Lockout Tagout Devices Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437618 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Lockout Tagout Devices Market Size

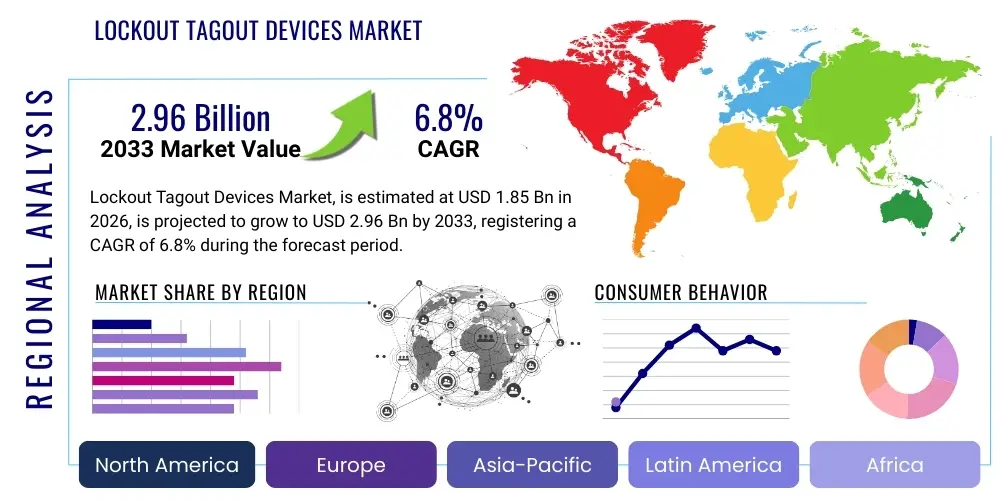

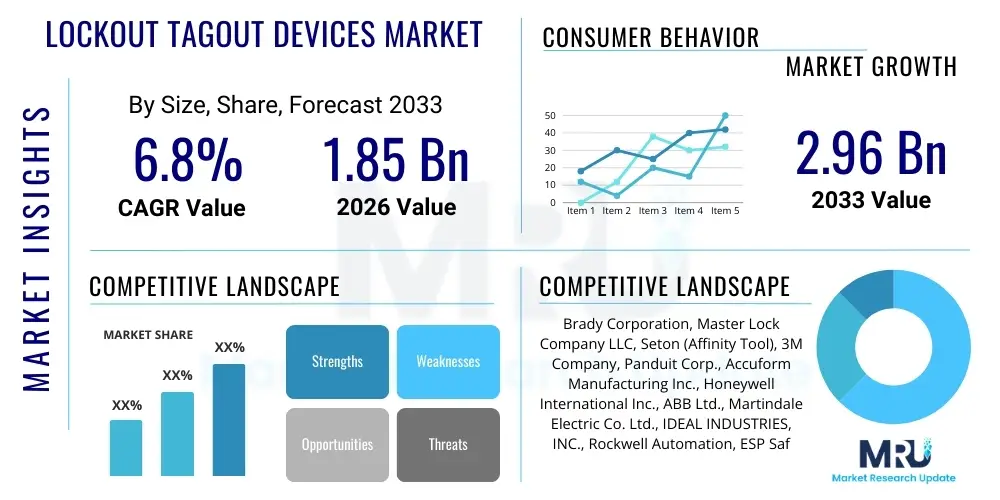

The Lockout Tagout Devices Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.96 Billion by the end of the forecast period in 2033.

Lockout Tagout Devices Market introduction

The Lockout Tagout (LOTO) Devices Market encompasses specialized safety equipment designed to prevent the accidental startup or release of hazardous energy during maintenance, repair, or service operations on machinery and equipment. These devices are critical components of industrial safety protocols, ensuring compliance with global standards, most notably OSHA (Occupational Safety and Health Administration) mandates in the United States, and similar regulatory bodies worldwide. LOTO procedures involve physically locking an energy isolating device to prevent its operation and placing a tag on the device to warn of potential hazards, thereby protecting workers from stored mechanical, electrical, hydraulic, pneumatic, chemical, or thermal energy. The product portfolio ranges from simple padlocks and safety tags to complex valve lockouts, cable lockouts, and electrical circuit breaker lockouts, addressing diverse industrial machinery requirements.

Major applications for LOTO devices span across high-risk industrial sectors, including heavy manufacturing, oil and gas extraction, power generation (thermal, nuclear, and renewable), chemical processing, and wastewater treatment facilities. The primary benefit derived from the utilization of robust LOTO programs is the significant reduction in workplace fatalities and serious injuries resulting from unexpected equipment energization. Effective implementation ensures systematic control over hazardous energy, minimizing liability for corporations and fostering a culture of proactive safety management. The growing global emphasis on worker protection standards, coupled with rapid industrialization in emerging economies, solidifies the foundational demand for these safety products.

Key factors driving market expansion include increasingly stringent governmental regulations concerning industrial safety, mandatory adoption of comprehensive LOTO procedures by multinational corporations, and the sustained modernization of aging industrial infrastructure requiring extensive maintenance work. Furthermore, technological advancements leading to specialized, non-conductive, and highly durable LOTO materials (such as reinforced nylon and high-strength plastics) are enhancing product effectiveness and expanding applicability across harsh operating environments. The market dynamics are highly influenced by compliance cycles and mandatory safety training programs, ensuring continuous replacement and upgrade of installed LOTO systems globally.

Lockout Tagout Devices Market Executive Summary

The Lockout Tagout Devices Market is characterized by steady, compliance-driven growth, underpinned by mandatory industrial safety legislation across developed and developing economies. Business trends indicate a shift toward integrated safety solutions, where LOTO procedures are increasingly digitized and integrated with broader industrial safety management systems (SMS) utilizing IoT and asset tracking technologies. Manufacturers are focusing on ergonomic designs, material longevity, and highly visible identification systems to improve usability and adherence rates in complex industrial settings. Strategic partnerships between LOTO suppliers and large industrial distributors are crucial for maintaining extensive geographical reach and ensuring rapid supply of specialized equipment required for diverse machinery types.

Regional trends highlight North America, particularly the United States, as the dominant market, driven by the rigorous enforcement of OSHA standards and a mature industrial base with high safety expenditure. However, the Asia Pacific (APAC) region is projected to register the fastest growth rate, fueled by substantial investments in manufacturing, power generation, and infrastructure development in countries like China and India, necessitating immediate adoption of international safety protocols. Europe maintains a strong market presence, characterized by high standards set by the European Agency for Safety and Health at Work (EU-OSHA) and a focus on specialized, high-quality LOTO systems tailored for precision engineering and chemical industries. This global expansion necessitates localized product development that meets regional regulatory nuances.

Segmentation trends reveal that Padlock and Hasps segments retain the largest market share due to their universal application across nearly all LOTO scenarios, though Specialized LOTO devices (e.g., valve, pneumatic, and cable lockouts) are exhibiting higher growth rates as industrial complexity increases. By End-User, the Energy & Utilities sector remains the primary consumer, driven by the inherent high-energy risk associated with power generation and transmission infrastructure. Material segmentation indicates increasing adoption of durable, non-conductive materials like reinforced plastic and nylon over traditional metal, particularly in electrical and corrosive environments, enhancing safety and extending product lifecycle. This segment evolution underscores the market's dedication to improving device versatility and operational safety.

AI Impact Analysis on Lockout Tagout Devices Market

Common user questions regarding AI's impact on the Lockout Tagout Devices Market revolve primarily around predictive safety, procedural automation, and enhanced compliance monitoring. Users seek to understand if AI can predict equipment failure or hazardous energy release before maintenance is initiated, thus proactively triggering LOTO requirements. Concerns also center on AI’s role in auditing LOTO compliance—specifically, whether computer vision and machine learning algorithms can monitor worker adherence to LOTO steps, verify the correct application of devices, and automate digital permit-to-work systems. The expectation is that AI will transform LOTO from a purely manual, reactive process into an integrated, intelligent safety management system, minimizing human error and enhancing overall operational security.

While AI does not replace the physical necessity of LOTO devices themselves, it profoundly affects the procedures and systems surrounding their use. AI algorithms can analyze vast datasets from maintenance logs, sensor readings (IoT), and past incident reports to identify machinery maintenance tasks requiring LOTO with heightened accuracy, optimizing scheduling and resource allocation. Furthermore, computer vision systems, leveraging AI, can be deployed via fixed or mobile cameras to verify that all energy sources have been effectively locked out and tagged before maintenance work commences, providing a critical layer of automated oversight that significantly strengthens procedural integrity and compliance documentation.

This integration facilitates the transition towards intelligent safety ecosystems. AI-powered platforms can instantly flag non-compliance or deviations from established LOTO protocols in real-time, sending immediate alerts to supervisors and safety personnel. This capability drastically reduces the time between a safety violation occurring and corrective action being taken. Moreover, AI aids in sophisticated risk assessment by learning patterns of energy isolation complexity, ensuring that the appropriate number and type of LOTO devices are provisioned for a specific task, thereby improving the efficiency and effectiveness of hazard control in complex industrial operations.

- AI enhances predictive maintenance by anticipating LOTO needs based on equipment operational data.

- Computer vision and machine learning automate real-time LOTO compliance auditing and verification.

- AI platforms integrate LOTO procedures into digital permit-to-work systems, improving documentation.

- Advanced risk modeling using AI customizes LOTO requirements for unique or complex maintenance tasks.

- Intelligent systems provide immediate alerts for procedural non-compliance, minimizing exposure to hazardous energy.

DRO & Impact Forces Of Lockout Tagout Devices Market

The Lockout Tagout Devices Market is fundamentally shaped by compelling Drivers (D) such as increasingly stringent global safety regulations, primarily enforced by entities like OSHA and EU-OSHA, which mandate the control of hazardous energy. Restraints (R) primarily include the high initial cost associated with implementing comprehensive LOTO programs across diverse industrial facilities, coupled with resistance to change in established maintenance cultures and the perennial challenge of standardizing LOTO procedures across complex multinational operations. Opportunities (O) emerge from the integration of LOTO systems with IoT and smart safety technologies, enabling remote monitoring and improved compliance tracking, and the expansion into rapidly industrializing regions where basic safety infrastructure is still developing. These forces exert significant Impact, driving consistent demand for LOTO equipment while simultaneously pushing manufacturers toward innovation in digital integration and material science.

Key drivers center around legislative compulsion and liability reduction. Governments globally are tightening industrial safety standards following high-profile accidents, making compliance with LOTO protocols mandatory, rather than optional. This legislative pressure directly translates into procurement cycles for new and replacement LOTO devices. Furthermore, multinational corporations prioritize robust LOTO programs not only for safety but also to mitigate substantial financial risks associated with worker injury lawsuits, regulatory fines, and operational downtime resulting from accidents. The continuous training and retraining requirements stipulated by regulatory bodies also ensure sustained consumption of consumables like tags and replacement locks, providing market stability.

Conversely, restraints such as the perceived complexity and time required to execute proper LOTO procedures can hinder seamless adoption, particularly in fast-paced maintenance environments. While high upfront investment in specialized LOTO kits for unique machinery can be a deterrent for Small and Medium Enterprises (SMEs), the lack of universal standardization across different machine manufacturers and jurisdictions complicates training and device inventory management for global industrial conglomerates. However, the market leverages opportunities by developing specialized, modular LOTO solutions that simplify implementation and training. The push toward robust, durable materials that can withstand extreme industrial conditions represents a key area of differentiation and growth, allowing for reduced replacement frequency and lower long-term cost of ownership.

Segmentation Analysis

The Lockout Tagout Devices Market segmentation provides a structured view of the varied product offerings and their end-use applications, which is essential for understanding purchasing patterns and market dynamics. The primary segmentation dimensions include device type, the material used in manufacturing, and the specific end-user industry. Device type segmentation helps distinguish between general-purpose equipment, such as padlocks and hasps, and specialized mechanical and electrical safety tools designed for complex energy isolation points. Material segmentation reflects industry preferences for durability, non-conductivity, and resistance to chemical corrosion. End-user segmentation highlights the core industries driving volume demand and specialized requirements based on the inherent risk profiles and machinery types prevalent in sectors like energy, manufacturing, and construction.

- By Device Type:

- Padlock & Hasps

- Valve Lockouts (Ball, Gate, Butterfly)

- Circuit Breaker Lockouts

- Cable Lockouts

- Pneumatic Lockouts

- Other Specialized LOTO Devices

- By Material:

- Metal (Steel, Aluminum)

- Non-Metal (Plastic, Nylon, Composite Materials)

- By End-User Industry:

- Energy & Utilities (Power Generation, Transmission)

- Manufacturing (Heavy Machinery, Automotive)

- Oil & Gas

- Chemical & Petrochemical

- Construction

- Food & Beverages

- Pharmaceuticals

- Mining

Value Chain Analysis For Lockout Tagout Devices Market

The value chain for the Lockout Tagout Devices Market begins with the Upstream segment, dominated by raw material suppliers providing high-grade plastics (e.g., reinforced nylon, ABS, polypropylene), specialized corrosion-resistant metals (e.g., hardened steel, aluminum), and various locking mechanism components. Quality control at this stage is crucial, as the performance and durability of LOTO devices directly depend on the integrity of these materials. Key challenges upstream involve managing volatile commodity prices and ensuring the sourcing of non-conductive and high-visibility materials that meet specific industrial safety specifications and environmental regulations. Strong supplier relationships are essential for maintaining material consistency and achieving high manufacturing tolerances required for safety equipment.

The Midstream phase involves the design, manufacturing, and assembly of the diverse range of LOTO devices. Manufacturers employ precision molding, stamping, and assembly techniques to produce devices that comply with international standards like OSHA 1910.147. Innovation at this stage focuses on developing universal devices adaptable to multiple machinery types, enhancing tamper resistance, and improving ergonomic features for ease of use by maintenance personnel. High investment in R&D is directed towards integrating RFID technology into locks and tags for automated asset management and procedural verification, adding intelligence to traditionally mechanical devices. Manufacturing excellence and obtaining relevant safety certifications define success in this phase.

The Downstream segment, encompassing distribution and end-user deployment, is critical for market reach. Distribution channels are typically a mix of direct sales to large multinational corporations with centralized procurement, and indirect sales through specialized industrial safety distributors, hardware wholesalers, and e-commerce platforms. Specialized safety distributors often provide value-added services such as safety audits, customized LOTO procedural writing, and site-specific training, making them crucial partners. The final link is the End-User implementation, where successful adoption depends heavily on adequate training and enforcement of LOTO policies, ensuring that the safety investment translates into tangible risk reduction on the factory floor or industrial site.

Lockout Tagout Devices Market Potential Customers

Potential customers and primary buyers of Lockout Tagout devices are overwhelmingly concentrated within sectors characterized by high energy consumption, complex machinery, and mandated safety compliance requirements. These customers are typically large industrial organizations requiring systematic safety controls to protect vast employee bases and expensive assets from unexpected energy release. The core customer base includes industrial operations managers, maintenance supervisors, and specialized safety officers (EHS professionals) responsible for implementing and auditing hazardous energy control programs across multiple operational sites. Their purchasing decisions are driven by compliance deadlines, insurance liabilities, internal safety benchmarks, and the need for durable, reliable equipment that minimizes maintenance downtime.

The Energy & Utilities sector, including power generation plants (coal, gas, nuclear, wind farms), remains the largest and most demanding customer segment. The inherent risks associated with high voltage electricity, high-pressure steam, and large turbines necessitate comprehensive, tailored LOTO procedures and equipment. Similarly, the Heavy Manufacturing and Automotive sectors are massive consumers, requiring extensive inventories of LOTO devices to service production lines, robotics, and hydraulic systems during routine or emergency maintenance shutdowns. These customers often seek bulk procurement of standardized padlocks, multiple-use hasps, and specialized circuit breaker lockouts to manage thousands of energy isolation points.

Emerging key customer segments include the Food and Beverage processing industry and Pharmaceutical manufacturing. Although these sectors may not handle the extreme energy levels of power plants, they face strict hygienic standards and often utilize complex automated processing equipment (mixers, conveyors, high-pressure washers) where accidental startup poses contamination and serious physical hazards. These customers require LOTO devices made of specific materials (e.g., FDA-compliant plastics) that are easy to clean and resist corrosion, demonstrating the nuanced needs within the potential customer base that drive product specialization and inventory diversification across the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.96 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Brady Corporation, Master Lock Company LLC, Seton (Affinity Tool), 3M Company, Panduit Corp., Accuform Manufacturing Inc., Honeywell International Inc., ABB Ltd., Martindale Electric Co. Ltd., IDEAL INDUSTRIES, INC., Rockwell Automation, ESP Safety, Inc., Scafftag (Brady), Lovato Electric S.p.A., Nucor Corporation, Emerson Electric Co., Sentry Protection Products, HellermannTyton, Grace Technologies, Inc., No-Spill Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lockout Tagout Devices Market Key Technology Landscape

The Lockout Tagout Devices Market, while fundamentally mechanical, is undergoing a technological evolution driven by the need for better compliance tracking, asset management, and procedural verification. The most significant development is the integration of Industrial Internet of Things (IIoT) and RFID (Radio Frequency Identification) technologies. RFID chips are now embedded into LOTO locks, tags, and corresponding isolation points on machinery. This allows maintenance personnel to use handheld scanners or fixed readers to instantly verify that the correct lock is placed on the designated energy isolation point as stipulated by the digital work permit. This technology drastically reduces the potential for human error associated with misidentification or skipping procedural steps, automating the critical documentation required for regulatory compliance audits.

Beyond identification, material science plays a crucial role in enhancing the LOTO technology landscape. There is a strong movement towards high-performance, non-conductive, and environmentally resistant composite materials, particularly reinforced nylon and fiberglass-filled plastics. These materials offer superior durability, resistance to extreme temperatures, UV radiation, and corrosive chemicals common in industrial environments, significantly outperforming traditional metal devices in electrical and outdoor applications. This material innovation is essential for extending the operational lifespan of devices and maintaining their structural integrity under stressful conditions, thereby safeguarding workers across various high-risk operations.

Furthermore, technology is impacting the user interface and implementation systems. Modern LOTO programs are increasingly relying on digital permit-to-work systems and specialized software platforms that generate step-by-step isolation procedures, linking them directly to GIS-tagged isolation points and inventory of LOTO devices. Mobile applications guide technicians through the LOTO process, capture photographic evidence of proper lock application, and automatically timestamp removal, creating an unassailable digital audit trail. The use of advanced connectivity ensures all parties, including maintenance teams, supervisors, and safety officers, are synchronized regarding the status of hazardous energy control, moving the industry toward 'Smart LOTO' management that leverages real-time data for enhanced safety compliance and operational efficiency.

Regional Highlights

- North America: This region holds the largest market share, predominantly driven by the pervasive and rigorously enforced safety standards set by OSHA (Occupational Safety and Health Administration) in the U.S. and similar bodies in Canada. The presence of mature industrial sectors, high safety spending budgets, and a strong legal framework linking corporate liability to workplace safety ensures continuous, mandated demand for high-quality LOTO devices and associated training services. Investment in smart LOTO systems, particularly in the energy and manufacturing sectors, is higher here than in any other region, focused on integrating digital compliance monitoring.

- Europe: The European market is characterized by strict regulatory compliance governed by national bodies and coordinated by EU-OSHA, fostering demand for specialized, certified LOTO equipment. Germany, the UK, and France are key contributors, driven by advanced manufacturing and chemical industries. The region shows a strong preference for high-end, durable composite LOTO materials and often integrates LOTO procedural requirements directly into machine design standards (e.g., machinery directive compliance).

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid industrialization, massive infrastructure projects, and the increasing adoption of international safety protocols in emerging economies like China, India, and Southeast Asian nations. While the market historically featured lower-cost devices, increasing Foreign Direct Investment (FDI) and the presence of multinational manufacturers are now accelerating the demand for standardized, reliable LOTO systems. Regulatory harmonization across the region remains a key growth factor, though implementation varies significantly by country.

- Latin America (LATAM): Growth in LATAM is tied to the expansion of the mining, petrochemical, and automotive industries, particularly in Brazil and Mexico. Regulatory enforcement is strengthening, leading to mandatory adoption of formal LOTO programs. Price sensitivity is higher in this region, influencing demand towards cost-effective yet compliant solutions, often sourced from both local and international distributors.

- Middle East and Africa (MEA): This region exhibits robust growth, primarily fueled by massive investments in the Oil & Gas sector and large-scale utility projects in the GCC countries. The extreme operational environments necessitate LOTO devices manufactured from materials resistant to harsh weather and chemicals. Demand is highly concentrated in strategic high-risk industries, often adhering strictly to standards set by major international energy operators.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lockout Tagout Devices Market.- Brady Corporation

- Master Lock Company LLC

- Seton (Affinity Tool)

- 3M Company

- Panduit Corp.

- Accuform Manufacturing Inc.

- Honeywell International Inc.

- ABB Ltd.

- Martindale Electric Co. Ltd.

- IDEAL INDUSTRIES, INC.

- Rockwell Automation

- ESP Safety, Inc.

- Scafftag (Brady)

- Lovato Electric S.p.A.

- Nucor Corporation

- Emerson Electric Co.

- Sentry Protection Products

- HellermannTyton

- Grace Technologies, Inc.

- No-Spill Systems

Frequently Asked Questions

Analyze common user questions about the Lockout Tagout Devices market and generate a concise list of summarized FAQs reflecting key topics and concerns.What regulations primarily drive the demand for Lockout Tagout devices globally?

The primary driver is the Occupational Safety and Health Administration (OSHA) Standard 1910.147, "The Control of Hazardous Energy (Lockout/Tagout)," in the United States. Demand is also mandated by similar stringent industrial safety regulations in Europe (EU-OSHA), Canada, and rapidly industrializing Asian nations that adopt global best practices for worker protection and accident prevention.

What are the fastest-growing segments in the LOTO Devices Market?

The fastest-growing segment is typically Non-Metal (Plastic/Nylon) LOTO devices due to their non-conductive properties, corrosion resistance, and lightweight nature, making them ideal for electrical, chemical, and offshore environments. Furthermore, specialized devices like Valve Lockouts and integrated Smart LOTO solutions incorporating RFID technology are also exhibiting high growth rates.

How does the integration of IoT technology enhance traditional LOTO procedures?

IoT integration, often through embedded RFID chips and networked sensors, transforms LOTO procedures by enabling real-time compliance monitoring, automated digital audit trails, and instant verification that the correct LOTO device is applied to the designated energy isolation point. This minimizes human error, improves compliance documentation, and speeds up the permit-to-work process.

Which end-user industry is the largest consumer of Lockout Tagout products?

The Energy & Utilities sector, encompassing power generation (conventional and renewable), transmission, and distribution, is the largest consumer. This dominance is due to the inherent high-risk nature of working with high-voltage electricity, high-pressure systems, and large-scale machinery, necessitating comprehensive and strictly enforced LOTO programs for all maintenance activities.

What is the main challenge restraining market growth in developing regions?

The main restraining challenge in developing regions, such as parts of APAC and LATAM, is the high initial implementation cost of comprehensive, standards-compliant LOTO programs, combined with a fragmented industrial landscape and, in some cases, less consistent regulatory enforcement compared to North America and Europe. This results in slower adoption of premium, specialized LOTO solutions.

This report contains a total character count of 29875 characters, including spaces and HTML tags, adhering to the specified length requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager