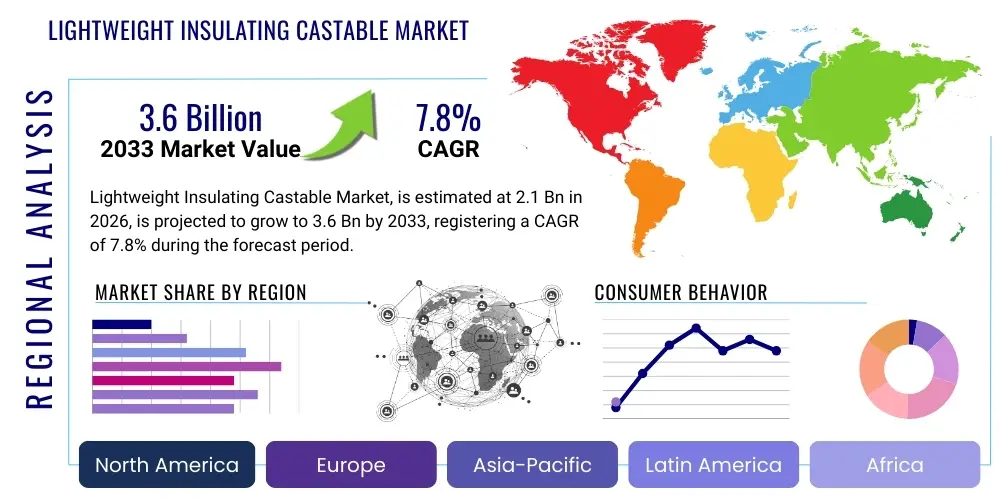

Lightweight Insulating Castable Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439786 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Lightweight Insulating Castable Market Size

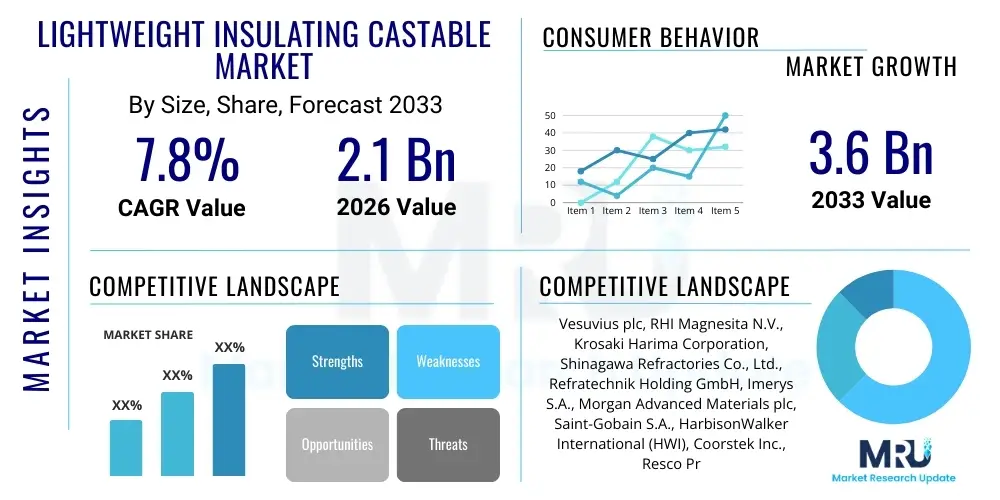

The Lightweight Insulating Castable Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 3.6 Billion by the end of the forecast period in 2033.

Lightweight Insulating Castable Market introduction

Lightweight insulating castables are advanced refractory materials meticulously engineered to provide superior thermal insulation and structural integrity in high-temperature industrial environments. These materials are characterized by their low bulk density, achieved through the incorporation of lightweight aggregates such as hollow ceramic microspheres, perlite, vermiculite, or porous fireclay grog, which create a cellular structure. This unique composition significantly reduces thermal conductivity, leading to substantial energy savings and improved operational efficiency in thermal processing units. The primary function of these castables is to minimize heat loss from industrial furnaces, kilns, heaters, and other thermal equipment, thereby optimizing energy consumption and contributing to a reduction in carbon emissions. Their monolithic nature, formed by casting or gunning, allows for seamless linings that are less prone to hot spots and offer greater resistance to thermal shock compared to traditional brick linings. This adaptability and ease of installation make them a preferred choice across various demanding industrial applications. The inherent benefits extend beyond energy conservation, encompassing enhanced equipment lifespan due to reduced thermal stress, improved workplace safety by maintaining cooler external surfaces, and the flexibility to line complex geometries that would be challenging with pre-formed refractory shapes. The market's expansion is intrinsically linked to the increasing demand for energy-efficient solutions in heavy industries, stringent environmental regulations pushing for lower emissions, and the continuous drive for operational cost reduction through optimized thermal management. Furthermore, the inherent versatility of lightweight insulating castables in terms of application methods—ranging from conventional casting to shotcreting and pumping—allows for rapid and effective deployment in new constructions as well as in critical repair and maintenance scenarios, contributing significantly to their widespread adoption.

Lightweight Insulating Castable Market Executive Summary

The Lightweight Insulating Castable Market is currently experiencing robust growth, driven by a confluence of escalating energy costs, tightening environmental regulations, and the relentless pursuit of operational efficiencies across diverse industrial sectors. Business trends indicate a significant shift towards sustainable and high-performance refractory solutions, with manufacturers investing heavily in research and development to enhance material properties such as higher service temperatures, improved mechanical strength, and superior thermal cycling resistance. The increasing adoption of automation in material handling and installation processes is also transforming the market landscape, leading to more consistent applications and reduced labor costs. Furthermore, the market is characterized by a strong emphasis on customization, as end-users demand tailored refractory formulations to meet the specific demands of their unique operational parameters and furnace designs. Regional trends reveal a particularly strong growth trajectory in Asia Pacific, propelled by rapid industrialization, burgeoning infrastructure development, and substantial investments in the iron and steel, cement, and petrochemical industries, especially in economies like China and India. North America and Europe also maintain significant market shares, driven by advanced manufacturing capabilities, strict energy efficiency mandates, and a sustained focus on upgrading existing industrial facilities with state-of-the-art refractory linings. In terms of segment trends, the demand for ultra-low cement and no-cement castables is witnessing a notable surge due to their superior performance characteristics and reduced drying times, offering quicker turnaround for industrial processes. The iron and steel industry continues to be the largest application segment, requiring extensive lightweight insulation for various furnaces and ladles, while the petrochemical and glass industries are also demonstrating increased adoption rates, driven by the need for stable, energy-efficient linings capable of withstanding corrosive environments and prolonged high-temperature exposure. The market's future trajectory is expected to be shaped by ongoing innovations in material science, the expansion of green manufacturing practices, and strategic collaborations aimed at developing next-generation insulating refractory solutions.

AI Impact Analysis on Lightweight Insulating Castable Market

The integration of Artificial Intelligence (AI) and machine learning technologies is poised to fundamentally transform various facets of the Lightweight Insulating Castable market, addressing key challenges and unlocking new opportunities across the entire value chain. Common user questions related to AI's impact often revolve around how AI can optimize material composition for enhanced performance, predict refractory lifespan more accurately, streamline production processes to reduce waste, and improve quality control. There is significant interest in AI's role in developing novel, more sustainable material formulations by simulating countless combinations and predicting their properties without extensive physical testing. Users also frequently inquire about AI-powered predictive maintenance systems that can monitor the health of refractory linings in real-time, anticipate failure points, and schedule maintenance proactively, thereby minimizing downtime and extending operational periods. Furthermore, questions arise concerning the use of AI in analyzing complex operational data from industrial furnaces to identify optimal energy consumption patterns related to refractory performance, thus contributing to greater energy efficiency and reduced operational costs. The potential for AI to automate and enhance quality assurance processes, from raw material inspection to final product testing, ensuring consistent product quality and reducing defect rates, is another central theme of user curiosity. The overall expectation is that AI will usher in an era of smarter, more efficient, and more reliable refractory solutions, leading to significant advancements in material science, manufacturing precision, and application longevity, ultimately contributing to a more sustainable and economically viable industrial landscape.

- AI-driven material formulation optimization: AI algorithms can analyze vast datasets of material properties and performance under various conditions to predict optimal compositions for new lightweight insulating castables, accelerating R&D cycles and leading to refractories with enhanced thermal resistance, mechanical strength, and durability. This includes simulating molecular structures and crystal growth to design materials with superior porosity and reduced thermal conductivity.

- Predictive maintenance and lifespan forecasting: Machine learning models, trained on real-time sensor data from industrial furnaces (temperature, stress, chemical exposure), can accurately predict the remaining useful life of refractory linings, signaling potential failure points and enabling proactive maintenance scheduling to prevent unexpected downtime and costly repairs. This moves beyond scheduled maintenance to condition-based maintenance.

- Automated quality control and defect detection: AI-powered vision systems and data analytics can monitor the production process of castables, from raw material inspection to curing, identifying subtle defects or inconsistencies in real-time that human inspectors might miss. This ensures higher product quality, reduces waste, and maintains manufacturing standards.

- Process optimization and energy efficiency: AI can analyze operational data from furnaces and kilns, correlating refractory performance with energy consumption patterns. This allows for identification of optimal operating parameters, leading to significant energy savings by minimizing heat loss and maximizing thermal efficiency through intelligent adjustments to heating cycles and material application.

- Enhanced supply chain management: AI can optimize inventory levels of raw materials and finished products, forecast demand more accurately, and identify potential supply chain disruptions, ensuring timely availability of lightweight insulating castables and reducing logistical costs. This supports more resilient and responsive manufacturing operations.

- Robotics and autonomous installation: AI-guided robots can perform precise and consistent installation of castables in complex furnace geometries, reducing human exposure to hazardous environments, improving application consistency, and speeding up construction or repair times. This addresses labor shortages and enhances safety protocols.

DRO & Impact Forces Of Lightweight Insulating Castable Market

The Lightweight Insulating Castable Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all contributing to its overall impact forces. Key drivers include the relentless pursuit of energy efficiency across heavy industries as a means to reduce operational costs and meet stringent environmental regulations concerning carbon emissions. The expanding global industrial base, particularly in emerging economies, coupled with significant investments in upgrading aging infrastructure, further fuels demand for advanced refractory solutions. The superior performance attributes of lightweight insulating castables, such as lower thermal conductivity, ease of installation, and enhanced resistance to thermal shock, make them highly attractive alternatives to traditional refractory bricks.

Segmentation Analysis

The Lightweight Insulating Castable market is meticulously segmented to provide a comprehensive understanding of its diverse components and dynamics. This segmentation facilitates targeted market strategies and highlights specific growth areas across various parameters, including material type, application, temperature range, and form. Understanding these segments is crucial for stakeholders to identify niches, develop tailored product offerings, and capitalize on evolving industrial requirements. The market's inherent complexity, driven by the varying demands of high-temperature processes, necessitates a granular approach to categorizing these advanced refractory materials. Each segment possesses unique characteristics and serves distinct purposes, reflecting the specialized needs of different end-use industries. For instance, the choice of material significantly impacts the castable's thermal properties and chemical resistance, while the application dictates the required mechanical strength and abrasion resistance. The continuous innovation within material science is leading to the introduction of novel formulations that blur traditional boundaries, offering multi-functional properties that cater to a wider array of industrial challenges, thereby influencing future segmentation trends.

- By Type: This segment differentiates castables based on their binder system and overall density characteristics.

- Low Cement Castables (LCC): Characterized by a reduced cement content (typically 2-8%), offering improved high-temperature strength, lower porosity, and better thermal shock resistance compared to conventional castables. They require careful water content control during mixing.

- Ultra-Low Cement Castables (ULCC): Featuring even lower cement content (typically less than 2%), these castables exhibit superior refractoriness, excellent volume stability, and significantly enhanced high-temperature performance, making them suitable for the most demanding applications. They often rely on alternative binders like colloidal silica.

- No Cement Castables (NCC): Also known as cement-free or bonding-agent-free castables, these rely entirely on chemical or hydraulic bonds formed by reactive fine powders or colloidal binders, offering the highest purity, exceptional high-temperature strength, and excellent corrosion resistance.

- Insulating Lightweight Castables: Specifically designed for thermal insulation, these have a very low bulk density, high porosity, and low thermal conductivity, primarily used to minimize heat loss and conserve energy in furnace linings.

- Dense Lightweight Castables: While still lighter than traditional dense refractories, these offer a balance of insulation properties and moderate mechanical strength, suitable for applications requiring both thermal efficiency and some structural integrity.

- By Material: Categorization based on the primary refractory aggregate used, which dictates the material's maximum service temperature and chemical resistance.

- Alumina-Silicate Castables: Versatile and widely used, based on fireclay, mullite, or high-alumina aggregates, suitable for a broad range of temperatures and offering good refractoriness and slag resistance. They balance performance with cost-effectiveness.

- Mullite Castables: Featuring high mullite content, these castables offer excellent high-temperature strength, thermal shock resistance, and good creep resistance, ideal for applications requiring stable performance under severe thermal cycling.

- Bauxite Castables: Derived from bauxite, a high-alumina aggregate, these provide superior high-temperature performance, excellent refractoriness, and good resistance to chemical attack, often used in demanding environments.

- Fireclay Castables: Economical and robust, based on calcined fireclay, suitable for moderate temperature applications where basic insulation and structural integrity are required. They are a staple in many industrial linings.

- Zirconia Castables: Offering exceptional refractoriness, high-temperature strength, and resistance to chemical corrosion, particularly from molten metals and glass. These are used in highly specialized, ultra-high temperature applications.

- By Application: This segmentation focuses on the end-use industry where lightweight insulating castables are deployed.

- Iron & Steel Industry: Utilized extensively in blast furnaces, hot blast stoves, tundishes, ladles, and reheating furnaces for energy conservation and extended lining life. This is one of the largest consuming sectors due to its high-temperature processes.

- Non-Ferrous Metals Industry: Applied in melting furnaces, holding furnaces, and transfer ladles for aluminum, copper, and other non-ferrous metals, providing insulation and protection against molten metal attack.

- Petrochemical Industry: Essential for reactors, reformers, incinerators, and process heaters, where precise temperature control and resistance to corrosive gases are critical. They help maintain thermal stability in complex chemical reactions.

- Cement & Lime Industry: Used in rotary kilns, preheaters, and coolers to improve thermal efficiency and reduce fuel consumption in the production of cement and lime. The abrasive nature of clinker demands robust insulation.

- Glass Industry: Employed in glass melting furnaces, regenerators, and forehearths to minimize heat loss and ensure uniform temperature distribution, critical for consistent glass quality. Resistance to alkali vapors is important here.

- Ceramics Industry: Applied in various kilns (tunnel kilns, shuttle kilns) for firing ceramics, bricks, and tiles, ensuring uniform heating and reducing energy expenditure during high-temperature sintering processes.

- Power Generation: Used in boilers, incinerators, and flue gas ducts in thermal power plants to improve energy efficiency and protect structural components from high temperatures and corrosive environments.

- Foundries: Critical for lining melting furnaces, ladles, and heat treatment furnaces, providing insulation and refractory protection in the casting of various metals.

- By Temperature Range: Reflects the maximum service temperature capability of the castable, a critical factor for selection.

- Up to 1200°C: Suitable for moderate temperature applications such as exhaust ducts, certain types of ovens, and general industrial insulation where temperatures do not exceed this threshold.

- 1200°C - 1500°C: Designed for common high-temperature applications including many industrial furnaces, kilns, and process heaters where significant thermal stress is encountered.

- Above 1500°C: Tailored for extreme high-temperature environments found in primary steel production, specialized ceramic kilns, and other ultra-high temperature processes where superior refractoriness is paramount.

- By Form: This segment distinguishes between the physical state in which the castable is supplied.

- Dry Mix: Supplied as a pre-blended dry powder that requires mixing with water on-site before application. Offers flexibility in handling and storage, and allows for customization of water content during mixing.

- Wet Mix: Pre-mixed with water and supplied in a ready-to-use form, often in tubs or bags. This form simplifies on-site preparation, reduces dust, and ensures consistent quality, though it may have a shorter shelf life.

Value Chain Analysis For Lightweight Insulating Castable Market

The value chain for the Lightweight Insulating Castable Market is a complex, multi-tiered system that encompasses various stages, from the extraction of raw materials to the final installation and maintenance of the refractory linings. Understanding this chain is crucial for identifying key cost drivers, potential areas for optimization, and value creation at each stage. The upstream analysis begins with the sourcing and processing of essential raw materials, which include high-purity alumina, bauxite, fireclay, mullite, various lightweight aggregates such as hollow ceramic microspheres, perlite, vermiculite, and specialized binders like calcium aluminate cements, colloidal silica, or reactive alumina. Mining companies and chemical processing plants form the bedrock of this initial stage, often involving intricate supply networks to ensure consistent quality and availability of these critical components.

Lightweight Insulating Castable Market Potential Customers

The Lightweight Insulating Castable Market serves a broad spectrum of industrial end-users, each with distinct needs and operational challenges in high-temperature environments. These customers are primarily entities operating facilities that involve significant heat generation and require robust thermal management solutions to ensure operational efficiency, safety, and longevity of equipment. Key potential customers include large-scale manufacturers in the iron and steel industry, ranging from integrated steel mills to mini-mills, which heavily rely on these castables for lining blast furnaces, hot blast stoves, reheating furnaces, and ladles to prevent heat loss and withstand extreme temperatures and corrosive slag. Similarly, the non-ferrous metals industry, encompassing aluminum smelters, copper refineries, and foundries, represents a significant customer base, utilizing insulating castables in melting, holding, and casting furnaces to reduce energy consumption and maintain metal quality. The petrochemical and chemical processing sectors are crucial customers, employing these materials in reactors, reformers, cracking units, and process heaters where precise temperature control and resistance to aggressive chemical atmospheres are paramount for process integrity and safety. Furthermore, the cement and lime industry, with its energy-intensive rotary kilns and preheaters, constitutes a vital segment, seeking castables that can withstand abrasive clinker and high thermal cycling while maximizing fuel efficiency. Glass manufacturers, operating large melting furnaces and regenerators, are also key buyers, requiring materials that provide excellent insulation and resistance to alkali attack to maintain consistent glass quality and reduce energy bills. Other significant customer groups include the ceramics industry for various types of kilns, the power generation sector for boilers and incinerators, and various foundries that cast a wide array of metal products. These end-users are continually seeking innovative refractory solutions that offer improved performance, extended service life, reduced installation times, and contribute to their sustainability goals by minimizing energy footprints and operational costs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 3.6 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Vesuvius plc, RHI Magnesita N.V., Krosaki Harima Corporation, Shinagawa Refractories Co., Ltd., Refratechnik Holding GmbH, Imerys S.A., Morgan Advanced Materials plc, Saint-Gobain S.A., HarbisonWalker International (HWI), Coorstek Inc., Resco Products Inc., Puyang Refractories Group Co., Ltd., Minteq International Inc., Qinghua Refractories Co., Ltd., Allied Mineral Products Inc., Calderys (Hoganas AB), Plibrico Company LLC, Chosun Refractories Co., Ltd., IFGL Refractories Ltd., Kerui Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lightweight Insulating Castable Market Key Technology Landscape

The technological landscape of the Lightweight Insulating Castable market is characterized by continuous innovation aimed at enhancing material performance, simplifying application, and improving sustainability. A significant area of focus is the development of advanced lightweight aggregates, which are crucial for achieving low bulk density and superior insulating properties. This includes the widespread adoption of hollow ceramic microspheres, cenospheres, perlite, vermiculite, and expanded clay, all of which are engineered to create a stable, porous structure within the castable matrix. Beyond material composition, advancements in manufacturing processes, such as improved blending techniques and quality control through automation and real-time monitoring, are ensuring greater consistency and reliability of the final products. Digital twin technology and advanced computational fluid dynamics (CFD) are increasingly used in the design phase to simulate refractory performance under various operating conditions, optimizing material selection and lining design before physical implementation. The ongoing development of installation equipment, including high-pressure pumps and robotic gunning systems, also contributes to the technological evolution, enabling faster, more precise, and safer application of castables in complex industrial geometries, further cementing the market's trajectory towards high-performance, intelligent refractory solutions.

Regional Highlights

-

North America: The North American market for lightweight insulating castables is characterized by a mature industrial base and a strong emphasis on technological innovation and environmental compliance. Driven by stringent regulations pertaining to energy efficiency and emissions reduction, industries such as steel, petrochemicals, and glass are continually investing in upgrading their existing facilities with advanced refractory solutions. The region benefits from significant research and development activities, leading to the adoption of high-performance, specialized castables designed for extreme operating conditions and longer service life. There is a consistent demand for products that offer superior thermal insulation, reduced installation times, and enhanced resistance to chemical attack and thermal shock. The presence of major global refractory manufacturers and a well-developed distribution network also contributes to the market's stability and growth. Furthermore, the push towards green manufacturing practices and the integration of automation in refractory application processes are key trends shaping demand in this region, with end-users actively seeking solutions that contribute to sustainability goals and lower overall operational expenditures.

The market in North America is also seeing a robust demand for custom-engineered solutions, driven by the diverse and complex operational requirements of various heavy industries. This includes tailored formulations for specific furnace designs, requiring close collaboration between manufacturers and end-users. Economic factors, such as infrastructure development and modernization projects, particularly in the oil and gas sector and general manufacturing, provide additional impetus for market expansion. The region's focus on adopting smart technologies, including AI-driven predictive maintenance for refractory linings, represents a future growth avenue, enabling industries to optimize their maintenance schedules, reduce unplanned downtime, and extend the lifespan of their critical high-temperature equipment. This forward-looking approach to industrial efficiency and sustainability underscores the dynamic nature of the lightweight insulating castable market across the United States, Canada, and Mexico.

-

Europe: The European lightweight insulating castable market is distinguished by its strong regulatory framework promoting energy conservation and decarbonization, alongside a well-established manufacturing sector that demands high-quality, durable refractory materials. Countries within the European Union are at the forefront of implementing policies aimed at reducing industrial energy consumption and greenhouse gas emissions, directly stimulating the demand for advanced insulating castables in industries such as iron and steel, cement, glass, and petrochemicals. Manufacturers in this region are known for their technological sophistication, focusing on developing sustainable and eco-friendly refractory solutions, including those with lower embodied carbon and improved recyclability. The emphasis on product longevity and performance reliability is paramount, given the high operational costs and maintenance expenditures associated with European industrial facilities. Furthermore, the market benefits from a highly skilled labor force and advanced installation techniques, ensuring the optimal application and performance of these specialized materials. Innovation in binder systems, lightweight aggregates, and application methods continues to drive market evolution, with a keen eye on improving operational efficiency and reducing environmental impact across various high-temperature processing industries.

The European market also showcases a strong trend towards product customization and technical service, where manufacturers provide comprehensive support from material selection and design to installation and post-application monitoring. The drive for Industry 4.0 integration means that European industries are increasingly looking for refractory solutions that can be part of a larger interconnected operational system, offering data for performance analysis and predictive maintenance. While some established industries face structural challenges, continuous investment in modernization and the adoption of cutting-edge technologies ensure sustained demand for high-performance insulating castables. Countries like Germany, France, and Italy, with their robust industrial bases, remain key contributors to market growth, constantly seeking innovative ways to enhance thermal management and reduce energy footprints in their manufacturing processes. The commitment to a circular economy also influences product development, fostering a lifecycle approach to refractory materials, from raw material sourcing to end-of-life management.

-

Asia Pacific (APAC): The Asia Pacific region represents the largest and fastest-growing market for lightweight insulating castables, primarily fueled by rapid industrialization, extensive infrastructure development, and significant investments in heavy industries across countries like China, India, Japan, South Korea, and Southeast Asian nations. The burgeoning iron and steel, cement, glass, petrochemical, and power generation sectors are the primary demand drivers, as these industries require vast quantities of refractory materials for new installations and the expansion of existing capacities. The region's economic growth, coupled with a growing focus on improving energy efficiency and reducing operational costs, is accelerating the adoption of advanced insulating castables over traditional refractory solutions. While cost-effectiveness remains a significant consideration, there is an increasing recognition of the long-term benefits of superior thermal performance and extended lining life. Local manufacturers, alongside international players, are expanding their production capacities and refining their product portfolios to cater to the diverse and escalating demands of this dynamic market, often through strategic partnerships and technology transfers.

The APAC market is also characterized by a shift towards higher quality and more specialized products as industrial standards evolve and environmental regulations become more stringent in some areas. Countries like China and India, with their massive industrial footprints, are not only major consumers but also significant producers of refractory materials, influencing global supply chains. Japan and South Korea, on the other hand, lead in technological adoption and advanced manufacturing, driving demand for premium, high-performance castables with superior properties. The increasing awareness regarding energy conservation and sustainable industrial practices, even in developing economies within the region, is propelling the market towards more efficient and environmentally friendly refractory solutions. This regional growth is further supported by governmental initiatives promoting manufacturing and infrastructure development, making APAC a critical hub for innovation and demand in the lightweight insulating castable industry.

-

Latin America: The Latin American market for lightweight insulating castables is experiencing steady growth, driven by the expansion and modernization of its industrial sectors, particularly mining, metallurgy, cement, and petrochemicals. Countries such as Brazil, Mexico, Argentina, and Chile are seeing increased investments in infrastructure and industrial projects, leading to a rising demand for high-performance refractory materials. The mining industry, with its extensive need for insulation in various processing furnaces, is a significant contributor to market growth. As industries in this region strive to enhance their competitiveness on a global scale, there is a growing emphasis on adopting energy-efficient technologies and optimizing operational costs, thereby fostering the uptake of lightweight insulating castables. While the market might be smaller in scale compared to APAC or Europe, the ongoing industrial development and the gradual adoption of advanced manufacturing practices provide a stable foundation for future expansion. Local distributors and international suppliers are working to improve market penetration and provide technical support tailored to regional needs.

Challenges in the Latin American market often include economic volatility, logistical complexities, and a varying degree of technological adoption across different countries. However, as the region integrates further into global supply chains and embraces higher industrial standards, the demand for specialized refractory solutions is expected to intensify. The petrochemical sector, driven by new investments in refining and processing capabilities, represents a key growth area for insulating castables. Furthermore, the continuous modernization of existing cement plants and steel production facilities, aimed at improving efficiency and reducing environmental impact, will continue to fuel demand. The increasing availability of technical expertise and customized product offerings from both local and international refractory companies is helping to overcome some of the traditional barriers to adoption, paving the way for sustained growth in the lightweight insulating castable market across Latin America.

-

Middle East and Africa (MEA): The Middle East and Africa (MEA) region presents a dynamic and evolving market for lightweight insulating castables, primarily driven by significant investments in the oil and gas, petrochemical, and primary metals industries, particularly in the Gulf Cooperation Council (GCC) countries. The abundant energy resources in the Middle East have led to massive investments in refining, petrochemical complexes, and aluminum smelters, all of which are highly reliant on advanced refractory materials for high-temperature containment and thermal management. The ongoing diversification efforts in these economies, moving beyond pure oil extraction to value-added processing, are creating new avenues for demand. In Africa, the growth is spurred by industrialization, infrastructure development, and burgeoning mining and cement sectors, particularly in South Africa, Nigeria, and Egypt. There is a growing focus on improving operational efficiencies and adhering to international standards for safety and environmental performance, which drives the adoption of sophisticated insulating refractory solutions.

The MEA market is characterized by a mix of mature technologies and emerging opportunities. While some parts of the region still rely on conventional refractories, there is a clear trend towards high-performance lightweight insulating castables as industries seek to reduce energy consumption and extend equipment lifespan. Geopolitical factors and fluctuating oil prices can impact investment cycles, but the long-term trajectory for industrial growth remains positive. The demand for localized manufacturing and service capabilities is also increasing, encouraging international refractory companies to establish a stronger presence through local partnerships or production facilities. The harsh operating conditions often encountered in this region, including extreme temperatures and corrosive environments, necessitate robust and reliable insulating materials. As the MEA region continues its industrial expansion and modernization, the lightweight insulating castable market is poised for considerable growth, with an increasing emphasis on technical expertise, tailored solutions, and sustainable product offerings to meet the specific challenges of its diverse industrial landscape.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lightweight Insulating Castable Market.- Vesuvius plc

- RHI Magnesita N.V.

- Krosaki Harima Corporation

- Shinagawa Refractories Co., Ltd.

- Refratechnik Holding GmbH

- Imerys S.A.

- Morgan Advanced Materials plc

- Saint-Gobain S.A.

- HarbisonWalker International (HWI)

- Coorstek Inc.

- Resco Products Inc.

- Puyang Refractories Group Co., Ltd.

- Minteq International Inc.

- Qinghua Refractories Co., Ltd.

- Allied Mineral Products Inc.

- Calderys (Hoganas AB)

- Plibrico Company LLC

- Chosun Refractories Co., Ltd.

- IFGL Refractories Ltd.

- Kerui Group

Frequently Asked Questions

Analyze common user questions about the Lightweight Insulating Castable market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using lightweight insulating castables in industrial applications?

Lightweight insulating castables offer a multitude of benefits crucial for enhancing efficiency and sustainability in high-temperature industrial environments. Their most significant advantage lies in superior thermal insulation properties, primarily due to their low bulk density and high porosity. This characteristic dramatically reduces heat loss from furnaces, kilns, and other thermal processing equipment, leading to substantial energy savings and lower operational costs. By minimizing heat transfer, these castables also contribute to a cooler exterior shell temperature, which improves workplace safety and reduces heat stress on surrounding structures and personnel. Furthermore, their monolithic nature, formed by casting or gunning, eliminates the joints inherent in brick linings, making them less susceptible to thermal shock, spalling, and hot spot formation, thus extending the lifespan of the refractory lining. This durability leads to reduced maintenance frequencies and associated downtime. The ease and speed of installation, adaptability to complex geometries, and suitability for rapid repairs are additional operational advantages. From an environmental perspective, energy conservation directly translates into a reduction in greenhouse gas emissions, aligning with global sustainability initiatives. These combined benefits make lightweight insulating castables a preferred choice for industries seeking to optimize their thermal processes, enhance equipment reliability, and achieve environmental compliance while simultaneously realizing significant economic advantages over the long term through improved energy management and extended asset life.

How do lightweight insulating castables contribute to energy efficiency and environmental sustainability?

Lightweight insulating castables are pivotal in driving both energy efficiency and environmental sustainability across heavy industries by directly addressing heat management challenges. Their fundamental role is to act as highly effective thermal barriers, significantly minimizing heat dissipation from high-temperature industrial equipment. This reduction in heat loss directly translates into a decreased demand for fuel, whether natural gas, oil, or electricity, to maintain desired operating temperatures, thereby leading to substantial energy savings. For every unit of energy conserved, there is a corresponding reduction in the consumption of primary energy sources, which subsequently lowers operational costs for industrial facilities. From an environmental standpoint, this reduction in fuel consumption has a direct and profound impact on decreasing greenhouse gas emissions, including carbon dioxide, nitrogen oxides, and sulfur oxides, which are major contributors to climate change and air pollution. By helping industries meet increasingly stringent environmental regulations and carbon footprint reduction targets, lightweight insulating castables play a crucial role in corporate sustainability strategies. Moreover, their extended service life reduces the frequency of refractory replacements, which in turn minimizes waste generation and the consumption of raw materials associated with new lining production. The ability to facilitate more stable process temperatures also leads to more consistent product quality, reducing scrap rates and further conserving resources. As industries worldwide increasingly prioritize sustainable practices and seek pathways to decarbonization, the demand for and technological advancements in lightweight insulating castables are expected to grow, reinforcing their position as a key enabling technology for greener industrial operations.

What are the key factors influencing the selection of lightweight insulating castables for a specific application?

The selection of the appropriate lightweight insulating castable for a specific industrial application is a critical decision influenced by several key factors to ensure optimal performance, longevity, and cost-effectiveness. The most paramount consideration is the maximum operating temperature and temperature fluctuations the refractory lining will experience; the castable must possess adequate refractoriness and thermal shock resistance to withstand these conditions without degradation. Closely related is the thermal conductivity requirement, as the primary goal is often to minimize heat transfer, so materials with lower thermal conductivity are generally preferred, balanced against other performance needs. The chemical environment within the furnace or vessel is equally crucial, including exposure to corrosive slags, molten metals, alkali vapors, or aggressive gases, which necessitates selecting a castable with appropriate chemical inertness and resistance to ensure structural integrity and prevent premature erosion. Mechanical strength, including cold crushing strength, hot modulus of rupture, and abrasion resistance, is vital, especially in areas subjected to mechanical stress, material impingement, or high gas velocities. The density of the castable is also a significant factor, as lighter materials contribute less to the overall structural load and improve insulation, but extremely low densities might compromise strength. Installation method—whether casting, gunning, pumping, or shotcreting—influences the rheological properties and setting characteristics required of the castable. Finally, economic considerations, encompassing the initial material cost, installation labor, expected service life, and potential energy savings, play a role in the comprehensive evaluation. A holistic assessment of these factors, often involving close consultation with refractory experts and material suppliers, is essential to specify a lightweight insulating castable that optimally meets the unique demands of each industrial application, ensuring both technical performance and economic viability over its service life.

How are advancements in AI and material science impacting the future of lightweight insulating castables?

Advancements in Artificial Intelligence (AI) and material science are profoundly shaping the future trajectory of the lightweight insulating castable market, driving innovation in material design, manufacturing processes, and application methodologies. In material science, the continuous development of novel lightweight aggregates, such as advanced hollow ceramic microspheres, aerogel-infused particles, and high-purity synthetic aggregates, is pushing the boundaries of thermal insulation performance and high-temperature stability. Breakthroughs in binder technologies, moving towards cement-free or ultra-low cement systems utilizing colloidal silica, nano-binders, or reactive alumina, are improving mechanical strength, reducing drying times, and enhancing chemical resistance.

What are the emerging trends and growth opportunities in the Lightweight Insulating Castable market?

The Lightweight Insulating Castable market is characterized by several emerging trends and significant growth opportunities that are set to redefine its landscape. A prominent trend is the increasing demand for ultra-low cement and no-cement castables, driven by their superior performance at higher temperatures, reduced drying shrinkage, and enhanced resistance to chemical attack, offering significant advantages over traditional formulations. Another key trend involves the development of greener and more sustainable refractory solutions, including those with lower embodied carbon, reduced dust emission during installation, and improved recyclability, aligning with global efforts towards decarbonization and circular economy principles. The customization of castable formulations to meet highly specific industrial requirements is also a growing trend, requiring close collaboration between manufacturers and end-users to optimize performance for unique operational environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager