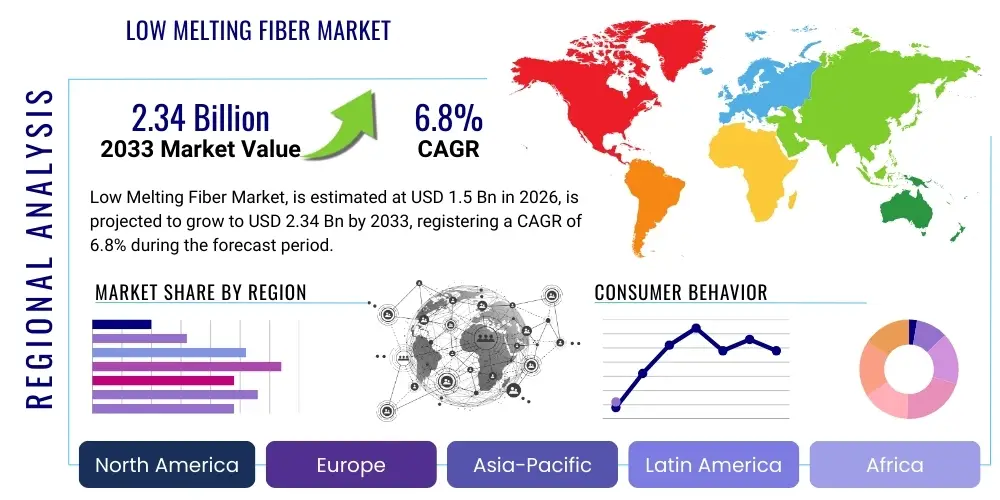

Low Melting Fiber Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436304 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Low Melting Fiber Market Size

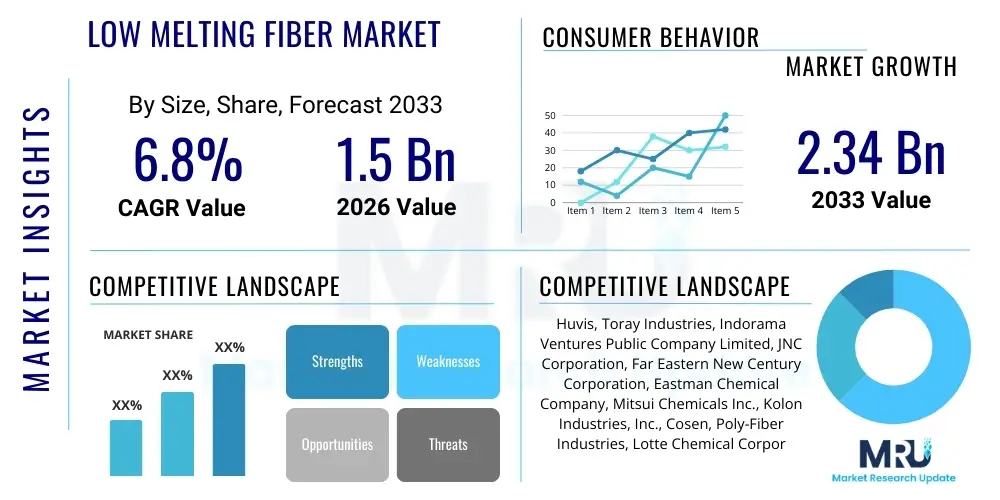

The Low Melting Fiber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.34 Billion by the end of the forecast period in 2033.

Low Melting Fiber Market introduction

Low Melting Fiber (LMF) serves as a thermal binder fiber, characterized by a low melting point sheath surrounding a higher melting point core, typically produced through bi-component spinning technology. The primary function of LMF is to facilitate thermal bonding in nonwoven fabrics, composites, and other applications without the need for chemical adhesives. Upon heating, the sheath component melts, adhering the surrounding fibers together, and upon cooling, forms a rigid, cohesive structure. This process offers significant advantages over traditional bonding methods, primarily due to its non-toxic nature, energy efficiency, and superior structural integrity.

The product is predominantly manufactured using polymers such as Polyester (PET), Polyamide (Nylon), and Polypropylene (PP), with PET LMF being the most widely utilized owing to its cost-effectiveness and excellent mechanical properties. Major applications span high-growth sectors including automotive interiors, filtration media, construction materials, and a wide array of hygiene products suchens as diapers and feminine care items. The versatility of LMF allows for the creation of lightweight, durable, and highly porous structures crucial for modern material science applications.

Driving factors for market expansion include the increasing demand for sustainable and recyclable nonwoven materials, stringent regulatory standards mandating VOC reduction in automotive and construction sectors, and the global push towards lightweight materials to improve energy efficiency. The efficiency of thermal bonding streamlines manufacturing processes, reducing costs and accelerating production cycles, thereby cementing LMF’s role as an essential raw material in advanced textiles and composites.

Low Melting Fiber Market Executive Summary

The Low Melting Fiber (LMF) market is currently undergoing robust expansion, driven primarily by evolving business trends centered on sustainability and performance enhancement in end-use industries. Global business trends indicate a significant shift from chemically bonded nonwovens to thermal bonded counterparts, emphasizing cleaner production processes and improved material recyclability. The key market segments, particularly automotive and construction, are showing accelerated adoption rates as manufacturers seek lightweighting solutions and enhanced structural integrity. Furthermore, increased investment in continuous filament LMF for technical textiles and high-performance composites represents a major business opportunity, pushing technological boundaries in polymer blending and bi-component fiber extrusion.

Regionally, the Asia Pacific (APAC) continues to dominate the market landscape, primarily due to the concentration of major textile and nonwoven manufacturing hubs, coupled with surging demand from rapidly expanding hygiene product and infrastructure sectors in China, India, and Southeast Asia. North America and Europe, while mature, exhibit strong growth in premium applications, particularly within sustainable filtration and advanced engineered composites, driven by strict environmental regulations and high consumer disposable income favoring premium nonwoven goods. Strategic regional expansion by global manufacturers, focusing on localized production facilities, is a dominant trend to mitigate supply chain disruptions and volatile logistics costs.

Segment trends highlight the dominance of Polyester (PET) LMF due to its favorable cost-to-performance ratio and wide applicability. However, Polyamide (Nylon) and Polypropylene (PP) LMF are experiencing higher growth rates in specialized, demanding applications such as high-temperature filtration and durable automotive components where chemical resistance and heat stability are paramount. The nonwovens segment remains the largest end-use consumer, though the composites segment is projected to record the highest Compound Annual Growth Rate (CAGR), fueled by its integral role in high-strength, lightweight material formulation across aerospace and construction.

AI Impact Analysis on Low Melting Fiber Market

Common user questions regarding AI's impact on the Low Melting Fiber (LMF) market often center on whether artificial intelligence can optimize the complex bi-component fiber spinning process, how AI-driven predictive analytics can mitigate raw material price volatility, and if machine vision systems can improve the notoriously difficult quality control aspects of nonwoven thermal bonding. Users are keenly interested in operational efficiencies, specifically reducing waste, optimizing energy consumption during the melting phase, and speeding up R&D cycles for novel LMF formulations. The underlying themes reflect a desire to leverage AI for enhanced precision, cost reduction, and superior product consistency, which are critical differentiators in the highly competitive fiber market.

The implementation of Artificial Intelligence and Machine Learning (ML) algorithms is set to revolutionize LMF manufacturing. AI-driven predictive maintenance systems analyze real-time data from extruder temperature sensors, spinning speed monitors, and fiber tension sensors, forecasting potential equipment failures before they occur. This significantly reduces unplanned downtime and maintains consistent fiber characteristics, which is paramount for achieving uniform low melting points and superior bonding performance. Furthermore, ML models are utilized in optimizing polymer blends and additive concentrations, accelerating the discovery of new fiber properties tailored for specific end-use applications, such as high-loft nonwovens or flame-retardant composites.

In the downstream nonwoven production process, AI-powered computer vision systems are deployed for instantaneous defect detection and process adjustment. These systems monitor the bonding line to ensure uniform thermal activation of the LMF sheath, adjusting heat or pressure dynamically to prevent over-melting or insufficient bonding. This level of granular, automated quality control minimizes material waste and ensures compliance with stringent industry standards, especially in hygiene and medical textile production where zero tolerance for defects is required. Supply chain optimization is another critical area; AI algorithms predict raw material (e.g., purified terephthalic acid, PTA) price fluctuations and demand shifts, enabling manufacturers to implement dynamic sourcing strategies and inventory management, thereby stabilizing profit margins.

- AI optimizes bi-component spinning parameters for improved fiber uniformity and lower energy consumption.

- Machine learning models accelerate the R&D of novel LMF polymer compositions with targeted melting points.

- Predictive maintenance systems reduce unplanned downtime of extruders and spinning equipment.

- AI-powered computer vision enhances real-time quality control in thermal bonding processes, minimizing defects.

- ML algorithms predict raw material price volatility, optimizing sourcing and inventory levels.

- AI facilitates process automation in high-speed nonwoven production, ensuring bonding consistency.

DRO & Impact Forces Of Low Melting Fiber Market

The Low Melting Fiber (LMF) market trajectory is primarily shaped by a dynamic interplay of potent drivers, significant restraints, and compelling strategic opportunities, collectively constituting the market's impact forces. Key drivers include the exponential growth of the global nonwovens industry, fueled by increased consumer awareness regarding personal hygiene and the expanding healthcare sector, particularly in emerging economies. Concurrently, the imperative for automotive manufacturers to reduce vehicle weight to meet stringent fuel efficiency and emission standards mandates the use of lightweight, thermally bonded composites and interior materials incorporating LMF. The inherent recyclability and chemical-free bonding process of LMF strongly aligns with global sustainability mandates, offering a significant competitive advantage over traditional adhesives.

However, the market faces notable restraints, chiefly concerning the high volatility of raw material prices, particularly petrochemical derivatives used in polymer production (PET, PP, Nylon). These fluctuations directly impact manufacturing costs and profitability, necessitating complex hedging strategies. Furthermore, the technical complexity of achieving precise bi-component extrusion and maintaining quality consistency across various fiber deniers and lengths presents manufacturing challenges. Although LMF is considered a low-toxicity bonding agent, competition from alternative bonding technologies, such as chemical binders or hydro-entanglement methods in specific nonwoven applications, slightly moderates its market penetration in certain specialized domains.

Significant opportunities exist in the development of high-performance LMF for advanced applications. This includes specialty fibers with enhanced UV resistance, flame retardancy, or bio-degradable components designed for niche markets like geo-textiles, advanced filtration systems, and surgical textiles. The integration of LMF into additive manufacturing (3D printing) feedstock, especially for reinforcing complex geometries in composite structures, presents a nascent but highly promising growth vector. Strategic vertical integration by key market players, encompassing polymer synthesis to final fiber production, also offers an opportunity to control costs and enhance supply chain resilience, effectively maximizing profitability across the value chain and strengthening market leadership.

Segmentation Analysis

The Low Melting Fiber (LMF) market segmentation provides a comprehensive view of consumption patterns, technological preferences, and growth trajectories across various material types and end-use applications. This detailed breakdown is essential for strategic planning, revealing which product formulations and geographical regions offer the highest potential returns. Segmentation is critical in understanding the nuanced demand characteristics, ranging from high-volume, cost-sensitive hygiene products to specialized, high-performance composites requiring specific thermal and mechanical properties.

The market is primarily segmented by Fiber Type, Application, and End-Use Industry. By Fiber Type, Polyester (PET) LMF holds the largest share due to its cost-efficiency, availability, and versatility in standard nonwoven processes. However, specialized polymers like Polyamide (Nylon) and Polypropylene (PP) LMF are accelerating in growth, catering to niche applications demanding superior chemical resistance, higher temperature stability, or better abrasion performance. Analyzing these material preferences allows manufacturers to optimize their production lines and focus R&D efforts on advanced polymer blends.

Application-wise, the market is broadly classified into nonwovens (which includes hygiene and medical), automotive interiors, construction materials, and filtration media. The robust growth in nonwovens continues to dominate consumption volumes, but the automotive segment demonstrates the highest value growth due to the premium pricing of technical textiles used for sound insulation, headliners, and trunk liners. Understanding this dual growth trajectory—volume in hygiene and value in automotive—is pivotal for developing diversified market entry and pricing strategies.

- By Fiber Type:

- Polyester (PET) LMF

- Polyamide (Nylon) LMF

- Polypropylene (PP) LMF

- Other Fiber Types (e.g., PLA, Specialty Polymers)

- By Application:

- Nonwovens (Hygiene Products, Wipes, Medical Textiles)

- Automotive Interiors (Headliners, Carpets, Sound Insulation)

- Construction Materials (Roofing, Insulation, Geo-textiles)

- Filtration Media (Air, Liquid)

- Apparel and Textiles (Interlinings, Padding)

- Others (Composites, Agriculture)

- By End-Use Industry:

- Textiles and Apparels

- Healthcare and Hygiene

- Automotive and Transportation

- Construction and Infrastructure

- Consumer Goods

Value Chain Analysis For Low Melting Fiber Market

The Value Chain for the Low Melting Fiber market is complex, beginning with petrochemical feedstock suppliers and culminating in diverse end-use manufacturing sectors. Upstream analysis focuses on the supply and pricing volatility of key raw materials, primarily PTA (Purified Terephthalic Acid), MEG (Monoethylene Glycol) for PET production, and propylene for PP. Integrated fiber manufacturers often mitigate price risks through long-term procurement contracts or backward integration into polymer synthesis, ensuring stability in the high-cost, high-volume fiber production phase, which involves advanced bi-component extrusion and spinning technologies.

Midstream activities involve the specialized manufacturing of the LMF itself, where technology and proprietary formulations are crucial. Fiber producers convert polymers into staple fibers or continuous filaments, ensuring specific denier, cut length, and melting characteristics suitable for thermal bonding. Distribution channels are varied: Direct sales are common for large-volume customers like major global nonwoven producers, allowing for tailored specifications and technical support. Indirect distribution involves specialized distributors and agents, particularly serving smaller manufacturers or penetrating niche geographical markets, optimizing logistics and inventory management across diverse client bases.

Downstream analysis centers on the vast array of end-user converters, including nonwoven fabric manufacturers who utilize LMF via processes such as carding, airlaid, or wetlaid before thermal bonding. These fabrics are then supplied to final product manufacturers (e.g., diaper makers, automotive Tier 1 suppliers, filtration specialists). The potential customers are highly diversified, requiring LMF suppliers to offer not only competitive pricing but also extensive technical collaboration to integrate the LMF effectively into high-speed production lines, ensuring consistent final product performance and optimizing material consumption.

Low Melting Fiber Market Potential Customers

Potential customers for Low Melting Fiber (LMF) represent a broad spectrum of manufacturing industries that require lightweight, durable, and chemically inert bonding agents, prioritizing non-toxic and recyclable solutions over traditional chemical adhesives. The largest segment of buyers comprises high-volume nonwoven producers specializing in hygiene products such as disposable diapers, adult incontinence products, and facial wipes, where soft touch, fluid management, and cost-effectiveness are critical purchasing criteria. These manufacturers rely on LMF for forming stable, non-shedding webs that maintain structural integrity during use and disposal. Another significant customer base includes manufacturers of medical textiles, such as surgical gowns and sterilization wraps, requiring stringent performance standards related to barrier protection and lint-free operation.

Beyond hygiene, the automotive sector constitutes a high-value customer group. Automotive Tier 1 and Tier 2 suppliers purchase LMF to manufacture interior components, including headliners, sound insulation pads (NVH reduction), trunk liners, and carpet backing. The adoption here is driven by the industry's need for lightweighting materials that comply with increasingly strict volatile organic compound (VOC) regulations, as thermal bonding using LMF is generally a low-emission process. Furthermore, construction and infrastructure companies use LMF-bonded geo-textiles, roofing membranes, and insulation materials for enhanced durability, moisture resistance, and dimensional stability in harsh environments, making civil engineering and building materials firms key strategic buyers.

A rapidly growing customer segment encompasses producers of advanced filtration media (for air, oil, and water purification) and composite materials. For filtration, LMF helps create structured, high-efficiency media with controlled pore size distribution. In composites, particularly those involving natural fibers or high-performance polymers, LMF serves as an effective matrix binder, enabling the formation of strong, customized composite sheets used in specialized industrial and consumer goods applications. LMF suppliers must therefore tailor product specifications—such as melting temperature and fiber fineness—to meet the precise technical requirements of these diverse end-user applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.34 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Huvis, Toray Industries, Indorama Ventures Public Company Limited, JNC Corporation, Far Eastern New Century Corporation, Eastman Chemical Company, Mitsui Chemicals Inc., Kolon Industries, Inc., Cosen, Poly-Fiber Industries, Lotte Chemical Corporation, Jiangsu Sanfangxiang Group Co., Ltd., Zhejiang Huarui Fiber Co., Ltd., Xiang Lu Chemical Fiber Co., Ltd., Fibre Valsa, ADFAN, Unitika Ltd., Kuraray Co., Ltd., Silon s.r.o., Di-Wo Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Melting Fiber Market Key Technology Landscape

The manufacturing of Low Melting Fiber (LMF) is highly dependent on sophisticated polymer science and precision fiber extrusion techniques, primarily revolving around bi-component spinning technology. The core principle involves simultaneously extruding two different polymers, often with distinct melting points, through a single spinneret to create a single fiber structure. The dominant technologies include sheath-core, side-by-side, and segmented-pie configurations. Sheath-core is the most prevalent for LMF, where the low-melting polymer forms the outer layer (sheath) and the high-melting polymer forms the internal structure (core). Achieving precise concentricity and uniform sheath thickness is a critical technological challenge that dictates the quality and consistency of the final thermal bonding performance.

Further technological advancements focus on enhancing fiber properties and manufacturing efficiency. High-speed spinning technology has been instrumental in increasing throughput and reducing production costs, making LMF more competitive against chemical binders. Furthermore, manufacturers are increasingly adopting proprietary additive packages to enhance the functionality of the fibers, such as incorporating anti-microbial agents, UV stabilizers, or flame retardants directly into the polymer matrix. This functionalization allows LMF to meet the rigorous performance requirements of specialized applications like medical textiles and outdoor construction materials, extending the application scope beyond conventional hygiene products.

The landscape is also seeing a push towards sustainable manufacturing processes. This involves research into bio-based and recycled polymers for LMF production, utilizing recycled PET (rPET) or developing biopolymers like PLA (Polylactic Acid) to create bio-degradable LMF variants. Process optimization using advanced robotics and digital twin modeling ensures that even with complex polymer blends, the thermal properties (onset melting temperature and flow index) remain tightly controlled. This technological focus on precision, performance additives, and sustainability is driving the next generation of LMF products, ensuring their continued relevance in lightweight material composition.

Regional Highlights

The global Low Melting Fiber (LMF) market exhibits distinct growth patterns influenced by regional industrialization levels, regulatory environments, and consumer demographics. Asia Pacific (APAC) is unequivocally the dominant region, accounting for the largest market share and demonstrating the fastest growth trajectory. This leadership is fueled by the presence of large-scale textile and nonwoven manufacturing bases in China, India, and Southeast Asian nations. The surging demand for hygiene products, coupled with massive government investments in infrastructure and construction, creates an immense consumer base for LMF-bonded materials. Furthermore, lower operating costs and governmental support for manufacturing industries make APAC the primary hub for both production and consumption.

North America and Europe represent mature markets characterized by high value consumption and stringent quality requirements. In these regions, growth is primarily driven by the adoption of high-performance LMF in specialized applications, such as premium automotive interiors (focused on noise reduction and low VOC emissions) and advanced filtration media complying with strict air quality standards. European manufacturers, particularly in Germany and Italy, focus heavily on innovation, utilizing LMF in sophisticated technical textiles and prioritizing sustainable, recyclable product offerings, often pushing the boundaries of rPET and bio-based LMF adoption to meet aggressive environmental targets.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging markets showing promising growth, albeit from a lower base. LATAM’s growth is concentrated in the expansion of personal hygiene markets, particularly Brazil and Mexico, due to increasing urbanization and rising disposable incomes. MEA’s market expansion is tied to infrastructural development projects, driving demand for geo-textiles and construction materials, alongside localized growth in basic nonwovens production. However, these regions often face supply chain challenges and greater reliance on imports, which influences pricing structures and market stability.

- Asia Pacific (APAC): Dominant market share and highest growth rate; driven by massive nonwoven production, population size, infrastructure spending (China, India), and strong hygiene market expansion.

- North America: High-value market focused on technical applications; strong adoption in automotive lightweighting, advanced air and liquid filtration, driven by stringent quality standards and high R&D investment.

- Europe: Mature market emphasizing sustainability and high-end textiles; focus on VOC reduction, recyclable PET LMF, and sophisticated construction insulation materials, adhering to strict EU environmental directives.

- Latin America (LATAM): Emerging market growth fueled by increasing urbanization and improved hygiene product penetration, especially in Brazil and Mexico.

- Middle East and Africa (MEA): Growth tied to large-scale construction and infrastructure projects; nascent but developing local nonwoven manufacturing base addressing regional hygiene needs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Melting Fiber Market.- Huvis

- Toray Industries

- Indorama Ventures Public Company Limited

- JNC Corporation

- Far Eastern New Century Corporation

- Eastman Chemical Company

- Mitsui Chemicals Inc.

- Kolon Industries, Inc.

- Cosen

- Poly-Fiber Industries

- Lotte Chemical Corporation

- Jiangsu Sanfangxiang Group Co., Ltd.

- Zhejiang Huarui Fiber Co., Ltd.

- Xiang Lu Chemical Fiber Co., Ltd.

- Fibre Valsa

- ADFAN

- Unitika Ltd.

- Kuraray Co., Ltd.

- Silon s.r.o.

- Di-Wo Group

Frequently Asked Questions

Analyze common user questions about the Low Melting Fiber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Low Melting Fiber (LMF) in nonwovens?

LMF serves as a thermal binder, utilizing its low-melting polymer sheath to bond surrounding fibers when heated, eliminating the need for chemical adhesives. This provides structural integrity and is crucial for producing lightweight, durable, and recyclable nonwoven materials in sectors like hygiene and automotive.

Which polymer type dominates the Low Melting Fiber market and why?

Polyester (PET) Low Melting Fiber dominates the market due to its excellent balance of cost-effectiveness, high tensile strength, and versatile thermal bonding properties, making it the preferred choice for high-volume applications, particularly in the hygiene and standard nonwoven segments.

What are the main growth drivers for LMF in the automotive industry?

The key drivers are the stringent regulatory requirements for vehicle lightweighting to enhance fuel efficiency and the increasing demand for materials with low Volatile Organic Compound (VOC) emissions, which LMF-bonded components provide as a clean alternative to chemical adhesives in interiors.

How does the volatile price of petrochemical raw materials affect the LMF market?

The volatility in the prices of petrochemical raw materials, such as PTA and MEG (used for PET), directly increases the production costs for LMF manufacturers. This necessitates robust supply chain management, hedging strategies, and potential vertical integration to maintain stable profit margins and competitive pricing.

What technological innovations are shaping the future of Low Melting Fiber?

Future technological advancements are focused on developing sustainable LMF (using recycled PET or bio-polymers like PLA), enhancing functional properties through additives (flame retardancy, anti-microbial features), and optimizing bi-component spinning using AI for superior quality control and consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager