arms for seamless transfer between processing stations, minimize manual intervention, drastically increase throughput, and ensure consistent quality in high-volume laboratory environments. IoT connectivity allows edger systems to be integrated into broader digital networks, facilitating remote diagnostics, real-time performance monitoring, and secure data exchange with other laboratory equipment and practice management software. This interconnectedness enables proactive maintenance scheduling, optimizes machine uptime, and provides valuable data analytics for continuous process improvement. Additionally, ongoing advancements in abrasive materials and polishing techniques contribute significantly, enabling the processing of an ever-wider variety of lens materials, from tough polycarbonate to brittle glass, while consistently achieving superior surface finishes and edge quality that meet the highest ophthalmic standards, continually pushing the boundaries of what is achievable in lens manufacturing.

Regional Highlights

- North America: This region represents a mature yet highly dynamic market, characterized by elevated adoption rates of cutting-edge ophthalmic technologies, substantial consumer demand for premium and customized eyewear solutions, and a robust investment landscape in healthcare infrastructure. The market here is consistently driven by an aging population requiring vision correction and a strong emphasis on integrating digital and automated solutions within optical practices and large laboratories. Replacement cycles for existing equipment also contribute significantly to market activity.

- Europe: The European market demonstrates steady growth, primarily fueled by its significant aging demographic, substantial healthcare expenditures, and a pronounced focus on technological innovation coupled with stringent quality standards. Key contributing countries like Germany, France, and the UK are at the forefront of adopting advanced automation, integrated digital workflows, and sophisticated edger systems to meet the demands of a discerning consumer base and evolving regulatory environments.

- Asia Pacific (APAC): Positioned as the fastest-growing market globally, APAC's expansion is underpinned by a rapidly burgeoning middle-class population, escalating disposable incomes, a heightened awareness regarding eye health, and considerable government and private sector investments in expanding healthcare and optical retail infrastructure. Countries such as China, India, and Japan are pivotal to this growth, experiencing rapid increases in both the volume of eye care services and the adoption of modern ophthalmic equipment.

- Latin America: This region stands out as an emerging market with considerable untapped potential, propelled by improving economic conditions, increased access to basic and advanced eye care services, and a rising prevalence of vision impairments across its diverse populations. Market expansion here is largely driven by the establishment of new optical practices, the modernization of existing clinics, and the growing consumer demand for affordable yet quality eyewear.

- Middle East and Africa (MEA): A developing market that holds promising growth prospects, particularly within the Gulf Cooperation Council (GCC) countries. Growth is stimulated by significant infrastructure development, increasing healthcare expenditures, and a growing expatriate population often associated with higher disposable incomes and a preference for advanced medical technologies. The adoption of modern ophthalmic equipment, including lens edger systems, is progressively increasing, though it originates from a comparatively smaller market base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lens Edger System Market.- Essilor Instruments

- NIDEK CO., LTD.

- Topcon Corporation

- MEI S.R.L.

- Fuji Giken Co., Ltd.

- WECO Vision Technology GmbH

- Takubomatic Co., Ltd.

- Huvitz Corp

- Satisloh AG

- Briot International (Luneau Technology Group)

- A&R Optical Co., Inc.

- Visslo

- Indo Lens Private Limited

- OptiGroup

- Gerber Coburn

- DIA Optical Co., Ltd.

- Nakanishi Inc.

- Santinelli International

- Visionix (part of Luneau Technology Group)

- OptoTech Optikmaschinen GmbH

Frequently Asked Questions

What is a lens edger system and how does it benefit modern optical practices?

A lens edger system is an advanced machine used to precisely shape, grind, and polish spectacle lenses to fit eyeglass frames according to prescription. It benefits modern optical practices by ensuring high accuracy and consistency in lens production, enabling customization for diverse frame styles, significantly increasing processing efficiency, and reducing the potential for manual errors, which collectively enhances customer satisfaction and turnaround times for eyewear delivery. Modern systems integrate digital technology to handle complex lens designs and materials.

What are the key technological advancements currently shaping the Lens Edger System market?

The market is predominantly shaped by the integration of 3D scanning and Computer-Aided Design/Manufacturing (CAD/CAM) for precise lens geometry matching, the increasing adoption of Artificial Intelligence (AI) for enhanced operational efficiency and predictive maintenance, and the development of fully automated, robotic systems that minimize human intervention. Additionally, advanced optical measurement capabilities and IoT connectivity for seamless digital workflow integration and remote diagnostics are critical technological drivers.

How does the global aging population influence the demand for lens edger systems?

The global aging population significantly influences demand by increasing the prevalence of age-related vision conditions, such as presbyopia and cataracts, which necessitate a higher volume of corrective lenses. This demographic trend directly translates into a greater need for efficient, precise, and technologically advanced lens edger systems within optical practices and laboratories to accommodate the growing and diverse requirements for eyeglasses.

What are the primary challenges hindering the growth of the Lens Edger System market?

Key challenges include the substantial initial capital investment required for purchasing advanced edger systems, which can be prohibitive for smaller businesses. The market also faces restraints from the need for highly skilled technicians to operate and maintain these sophisticated machines, alongside intense competitive pressure from online eyewear retailers offering more standardized and often lower-cost lens solutions that bypass traditional edging services.

Which geographical regions are anticipated to exhibit the most substantial growth in the Lens Edger System market?

The Asia Pacific (APAC) region is forecasted to demonstrate the most significant market growth. This is primarily attributed to a rapidly expanding middle-class population, rising disposable incomes, increasing awareness about eye health, and considerable investments in healthcare infrastructure across key countries such as China, India, and Japan, all contributing to a surge in demand for modern ophthalmic equipment and services.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager