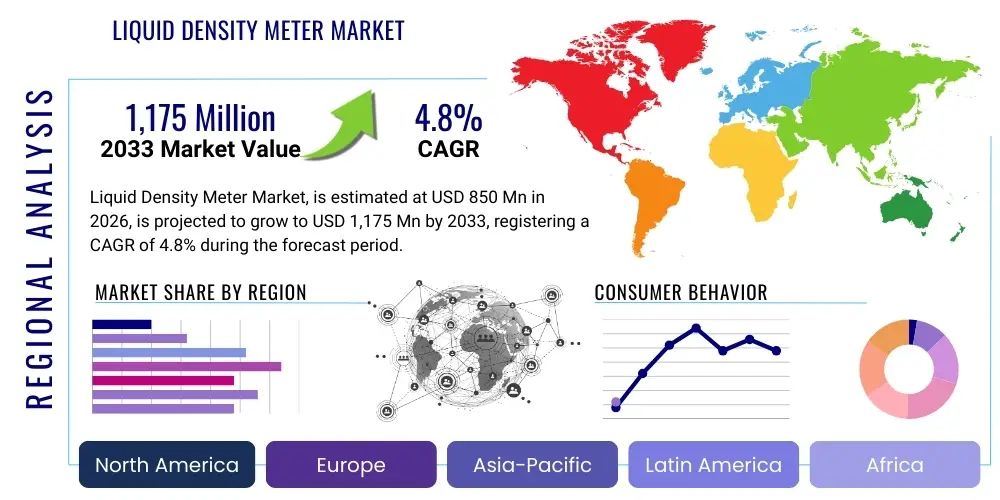

Liquid Density Meter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438211 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Liquid Density Meter Market Size

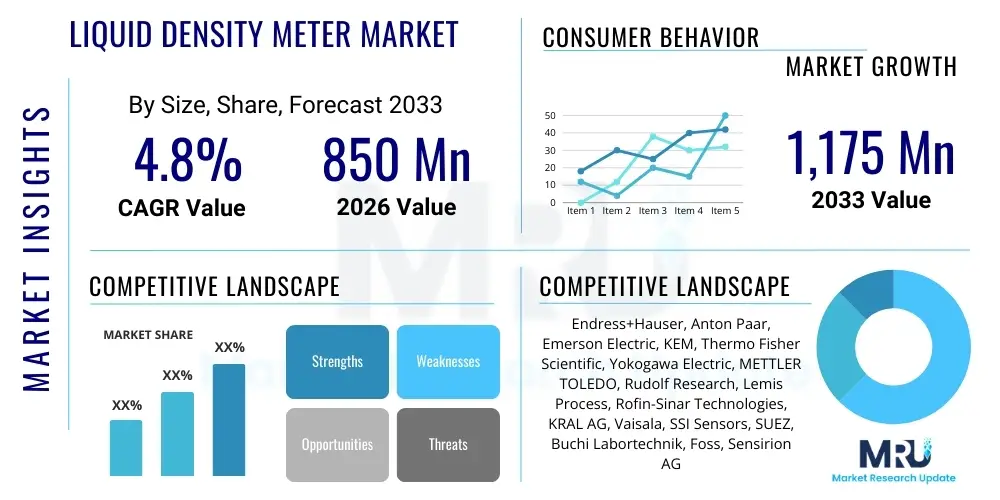

The Liquid Density Meter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,175 Million by the end of the forecast period in 2033.

Liquid Density Meter Market introduction

The Liquid Density Meter Market encompasses sophisticated instrumentation designed for the precise measurement of liquid density, a critical parameter across numerous industrial processes and scientific research applications. These instruments operate based on various principles, including oscillating U-tubes, resonant frequency analysis, and hydrostatic balance, providing real-time or laboratory-grade density data. The fundamental product offering includes benchtop laboratory models, portable handheld devices, and inline process meters, catering to a diverse set of requirements ranging from quality control and regulatory compliance to continuous process optimization in challenging industrial environments. Liquid density meters are essential for determining concentration, quality, and purity of substances, driving their pervasive use in sectors that require stringent material specifications, such as petrochemical refining and pharmaceutical manufacturing.

Major applications of liquid density meters span high-stakes industries where small variations in density can significantly impact product efficacy or financial metrics. In the oil and gas sector, these meters are crucial for custody transfer measurements, determining the quality of crude oil and refined products, and monitoring blending operations. Within the food and beverage industry, they ensure consistency and regulatory adherence by measuring sugar concentration (Brix) in soft drinks or alcohol content in spirits. Key benefits derived from utilizing high-precision density meters include enhanced operational efficiency, reduced material waste through accurate blending, improved process safety, and consistent product quality assurance. The market growth is substantially driven by increasing automation in process industries, stricter environmental and quality regulations, and the rising demand for real-time monitoring solutions to minimize human error and operational variability.

Liquid Density Meter Market Executive Summary

The Liquid Density Meter Market is witnessing robust expansion, primarily propelled by global trends toward Industry 4.0 integration and the mandatory requirement for high-accuracy measurement systems in regulated industries. Business trends highlight a strong shift from traditional manual methods towards highly automated, inline, and digital density measurement solutions, which offer continuous data acquisition and seamless integration with distributed control systems (DCS) and SCADA systems. Furthermore, market competition is fostering innovation, particularly in developing sensor technology that can withstand harsh operating conditions, including high temperatures, high pressures, and corrosive media, thereby expanding the applicability of these meters in challenging chemical processing environments. Strategic partnerships focusing on software integration and predictive maintenance capabilities are becoming prevalent among leading vendors to offer comprehensive solution packages rather than standalone hardware.

Regional trends indicate that Asia Pacific (APAC) is emerging as the fastest-growing market segment, fueled by rapid industrialization, extensive investments in infrastructure, and the expansion of chemical, pharmaceutical, and F&B manufacturing bases, particularly in China and India. North America and Europe retain significant market shares, characterized by a high demand for premium, high-accuracy instruments driven by strict quality control standards and established regulatory frameworks in the healthcare and oil & gas sectors. Segment trends show that the Vibrating U-tube technology remains the dominant segment due to its reliability and proven accuracy, while the application of portable handheld meters is surging across quality control laboratories and field testing scenarios, driven by convenience and cost-effectiveness. The pharmaceuticals segment is a key vertical showing accelerating demand, necessitating highly validated and accurate density measurement for drug formulation consistency and quality assurance throughout the production lifecycle.

AI Impact Analysis on Liquid Density Meter Market

Users frequently inquire about how Artificial Intelligence (AI) and machine learning (ML) can transform data generated by liquid density meters, moving beyond mere measurement into actionable predictive insights. Common questions center on the ability of AI to detect subtle anomalies in density trends that might indicate impending equipment failure or process drift before human operators notice, and how AI integration can enhance calibration frequency and accuracy autonomously. Furthermore, stakeholders are keen to understand the feasibility of using ML algorithms to correlate density data with other process variables (such as temperature, viscosity, or concentration) to build highly accurate digital twins of industrial processes, thereby optimizing input materials and minimizing batch variations. The core expectation is that AI will shift density measurement from a reactive monitoring tool to a proactive, diagnostic, and optimization mechanism.

The convergence of AI with Liquid Density Meter technology is focused on advanced data processing and system optimization rather than fundamental measurement principles. AI algorithms are being applied to analyze vast datasets generated by inline density meters, identifying complex correlations and patterns indicative of material quality variations or maintenance needs. This predictive capability significantly reduces unplanned downtime and streamlines calibration schedules, ensuring the long-term reliability and accuracy of the instruments. Integrating AI-powered diagnostics into density meters enhances their functional value, transforming them from simple sensing devices into smart, self-optimizing components within a larger industrial internet of things (IIoT) framework, ultimately lowering total cost of ownership and maximizing measurement efficacy in dynamic industrial settings.

- Enhanced Predictive Maintenance: AI models analyze density drift and vibration patterns to forecast sensor failure, maximizing uptime.

- Automated Calibration Scheduling: Machine learning optimizes calibration frequency based on usage and environmental variables, ensuring AEO.

- Real-Time Process Optimization: AI correlates density readings with flow rates and temperature to recommend adjustments for ideal product consistency.

- Anomaly Detection and Quality Control: Algorithms identify minute, non-linear deviations in density data signaling potential contamination or batch inconsistencies.

- Improved Data Integrity and Reporting: AI assists in validating measurement data against historical trends, reducing human error in regulatory documentation.

DRO & Impact Forces Of Liquid Density Meter Market

The Liquid Density Meter Market is fundamentally shaped by several powerful drivers, chief among them being the increasing stringency of global regulatory standards, particularly in the pharmaceutical and petrochemical industries, which mandate precise quality control and documentation of material properties. The pervasive trend of industrial automation across developing economies also fuels demand, as density meters are essential components in optimizing closed-loop control systems. Opportunities for market expansion reside in the growing adoption of Coriolis mass flow meters, which inherently provide both flow rate and density measurements, offering a multi-parameter solution, and the untapped potential in emerging applications such as carbon capture and storage (CCS) and specialized biotechnology processes. However, the market faces restraints, primarily the high initial cost associated with advanced digital density meters and the requirement for highly skilled personnel for their installation, calibration, and maintenance, which can be prohibitive for small and medium-sized enterprises (SMEs).

The impact forces influencing the market trajectory include technological advancements in micro-electro-mechanical systems (MEMS) and sensor miniaturization, leading to more compact and robust devices suitable for harsh environments. The increasing focus on sustainability and energy efficiency also acts as a driver, as precise density measurement contributes to optimized blending and reduced energy consumption in fluid handling processes. Restraining forces also include measurement challenges posed by complex, non-Newtonian, or abrasive fluids, which can affect sensor longevity and accuracy, requiring costly specialized solutions. The competitive landscape is characterized by established players maintaining dominance through patent portfolios and brand loyalty, while new entrants often focus on niche applications or specialized portable units. Successfully navigating the high capital expenditure required for R&D and meeting diverse industry-specific certification standards are key factors determining market success and long-term viability within this specialized instrument sector.

Segmentation Analysis

The Liquid Density Meter Market is comprehensively segmented based on technology, application, and end-use industry, reflecting the diverse operational needs across the industrial and scientific landscape. Technological segmentation differentiates instruments based on their working principle, impacting their accuracy, cost, and suitability for inline or laboratory use. Application segmentation highlights the specific use cases, such as quality assurance, concentration measurement, or process control, defining the primary function within the user’s workflow. Furthermore, end-use industry segmentation provides a clear picture of demand distribution across high-value sectors like Oil & Gas, Chemicals, and Pharmaceuticals, which dictates regulatory and performance requirements. This granular segmentation is crucial for vendors to tailor their product offerings and marketing strategies to address specific vertical market needs efficiently.

The dominant segmentation factors driving market dynamics are technology and end-use industry. The vibrating U-tube segment, particularly the digital models, commands the largest share due to its superior accuracy and ability to perform reliably across a wide range of temperatures and pressures, making it the standard in laboratory and high-end industrial applications. Conversely, the rise of specialized industries like wastewater treatment and biotechnology demands customized sensor materials and designs, driving the growth of niche technology segments such as resonant frequency methods. Understanding these interdependencies allows market participants to prioritize R&D investments, focusing on developing ruggedized instruments for challenging sectors like upstream oil and gas, while simultaneously improving user interface and data connectivity for regulated sectors like pharmaceuticals, where data integrity is paramount.

- By Technology:

- Vibrating U-tube (Digital/Analog)

- Coriolis Mass Flow Meters (Integrated Density Measurement)

- Hydrostatic Weighing

- Differential Pressure

- Electromagnetic/Radiometric

- By Type:

- Laboratory/Benchtop Density Meters

- Inline/Process Density Meters

- Portable/Handheld Density Meters

- By Application:

- Concentration Measurement (Brix, Alcohol, Acids)

- Quality Control and Assurance

- Process Control and Monitoring

- Custody Transfer and Inventory Management

- By End-Use Industry:

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical and Petrochemical

- Food and Beverage

- Pharmaceuticals and Biotechnology

- Water and Wastewater Treatment

- Power Generation and Energy

Value Chain Analysis For Liquid Density Meter Market

The value chain for the Liquid Density Meter Market begins with upstream activities involving the sourcing and refinement of high-purity materials, including specialized metals (like Tantalum or Hastelloy for corrosive applications), piezoelectric materials, and advanced electronic components necessary for sensor and transducer construction. Key upstream risks include volatility in raw material prices and securing components that meet strict industrial specifications and certification standards (e.g., ATEX, IECEx for hazardous environments). Research and Development forms a critical component upstream, focusing on improving measurement stability, temperature compensation capabilities, and miniaturization of sensing elements, thus directly influencing the final product's precision and applicability. Collaboration with specialized materials science firms is often essential at this stage to develop corrosion-resistant and highly responsive sensor components required for demanding chemical and high-temperature processes.

Downstream activities center on manufacturing, assembly, rigorous quality testing, and market distribution. Manufacturing involves highly technical processes, especially the precision fabrication and welding of U-tubes and Coriolis sensors, which require specialized machinery and cleanroom environments to maintain accuracy. Distribution channels are typically complex, involving a mix of direct sales teams for large industrial clients (like major petrochemical companies) requiring custom integration and technical support, and indirect channels such as authorized distributors, systems integrators, and value-added resellers (VARs) who handle localized sales, installation, and after-sales service, particularly for portable or standardized laboratory units. The service component, including regular calibration, maintenance contracts, and certified repairs, represents a significant and high-margin segment of the downstream value chain, ensuring prolonged operational life and regulatory compliance for end-users, thus reinforcing brand loyalty and continuous revenue streams beyond the initial hardware sale.

Liquid Density Meter Market Potential Customers

The potential customer base for Liquid Density Meters is highly diversified, spanning multiple industrial sectors that rely on precise fluid characterization for operational success and regulatory adherence. End-users fall broadly into two categories: industrial process control environments and dedicated research/quality control laboratories. In industrial settings, the primary buyers are operations managers, process engineers, and automation specialists in sectors like oil refineries and chemical plants, where meters are integrated directly into pipelines for real-time monitoring of concentration, purity, and mass flow. These customers prioritize robustness, reliability, ease of integration with existing DCS infrastructure, and certifications for hazardous area classification. The purchase decision is typically high-value and long-term, focused on total cost of ownership (TCO) and maintenance requirements.

Conversely, laboratory and research institutions, including government testing labs, university research centers, and pharmaceutical QA/QC departments, primarily purchase high-precision benchtop and portable models. These buyers—often lab managers or research scientists—prioritize extreme accuracy, minimum sample volume requirements, and comprehensive data traceability features necessary for compliance with standards like GMP (Good Manufacturing Practice) and ISO. Specific high-growth segments of buyers include contract manufacturing organizations (CMOs) in pharmaceuticals and large-scale breweries and distilleries who utilize density meters for critical blending and formulation steps. Furthermore, environmental monitoring agencies are increasingly becoming important customers, using portable meters for field measurement of pollutants and water quality parameters, driven by global environmental mandates and rigorous effluent control regulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,175 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Endress+Hauser, Anton Paar, Emerson Electric, KEM, Thermo Fisher Scientific, Yokogawa Electric, METTLER TOLEDO, Rudolf Research, Lemis Process, Rofin-Sinar Technologies, KRAL AG, Vaisala, SSI Sensors, SUEZ, Buchi Labortechnik, Foss, Sensirion AG, Honeywell International, Siemens AG, Hach Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Liquid Density Meter Market Key Technology Landscape

The technological landscape of the Liquid Density Meter Market is dominated by resonance-based methods, primarily the Vibrating U-tube and Coriolis technologies, which offer superior accuracy and repeatability crucial for commercial and regulatory applications. Vibrating U-tube technology, utilized in both laboratory and inline settings, relies on measuring the change in the resonant frequency of a tube containing the fluid; the denser the liquid, the lower the frequency. Recent advancements in this area focus on integrating advanced temperature and pressure compensation algorithms to maintain high accuracy even under rapidly changing process conditions, addressing a historical limitation. Furthermore, vendors are heavily investing in miniaturization using MEMS technology to create robust, low-power portable devices that offer near-laboratory grade precision in field environments, expanding the utility beyond fixed installations into field monitoring and remote asset management applications.

The increasing prominence of Coriolis Mass Flow Meters represents a significant technological convergence, as these devices simultaneously deliver highly accurate measurements of mass flow, volumetric flow, and fluid density. This inherent capability makes Coriolis meters increasingly competitive against specialized density meters in applications where both flow and density parameters are required, particularly in custody transfer and high-value blending operations. Other key technologies include hydrostatic density meters, often preferred for measuring slurries or extremely viscous materials due to their simpler, robust design, and radiometric techniques used in applications where sensors cannot be in direct contact with the fluid due to high temperatures or corrosive properties. The future trajectory involves greater emphasis on digital connectivity, leveraging industrial protocols (like HART, Profibus, EtherNet/IP) and cloud-based data platforms to facilitate remote diagnostics, automatic data logging, and seamless integration into complex IIoT ecosystems, transforming sensor data into enterprise-wide operational intelligence.

Regional Highlights

- North America: North America holds a substantial share of the Liquid Density Meter Market, driven primarily by the extensive oil and gas industry, particularly in the United States and Canada, where high-precision meters are essential for crude oil quality assessment, pipeline management, and custody transfer. The regional market is characterized by high adoption rates of advanced, integrated density solutions, including Coriolis meters, necessary for compliance with stringent environmental and financial reporting standards. Furthermore, the strong presence of major pharmaceutical and biotechnology companies drives consistent demand for high-accuracy benchtop meters used in R&D and quality assurance processes, with an emphasis on validated systems and regulatory adherence.

- Europe: Europe is a mature market distinguished by high regulatory focus and technological innovation, particularly within Germany, the UK, and Switzerland. The region’s growth is underpinned by the robust chemical manufacturing sector and the demanding food and beverage industry (e.g., brewing and dairy), which require highly accurate and certified measurement instruments for consistent product quality. European market penetration is high for high-end digital density meters, with significant investment directed towards implementing Industry 4.0 standards, promoting the use of smart sensors with enhanced diagnostic capabilities and integrated communication protocols across manufacturing sites.

- Asia Pacific (APAC): APAC is projected to exhibit the highest Compound Annual Growth Rate (CAGR) during the forecast period. This rapid expansion is a result of large-scale infrastructure development, massive investments in industrialization across countries like China, India, and Southeast Asia, and the establishment of new chemical and refinery complexes. The demand is currently accelerating for both cost-effective analog units and modern digital meters necessary for scaling up production capacity while maintaining quality standards. Government initiatives promoting domestic manufacturing and the burgeoning middle class driving demand for packaged food and beverages further cement APAC’s position as the leading growth engine for density meter deployment.

- Latin America: The Latin American market, anchored by Brazil and Mexico, demonstrates moderate growth, significantly influenced by developments in the regional oil and gas sector and agricultural processing industries. Market stability relies heavily on national investments in energy infrastructure and mining operations, where robust inline meters are needed for continuous process monitoring. Challenges include economic volatility and a preference for cost-sensitive solutions, though increased foreign direct investment in sophisticated manufacturing operations is gradually driving demand for higher-precision instruments.

- Middle East and Africa (MEA): The MEA region's demand is overwhelmingly dominated by the massive oil and gas sector, particularly the Gulf Cooperation Council (GCC) countries. Liquid density meters are indispensable for upstream exploration, midstream pipeline operations, and downstream refining processes, specifically for determining the API gravity of crude oil and ensuring accurate measurement during export. Investment in large-scale desalination and water treatment projects in the region also contributes to market demand for density and concentration measurement solutions, focusing on instruments built to withstand harsh, arid operating conditions and high salinity levels.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Liquid Density Meter Market.- Endress+Hauser

- Anton Paar

- Emerson Electric

- KEM Küppers Elektromechanik

- Thermo Fisher Scientific

- Yokogawa Electric Corporation

- METTLER TOLEDO

- Rudolf Research Analytical

- Lemis Process

- Rofin-Sinar Technologies (Coherent)

- KRAL AG

- Vaisala

- SSI Sensors

- SUEZ (Water Technologies & Solutions)

- Buchi Labortechnik AG

- Foss A/S

- Sensirion AG

- Honeywell International Inc.

- Siemens AG

- Hach Company

Frequently Asked Questions

Analyze common user questions about the Liquid Density Meter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technology driving accuracy in modern liquid density meters?

The Vibrating U-tube technology is the industry standard, offering high precision through the measurement of resonant frequency changes caused by variations in fluid density. Advanced digital models incorporate rigorous temperature and pressure compensation to ensure accuracy across diverse industrial conditions, making it vital for regulatory compliance.

How do inline liquid density meters differ from laboratory benchtop models in industrial applications?

Inline meters are robustly designed for continuous, real-time process monitoring within pipelines, requiring high resistance to pressure and temperature variations, and integration with control systems (DCS). Benchtop models, conversely, prioritize maximum precision and minimal sample volume, typically used for final product quality control and detailed research analysis in controlled environments.

Which end-use industry represents the largest market share for liquid density meters?

The Oil and Gas industry commands the largest market share globally. Density meters are critical for determining API gravity, ensuring efficient custody transfer, monitoring blending operations, and complying with international standards regarding the quality and composition of crude oil and refined petroleum products.

What role does Coriolis technology play in the Liquid Density Meter Market expansion?

Coriolis meters offer a multi-variable solution by measuring mass flow, volumetric flow, and fluid density simultaneously with high accuracy. This integration enhances operational efficiency, reduces the need for multiple instruments, and drives market expansion, particularly in high-value custody transfer and complex blending applications within the chemical sector.

What are the main market restraints impacting the global adoption of liquid density meters?

The key restraints include the substantial initial capital investment required for high-end digital and inline density meters, which can deter SMEs, and the need for specialized technical expertise for installation, complex calibration routines, and certified long-term maintenance required to meet stringent industry regulatory standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Liquid Density Meter Market Statistics 2025 Analysis By Application (Chemical and Petrochemical, Beverage, Pharmaceutical), By Type (Inline Type, Desktop Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- High Precision Liquid Density Meter Market Statistics 2025 Analysis By Application (PharmacEuropetical, Chemical & Petrochemical, Beverage), By Type (Oscillating U-tube, Archimedes Principle), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- High Precision Liquid Density Meter Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (In Line, Desktop), By Application (Biochemistry, Medical, Food & Beverage, Industrial, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Liquid Density Meter Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Flоаt tуре, Нуdrоѕtаtіс tуре, Vіbrаtоrу tуре, Rаdіаtіоn tуре, Ultrаѕоnіс tуре, Оthеrѕ), By Application (Oіl аnd Gаѕ, Pеtrосhеmісаl, Chеmісаl, Fооd аnd Bеvеrаgе, Gеnеrаl Prосеѕѕ Induѕtrіеѕ), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager