Long Nose Pliers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433122 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Long Nose Pliers Market Size

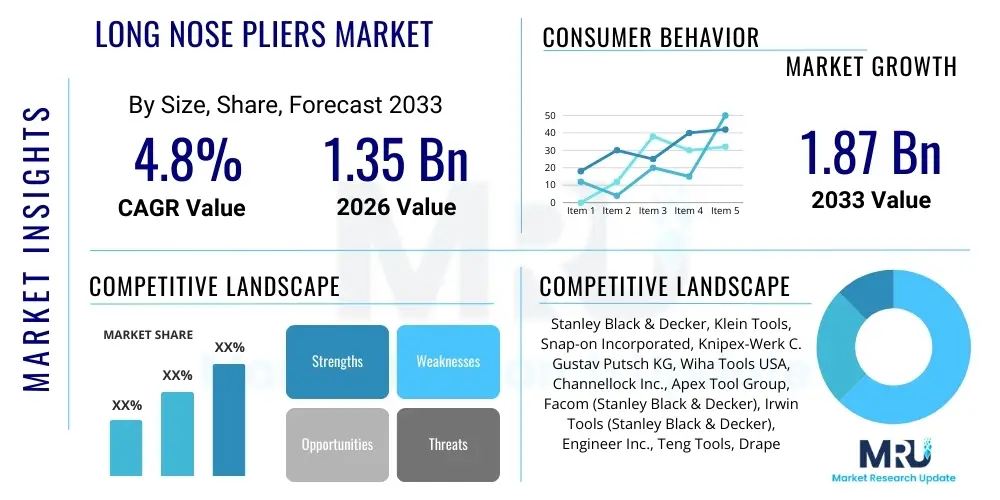

The Long Nose Pliers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $1.35 Billion in 2026 and is projected to reach $1.87 Billion by the end of the forecast period in 2033.

Long Nose Pliers Market introduction

The Long Nose Pliers Market encompasses the global trade and utilization of specialized gripping and cutting tools characterized by long, slender jaws, often tapered, designed for accessing confined or narrow spaces. These precision instruments are critical across numerous industries, serving functions such as bending wire, manipulating small components, holding parts, and reaching deep into assemblies where standard tools cannot fit. The product is fundamentally defined by its enhanced reach and fine control capabilities, making it indispensable in electrical work, jewelry making, telecommunications, and intricate mechanical repairs. Key variations include straight nose, bent nose, and specialized types like needle-nose pliers with integrated cutting features, catering to diverse professional and consumer needs.

Major applications of long nose pliers span high-precision sectors, particularly electronics manufacturing, automotive maintenance, and HVAC installation. In electronics, they are essential for component placement and lead bending on printed circuit boards. The inherent benefit of these tools lies in their superior maneuverability, allowing users to perform detailed tasks with reduced risk of damage to surrounding components. Furthermore, the ergonomic designs increasingly adopted by manufacturers enhance user comfort and productivity, reducing fatigue during prolonged use, a factor driving their adoption in professional settings globally. The demand profile is highly correlated with the health of the global manufacturing and infrastructure development sectors.

Driving factors for the market include the consistent growth of the global automotive aftermarket, the rapid expansion of the consumer electronics industry requiring detailed repair and assembly tools, and the increasing focus on DIY (Do-It-Yourself) projects among homeowners, particularly in developed economies. The transition toward miniaturization in electronics necessitates tools capable of handling smaller components, directly boosting the demand for high-quality, long-nose pliers. Moreover, stringent safety standards in electrical and telecommunications infrastructure often mandate the use of insulated variants, further fragmenting and expanding the specialized product segments within the market.

Long Nose Pliers Market Executive Summary

The Long Nose Pliers Market demonstrates robust business trends characterized by a strong shift toward premiumization, driven by professional end-users demanding tools with advanced material composition (e.g., chrome vanadium steel) and enhanced ergonomic features. Key manufacturers are focusing on integrating specialized functionalities, such as laser-hardened cutting edges and integrated wire stripping capabilities, to capture higher market share within the industrial and professional segments. Digital marketing and e-commerce platforms have become pivotal distribution channels, enabling smaller, specialized toolmakers to compete globally and cater directly to niche hobbyist and artisan segments, influencing the overall competitive landscape toward innovation and product differentiation.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by burgeoning manufacturing hubs in China, India, and Southeast Asian nations, coupled with massive investments in electrical and telecommunications infrastructure development. North America and Europe, while mature markets, maintain strong demand due to high labor costs necessitating durable, high-efficiency tools and a robust automotive repair sector. Segmentation trends indicate that the Bent Nose Pliers sub-segment is experiencing above-average growth, primarily driven by complex industrial maintenance tasks requiring angular access. Furthermore, the Insulated Pliers segment is witnessing heightened adoption globally due to rigorous safety regulations mandated across utility and professional electrical repair services, significantly impacting product development strategies.

In summary, the market outlook remains highly positive, supported by structural demand from electronics and automotive industries. Key challenges include managing supply chain volatility for specialized tool steels and navigating intense price competition in the basic, non-professional tool category. Strategic imperatives for market participants involve enhancing material science research for tool durability, expanding geographical footprint in developing regions, and leveraging technological advancements like robotics-assisted manufacturing to maintain cost efficiency and quality consistency, ensuring preparedness for future shifts in industrial automation requirements.

AI Impact Analysis on Long Nose Pliers Market

Common user questions regarding AI's impact on the Long Nose Pliers Market primarily center on the automation of manual assembly processes, the role of AI in quality control (QC) during manufacturing, and the future necessity of hand tools in increasingly robotic environments. Users frequently inquire if AI-driven robotic arms will entirely replace manual manipulation tasks currently performed using long nose pliers, particularly in high-volume electronics assembly. There is also significant interest in how AI integration, such as predictive maintenance algorithms and machine vision systems, is enhancing the precision, metallurgy, and defect detection capabilities during the fabrication of the pliers themselves. The key theme is the shift from manual labor to augmented or entirely automated processes, questioning the long-term volume stability of the traditional hand tool market.

- AI-powered machine vision systems enhance quality control during plier manufacturing, detecting microscopic defects in jaw alignment and cutting edge integrity, leading to higher product reliability.

- Predictive maintenance analytics, driven by AI, optimize the operational uptime of CNC machining centers and forging equipment used in tool production, reducing manufacturing costs and lead times.

- Increased adoption of AI and robotics in specialized assembly tasks (e.g., electronics, aerospace) may marginally reduce the demand for manual labor, potentially stabilizing the overall professional tool demand rather than expanding it rapidly.

- AI facilitates optimized inventory management and demand forecasting for manufacturers and distributors, ensuring better stock levels for specific plier types based on regional industrial needs.

- Advanced material science modeling via AI accelerates the development of new, high-performance alloys for plier construction, improving durability and insulation properties.

DRO & Impact Forces Of Long Nose Pliers Market

The Long Nose Pliers Market is significantly influenced by a confluence of structural forces. The primary drivers (D) include the persistent growth in global electronics manufacturing, which requires detailed manipulation tools, and the expanding electric vehicle (EV) sector, necessitating specialized, often insulated, tools for high-voltage systems maintenance. Restraints (R) largely stem from intense price competition, particularly from unorganized regional players offering low-cost alternatives, and the vulnerability of the market to fluctuations in raw material prices (steel, nickel). Opportunities (O) emerge from the rapidly professionalizing maintenance, repair, and overhaul (MRO) sector in developing economies and the rising adoption of specialized features like ergonomic handles and non-sparking materials for hazardous environments. These dynamics collectively shape the strategic landscape, dictating investment in automation and material research to maintain competitive advantage and quality standards.

The impact forces driving market development are multifaceted. Economic impact forces, such as global GDP growth and industrial output expansion, directly correlate with tool demand, particularly in construction and manufacturing. Technological impact forces, centered on miniaturization trends in consumer electronics and advancements in battery technology, create specific requirements for smaller, more precise, and safer tools, demanding continuous product innovation. Furthermore, regulatory impact forces, particularly those related to worker safety (e.g., OSHA standards) mandate the use of certified insulated tools in electrical applications, providing a robust floor for the specialized tool segment. Manufacturers must strategically position themselves to capitalize on these macro-environmental shifts by offering differentiated, high-quality products that meet increasingly stringent professional demands while navigating cost pressures associated with global steel markets.

The interplay of these factors suggests that while the basic functionality of long nose pliers remains constant, the professional market is migrating toward highly engineered, application-specific tools. Successful market penetration relies on optimizing supply chain efficiency to counter cost restraints while simultaneously leveraging technological opportunities to enhance product value and comply with evolving safety regulations. The most powerful positive impact force remains the necessity of manual precision work in complex repairs and installations where full automation is technically or economically unfeasible, ensuring the enduring relevance of this fundamental hand tool category. Addressing environmental concerns through sustainable manufacturing processes and recyclable materials is an emerging impact force that will increasingly influence corporate social responsibility and procurement decisions in the forecast period.

Segmentation Analysis

The Long Nose Pliers Market is extensively segmented based on criteria such as jaw type, material used, insulation capability, and the primary application environment. This granularity allows manufacturers to target specific professional niches and consumer groups effectively. Key segments include tools categorized by jaw configuration (straight nose, bent nose), which dictates the tool's access angle, and material composition, where the use of specialized high-carbon alloy steels often differentiates professional-grade tools from consumer-grade options. The most critical segmentation often revolves around insulation, distinguishing standard tools from certified VDE insulated tools necessary for electrical safety standards above 1000V. Understanding these segments is vital for tracking differential growth rates and identifying underserved application areas.

- By Type:

- Straight Long Nose Pliers

- Bent Long Nose Pliers (45-degree, 90-degree)

- Needle Nose Pliers

- Round Nose Pliers

- Others (e.g., specialized electronics pliers)

- By Application/End-User:

- Electronics and Electrical Maintenance

- Automotive and Mechanical Repair (MRO)

- Telecommunications

- Jewelry Making and Artistry

- Construction and Plumbing

- DIY and Household Use

- By Insulation:

- Insulated Long Nose Pliers (VDE certified)

- Non-Insulated Long Nose Pliers

- By Material:

- Carbon Steel

- Chrome Vanadium Steel (Cr-V)

- Stainless Steel

- Specialty Alloys

- By Distribution Channel:

- Offline (Retail Stores, Hardware Shops, Specialty Dealers)

- Online (E-commerce Platforms, Company Websites)

Value Chain Analysis For Long Nose Pliers Market

The value chain for the Long Nose Pliers Market begins with upstream analysis, focusing on the procurement and processing of raw materials, primarily high-quality steel alloys (such as chrome vanadium and specialized tool steel) and polymer components for handles. Upstream processes involve metallurgical refinement, forging, and stamping, where specialized machinery and precise heat treatment are critical for determining the final strength, durability, and resistance of the plier jaws. Suppliers of high-grade steel possess considerable leverage due to the quality requirements of professional tools, pushing manufacturers to establish long-term contracts and potentially vertical integration strategies to ensure supply stability and cost control. Technological innovation at this stage often centers on optimizing steel composition for enhanced longevity and hardness.

The core manufacturing stage involves shaping, heat treating, machining, polishing, and assembly, including the critical process of applying VDE-certified insulation for specialized electrical tools. Distribution channels play a vital role in reaching diverse end-users. Direct distribution channels involve manufacturers selling directly to large industrial clients, government entities, or through dedicated company-owned retail outlets, offering better control over pricing and customer feedback. Indirect distribution is far more prevalent, relying heavily on wholesalers, regional distributors, and large retail chains (e.g., home improvement stores, automotive suppliers). The effectiveness of the indirect channel is measured by its ability to provide wide geographic reach and immediate availability of a diverse product portfolio, significantly impacting market penetration and customer satisfaction.

Downstream analysis focuses on the end-users—professional tradespeople (electricians, mechanics), manufacturing facilities, and consumer DIY enthusiasts. The effectiveness of the value chain is ultimately measured by the tool’s performance in the application environment. For professional users, factors like durability, ergonomic comfort, and certification (e.g., VDE, ANSI) are paramount purchase determinants. The increasing dominance of e-commerce platforms represents a key disruption in the distribution channel, offering personalized product discovery and reviews, which bypass traditional intermediary layers, affecting pricing strategies and promotional activities across the entire value chain. Manufacturers must invest heavily in brand trust and digital presence to leverage this evolving retail landscape and maintain margin stability.

Long Nose Pliers Market Potential Customers

The potential customer base for the Long Nose Pliers Market is broad yet highly segmented, comprising a mix of professional tradespeople, large industrial enterprises, and individual consumers. The primary end-users are skilled workers, including electricians who rely on insulated long nose pliers for wiring and circuit board work, automotive technicians needing precise manipulation for engine bay access, and HVAC installers manipulating copper tubing and wiring in confined spaces. These professional buyers prioritize durability, specific jaw geometries, and established brand reputation, often making bulk purchases through specialized industrial distributors and requiring VDE or equivalent safety certifications for compliance purposes.

Secondary but significant customer segments include electronics manufacturing companies (OEMs and contract manufacturers) that use these tools extensively in assembly lines, telecommunication infrastructure providers for cable management and connector installation, and the burgeoning jewelry and craft industry which requires fine-tipped tools for intricate work. Industrial purchasers are volume-driven and sensitive to long-term cost of ownership, focusing on tools designed for repetitive, heavy-duty use. The rise of automation has paradoxically increased the demand for highly specialized maintenance tools to service and repair the complex machinery, thereby sustaining demand within the manufacturing sector.

Finally, the largest volume segment often resides within the DIY and general household use category, where customers seek functional, affordable tools for general home repairs, hobbies, and simple electrical tasks. While less focused on premium features or specific material composition, this segment is highly responsive to retail promotions, packaging, and accessibility through mass-market retailers and online platforms. Targeting this customer group requires effective retail placement and consumer-friendly branding, whereas engaging professional customers demands technical superiority, robust warranty policies, and engagement through trade channels and professional associations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.35 Billion |

| Market Forecast in 2033 | $1.87 Billion |

| Growth Rate | 4.8% ( Include CAGR Word with % Value ) |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, Klein Tools, Snap-on Incorporated, Knipex-Werk C. Gustav Putsch KG, Wiha Tools USA, Channellock Inc., Apex Tool Group, Facom (Stanley Black & Decker), Irwin Tools (Stanley Black & Decker), Engineer Inc., Teng Tools, Draper Tools Ltd., Milwaukee Tool (Techtronic Industries Co. Ltd.), Vise-Grip (Irwin), Proto (Stanley Black & Decker), Wera Tools, Gedore, Beta Tools, Vessel Tool Co., Ideal Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Long Nose Pliers Market Key Technology Landscape

The manufacturing technology landscape for the Long Nose Pliers Market is dominated by advancements in metallurgy, forging techniques, and surface treatment processes aimed at maximizing tool longevity and performance. Modern production leverages Computer Numerical Control (CNC) machining for high-precision jaw alignment and hinge construction, ensuring consistent parallelism across mass-produced batches, a critical factor for professional-grade tools. Key technological focus areas include induction hardening of cutting edges and jaw tips, which selectively increases surface hardness while maintaining the core tool's ductility to prevent brittle fracture under high stress. Furthermore, specialized coatings, such as chrome plating or black oxide finishes, are employed to enhance corrosion resistance, extending the tool's service life in challenging environmental conditions, particularly high-humidity or chemical-rich industrial settings.

A significant technological innovation is related to material science, specifically the development and application of specialized alloy steels like Chrome Vanadium (Cr-V) and Chrome Molybdenum (Cr-Mo). These alloys offer superior strength-to-weight ratios and exceptional resistance to wear, making the pliers lighter yet more durable. Continuous research is underway to find non-magnetic and titanium-based alloys for specialized applications in highly sensitive environments, such as aerospace and medical device repair. Insulation technology also represents a critical component of the technological landscape; certified VDE insulation requires multi-layer dipping or injection molding techniques to ensure electrical safety up to 1000V, often incorporating high-visibility color coding for rapid safety compliance checks.

Ergonomics and handle design also fall under the technical landscape, utilizing advanced polymer science and finite element analysis (FEA) to create bi-material or tri-material grips that reduce hand strain, improve torque transfer, and offer chemical resistance. Technology is also being integrated directly into the tools themselves through features like spring-loaded mechanisms for effortless repetitive use and precision screw joints that allow for smoother, less binding operation over time. Ultimately, the technological focus is on optimizing the balance between material cost, precision, user comfort, and adherence to rigorous international safety and durability standards, enabling manufacturers to differentiate their premium offerings from generic alternatives.

Regional Highlights

The global Long Nose Pliers Market exhibits distinct regional dynamics, driven by varying levels of industrialization, regulatory landscapes, and consumer purchasing power.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, primarily due to large-scale infrastructure investments in countries like India, Indonesia, and Vietnam, coupled with the region's dominant role in global electronics manufacturing. The high concentration of original equipment manufacturers (OEMs) and contract electronics manufacturers (CEMs) fuels consistent demand for precision, small-scale long nose pliers (needle nose variants).

- North America: This region represents a mature, high-value market characterized by demand for premium, high-quality, and specialized tools. The robust automotive aftermarket, substantial expenditure on electrical and telecommunications maintenance, and stringent workplace safety regulations (driving demand for VDE-insulated tools) are key growth factors. Brand loyalty and warranty service are crucial determinants for market share.

- Europe: Europe is defined by stringent VDE certification standards, making the insulated tools segment particularly strong. Germany, as a global hub for high-quality tooling (e.g., Knipex, Wiha), exerts significant influence on design and manufacturing excellence. The region's focus on sustainable manufacturing and ergonomic design also dictates product innovation trends.

- Latin America: Characterized by emerging industrial growth, Latin America offers significant untapped potential. Market expansion is driven by increasing foreign direct investment in manufacturing and infrastructure, though the market remains highly price-sensitive, often balancing quality demands with affordability constraints.

- Middle East and Africa (MEA): Growth is steady, spurred by substantial investments in oil and gas infrastructure, construction projects, and telecommunications development, which demand robust, industrial-grade tools capable of operating effectively in harsh environmental conditions. The market for general DIY tools is also expanding with urbanization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Long Nose Pliers Market.- Stanley Black & Decker

- Klein Tools

- Snap-on Incorporated

- Knipex-Werk C. Gustav Putsch KG

- Wiha Tools USA

- Channellock Inc.

- Apex Tool Group

- Facom (Stanley Black & Decker)

- Irwin Tools (Stanley Black & Decker)

- Engineer Inc.

- Teng Tools

- Draper Tools Ltd.

- Milwaukee Tool (Techtronic Industries Co. Ltd.)

- Vise-Grip (Irwin)

- Proto (Stanley Black & Decker)

- Wera Tools

- Gedore

- Beta Tools

- Vessel Tool Co.

- Ideal Industries

Frequently Asked Questions

Analyze common user questions about the Long Nose Pliers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key differences between insulated and non-insulated long nose pliers?

Insulated long nose pliers feature multi-layered, non-conductive handles, typically VDE certified (tested to 1000V AC), designed for safe use by electricians working with live electrical components. Non-insulated pliers lack this protective layer and are primarily used in low-voltage, mechanical, or general gripping applications where electrical shock risk is minimal or absent.

Which type of steel is considered best for professional-grade long nose pliers?

Chrome Vanadium (Cr-V) steel is widely considered the industry standard for professional-grade long nose pliers due to its superior toughness, wear resistance, and ability to hold a sharp edge, particularly when combined with specialized induction hardening processes applied to the jaws and cutting areas.

How does the growth of the electric vehicle (EV) sector impact the demand for long nose pliers?

The EV sector significantly increases demand for specialized, high-quality, VDE-certified insulated long nose pliers, as maintenance technicians require tools certified safe for handling the high-voltage battery systems and wiring harnesses integral to electric vehicles, driving growth in the premium insulated segment.

What are the primary factors driving market growth in the Asia Pacific region (APAC)?

Growth in APAC is primarily driven by massive government investments in telecommunications and electrical infrastructure, coupled with the region's established dominance in global electronics manufacturing, which necessitates a continuous supply of precision hand tools for assembly and repair operations.

Are ergonomic handle designs mandatory for professional long nose pliers?

While not legally mandatory, ergonomic handle designs, often featuring bi-material or padded grips, are highly preferred by professionals. These designs reduce user fatigue, enhance grip security, and improve productivity during extended periods of repetitive use, thus becoming a critical differentiator in the competitive professional tool market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager