Light Olefins Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431619 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Light Olefins Market Size

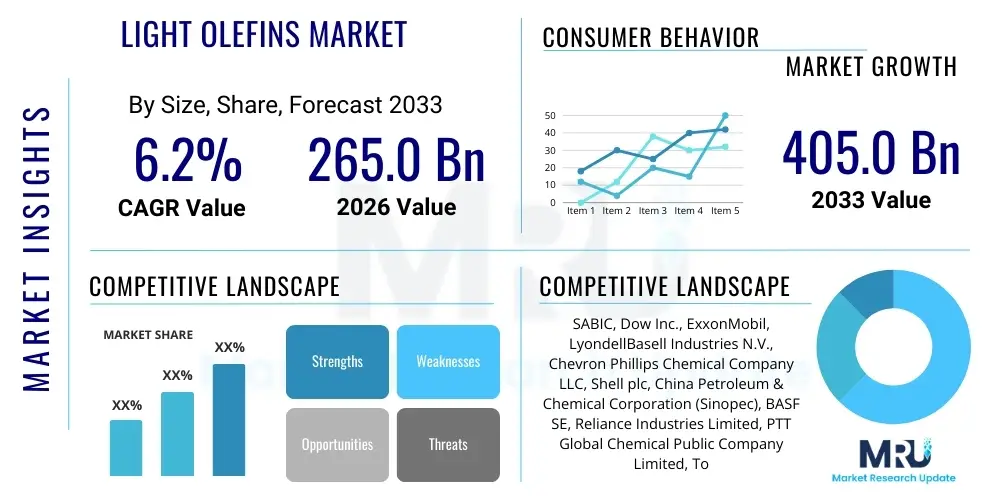

The Light Olefins Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 265.0 Billion in 2026 and is projected to reach USD 405.0 Billion by the end of the forecast period in 2033.

Light Olefins Market introduction

Light olefins, primarily encompassing ethylene, propylene, and butadiene, represent the foundational building blocks of the modern petrochemical and chemical industries. These unsaturated hydrocarbons are predominantly derived from steam cracking of hydrocarbon feedstocks such as naphtha, ethane, or propane, though alternative methods like Propane Dehydrogenation (PDH) and Methanol-to-Olefins (MTO) are gaining commercial traction. Ethylene and propylene, in particular, are indispensable precursors for producing a vast array of high-volume polymers, including polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), which are essential materials across packaging, construction, automotive, and textile sectors.

The market dynamics for light olefins are intrinsically linked to global industrialization, population growth, and the shift towards advanced material applications. The unparalleled versatility of these intermediates allows for the synthesis of countless derivative chemicals, ranging from solvents and adhesives to synthetic rubber and specialized fine chemicals. Furthermore, the increasing demand for high-performance plastics and lightweight materials in the electric vehicle (EV) sector and sustainable infrastructure projects continues to drive volume growth, particularly for high-density polyethylene and specialty propylene derivatives.

Key market drivers include the sustained expansion of downstream industries, particularly in Asia Pacific, coupled with the structural advantage provided by cheap and abundant shale gas-derived ethane and propane feedstocks in North America. The primary benefits of light olefins lie in their foundational role in creating durable, cost-effective, and scalable materials crucial for modern living, making this sector a barometer for global economic health and industrial output. However, the market faces challenges related to feedstock price volatility and the escalating pressure from environmental regulations regarding plastic waste.

Light Olefins Market Executive Summary

The Light Olefins Market is experiencing robust growth driven by significant capacity expansions, especially in ethane-rich regions like the U.S. Gulf Coast and the Middle East, alongside aggressive petrochemical infrastructure development across China and Southeast Asia. Business trends indicate a strong move towards diversification of feedstock sources, reducing reliance solely on naphtha cracking, evidenced by the proliferation of PDH and MTO plants globally to enhance propylene supply security and manage operational costs. Capacity utilization remains a critical factor, with temporary oversupply pressures occasionally impacting margins, though long-term demand fundamentals tied to plastic consumption remain exceptionally strong, suggesting a sustained upward trajectory through 2033.

Regional trends highlight Asia Pacific (APAC) as the epicenter of demand growth, fueled by rapid urbanization, massive investment in manufacturing, and rising disposable incomes driving consumer goods and packaging needs. North America maintains a competitive advantage in cost structure due to access to low-cost shale gas liquids, positioning it as a major global exporter of ethylene and propylene derivatives. Meanwhile, Europe is focusing heavily on sustainability, circular economy initiatives, and utilizing advanced recycling technologies, which is spurring innovation in bio-based and chemically recycled olefins, shaping a more segmented, value-driven market landscape in the West.

Segmentation trends reveal that ethylene remains the largest segment by volume, predominantly consumed in polyethylene production, while propylene is the fastest-growing segment, benefiting from increased use in advanced automotive components and high-value chemical intermediaries. The market structure is evolving towards greater integration, with major chemical producers investing heavily in integrated cracking and derivatives facilities to capture full value chain margins, minimizing exposure to price volatility in intermediate products. Sustainability and feedstock flexibility are becoming key competitive differentiators, influencing investment decisions across all major market participants.

AI Impact Analysis on Light Olefins Market

Common user questions regarding AI's impact on the Light Olefins Market frequently center on operational efficiency, optimization of complex production processes, and predictive market intelligence necessary for navigating feedstock volatility. Users are keenly interested in how Artificial Intelligence can minimize energy consumption in highly energy-intensive processes like steam cracking, a major operational concern. Key themes include the implementation of AI-driven control systems for real-time feedstock switching (e.g., maximizing profit based on instantaneous ethane vs. propane costs), enhancing catalyst performance prediction, and improving maintenance schedules through predictive analytics to avoid costly unplanned shutdowns. Furthermore, there is significant curiosity about how AI-powered supply chain algorithms can optimize logistics for high-volume movement of light olefin intermediates and finished polymer products across global trade routes, mitigating supply chain risks and improving reliability. The overriding expectation is that AI will be a critical tool for achieving significant cost savings and superior operational reliability in a highly competitive and capital-intensive industry.

- AI optimizes furnace temperature profiles and residence time in steam cracking, maximizing olefin yield and energy efficiency.

- Predictive maintenance schedules utilize machine learning models to analyze sensor data, anticipating equipment failure and preventing costly unscheduled downtime.

- Advanced process control (APC) systems, powered by AI, enable real-time adjustment of operational parameters based on dynamic feedstock prices and product demand forecasts.

- Machine learning algorithms enhance catalyst discovery and formulation, accelerating the development of more selective and efficient catalysts for MTO and PDH processes.

- AI-driven supply chain management improves logistics for feedstock procurement and derivative product distribution, balancing inventory levels and reducing transportation costs.

- Market forecasting tools leverage AI to analyze complex global macroeconomic indicators, providing producers with highly accurate predictions of future olefin demand and pricing trends.

DRO & Impact Forces Of Light Olefins Market

The Light Olefins Market is fundamentally shaped by several powerful drivers, chief among them the unrelenting global demand for polymers, especially in emerging economies, which necessitates continuous expansion of olefin production capacity. Simultaneously, the abundance of low-cost natural gas liquids (NGLs) derived from the shale revolution in North America provides a structural cost advantage for US-based producers, heavily influencing global trade flows and profitability across the value chain. However, this market is restrained by the inherent volatility of crude oil and natural gas prices, which directly impact feedstock costs (naphtha, ethane, propane), introducing significant margin uncertainty. Regulatory pressures concerning plastic waste management and emissions also present a restraint, compelling producers to invest heavily in sustainable practices and advanced recycling technologies.

Opportunities abound primarily in the realm of technological advancement and sustainable sourcing. The development and commercial scaling of technologies such as bio-based olefins production from renewable sources, and high-efficiency on-purpose propylene technologies (like advanced PDH), offer pathways to diversify the feedstock base and appeal to environmentally conscious downstream markets. Furthermore, significant opportunities exist in developing specialized, high-performance derivatives used in lightweight materials for electric vehicles and advanced infrastructure, providing higher margin avenues away from commoditized bulk polymers.

The impact forces operating on the light olefins market are multifaceted. Demand elasticity is high, strongly correlating with GDP growth and manufacturing output. Technological advancements exert a high impact, constantly lowering conversion costs and improving selectivity. Regulatory mandates regarding emissions and the circular economy represent a critical external force, pushing the industry towards closed-loop systems and alternative feedstock adoption. The interplay between low-cost NGL supply and burgeoning Asian demand acts as the primary gravitational force defining the current global petrochemical landscape, driving major capital expenditure decisions globally.

Segmentation Analysis

The Light Olefins Market is meticulously segmented based on product type, application, production process, and geography, reflecting the complex and interconnected nature of the petrochemical supply chain. The segmentation analysis provides granular insights into specific market dynamics, revealing where the fastest growth areas lie and how technological shifts, such as the adoption of MTO and PDH, are altering the traditional dominance of steam cracking. Understanding these segments is crucial for strategic planning, resource allocation, and identifying lucrative niche markets within the broader olefins ecosystem.

- By Product Type:

- Ethylene

- Propylene

- Butadiene

- Isobutylene

- Others (e.g., butene, pentenes)

- By Application:

- Polymers (Polyethylene, Polypropylene, Polyvinyl Chloride, Polystyrene, Polybutadiene)

- Chemical Intermediates (Ethylene Oxide, Propylene Oxide, Vinyl Acetate Monomer, Acrylonitrile)

- Solvents

- Antifreeze and Coolants

- Others (e.g., Synthetic Rubber, Detergents)

- By Production Process:

- Steam Cracking (Naphtha, Ethane, Propane, Butane)

- Propane Dehydrogenation (PDH)

- Methanol-to-Olefins (MTO) / Methanol-to-Propylene (MTP)

- Fluid Catalytic Cracking (FCC) Off-gas

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Light Olefins Market

The Light Olefins value chain begins with the upstream segment, which involves the exploration, extraction, and processing of primary hydrocarbon feedstocks, predominantly crude oil (yielding naphtha) and natural gas (yielding ethane and propane). The security of feedstock supply and volatility in commodity prices at this stage directly dictates the cost structure for downstream producers. Key players in the upstream sector include major integrated oil and gas companies and national oil companies. Ensuring a reliable, cost-effective supply of NGLs, particularly ethane and propane, is critical for achieving competitive advantage in the olefins production stage, especially for operators in North America and the Middle East.

The midstream segment is characterized by the conversion processes—primarily steam cracking, PDH, and MTO—where the light olefins (ethylene, propylene, butadiene) are produced. This segment is highly capital-intensive and requires sophisticated process technology and scale efficiency to maintain profitability. Following production, the logistics of storing and transporting these reactive gases and liquids via pipelines, specialized tankers, or pressurized railcars form a critical link. Downstream operations involve the conversion of these basic olefins into a vast array of derivative products, most notably polymers such as polyethylene and polypropylene, which serve myriad end-use markets. Integrated petrochemical complexes, which combine cracking units with several derivative plants, are highly prevalent, designed to maximize operational synergy and minimize logistics costs.

The final stage encompasses the distribution channels, which can be direct or indirect. Direct channels involve large producers supplying major industrial customers (e.g., automotive manufacturers, large packaging firms) under long-term contracts. Indirect channels utilize distributors and compounders who purchase bulk polymers and chemicals, process them further, and distribute smaller quantities to niche manufacturers and secondary end-users. The efficiency of the distribution network, coupled with strategic warehousing capabilities, is crucial for maintaining market responsiveness. The emerging focus on chemical recycling and circular economy models introduces new reverse logistics into this value chain, demanding new infrastructure for collecting, sorting, and processing plastic waste back into virgin-quality light olefins.

Light Olefins Market Potential Customers

The primary consumers and end-users of light olefins are global manufacturers operating in the chemical, polymer, and finished goods industries, where these materials serve as indispensable building blocks. The largest segment of buyers comprises polyethylene and polypropylene manufacturers, who utilize high volumes of ethylene and propylene to produce resins for packaging films, pipes, containers, and consumer durables. These polymer producers require consistent, high-purity supply to ensure the integrity and specifications of their end products, often entering into long-term supply agreements with major olefin producers to secure feedstock stability and pricing predictability. The demand from this sector is driven directly by global consumption patterns for packaged food, healthcare products, and construction materials.

Another major category of potential customers includes producers of chemical intermediates such as ethylene oxide (EO), propylene oxide (PO), and acrylonitrile (AN). EO is essential for producing ethylene glycol (antifreeze and polyester fibers), while PO is critical for polyurethanes (foams and insulation). These buyers represent specialized, high-value segments, often requiring olefins with specific purity levels tailored to their conversion technology. Furthermore, the automotive and construction industries are significant indirect consumers, heavily relying on downstream derivatives for lightweight components (e.g., high-performance plastics), insulation materials, and infrastructure piping, making them key market influencers whose purchasing trends dictate derivative demand.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 265.0 Billion |

| Market Forecast in 2033 | USD 405.0 Billion |

| Growth Rate | CAGR 6.2% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SABIC, Dow Inc., ExxonMobil, LyondellBasell Industries N.V., Chevron Phillips Chemical Company LLC, Shell plc, China Petroleum & Chemical Corporation (Sinopec), BASF SE, Reliance Industries Limited, PTT Global Chemical Public Company Limited, TotalEnergies S.E., Formosa Plastics Corporation, INEOS Group, LG Chem, Braskem S.A., Borouge, Eni S.p.A., Qatar Energy, Mitsubishi Chemical Corporation, Hanwha Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Light Olefins Market Key Technology Landscape

The Light Olefins market is technologically dynamic, dominated historically by Steam Cracking, which utilizes high temperatures to break down feedstocks ranging from light ethane to heavy naphtha. The choice of feedstock dictates the product slate, with ethane yielding high amounts of ethylene and minimal co-products, while heavier feedstocks generate more propylene, butadiene, and aromatics. Recent technological advancements in steam cracker design focus on optimizing furnace efficiency, reducing energy consumption (a major cost component), and improving feedstock flexibility to allow producers to switch between naphtha and NGLs based on market pricing, thereby enhancing cost competitiveness and operational resilience.

The drive for securing specific olefin supply, especially propylene, has accelerated the adoption of On-Purpose Propylene (OPP) technologies. The most prominent OPP technology is Propane Dehydrogenation (PDH), which catalytically converts propane directly into propylene. PDH units offer high selectivity and are particularly prevalent in regions with abundant propane supply (North America, Middle East). Furthermore, Methanol-to-Olefins (MTO) and Methanol-to-Propylene (MTP) technologies have become crucial in feedstock-scarce regions, particularly China, where coal is used to produce methanol, which is then converted into light olefins. These MTO/MTP processes offer significant strategic independence from traditional oil and gas supply chains, although they face scrutiny regarding the environmental footprint of coal-derived methanol.

Future technology development is centered on sustainability and circularity. Advanced Chemical Recycling technologies are emerging rapidly, focused on depolymerizing post-consumer plastic waste back into pyrolysis oil or monomers, which can then be fed back into existing steam crackers to produce virgin-quality light olefins. Furthermore, significant research and investment are targeting Bio-based Olefins production, utilizing non-food biomass, waste oils, or fermentation processes to generate bio-ethylene or bio-propylene. While these technologies are currently small scale, they represent a fundamental shift towards sustainable chemistry and are expected to play a critical role in meeting stringent regulatory targets and consumer demand for circular materials in the coming decade.

Regional Highlights

Regional dynamics in the Light Olefins Market are crucial for understanding global supply-demand balances and investment flows. Asia Pacific (APAC) stands as the largest and fastest-growing region, driven primarily by China, India, and Southeast Asia. This region's massive industrial base, rapidly expanding middle class, and continuous infrastructure development necessitate huge volumes of polymers, making it the net importer of light olefins and derivatives. Capacity additions in APAC, particularly coal-to-olefins (CTO) and imported PDH units in China, are aggressively attempting to meet domestic demand, though the region is expected to remain central to global petrochemical growth.

North America, particularly the U.S. Gulf Coast, is characterized by a significant cost advantage stemming from the shale gas revolution. Access to low-cost ethane and propane feedstock has positioned the region as a primary global exporter of ethylene and propylene derivatives, driving massive capital investments in new cracker and derivative capacity. The focus in North America is on efficiency, scale, and integration, maintaining its status as the world's most cost-competitive production hub.

Europe faces challenges due to higher feedstock costs and stringent environmental regulations. Consequently, the European market is highly focused on sustainability, innovation in high-performance materials, and developing advanced chemical recycling capabilities. European producers are leading the transition towards circular polymers, aiming to secure high-value markets by incorporating bio-based and recycled content into their olefin derivatives. The Middle East remains a strong production center, utilizing abundant, low-cost associated gas to produce light olefins, primarily targeting export markets in Asia and Europe, leveraging strategic geographic location and strong government backing.

- Asia Pacific (APAC): Dominates consumption and is the primary driver of new global capacity; characterized by aggressive expansion in polymer production, particularly in China and India, utilizing diverse feedstocks including coal and imported methanol.

- North America: Cost leader due to prolific shale gas production (ethane/propane); focuses on massive, integrated facilities and remains the largest net exporter of ethylene derivatives globally.

- Europe: Mature market focused on high-value, specialty chemicals and pioneering the transition to the circular economy; strong regulatory environment pushing adoption of chemical recycling and bio-based feedstocks.

- Middle East and Africa (MEA): Large-scale, export-oriented production utilizing locally sourced, low-cost gas feedstocks; strategically positioned to supply high-growth Asian markets.

- Latin America: Characterized by regional supply fragmentation and reliance on imports; key developments focused on optimizing existing capacity and integrating biofuel production with petrochemical processes, particularly in Brazil.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Light Olefins Market.- SABIC (Saudi Basic Industries Corporation)

- Dow Inc.

- ExxonMobil

- LyondellBasell Industries N.V.

- Chevron Phillips Chemical Company LLC

- Shell plc

- China Petroleum & Chemical Corporation (Sinopec)

- BASF SE

- Reliance Industries Limited

- PTT Global Chemical Public Company Limited

- TotalEnergies S.E.

- Formosa Plastics Corporation

- INEOS Group

- LG Chem

- Braskem S.A.

- Borouge (ADNOC/Borouge)

- Eni S.p.A.

- Qatar Energy

- Mitsubishi Chemical Corporation

- Hanwha Solutions

- Maire Tecnimont S.p.A. (Technology Provider focus)

- Haldor Topsoe (Technology Provider focus)

Frequently Asked Questions

Analyze common user questions about the Light Olefins market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key drivers propelling the demand for light olefins?

The primary drivers are escalating global demand for plastic packaging and consumer goods, driven by population growth and urbanization in Asia Pacific. Additionally, the structural cost advantage afforded by abundant shale gas liquids (ethane and propane) in North America incentivizes continuous capacity expansion and maintains market competitiveness.

How is the feedstock landscape evolving in the light olefins market?

The feedstock landscape is diversifying away from heavy naphtha toward lighter feedstocks, driven by cost-efficiency. Ethane remains crucial for ethylene production, but the rise of on-purpose technologies like Propane Dehydrogenation (PDH) and Methanol-to-Olefins (MTO) is critical for securing reliable, flexible supply of propylene, especially in regions lacking domestic oil resources.

What impact do sustainability initiatives have on olefin production?

Sustainability initiatives are profoundly impacting the market by necessitating investments in chemical recycling technologies and bio-based feedstock utilization. Regulatory pressure to increase recycled content in polymers, especially in Europe, is pushing major producers to incorporate pyrolysis oil (derived from plastic waste) back into steam crackers, driving the transition towards a circular economy model for light olefins.

Which region currently holds the largest share in the light olefins market and why?

Asia Pacific (APAC), led by China, holds the largest market share in terms of consumption and is the principal source of future demand growth. This dominance is due to rapid industrial expansion, high manufacturing output, significant infrastructure projects, and the immense consumer base requiring polymer-based products across all sectors.

What is the main difference between steam cracking and PDH technology?

Steam cracking is a thermal process utilizing various feedstocks (naphtha, ethane) to produce a mixture of light olefins (primarily ethylene, propylene, and butadiene). In contrast, Propane Dehydrogenation (PDH) is a catalytic process that uses propane exclusively to produce propylene on purpose, offering high selectivity and reducing dependency on the co-product slate generated by steam crackers.

The strategic imperatives for light olefin producers in the forecasted period will center on achieving maximum feedstock flexibility to navigate commodity price cycles effectively, while simultaneously investing in digital transformation—specifically AI-driven optimization—to maintain operational excellence. The long-term success of major players will increasingly depend on their ability to integrate sustainability into their core operations, not just through compliance, but through the commercialization of bio-based and chemically recycled products that meet the evolving demands of environmentally conscious global customers.

Furthermore, the geopolitical environment, particularly regarding trade flows and energy security, continues to shape regional competitiveness. Producers in regions with secure, low-cost feedstocks, such as North America and the Middle East, are expected to maintain their volume dominance, while Asian players will focus on capacity self-sufficiency. The continuous evolution of catalyst technology, aimed at improving selectivity and reducing energy input in complex processes like MTO and PDH, will be vital for maintaining cost control and supporting the projected 6.2% CAGR growth through 2033. The light olefins market, therefore, stands at the crucial intersection of energy abundance, technological innovation, and environmental responsibility, defining the future of global chemical manufacturing.

Investment patterns across the globe show a distinct preference for integrated facilities that co-locate cracker units with derivative plants (e.g., polyethylene, polypropylene, ethylene glycol). This integration strategy mitigates exposure to volatile intermediate prices and captures greater value across the chain. Emerging markets are also witnessing substantial infrastructure development supported by government initiatives to establish domestic petrochemical capabilities, moving away from reliance on imported derivatives. This trend reinforces the high demand forecast for primary light olefins, solidifying their position as critical industrial commodities essential for economic development and industrial progress across the globe. Addressing the logistical complexities associated with transporting ethylene and propylene, which often require specialized cryogenic or pressurized facilities, remains a perennial challenge requiring continuous investment in pipeline infrastructure and global shipping fleets.

The market for butadiene, though smaller than ethylene and propylene, is experiencing steady growth driven by the tire and automotive industries, as butadiene is a key component in synthetic rubber (SBR, BR). Fluctuations in the automotive production cycle, particularly the increasing global shift toward electric vehicles (EVs) which still require specialized tires and components, significantly influence butadiene demand. The primary source of butadiene remains a co-product of steam cracking naphtha, meaning its supply is inherently linked to the operational decisions of ethylene producers. This supply inelasticity often leads to significant price spikes during periods of high demand, prompting investment in on-purpose butadiene technologies, though these are still niche compared to traditional co-production methods.

Strategic mergers, acquisitions, and joint ventures remain a consistent feature of the competitive landscape, as established players seek to consolidate market share, acquire new specialized technologies (e.g., advanced catalysts), or gain favorable access to low-cost feedstocks in North America or the Middle East. Capacity additions announced by state-owned enterprises in Asia and the Middle East continue to dominate the headlines, reflecting national strategies aimed at maximizing the value of domestic hydrocarbon resources and establishing self-sufficiency in polymer production. This intense level of capital competition necessitates a focus on operational expenditure reduction and efficiency maximization across all producers, making the adoption of AI and digitalization a foundational necessity, rather than a competitive luxury.

The role of regulatory frameworks cannot be overstated, particularly the influence of policies such as the European Union’s Green Deal and evolving national plastic waste laws in major Asian countries. These policies fundamentally alter the cost structure and commercial viability of specific derivative markets. For instance, restrictions on certain single-use plastics directly reduce demand for specific grades of commodity polyethylene, while simultaneously spurring immense research and development activity into certified renewable or circular polymer alternatives. Producers that successfully anticipate and adapt to these regulatory shifts, by rapidly scaling up bio-based or recycled content offerings, will secure a strategic advantage and access to premium, high-margin market segments, reinforcing the shift towards value-added differentiation over pure volume competition. This focus on compliance and sustainable materials procurement is integrating risk management and environmental, social, and governance (ESG) factors deeply into the long-term strategic planning for all major light olefin players.

Technological advancement extends beyond production to utilization, with continuous innovation in catalyst systems allowing for the creation of new, higher-performing grades of polyethylene (e.g., metallocene LLDPE) and polypropylene. These advanced materials offer superior mechanical properties, allowing end-users to achieve material reduction (less plastic per product), which indirectly supports sustainability goals and drives specialized demand. Consequently, while the volume growth of commodity grades remains robust, the highest growth in value is concentrated within these specialty polymer segments. Investment in R&D to develop proprietary catalyst systems and high-value derivative products is a core strategy for integrated chemical companies aiming to differentiate themselves from bulk commodity suppliers. Furthermore, process intensification, aimed at reducing the physical footprint and energy requirements of new chemical plants, is a growing trend, addressing both environmental concerns and the high land costs associated with new construction in densely populated industrial zones.

In summary, the Light Olefins Market is defined by a dynamic interplay between supply-side advantages (low-cost NGLs), overwhelming global demand for derivatives, and mounting pressure for environmental stewardship. The successful navigation of the market requires deep expertise in feedstock hedging, advanced process optimization facilitated by AI, strategic capacity deployment in high-growth regions, and a proactive commitment to developing circular and renewable chemical pathways. The projected CAGR of 6.2% underscores the fundamental, irreplaceable role these simple molecules play in the global industrial economy and validates the extensive ongoing capital commitments across the global petrochemical landscape through the forecast period to 2033.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- FCC Catalyst Additive Market Statistics 2025 Analysis By Application (Vacuum Gas Oil, Residue), By Type (Octane Number Improving Agent, Light Olefins Enhancing Agent, Sulphur Reducing Agent, Metal Passivation Agent), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- FCC Catalyst Additive Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Sulphur Reducing Agent, Light Olefins Enhancing Agent, Octane Number Improving Agent), By Application (Residue, Vacuum Gas Oil, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager