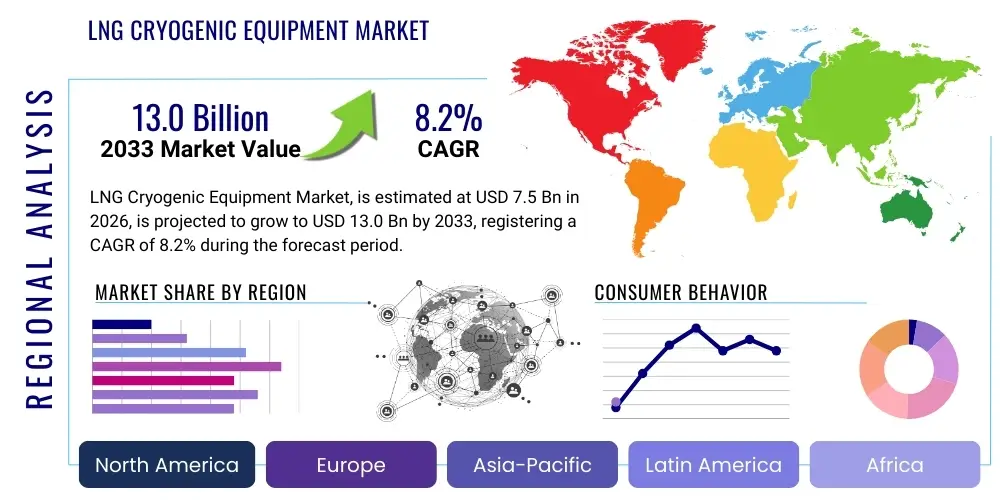

LNG Cryogenic Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439092 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

LNG Cryogenic Equipment Market Size

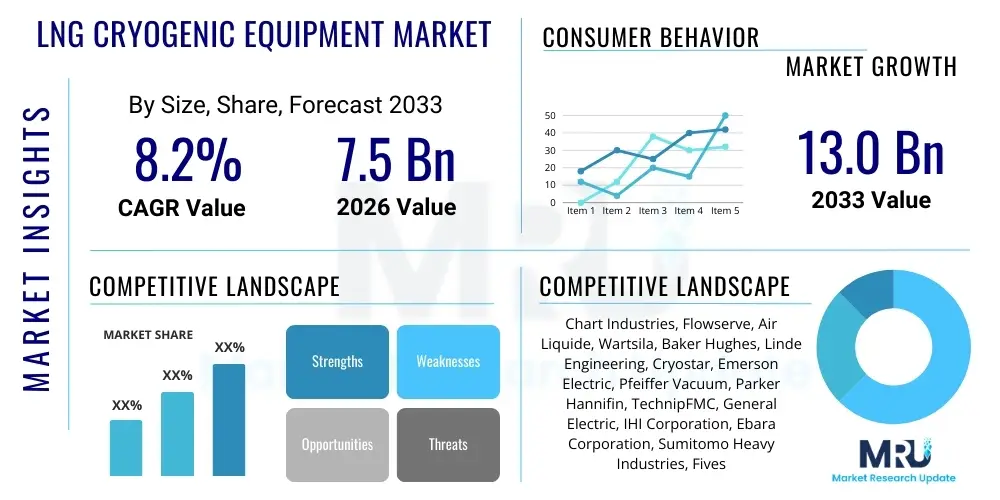

The LNG Cryogenic Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.2% between 2026 and 2033. The market is estimated at USD 7.5 Billion in 2026 and is projected to reach USD 13.0 Billion by the end of the forecast period in 2033.

LNG Cryogenic Equipment Market introduction

The LNG Cryogenic Equipment Market encompasses specialized machinery and infrastructure designed for handling, storage, transport, and regasification of Liquefied Natural Gas (LNG), which is stored at approximately -162°C (-260°F). These critical components include high-vacuum insulated storage tanks, advanced cryogenic pumps, compressors, heat exchangers, and specialized valves capable of operating under extreme temperature gradients and high pressure. The primary function of this equipment is to maintain LNG in its liquid state, optimizing volume efficiency for long-distance transportation and ensuring safe operational integrity across the entire LNG supply chain, from upstream liquefaction terminals to downstream distribution networks.

Major applications driving the demand for cryogenic equipment span large-scale natural gas liquefaction plants, Floating Storage and Regasification Units (FSRUs), LNG receiving terminals, and increasingly, the marine bunkering sector. The benefits derived from utilizing specialized cryogenic systems include significantly reduced operational energy losses (boil-off gas management), enhanced safety features through robust material science (e.g., austenitic stainless steels and nickel alloys), and the facilitation of global energy trade by making natural gas economically transportable across oceans. This infrastructure is foundational to the global shift towards cleaner energy sources, as LNG serves as a vital transition fuel replacing higher-carbon intensity alternatives in power generation and heavy transportation.

Driving factors for sustained market expansion are intrinsically linked to the increasing global demand for natural gas, supported by stringent environmental regulations encouraging the substitution of coal and heavy fuel oil. Furthermore, infrastructural investments in emerging economies, particularly in Asia Pacific, for establishing new import terminals and expanding gas pipeline networks, necessitate robust cryogenic solutions. The technological advancements leading to more compact, efficient, and standardized modular cryogenic equipment, suitable for offshore and remote installations, further accelerate market penetration, ensuring reliability and reducing capital expenditure for complex LNG projects.

LNG Cryogenic Equipment Market Executive Summary

The LNG Cryogenic Equipment Market exhibits strong growth trajectory, fundamentally driven by strategic shifts in the global energy landscape favoring natural gas consumption and robust cross-border trade via maritime routes. Business trends indicate a marked preference for modular and standardized liquefaction and regasification units, reducing construction timelines and lowering project risks. Key equipment manufacturers are focusing on improving boil-off gas management systems and developing highly efficient cryogenic pumps and compressors using digital twin technology for predictive maintenance, thereby enhancing operational efficiency and lowering lifecycle costs for terminal operators and vessel owners. Furthermore, there is a distinct move towards incorporating renewable energy sources to power ancillary cryogenic processes, aligning with broader decarbonization goals across the energy value chain.

Regionally, Asia Pacific maintains its dominance, spurred by massive investments in new LNG import infrastructure, particularly in China, India, and Southeast Asian nations aiming to secure reliable, cleaner energy supply for rapidly expanding industrial and residential sectors. North America, conversely, drives the market through large-scale LNG export projects, necessitating significant investment in high-capacity liquefaction and storage equipment. Segments trends highlight the transport and storage categories as the primary revenue generators. Within the equipment segment, cryogenic storage tanks, particularly those employing advanced insulation techniques and full containment designs, command the largest market share due to their integral role in both onshore terminals and LNG carrier fleets. The marine sector is emerging as a high-growth segment, fueled by regulatory mandates requiring cleaner marine fuels, driving the adoption of LNG bunkering infrastructure and LNG fuel tanks on ships.

AI Impact Analysis on LNG Cryogenic Equipment Market

User inquiries regarding AI's impact on the LNG cryogenic sector frequently center on themes such as predictive failure analysis for critical components (pumps, compressors, valves), optimization of liquefaction energy consumption, and autonomous boil-off gas (BOG) control systems in storage and transport vessels. Users are keen to understand how AI and machine learning (ML) algorithms can mitigate the high costs associated with equipment downtime, improve safety protocols, and enhance the overall energy efficiency of highly intensive cryogenic processes. The consensus expectation is that AI integration will transition the industry from reactive maintenance schedules to proactive, performance-based operations, thereby extending asset lifespan and reducing operational risks inherently associated with handling ultra-cold fluids.

The primary influence of AI lies in its ability to process vast streams of sensor data generated by sophisticated cryogenic equipment, including temperature, pressure, flow rates, and vibration analysis. By establishing baseline operational signatures and detecting subtle deviations, AI/ML models can predict equipment failure hours or days in advance, allowing operators to schedule maintenance without causing unplanned shutdowns or compromising the thermal integrity of the stored LNG. This shift towards AI-driven predictive maintenance significantly reduces the risk of catastrophic failure in high-pressure, low-temperature environments, which are characteristic of cryogenic systems.

Beyond maintenance, AI algorithms are crucial for optimizing the complex thermodynamics inherent in LNG processes, particularly during the liquefaction phase which accounts for a substantial portion of the overall energy costs. ML models can dynamically adjust compressor speeds, heat exchanger configurations, and refrigerant mixtures in real-time based on ambient conditions and throughput requirements, maximizing yield and minimizing energy wastage. Furthermore, AI enhances safety by integrating data from gas detectors and pressure sensors to provide immediate, context-aware responses to abnormal conditions, ultimately leading to safer, more efficient, and fully optimized LNG supply chain management.

- AI-driven Predictive Maintenance: Reduces unplanned downtime and operational expenditure (OPEX) by accurately forecasting failures in cryogenic pumps and valves based on vibration and temperature anomalies.

- Optimized Liquefaction Processes: Machine learning algorithms dynamically control cooling cycles and refrigerant usage to minimize energy consumption in high-intensity liquefaction terminals.

- Autonomous Boil-Off Gas (BOG) Management: AI systems intelligently manage BOG by adjusting tank pressure, utilizing reliquefaction units, or channeling gas for fuel, minimizing cargo loss during storage and transit.

- Enhanced Safety Protocols: Real-time anomaly detection and decision support systems improve hazard identification, particularly critical in handling flammable, extremely cold substances.

- Digital Twin Implementation: AI supports the creation of precise virtual models of cryogenic assets for simulation, scenario planning, and accelerated operator training.

DRO & Impact Forces Of LNG Cryogenic Equipment Market

The LNG Cryogenic Equipment Market is propelled by strong systemic Drivers, primarily global energy demand shifts and stringent environmental mandates, which are partially offset by significant Restraints such as high capital expenditure and complex regulatory environments. The market is fertile with Opportunities centered around technological innovation, particularly in small-scale LNG (ssLNG) and marine bunkering applications. These factors converge to create powerful Impact Forces that fundamentally shape investment decisions, asset design, and supply chain strategies across the entire natural gas value chain, emphasizing efficiency, safety, and sustainable operation.

Key drivers include the global push for reducing carbon emissions, positioning natural gas as a critical bridge fuel, leading to increased investment in LNG export and import capacity worldwide. The expansion of LNG infrastructure necessitates massive procurement of cryogenic tanks, pumps, and heat exchangers. Conversely, restraints predominantly involve the substantial initial investment required for constructing cryogenic terminals and carriers, coupled with the reliance on highly specialized materials (like Invar or stainless steel alloys) and labor expertise, which can inflate project costs and timelines. Furthermore, the sensitivity of public opinion and regulatory hurdles regarding the siting of large-scale LNG facilities sometimes delay market realization.

Opportunities for growth are concentrated in the rapid development of LNG as a marine fuel, driven by IMO 2020 regulations and subsequent targets for reducing sulfur and nitrogen oxide emissions in shipping. This opens up vast potential for cryogenic equipment manufacturers specializing in shipboard fuel gas supply systems (FGSS) and bunkering infrastructure. Technological advancements, such as modular design and vacuum jacketed piping systems for improved efficiency, also present opportunities. The interplay of these forces—strong inherent demand balanced by high technical barriers—results in an environment where established, technically competent players with deep pockets dominate, while innovation in efficiency and miniaturization determines future competitive advantage.

- Drivers (D)

- Rising global demand for natural gas as a cleaner alternative to coal and oil.

- Increasing cross-border trade of LNG, requiring robust transportation and storage infrastructure.

- Growth in the LNG bunkering segment driven by maritime decarbonization mandates (IMO regulations).

- Technological advancements leading to improved operational efficiency and reduced boil-off rates (BoR).

- Restraints (R)

- High initial capital expenditure (CAPEX) required for large-scale cryogenic projects.

- Volatile natural gas prices influencing final investment decisions (FIDs) for new terminals.

- Complex and stringent regulatory frameworks governing the design and safety of cryogenic systems.

- Technical complexities associated with material handling and thermal stresses at ultra-low temperatures.

- Opportunities (O)

- Development of small-scale LNG (ssLNG) infrastructure for remote power generation and regional distribution.

- Adoption of Floating Storage and Regasification Units (FSRUs) offering flexible, rapid deployment solutions.

- Integration of advanced sensor technology and AI for predictive maintenance and enhanced safety management.

- Expansion into non-traditional applications such as LNG-fueled heavy-duty vehicles and rail transport.

- Impact Forces

- Supply Chain Vulnerability: Reliance on specialized suppliers for high-grade materials (e.g., specific stainless steels and nickel alloys) increases vulnerability to geopolitical and trade disruptions.

- Thermal Efficiency Mandates: Continuous pressure from operators to reduce energy loss (BOG) drives rapid innovation in insulation and reliquefaction technologies.

- Standardization vs. Customization: A trend towards modular, standardized equipment packages conflicts with the need for highly customized solutions for ultra-large liquefaction projects, requiring manufacturers to balance scale economy with specific project demands.

- Safety Compliance: Strict adherence to codes (e.g., NFPA, IMO) profoundly impacts equipment design, material selection, and installation procedures, acting as a non-negotiable threshold for market entry.

Segmentation Analysis

The LNG Cryogenic Equipment Market is broadly segmented based on Equipment Type, Application, and End-Use Industry, providing a granular view of revenue streams and growth pockets. The equipment type segmentation is crucial as it differentiates between high-value capital goods like storage tanks and ancillary components such as pumps, valves, and heat exchangers, each possessing distinct market dynamics regarding material complexity, manufacturing lead times, and technological maturity. Analysis shows that segments critical to the handling and preservation of the LNG cargo, specifically storage tanks and reliquefaction units, constitute the majority of the market value, followed closely by high-performance cryogenic pumps and compressors necessary for efficient fluid movement across the supply chain.

The application segmentation reveals that large-scale infrastructure projects—namely liquefaction and regasification terminals—remain the foundational pillars of market demand due to the immense scale and complexity of equipment required. However, the transport segment, encompassing both large LNG carriers and smaller distribution tankers, is expected to exhibit the highest CAGR, primarily fueled by the continuous expansion of global trade routes and the need for new, highly efficient vessel designs. Furthermore, the shift in End-Use segmentation highlights the rising prominence of the marine industry, moving away from purely energy and utility sectors, as ships convert to LNG fuel, driving specialized demand for smaller, robust cryogenic fuel storage systems adaptable to harsh marine environments and constrained spaces.

Understanding these segments allows market participants to strategically align their product development and sales efforts. Manufacturers specializing in durable, high-pressure valves and vacuum-insulated piping, for instance, target both new terminal construction and maintenance/retrofit markets. Conversely, companies focusing on advanced heat exchangers and cold box technology prioritize complex, high-efficiency liquefaction projects. The integration of advanced diagnostics and remote monitoring capabilities across all equipment types is becoming a standard feature, driven by the end-users' need to maximize uptime and adhere to increasingly stringent operational efficiency metrics dictated by international energy regulators.

- By Equipment Type

- Cryogenic Storage Tanks (Full Containment, Membrane, Sphere, Flat Bottom Tanks)

- Cryogenic Pumps and Compressors

- Cryogenic Vaporizers (Ambient Air, Shell and Tube, Submerged Combustion)

- Cryogenic Valves (Ball, Globe, Gate, Check, Relief Valves)

- Cryogenic Heat Exchangers (Plate-Fin, Coil Wound)

- Cryogenic Piping and Accessories (Vacuum Jacketed Piping, Couplings)

- Reliquefaction Systems

- By Application

- Liquefaction Terminals (Upstream)

- Regasification Terminals (Downstream)

- Transportation and Storage (Onshore, Offshore, Maritime Vessels)

- Distribution and Bunkering

- By End-Use Industry

- Energy and Power Generation

- Marine (Shipping and Bunkering)

- Chemical and Petrochemical

- Automotive (Heavy-Duty Vehicles)

- Industrial Gases

Value Chain Analysis For LNG Cryogenic Equipment Market

The value chain for LNG Cryogenic Equipment is highly integrated and capital-intensive, starting with the upstream sourcing and processing of specialized materials. This phase involves procuring high-grade, low-temperature resistant materials such as 9% Nickel steel, austenitic stainless steels, and advanced insulation composites (e.g., perlite and vacuum insulation panels). Suppliers in this initial phase must meet exceptionally strict quality controls and traceability standards due to the critical nature of the equipment's operational environment. Following material preparation, the manufacturing stage involves complex precision engineering, welding, and assembly of components like cryogenic vessels, pumps, and compressors, which demands highly specialized fabrication facilities and skilled labor certified in low-temperature metallurgy.

The distribution channel is characterized by a mix of direct and indirect engagement. For large, custom-engineered projects such as massive onshore storage tanks or core components for liquefaction trains, sales are almost exclusively direct. Equipment manufacturers work closely with EPC (Engineering, Procurement, and Construction) firms and final asset owners (e.g., national energy companies or international oil companies) through highly competitive, multi-year tender processes. This direct sales model ensures technical alignment and complex contractual management. For standardized, smaller components like valves, instruments, and pumps used in smaller distribution networks or maintenance operations, indirect channels involving specialized industrial distributors and local authorized service partners are utilized to provide localized inventory and rapid replacement services.

The downstream analysis focuses on the installation, commissioning, and subsequent long-term maintenance lifecycle. Once manufactured, the equipment is delivered to the project site—often a remote port or specialized shipyard. Commissioning involves rigorous testing under cryogenic conditions, frequently managed by the equipment vendor or specialized third-party engineering firms. Post-installation, the value shifts towards aftermarket services, including mandatory inspections, spare parts supply, preventative maintenance contracts, and digital monitoring services. This long-tail revenue stream is vital for major equipment providers, fostering long-term relationships and ensuring the operational integrity and safety of the high-value LNG assets throughout their 30-40 year lifespan.

LNG Cryogenic Equipment Market Potential Customers

The primary customers for LNG cryogenic equipment are large-scale energy producers and infrastructure operators who possess the financial capacity and technical necessity for these specialized assets. These buyers fall mainly into three categories: national oil and gas companies (NOCs) and international oil companies (IOCs) investing in export terminals; independent power producers and utilities establishing import and regasification infrastructure; and global shipping firms transitioning their fleets to cleaner fuels. The purchasing decisions are heavily influenced by regulatory compliance, long-term energy security strategies, and the required specifications for thermal efficiency and operational reliability, given the immense financial consequences of equipment failure.

A crucial segment of potential buyers includes Engineering, Procurement, and Construction (EPC) companies, such as TechnipFMC, Bechtel, and KBR. While not the final end-users, EPCs act as major intermediaries, purchasing large volumes of equipment packages (e.g., entire cold boxes or pump skids) on behalf of the asset owner. These companies demand proven technologies, competitive pricing, and adherence to strict project timelines. Therefore, equipment vendors must maintain strong relationships and pre-qualification status with leading global EPCs to secure their participation in major LNG projects. The procurement cycle for these large contracts is extensive, often spanning 12 to 18 months, characterized by intense technical scrutiny and commercial negotiation.

Finally, the growing marine and bunkering sector represents an increasingly important customer base. Shipyards building LNG carriers, LNG-fueled container ships, cruise liners, and ferry operators are all potential customers requiring specialized, compact, and highly reliable shipboard cryogenic fuel tanks (Type C, Type B, or membrane tanks) and associated fuel gas supply systems (FGSS). Additionally, port authorities and specialized bunkering service providers investing in floating or shore-based bunkering facilities (truck-to-ship, ship-to-ship) also constitute key buyers, prioritizing safety certifications and efficient transfer capabilities in highly regulated maritime environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.5 Billion |

| Market Forecast in 2033 | USD 13.0 Billion |

| Growth Rate | 8.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Chart Industries, Flowserve, Air Liquide, Wartsila, Baker Hughes, Linde Engineering, Cryostar, Emerson Electric, Pfeiffer Vacuum, Parker Hannifin, TechnipFMC, General Electric, IHI Corporation, Ebara Corporation, Sumitomo Heavy Industries, Fives Group, Nikkiso Co. Ltd., Velan Inc., Samson AG, Mitsui OSK Lines (MOL) Technical Division |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

LNG Cryogenic Equipment Market Key Technology Landscape

The technological landscape of the LNG Cryogenic Equipment Market is characterized by a relentless pursuit of efficiency, safety, and operational reliability, driven primarily by the need to minimize boil-off gas (BOG) and reduce the energy intensity of liquefaction and regasification processes. A key technological focus is on insulation advancements. High-performance vacuum-insulated panels (VIPs) and optimized multi-layer insulation systems are increasingly replacing traditional perlite or foam glass to achieve superior thermal performance in storage tanks and piping, directly leading to lower boil-off rates (BoR) and substantial operational savings over the asset lifespan. Furthermore, the development of modular and standardized cold boxes, which integrate complex heat exchange and separation components into compact, factory-assembled units, accelerates project completion and reduces onsite construction risk, particularly beneficial for small-scale and remote LNG applications.

Another pivotal area is the innovation surrounding rotational equipment, specifically cryogenic pumps and compressors. Manufacturers are integrating magnetic bearing technology into high-speed cryogenic turbomachinery. Magnetic bearings eliminate the need for traditional lubrication systems, drastically reducing contamination risk and maintenance requirements, while enabling higher operational speeds and efficiency, crucial for large-scale LNG liquefaction trains. Alongside hardware improvements, the integration of advanced sensors and Industrial Internet of Things (IIoT) frameworks is standard practice. These smart systems monitor vibration, pressure, temperature, and material stress in real-time, feeding data into sophisticated diagnostic platforms for enhanced condition monitoring and predictive maintenance strategies.

The marine sector also features unique technological developments, particularly with the proliferation of Floating Storage and Regasification Units (FSRUs) and LNG bunkering infrastructure. FSRUs rely on highly efficient, often submerged, combustion vaporizers which utilize seawater or a closed loop system to convert LNG back to natural gas, demanding specialized material resistance to both cryogenic temperatures and corrosive marine environments. Similarly, ship-to-ship bunkering requires precise flow measurement and transfer systems (including specialized cryogenic hoses and coupling mechanisms) that must meet stringent international safety standards (e.g., IGF Code compliance), ensuring zero leakage and rapid disconnection capability under emergency scenarios, thereby guaranteeing the safety and speed necessary for commercial vessel operations.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant regional market and is projected to maintain the highest growth rate throughout the forecast period. This dominance stems from the region's massive energy infrastructure build-out, primarily driven by the need to meet surging industrialization and urbanization demands in developing economies like China, India, and Vietnam. These nations are aggressively transitioning from coal to natural gas, necessitating substantial investment in new LNG import terminals, FSRUs, and extensive domestic distribution networks, thereby fueling demand for large cryogenic storage tanks, regasification units, and associated piping systems. Government policies focused on improving air quality and securing long-term energy supplies further solidify APAC's position as the core revenue hub for the cryogenic equipment market.

- North America: North America, particularly the United States, is the leading region in terms of LNG export capacity expansion. The proliferation of liquefaction plants along the Gulf Coast and increasing domestic small-scale LNG usage for trucking and remote industrial operations drive high-value demand for complex cryogenic compression trains, large-capacity storage spheres, and advanced reliquefaction equipment. The U.S. acts as a technology incubator for advanced cryogenic technologies, leveraging its vast natural gas reserves to become a major global supplier, ensuring continuous investment in reliable, high-throughput equipment designed for extreme operational cycles.

- Europe: The European market demonstrates steady growth, highly influenced by energy security concerns and the rapid adoption of LNG as a marine fuel. Following recent geopolitical shifts, European nations are diversifying their gas supply, leading to investments in new import terminals and the expansion of existing receiving facilities, particularly in Germany and Eastern Europe. Furthermore, strict environmental regulations governing maritime transport across the North Sea and Baltic Sea zones stimulate demand for specialized LNG bunkering ports and advanced ship fuel gas supply systems (FGSS), positioning Europe as a leader in the marine cryogenic segment and related infrastructure upgrades.

- Middle East and Africa (MEA): MEA is critical due to its established position as a major LNG exporter (e.g., Qatar, Australia) and its emerging role as a gas consumer. While export terminals continue to be upgraded with state-of-the-art liquefaction components, regional infrastructure development, particularly in Africa, focuses on using LNG for power generation in decentralized or remote areas, driving demand for small-scale, modular cryogenic solutions and regional transport equipment. MEA's strategic importance lies in its role in global LNG supply stabilization, ensuring continued investment in asset integrity and high-capacity storage equipment.

- Latin America: This region presents localized opportunities, especially in countries like Brazil and Chile, which rely on FSRUs and flexible import solutions to meet seasonal power generation peaks and secure diversified energy supplies. The primary demand driver here is the rapid deployment capability of floating solutions (FSRUs) rather than large, permanent onshore terminals, requiring robust, marine-grade cryogenic equipment suitable for dynamic offshore environments and intermittent operation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the LNG Cryogenic Equipment Market.- Chart Industries

- Flowserve Corporation

- Air Liquide

- Wartsila Corporation

- Baker Hughes, a GE Company

- Linde Engineering

- Cryostar SAS (Part of Linde plc)

- Emerson Electric Co.

- Pfeiffer Vacuum Technology AG

- Parker Hannifin Corporation

- TechnipFMC PLC

- General Electric (GE) Oil & Gas

- IHI Corporation

- Ebara Corporation

- Sumitomo Heavy Industries, Ltd.

- Fives Group

- Nikkiso Co. Ltd.

- Velan Inc.

- Samson AG

- Mitsui OSK Lines (MOL) Technical Division

Frequently Asked Questions

Analyze common user questions about the LNG Cryogenic Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for LNG cryogenic storage tanks?

The primary driver is the accelerating global energy transition where Liquefied Natural Gas serves as a vital bridging fuel, leading to massive investments in new LNG import and export terminals worldwide, which necessitates large-scale, specialized cryogenic storage infrastructure.

How does the marine bunkering sector influence the LNG Cryogenic Equipment market growth?

The marine bunkering sector significantly boosts market growth by driving demand for specialized shipboard cryogenic fuel gas supply systems (FGSS), compact fuel tanks (Type C tanks), and shore-side bunkering facilities, driven by IMO regulations promoting LNG as a cleaner maritime fuel.

Which technological innovation is most critical for improving the efficiency of LNG transport?

The most critical innovation is advanced boil-off gas (BOG) management technology, including highly efficient reliquefaction systems and superior vacuum-insulated piping, which minimize cargo loss and maximize the economic viability of long-distance LNG transportation.

What are the key material requirements for equipment operating at LNG temperatures?

Key material requirements include high-tensile, low-temperature resistant alloys such as 9% Nickel steel and specific grades of austenitic stainless steel, which maintain ductility and structural integrity under sustained exposure to temperatures down to -162°C.

How is predictive maintenance implemented in LNG cryogenic equipment?

Predictive maintenance is implemented using IIoT sensors and AI algorithms that continuously monitor equipment parameters like vibration, pressure, and temperature. These systems forecast potential failures in pumps, compressors, and valves, allowing operators to schedule proactive maintenance before operational disruption occurs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager