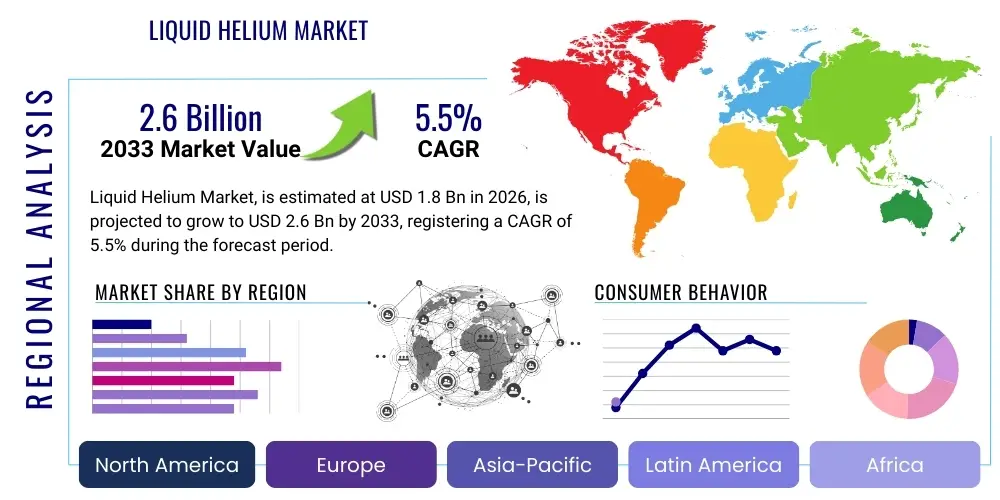

Liquid Helium Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437565 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Liquid Helium Market Size

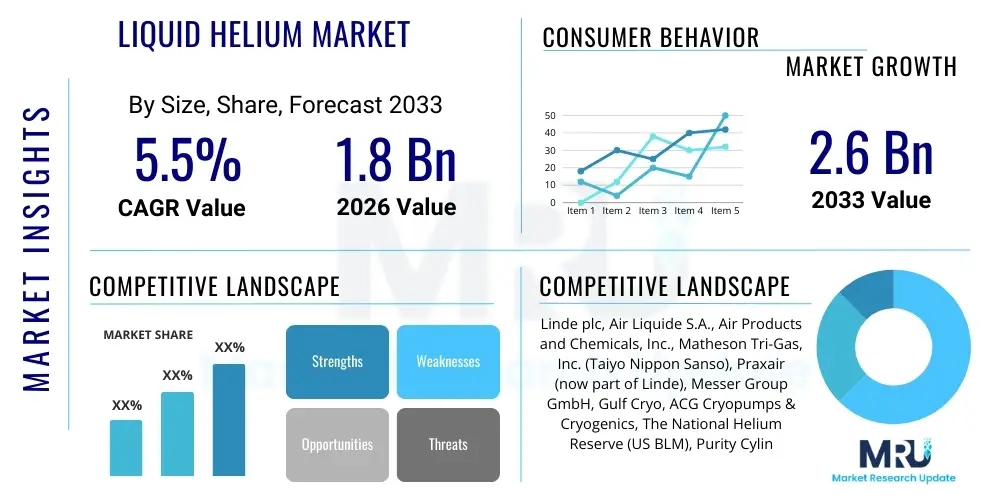

The Liquid Helium Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 2.6 Billion by the end of the forecast period in 2033.

Liquid Helium Market introduction

Liquid Helium (LHe) is a cryogenic fluid produced by cooling gaseous helium to approximately -269 degrees Celsius (4.2 Kelvin), making it the coldest known substance. This extremely low temperature, combined with its non-reactive nature, makes it indispensable across various high-technology and scientific applications. Helium, the second lightest element, exists naturally, but its liquid form requires complex and energy-intensive liquefaction processes. The unique properties of Liquid Helium, particularly its superfluid phase (Helium II), which exhibits zero viscosity and infinite thermal conductivity, are crucial for advanced cooling requirements where traditional refrigerants fail.

The primary applications of Liquid Helium revolve around the cooling of superconducting magnets, predominantly used in Magnetic Resonance Imaging (MRI) machines in healthcare and high-energy physics research, such as particle accelerators. Furthermore, it serves as an inert purging agent in rocketry and aerospace, and is vital for manufacturing processes requiring extremely low temperatures, including fiber optics and semiconductor production. The market growth is fundamentally driven by the escalating demand for high-resolution medical imaging and the rapid expansion of quantum computing research, both relying heavily on stable, ultra-low temperature environments maintained solely by Liquid Helium.

Key benefits derived from Liquid Helium include its ability to achieve temperatures necessary for superconductivity, enabling high-efficiency devices like advanced sensor systems and specialized scientific instruments. The primary driving factors encompass increased global investments in healthcare infrastructure, particularly in emerging economies, alongside robust governmental funding for large-scale scientific projects and defense applications utilizing sophisticated sensor technology. However, the market faces constraints related to its finite resource nature and complex supply chain logistics, often involving international transportation of large cryogenic dewars.

Liquid Helium Market Executive Summary

The Liquid Helium market trajectory is characterized by steady growth, primarily propelled by sustained demand from the medical and electronics sectors. Business trends indicate a focus on optimizing helium recovery and recycling technologies, aiming to mitigate the challenges associated with resource scarcity and volatile pricing structures. Key industry players are increasingly investing in proprietary liquefaction and storage technologies to enhance efficiency and reduce boil-off losses during transit and storage. Consolidation among major gas producers and increased strategic partnerships with end-use sectors, particularly large hospital networks and semiconductor fabrication plants, are defining the competitive landscape, emphasizing reliability and long-term supply agreements.

Regional trends reveal that North America and Europe currently dominate the market share, driven by advanced healthcare systems and significant expenditure on physics research and quantum technology development. However, the Asia Pacific (APAC) region is projected to exhibit the highest CAGR during the forecast period. This accelerated growth is attributed to massive governmental initiatives focused on establishing indigenous semiconductor manufacturing capabilities, coupled with expanding patient populations requiring MRI diagnostics in countries like China, India, and South Korea. Infrastructure improvements and rapid urbanization in APAC necessitate specialized cryogenic technology, further fueling local demand.

Segmentation analysis highlights the dominance of the healthcare segment (MRI systems) in terms of consumption volume, although the electronics and semiconductor segment is rapidly gaining ground due to the increasing complexity and miniaturization of chips requiring precise cooling during etching processes. By source, the segmentation leans heavily on natural gas reserves, but technological advancements are making non-traditional sources, such as helium recovery from geothermal vents, increasingly viable, signaling a potential diversification in sourcing strategies over the long term. These trends collectively underscore a market evolving towards greater sustainability, operational efficiency, and geographical diversification of demand centers.

AI Impact Analysis on Liquid Helium Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Liquid Helium market frequently center on two main themes: optimization of the cryogenic supply chain and the role of liquid helium in powering next-generation quantum computing systems, which are foundational to advanced AI model training. Key concerns often relate to whether AI can effectively predict and manage supply chain disruptions—given the scarcity and complex logistics of LHe—and how AI-driven optimization might reduce wastage (boil-off). Users are also keen on understanding the correlation between the exponential computational demand for AI and the subsequent need for specialized cooling environments, particularly in large data centers and future quantum devices.

The direct application of AI is primarily felt in enhancing operational efficiencies throughout the helium value chain. Predictive maintenance algorithms, powered by AI, are being deployed to monitor the performance of liquefiers, storage tanks, and transportation dewars, minimizing equipment failure and maximizing uptime. Furthermore, complex machine learning models are used to forecast regional demand fluctuations with higher accuracy, allowing suppliers to optimize routing and inventory levels, thereby reducing energy consumption during liquefaction and minimizing the inherent rate of boil-off during storage and transportation. This move towards intelligent supply chain management helps stabilize the erratic pricing structure historically associated with LHe scarcity.

Indirectly, AI acts as a significant demand driver. Quantum computing, often utilizing Liquid Helium to maintain the necessary superposition state of qubits at near absolute zero, is central to solving problems currently intractable by classical computing. As global technology firms accelerate their development of quantum processors to handle increasingly complex AI workloads (such as optimization, drug discovery, and advanced simulation), the demand for high-ppurity Liquid Helium directly proportional to the scale and operational frequency of these quantum labs will intensify. Thus, AI optimization improves the supply side efficiency, while AI-driven technologies (like quantum computing) simultaneously amplify the demand side.

- AI algorithms optimize logistics and routing for LHe transportation, minimizing transit time and boil-off loss.

- Predictive maintenance using AI monitors cryogenic equipment integrity, reducing unscheduled downtime for liquefiers and storage units.

- Machine learning models enhance demand forecasting accuracy for regional LHe consumption, allowing for better resource allocation.

- Quantum computing platforms, foundational for advanced AI research and processing, require stable LHe cooling, driving increased high-purity demand.

- AI aids in processing large datasets from geological surveys to identify and assess new, viable natural helium reserves efficiently.

- Smart sensors integrated with AI monitor dewar pressure and temperature in real-time, preventing critical failures and ensuring product quality.

DRO & Impact Forces Of Liquid Helium Market

The dynamics of the Liquid Helium market are governed by a complex interplay of drivers, restraints, and strategic opportunities that collectively shape its growth trajectory. The fundamental drivers are anchored in the relentless technological progression within high-tech sectors, particularly in medical diagnostics and advanced electronics. However, the market’s reliance on a finite, non-renewable resource, coupled with intricate geopolitical factors affecting sourcing, presents significant restraints. Opportunities lie in technological innovation, specifically in advanced recovery and recycling systems, which promise to decouple market growth partially from resource vulnerability, while the emerging demand from quantum technology offers a substantial future revenue stream.

Major driving forces include the global proliferation of MRI installations, which are the single largest commercial consumers of LHe, driven by rising chronic disease prevalence and improved healthcare access globally. Furthermore, the expansion of high-energy physics research, governmental investment in fusion energy projects, and the increased production of sophisticated semiconductor chips (requiring LHe for precision cooling during lithography) provide sustained demand impetus. These drivers ensure a baseline requirement for LHe purity and volume that is unlikely to diminish in the foreseeable future, compelling suppliers to seek stable, diversified supply channels.

Conversely, the market faces crucial restraints, primarily the inherent scarcity of helium gas, which is a byproduct of natural gas extraction, making its supply susceptible to the volatile oil and gas market. Compounding this is the high cost of liquefaction, storage, and transportation, which involves expensive cryogenic infrastructure. Geopolitical risks associated with major production hubs (e.g., the U.S., Qatar) introduce supply chain fragility. The primary mitigating opportunity involves advancing helium recycling technologies—both onsite (for large users like MRI centers) and large-scale recovery from non-traditional sources—which can significantly enhance resource efficiency and reduce dependency on primary extraction, thereby stabilizing future supply and pricing volatility. The impact forces indicate high bargaining power of suppliers due to resource concentration and critical nature of the product, counterbalanced slightly by the emergence of cryogen-free technologies (pulse tube refrigerators) in some lower-field applications.

- Drivers: Growing adoption of MRI technology globally; significant investment in high-energy physics and space exploration; rising demand for superconductors and advanced electronics.

- Restraints: Finite nature and scarcity of helium reserves; high energy consumption and capital cost associated with liquefaction and cryogenic storage; complex, volatile international supply chain logistics.

- Opportunity: Development and commercialization of advanced helium recovery and recycling systems; emerging demand from quantum computing and advanced magnetic levitation technologies.

- Impact Forces: Strong supplier concentration leading to high bargaining power; limited threat of substitutes due to LHe's unique temperature characteristics; increasing regulatory focus on resource conservation.

Segmentation Analysis

The Liquid Helium market is meticulously segmented based on end-use application, source, and distribution mode, allowing for detailed analysis of consumption patterns and strategic market positioning. The segmentation highlights the critical dependency of high-technology industries on this cryogenic substance, revealing distinct volume and purity requirements across sectors like healthcare, electronics, and research. Analyzing these segments provides strategic insights into investment areas, particularly where technological innovation (such as next-generation cryogen-free systems) might potentially disrupt traditional consumption models, or where emerging fields (like quantum technology) are poised to dramatically increase demand.

By application, the market is heavily skewed towards Medical Diagnostics (MRI), followed by Electronics and Semiconductors, and Scientific Research. The MRI segment requires substantial quantities of LHe to cool the superconducting magnets in high-field scanners, dictating high standards for reliable, bulk delivery. The electronics segment, conversely, demands ultra-high purity LHe for sophisticated manufacturing processes like crystal growth and high-throughput wafer fabrication, prioritizing quality over sheer volume. Understanding these purity and volume differences is crucial for suppliers to tailor production and logistics.

Source segmentation is vital for resource security assessment, primarily encompassing Natural Gas Extraction and Recovery & Recycling. While traditional natural gas extraction remains the dominant source, the focus on closed-loop recycling systems is intensifying due to resource scarcity. Distribution mode analysis distinguishes between bulk and cylinder deliveries, reflecting the scale of the customer base—large research facilities and hospitals typically requiring bulk cryogenic tankers, while smaller labs and universities rely on smaller, highly insulated cylinders.

- By Application:

- Medical Diagnostics (MRI, NMR)

- Electronics & Semiconductors

- Aerospace & Defense

- Scientific Research & Laboratory Applications (High-Energy Physics, Cryogenics)

- Energy (Nuclear Fusion Research)

- By Source:

- Natural Gas Extraction

- Recovery & Recycling

- By Distribution Mode:

- Bulk Supply (ISO Containers, Cryogenic Tankers)

- Cylinders & Dewars (Smaller volume vessels)

Value Chain Analysis For Liquid Helium Market

The Liquid Helium value chain is characterized by its high capital intensity and strict adherence to technical specifications across all stages, starting from geological exploration and ending with sophisticated end-user applications. The upstream segment involves the discovery, extraction, and purification of crude helium, typically a co-product of natural gas. This stage is dominated by a few global players operating large-scale natural gas processing facilities, defining high barriers to entry due to massive infrastructure investment and geopolitical resource control. Helium purification and subsequent liquefaction require highly specialized, energy-intensive cryogenic plants capable of reaching near absolute zero temperatures. Efficiencies at this stage directly impact final market price and availability.

The midstream operations focus on global logistics and storage, which is critical due to the persistent boil-off characteristic of LHe. Distribution channels are highly specialized, relying on a fleet of dedicated cryogenic ISO containers, trailers, and micro-bulk tanks, ensuring the product maintains its temperature during transit across continents. Direct distribution is common for large, anchor customers such as MRI original equipment manufacturers (OEMs) and national research labs, facilitating long-term supply contracts and tailored delivery schedules. Indirect distribution often utilizes regional industrial gas distributors who maintain smaller local inventories to serve universities, smaller medical centers, and industrial clients.

Downstream analysis centers on the integration of LHe into advanced technological processes. This includes onsite handling, transfer into specialized cryogenic systems (e.g., superconducting magnets, dilution refrigerators), and increasingly, the implementation of localized helium recovery and recycling systems within the end-user facility. The complexity of handling LHe means that technical support and associated cryogenic services (maintenance, refills) form a significant component of the value proposition. The stability and reliability of this downstream support are pivotal for continuous, high-stakes operations in medical and research fields, driving end-users to prefer suppliers who offer comprehensive service packages alongside the cryogenic product.

Liquid Helium Market Potential Customers

Potential customers for Liquid Helium are defined by their critical need for extreme cryogenic cooling and inert atmospheric conditions, spanning multiple high-value technological and scientific domains. The largest group of end-users consists of hospitals and diagnostic imaging centers globally, where Liquid Helium is the core enabling agent for high-field Magnetic Resonance Imaging (MRI) and Nuclear Magnetic Resonance (NMR) spectroscopy instruments. These customers prioritize guaranteed, uninterrupted supply and robust technical service contracts, as any disruption can halt essential medical procedures.

The second major consumer base includes the Electronics and Semiconductor industry, specifically fabrication plants involved in lithography, etching, and fiber optic production. These facilities require ultra-high purity LHe for processes sensitive to trace contaminants, focusing on quality control and ensuring minimal process variability. Additionally, government-funded research institutions, national laboratories conducting high-energy physics experiments (e.g., CERN), and aerospace organizations (for purging rocket fuel tanks and testing sensitive instruments) represent significant, high-volume purchasers of LHe for both research and operational deployment.

An emerging, high-growth customer segment comprises companies and academic institutions focused on Quantum Computing and advanced low-temperature materials science. These users demand highly reliable, often smaller-scale, localized supply for dilution refrigerators required to maintain qubit stability near absolute zero. Strategic market efforts are increasingly targeting these rapidly expanding technology hubs, recognizing their future consumption potential, which tends to be less price-sensitive than commodity industrial applications due to the mission-critical nature of the research.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 2.6 Billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linde plc, Air Liquide S.A., Air Products and Chemicals, Inc., Matheson Tri-Gas, Inc. (Taiyo Nippon Sanso), Praxair (now part of Linde), Messer Group GmbH, Gulf Cryo, ACG Cryopumps & Cryogenics, The National Helium Reserve (US BLM), Purity Cylinder Gases, Inc., Wesfarmers Chemicals, Energy & Fertilisers (Kleenheat), Iwatani Corporation, Buzwair Industrial Gases, Midland Cryogenics Ltd., Proton Gases (India) Pvt. Ltd., Advanced Gas Technologies Inc., Iceblick Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Liquid Helium Market Key Technology Landscape

The technology landscape supporting the Liquid Helium market is heavily focused on achieving ultra-low temperatures efficiently, ensuring purity, and minimizing thermal losses across the supply chain. Key technological advancements center around two main areas: large-scale, high-efficiency helium liquefiers and sophisticated cryogenic storage and transport vessels. Modern industrial liquefiers utilize complex thermodynamic cycles, often incorporating pre-cooling stages (like liquid nitrogen or specialized Joule-Thomson expanders) to maximize the yield and energy efficiency during the transformation of gaseous helium into its liquid state. Innovations in compressor design and heat exchanger technology are continually aimed at reducing the substantial energy footprint associated with liquefaction.

Crucially, the development of advanced cryostat and dewar technology is paramount for maintaining the liquid state during transit and use. These storage vessels incorporate multi-layer insulation (superinsulation) and high-vacuum jackets to drastically reduce the heat leak, thereby minimizing the rate of boil-off—a critical factor given the high cost and scarcity of LHe. Furthermore, integrated sensor technology and telemetry systems are increasingly deployed on bulk ISO containers and delivery tankers. These systems monitor real-time pressure, temperature, and volume, allowing suppliers to proactively manage inventory and predict potential system failures, improving overall supply chain reliability and reducing product loss.

Another major technological focus is in advanced helium recovery and purification systems employed at end-user sites. These recovery units, which capture boiled-off helium gas from cryogenic equipment (such as MRI machines or research dilution refrigerators), utilize specialized purification steps (including charcoal adsorption beds at cryogenic temperatures) to restore the gas to the required ultra-high purity levels before re-liquefaction. The increasing adoption of high-performance Cryocoolers, particularly Pulse Tube Refrigerators (PTRs) and Gifford-McMahon (GM) coolers, represents a technological shift. While these cryocoolers do not eliminate the need for LHe entirely in the highest-field applications (like specialized quantum systems), they reduce the frequency and volume of LHe consumption in intermediate-field applications, necessitating a more complex servicing model for the market.

Regional Highlights

The Liquid Helium market exhibits distinct consumption and production patterns across major global regions, influenced significantly by regional healthcare infrastructure development, government spending on fundamental research, and the concentration of high-tech manufacturing bases.

- North America: This region maintains a dominant position, driven by the presence of the largest helium reserves and primary extraction facilities (historically centered in the U.S.), coupled with high R&D intensity. The U.S. is home to major aerospace contractors, advanced medical technology developers, and leading quantum computing initiatives. High density of top-tier universities and national laboratories ensures a constant, substantial demand for LHe in scientific applications. Strict environmental and safety regulations also necessitate high-quality logistics and handling, driving technology adoption in advanced recovery systems.

- Europe: Europe represents a mature market characterized by robust healthcare systems and major collaborative scientific projects, such as CERN (Large Hadron Collider), which is one of the world's largest single consumers of LHe. Demand is stable, supported by strong governmental funding for physics, chemistry, and fusion energy research (e.g., ITER). Key markets like Germany, the UK, and France are focused on adopting closed-loop recycling technology to mitigate the risk posed by international supply volatility, aiming for greater resource self-sufficiency in high-tech sectors.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally. This exponential growth is fueled by massive investments in semiconductor fabrication plants, particularly in Taiwan, South Korea, and China, which require LHe for cooling during etching and deposition processes. Furthermore, rapid expansion of healthcare access in densely populated countries like India and China necessitates increased installation of MRI and diagnostic equipment. Government policies heavily promoting indigenous high-technology manufacturing and establishing domestic R&D centers are accelerating LHe consumption across the region.

- Latin America: This region accounts for a smaller share, with demand primarily concentrated in major economies like Brazil and Mexico. Consumption is largely driven by established urban healthcare sectors and moderate academic research activities. Market expansion is dependent on governmental infrastructure projects and sustained foreign direct investment in sophisticated medical equipment and high-tech manufacturing, often relying heavily on imports from North America.

- Middle East and Africa (MEA): The MEA region is crucial on the supply side, with Qatar being a global leader in helium production, leveraging its vast natural gas reserves. While production is concentrated here, consumption within the MEA region itself is moderate, primarily focused on oil and gas industry applications (inert purging) and limited high-end hospital facilities in the Gulf Cooperation Council (GCC) countries. Market growth is gradually accelerating due to diversification efforts aiming to build indigenous high-tech and research capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Liquid Helium Market.- Linde plc

- Air Liquide S.A.

- Air Products and Chemicals, Inc.

- Matheson Tri-Gas, Inc. (A subsidiary of Taiyo Nippon Sanso Corporation)

- Messer Group GmbH

- Gulf Cryo

- Iwatani Corporation

- ACSS (Advanced Cryogenic Solutions & Services)

- Sichuan Qiyuan Gas Co., Ltd.

- Air Water Inc.

- Nippon Gases (Formerly Praxair European assets)

- Buzwair Industrial Gases

- The National Helium Reserve (Managed by US Bureau of Land Management)

- Cryostar SAS

- Chart Industries, Inc. (Focusing on equipment and infrastructure)

- Weisbrod LLC

- Midland Cryogenics Ltd.

- Proton Gases (India) Pvt. Ltd.

- Advanced Gas Technologies Inc.

- Iceblick Ltd.

Frequently Asked Questions

Analyze common user questions about the Liquid Helium market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the current price volatility of Liquid Helium?

Price volatility is primarily driven by geopolitical factors affecting major production hubs (resource concentration in the U.S. and Qatar), unplanned outages at major liquefaction facilities, and the inherent supply inelasticity as helium is a non-renewable byproduct of natural gas extraction. Fluctuations in natural gas market pricing and complex global logistics further amplify cost variations.

How does the electronics and semiconductor industry utilize Liquid Helium?

The electronics sector uses Liquid Helium for critical, high-precision manufacturing processes. It is essential for cooling superconducting components used in advanced testing equipment, maintaining vacuum conditions, growing ultra-pure crystals, and facilitating deep ultraviolet (DUV) lithography used in the fabrication of high-density semiconductor chips.

Is there a viable alternative to Liquid Helium for cooling superconducting MRI magnets?

While Cryogen-free MRI systems utilizing high-performance Cryocoolers (such as Pulse Tube Refrigerators) are gaining traction, these systems currently often require initial or periodic use of LHe or rely on specialized, lower-field magnet designs. For the highest field-strength MRI and most advanced scientific research applications, Liquid Helium remains irreplaceable due to its unique combination of ultra-low temperature capability and stability.

What role does helium recycling play in ensuring long-term market sustainability?

Helium recycling is critical for market sustainability by recovering boiled-off gas from end-user equipment and re-purifying it for re-liquefaction. Increased adoption of sophisticated closed-loop recovery systems minimizes wastage, reduces dependency on new extraction, and helps mitigate long-term resource scarcity, ultimately contributing to a more stable supply chain.

How is the demand from the emerging quantum computing sector impacting the Liquid Helium supply?

The quantum computing sector requires ultra-high purity Liquid Helium to cool dilution refrigerators down to millikelvin temperatures necessary for qubit stability. Although current volumes are small relative to MRI demand, the exponential scaling of quantum research labs globally indicates that this emerging sector is poised to become a significant, non-negotiable driver of specialized LHe demand in the latter half of the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager