Low Power Handheld Laser Welding Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439922 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Low Power Handheld Laser Welding Machine Market Size

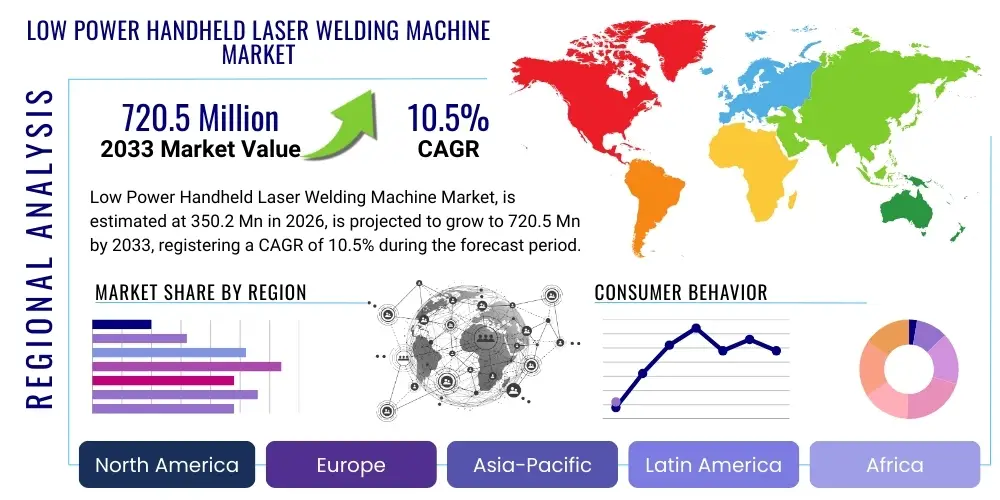

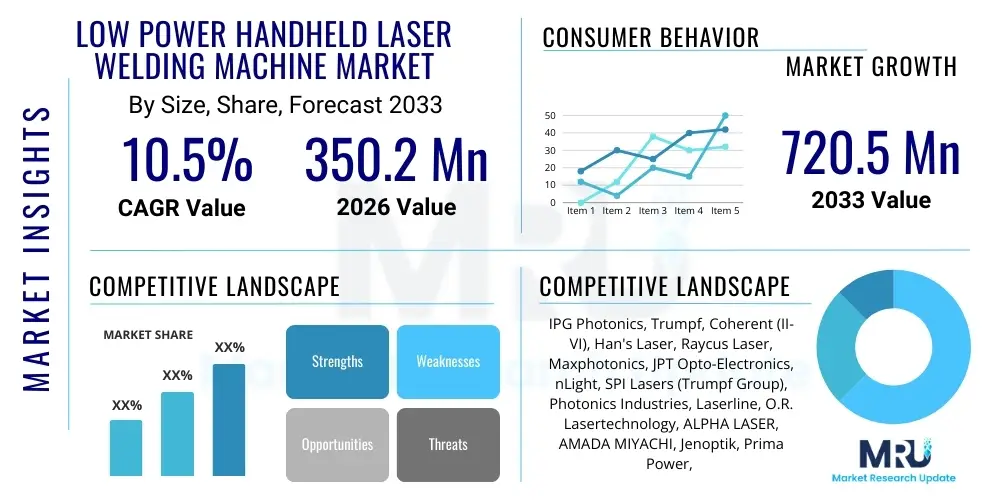

The Low Power Handheld Laser Welding Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 350.2 million in 2026 and is projected to reach USD 720.5 million by the end of the forecast period in 2033. This growth is primarily fueled by increasing demand across various industries for efficient, precise, and portable welding solutions that minimize heat input and offer superior weld quality. The adoption of advanced manufacturing techniques and the rising emphasis on automation in small to medium-scale enterprises (SMEs) are significant contributors to this upward trajectory, creating a robust market environment for low power handheld laser welding systems. The market's expansion is also underpinned by continuous technological advancements, making these machines more accessible, user-friendly, and cost-effective for a broader range of applications.

Low Power Handheld Laser Welding Machine Market introduction

The Low Power Handheld Laser Welding Machine Market encompasses innovative welding solutions characterized by their portability, precision, and efficiency, specifically designed for applications requiring minimal heat input and high-quality welds. These machines typically utilize fiber or diode lasers with power outputs generally below 1000W, making them suitable for thin-gauge metals and delicate components. Their compact design allows for manual operation and mobility, offering significant advantages over traditional welding methods such as TIG or MIG welding, particularly in terms of speed, weld aesthetics, and reduced post-processing requirements. The core product provides a versatile tool for various industries, delivering clean, strong, and visually appealing welds with minimal distortion, enhancing overall productivity and product quality.

Major applications for low power handheld laser welding machines span across diverse sectors including automotive repair, jewelry manufacturing, electronics assembly, medical device fabrication, dental prosthetics, and small-scale general manufacturing. In the automotive industry, they are invaluable for repairing intricate components and aesthetics. Jewelers benefit from their precision for joining precious metals without discoloration. The electronics sector utilizes them for delicate component joining where heat sensitivity is a concern. Medical device manufacturers rely on them for sterile, precise welds on small, critical components. The inherent benefits of these machines, such as ease of use, high welding speed, deep and narrow welds, minimal heat-affected zone, and reduced need for consumables, are significantly driving their adoption across these varied applications. These attributes translate into operational efficiencies and cost savings for end-users, making them an increasingly attractive investment.

The primary driving factors propelling the market forward include the increasing demand for high-quality, aesthetically pleasing welds, the growing need for automated and semi-automated manufacturing processes, and the rising labor costs associated with traditional welding methods that often require highly skilled operators. Furthermore, the portability and flexibility offered by handheld laser welders enable them to be deployed in diverse work environments, including remote sites or assembly lines where larger, stationary welding equipment might be impractical. Continuous innovations in laser technology, such as improved beam quality, enhanced power efficiency, and integrated smart features, are also contributing to market growth by making these machines more versatile and accessible. The expanding base of small and medium-sized enterprises (SMEs) seeking to upgrade their manufacturing capabilities with advanced, user-friendly tools further fuels this market's expansion.

Low Power Handheld Laser Welding Machine Market Executive Summary

The Low Power Handheld Laser Welding Machine Market is experiencing robust growth driven by evolving business trends centered on automation, precision manufacturing, and operational flexibility. Companies are increasingly investing in these advanced welding solutions to enhance productivity, reduce labor costs, and improve product quality across their value chains. Key business trends include the proliferation of customized welding solutions tailored to specific industry needs, the emergence of subscription-based models for machinery, and strategic collaborations between laser technology providers and industrial equipment manufacturers to integrate sophisticated features. There is also a notable trend towards developing more compact, energy-efficient, and user-friendly models that cater to a wider range of technical skill levels, expanding the market's accessibility to smaller workshops and repair centers. The focus remains on delivering high ROI through minimized post-processing and optimized material utilization, making these machines a compelling investment for forward-thinking businesses.

Regionally, the market exhibits dynamic growth patterns, with Asia Pacific emerging as a dominant force due to its burgeoning manufacturing sector, rapid industrialization, and significant investments in advanced manufacturing technologies, particularly in countries like China, India, and South Korea. North America and Europe continue to be strong markets, characterized by high adoption rates in precision engineering, medical device manufacturing, and automotive aftermarket services, driven by stringent quality standards and a strong emphasis on automation. Latin America, the Middle East, and Africa are showing promising potential, albeit from a smaller base, as industrial infrastructure develops and businesses seek to modernize their production capabilities. These regions are increasingly recognizing the efficiency and quality benefits offered by low power handheld laser welding, leading to a gradual but steady increase in adoption across various industrial applications, fostering a globally expanding market presence for these innovative tools.

Segmentation trends indicate a diversified market, with significant growth observed in applications requiring high precision and minimal heat input. The market is segmented by power output, with the sub-1000W category experiencing strong demand for delicate work, and by application, showing increasing penetration in jewelry, electronics, and small-batch production. End-user segments such as automotive repair, general fabrication, and medical device manufacturing are key drivers, each exhibiting unique requirements that push technological innovation. There is a growing trend towards multi-functional machines that can perform various tasks beyond welding, like cutting or cleaning, further enhancing their versatility. The continuous development of specialized consumables and accessories for specific material types also plays a crucial role in segment growth, enabling wider application scope and better performance. This diversification across power, application, and end-user segments underscores the market's adaptability and responsiveness to varied industrial needs, supporting sustained expansion.

AI Impact Analysis on Low Power Handheld Laser Welding Machine Market

User inquiries regarding AI's impact on the Low Power Handheld Laser Welding Machine Market frequently center on themes of enhanced automation, predictive maintenance, quality control, and the potential for upskilling or reskilling the workforce. Users are keen to understand how AI can make these handheld devices smarter, more intuitive, and capable of delivering even higher consistency and precision, particularly in dynamic or complex welding scenarios. Concerns often revolve around the cost implications of integrating AI, the complexity of implementation, and the reliability of AI-driven decisions in critical applications. There's also significant interest in AI's role in real-time process optimization, defect detection, and streamlining the training process for new operators, transforming the manual welding experience into a more augmented and data-driven operation. The overarching expectation is that AI will unlock new levels of efficiency, reduce human error, and expand the capabilities of handheld laser welding, pushing the boundaries of what these machines can achieve in diverse industrial settings.

- AI-powered vision systems enhance real-time weld quality monitoring and defect detection, ensuring superior finish and structural integrity.

- Predictive maintenance algorithms analyze operational data to anticipate potential equipment failures, minimizing downtime and extending machine lifespan.

- AI-driven parameter optimization assists operators in setting ideal welding parameters for various materials and thicknesses, reducing trial-and-error and material waste.

- Machine learning facilitates adaptive welding, allowing the machine to adjust power and speed in real-time based on material variations or joint inconsistencies.

- Generative design tools, influenced by AI, can help optimize future machine designs for improved ergonomics, efficiency, and integration with manufacturing workflows.

- AI integration enables voice commands and gesture control for more intuitive and hands-free operation, enhancing user experience and safety.

- Automated quality assurance systems, utilizing AI, can provide instant feedback on weld strength and aesthetics, significantly reducing manual inspection time.

- AI contributes to operator training by simulating complex welding scenarios and providing personalized feedback, accelerating skill development.

- Data analytics capabilities, leveraging AI, offer insights into operational performance, material consumption, and energy efficiency for continuous process improvement.

- Smart material recognition systems, powered by AI, can automatically identify material types and suggest appropriate welding settings, simplifying setup.

DRO & Impact Forces Of Low Power Handheld Laser Welding Machine Market

The Low Power Handheld Laser Welding Machine Market is primarily driven by the escalating demand for high-precision, low-heat input welding solutions across various industrial sectors. The imperative for cleaner, stronger, and more aesthetically pleasing welds without extensive post-processing is a significant catalyst. Furthermore, the increasing adoption of automation and semi-automation in manufacturing processes, coupled with the rising costs and scarcity of highly skilled traditional welders, pushes industries towards more accessible and efficient welding technologies. The inherent portability and ease of use of these handheld systems contribute to their appeal, enabling flexibility in manufacturing layouts and on-site repair operations. Technological advancements leading to more powerful, yet compact and energy-efficient laser sources, coupled with improved beam delivery systems, further fuel market expansion by enhancing performance and broadening application scope. The robust growth in sectors such as automotive, electronics, jewelry, and medical devices, all requiring precise joining of thin materials, ensures a steady uptake of these innovative welding solutions.

Despite the strong growth drivers, several restraints pose challenges to the market's full potential. The relatively high initial investment cost compared to traditional welding equipment can be a significant barrier for small businesses or those with limited capital, hindering widespread adoption. While easier to use than traditional methods, operating laser welding machines still requires a degree of specialized training and adherence to strict safety protocols, particularly concerning eye and skin protection, which can add to operational overheads. The power output limitations of low power handheld units restrict their application to thinner materials and certain welding tasks, making them unsuitable for heavy-duty industrial fabrication that demands higher power. Additionally, competition from established traditional welding techniques, which are often perceived as more versatile or robust for specific applications, also presents a challenge, requiring continuous market education and demonstration of the superior benefits of laser welding for appropriate use cases. These factors collectively impact the pace and scope of market penetration.

Opportunities for growth in this market are abundant, stemming from the continuous evolution of laser technology and the emergence of new application areas. Advancements in fiber laser technology, including improved efficiency, smaller footprints, and enhanced beam quality, are making these machines more attractive and capable. The expansion into niche markets such as customized artistic fabrication, specialized repair services for aerospace or defense components, and prototyping for advanced materials offers significant untapped potential. There is a growing opportunity to integrate these machines with robotics and advanced manufacturing systems, enabling hybrid solutions that combine the precision of laser welding with the automation of robotic arms. Furthermore, developing more affordable, modular, and multi-functional units that can perform cutting, cleaning, and welding tasks will broaden their appeal and market reach, particularly in developing economies and for small and medium-sized enterprises seeking versatile tools. Enhanced ergonomic designs and intelligent user interfaces also present opportunities to improve operator comfort and reduce the learning curve, further democratizing access to this advanced technology.

- Drivers:

- Increasing demand for precision welding in diverse industries like automotive, electronics, and medical devices.

- Growing need for automation and semi-automation to improve manufacturing efficiency and reduce labor costs.

- Superior weld quality, minimal heat-affected zone, and reduced post-processing requirements compared to traditional methods.

- Portability and flexibility of handheld units enabling on-site repairs and adaptable manufacturing setups.

- Technological advancements in laser sources, beam delivery, and control systems enhancing performance and usability.

- Restraints:

- High initial investment cost compared to conventional welding equipment, posing a barrier for some small and medium-sized enterprises.

- Requirement for specialized training and strict safety protocols due to laser radiation risks.

- Limitations in power output, restricting applications primarily to thinner materials and specific welding tasks.

- Competition from well-established and perceived more versatile traditional welding techniques.

- Challenges related to integrating handheld systems into fully automated production lines without complex modifications.

- Opportunities:

- Development of more cost-effective and energy-efficient laser sources, expanding market accessibility.

- Expansion into emerging applications and niche markets such as specialized artistic work, custom fabrication, and advanced material prototyping.

- Integration with robotics and IoT for smarter manufacturing ecosystems and enhanced automation capabilities.

- Innovation in ergonomic design and user-friendly interfaces to reduce operator learning curves and improve comfort.

- Growth in demand from developing economies seeking to modernize their manufacturing infrastructure and improve product quality.

- Impact Forces:

- Technological Innovation: Rapid advancements in laser diode efficiency, fiber laser technology, and beam shaping optics continuously enhance machine performance and broaden application possibilities.

- Regulatory Landscape: Evolving safety standards for laser equipment and industrial practices influence product design and market adoption, emphasizing user safety and compliance.

- Economic Shifts: Global economic conditions, including manufacturing output, industrial investment, and supply chain stability, directly affect purchasing decisions and market growth rates.

- Environmental Concerns: Emphasis on energy efficiency and reduced material waste in manufacturing drives demand for laser welding as a cleaner alternative.

- Skill Gap: The widening gap in skilled traditional welders accelerates the adoption of easier-to-operate laser welding machines, which require less extensive specialized training.

Segmentation Analysis

The Low Power Handheld Laser Welding Machine Market is comprehensively segmented across various parameters to provide a detailed understanding of its dynamics and growth trajectories. These segmentations typically include analyses by power output, application, end-user industry, and geographical region, each offering unique insights into market demands and opportunities. By dissecting the market along these lines, stakeholders can identify key growth areas, understand specific technological preferences, and tailor strategies to effectively address the needs of diverse customer bases. The segmentation analysis reveals the heterogeneous nature of demand, highlighting how different industries prioritize attributes like precision, speed, portability, or material compatibility, thereby driving distinct product development paths and market penetration strategies. This granular view is essential for navigating the competitive landscape and capitalizing on niche market potentials while also identifying overarching trends.

- By Power Output:

- Low Power (e.g., up to 500W): Primarily used for very thin materials, delicate components, and applications requiring minimal heat input, such as jewelry, dental, and small electronics.

- Medium-Low Power (e.g., 501W - 1000W): Suitable for a wider range of thin to medium-gauge metals, offering a balance of speed and precision for general fabrication, automotive repairs, and some medical device manufacturing.

- By Application:

- Spot Welding: Used for joining small, localized areas with high precision, common in electronics and micro-components.

- Seam Welding: For creating continuous, leak-tight welds along a joint, often employed in tank fabrication and enclosures.

- Overlap Welding: Joining two overlapping pieces of material, a frequent method in automotive and sheet metal work.

- Butt Welding: Joining two pieces end-to-end, requiring high precision for alignment.

- Repair Welding: Specifically for fixing defects or rejoining broken components in various industries.

- Others: Includes specialized applications like clad welding, hermetic sealing, and customized artistic fabrication.

- By End-User Industry:

- Automotive Industry: For body repair, component assembly, exhaust systems, and aesthetic modifications.

- Jewelry & Precious Metals: Repair, resizing, and fabrication of intricate designs with minimal discoloration.

- Electronics & Electrical: Joining delicate components, circuit board repair, and battery pack assembly.

- Medical Devices: Welding small, sterile components for surgical instruments, implants, and diagnostic tools.

- General Fabrication & Sheet Metal: Small-scale manufacturing, prototyping, and custom metalwork.

- Dental Industry: For welding dental prosthetics, crowns, and bridges.

- Aerospace & Defense: Repair of lightweight components, specialized part fabrication.

- Consumer Goods: Assembly of small appliances, eyewear, and other intricate consumer products.

- By Laser Type:

- Fiber Laser: Dominant due to high beam quality, efficiency, long lifespan, and low maintenance.

- Diode Laser: Offers good efficiency and compact size, suitable for certain applications.

- Nd:YAG Laser: Less common in handheld low power, but still present in some legacy or specific setups.

- By Distribution Channel:

- Direct Sales: Manufacturers selling directly to large industrial clients or through their own sales force.

- Distributors & Resellers: Third-party companies that stock and sell products, providing local support and reach.

- Online Retailers: E-commerce platforms catering to smaller businesses and individual buyers.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Low Power Handheld Laser Welding Machine Market

The value chain for the Low Power Handheld Laser Welding Machine Market begins with upstream activities focused on the procurement and manufacturing of critical components. This involves specialized suppliers of laser sources, such as fiber laser modules, diode laser stacks, and power supply units, which form the core of the welding system. Optical components, including lenses, mirrors, and beam delivery fibers, are also sourced from high-precision manufacturers. Additionally, control system manufacturers provide the sophisticated electronics and software that manage the laser output, motion, and user interface. These upstream suppliers are crucial for innovation and quality, as the performance of the final welding machine is highly dependent on the quality and integration of these foundational elements. Research and development in these component areas directly impacts the capabilities and cost-effectiveness of the handheld laser welding machines, driving continuous improvements in efficiency and functionality within the market.

Moving downstream, the value chain encompasses the assembly, testing, marketing, and distribution of the complete low power handheld laser welding machines. Manufacturers assemble the sourced components, integrate safety features, and conduct rigorous quality assurance tests to ensure optimal performance and compliance with industry standards. Post-manufacturing, the machines are channeled to end-users through a combination of direct and indirect distribution networks. Direct sales involve manufacturers engaging directly with large industrial customers, often providing customized solutions, installation, and after-sales service. This channel allows for deeper customer relationships and direct feedback, fostering product improvements. Indirect channels primarily involve a network of distributors, resellers, and increasingly, online retailers. These partners play a vital role in market penetration, particularly for reaching small to medium-sized enterprises (SMEs) and specialized workshops, by offering localized sales, technical support, and training, thereby expanding the market's reach significantly.

The distribution landscape for low power handheld laser welding machines is characterized by a hybrid approach, leveraging both direct engagement and broad intermediary networks. Direct distribution is typically favored for high-value sales to large industrial clients who require comprehensive technical support, bespoke configurations, and direct access to manufacturers' expertise. This approach ensures meticulous service and facilitates long-term strategic partnerships. Conversely, indirect distribution, primarily through a robust network of authorized distributors, specialized industrial equipment suppliers, and an expanding presence on e-commerce platforms, is crucial for reaching a wider market. Distributors often provide value-added services such as local inventory, immediate technical assistance, training programs, and regional marketing initiatives. The rise of online sales platforms is also creating a new avenue, particularly for smaller businesses and individuals seeking accessible purchase options and competitive pricing. This multi-channel strategy ensures that manufacturers can cater to the diverse purchasing preferences and technical support requirements of the global customer base, optimizing market accessibility and fostering widespread adoption.

Low Power Handheld Laser Welding Machine Market Potential Customers

Potential customers for Low Power Handheld Laser Welding Machines span a broad spectrum of industries and professional segments, all seeking enhanced precision, efficiency, and flexibility in their welding operations. Key end-users include independent automotive repair shops and collision centers that require precise, minimal-distortion welds for vehicle bodywork and component repair, especially on modern lightweight alloys. The jewelry industry is a significant customer base, encompassing custom jewelers, repair specialists, and manufacturers of precious metal items, who benefit immensely from the machine's ability to create clean, strong welds without disfiguring delicate pieces or heat-sensitive stones. In the electronics sector, manufacturers of intricate circuit boards, small components, and battery packs find these machines indispensable for precise, localized joining that protects sensitive surrounding materials from heat damage. These customers prioritize the machine's ability to deliver high-quality, aesthetic results while improving productivity and reducing manual labor.

Beyond these core industries, the market extends to the medical device manufacturing sector, where the precision and sterile welding capabilities are crucial for fabricating implants, surgical instruments, and diagnostic equipment. Dental laboratories also utilize these machines for the creation and repair of prosthetics, crowns, and bridges, ensuring strong and biocompatible joints. Small to medium-sized enterprises (SMEs) involved in general fabrication, sheet metal work, and custom metal projects represent a growing customer segment, attracted by the portability and versatility that enables them to undertake a wider range of jobs with higher quality output. Hobbyists and educational institutions are also emerging as potential buyers, driven by the increasing accessibility and ease of use of these advanced tools for learning and small-scale projects. Each of these customer groups values the cost-effectiveness derived from reduced consumables, minimal post-processing, and the ability to handle diverse materials with greater efficiency.

The appeal of low power handheld laser welding machines to these diverse customer segments lies in their transformative impact on operational workflows and product quality. For businesses operating in high-mix, low-volume production environments or those requiring frequent on-site repairs, the portability and quick setup times offer unparalleled flexibility. Companies looking to modernize their welding processes, reduce their reliance on highly specialized manual welders, and adopt greener manufacturing techniques are increasingly turning to these laser solutions. Furthermore, the growing trend towards customization in consumer goods and specialized industrial components creates a demand for welding tools that can adapt quickly to different designs and materials without extensive retooling. The ability to deliver consistent, high-quality welds with minimal training requirements, combined with long-term operational savings, positions low power handheld laser welding machines as a strategic investment for any entity striving for excellence in precision metal joining.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.2 million |

| Market Forecast in 2033 | USD 720.5 million |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IPG Photonics, Trumpf, Coherent (II-VI), Han's Laser, Raycus Laser, Maxphotonics, JPT Opto-Electronics, nLight, SPI Lasers (Trumpf Group), Photonics Industries, Laserline, O.R. Lasertechnology, ALPHA LASER, AMADA MIYACHI, Jenoptik, Prima Power, Bystronic, Universal Laser Systems, Hypertherm, Lincoln Electric |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Power Handheld Laser Welding Machine Market Key Technology Landscape

The technology landscape for the Low Power Handheld Laser Welding Machine Market is primarily dominated by advancements in fiber laser technology, which has become the de facto standard due to its superior beam quality, high efficiency, compact size, and long lifespan. Fiber lasers, typically ytterbium-doped, deliver a highly focused and stable beam that allows for very precise and fast welding with minimal heat input, crucial for delicate applications. Alongside fiber lasers, high-power diode lasers are also used, offering a more compact and cost-effective alternative for certain applications, especially where beam quality requirements are slightly less stringent. These laser sources are coupled with sophisticated beam delivery systems, often utilizing flexible optical fibers that enable the handheld design and allow operators to maneuver the welding head with ease around complex geometries. The evolution of these core laser technologies continues to drive the market forward, offering greater power stability, improved uptime, and reduced operational costs for end-users, thus enhancing their overall value proposition.

Beyond the laser source and beam delivery, critical technologies shaping this market include advanced control systems, human-machine interfaces (HMIs), and integrated safety features. Modern machines incorporate intelligent control software that allows for precise manipulation of welding parameters such as power, pulse duration, and waveform, enabling operators to achieve optimal weld quality across various materials and thicknesses. User-friendly HMIs, often featuring touchscreens and intuitive software, simplify the setup and operation process, reducing the learning curve for new users. Furthermore, robust safety mechanisms, including interlock systems, laser safety glasses, and enclosed welding zones (even for handheld operations, through accessories), are integral to product design, ensuring operator protection from laser radiation and fume exposure. The integration of real-time monitoring sensors and feedback loops further enhances process stability and consistency, contributing to the high reliability and repeatability expected from these advanced welding tools. This technological confluence makes modern handheld laser welders highly efficient and safe.

The ongoing development of auxiliary technologies, such as advanced optics, cooling systems, and material handling solutions, further strengthens the low power handheld laser welding machine market. Specialized optics, including various collimators, scanners, and focusing lenses, are crucial for tailoring the laser beam characteristics to specific welding tasks, optimizing spot size, and energy distribution. Efficient cooling systems, often closed-loop water chillers, are essential for maintaining stable operating temperatures of the laser source and optics, which directly impacts the longevity and performance of the machine. The integration of vision systems, often incorporating cameras and magnifiers, aids operators in precise targeting and real-time inspection of the weld area, particularly for micro-welding applications. Furthermore, the trend towards connectivity, enabling remote diagnostics, software updates, and data logging, is increasingly shaping the technological landscape, offering opportunities for enhanced serviceability and process optimization. These synergistic technological advancements collectively contribute to the increasing adoption and versatility of low power handheld laser welding machines across industrial applications.

Regional Highlights

- Asia Pacific (APAC): This region is projected to be the largest and fastest-growing market for low power handheld laser welding machines, driven by rapid industrialization, massive manufacturing base expansion, and significant investments in advanced production technologies, particularly in countries like China, India, Japan, and South Korea. The automotive, electronics, and general fabrication sectors in APAC are experiencing booming demand, creating a substantial market for efficient and precise welding solutions. Government initiatives supporting local manufacturing and technology adoption also contribute to this robust growth.

- North America: Characterized by high technological adoption, stringent quality standards, and a strong presence of advanced manufacturing industries such as aerospace, medical devices, and high-tech electronics, North America represents a mature yet continually growing market. The demand here is driven by the need for automation, precision, and efficiency to maintain competitive advantage and reduce reliance on manual labor. The automotive aftermarket and repair sector also plays a significant role in adopting these portable welding solutions.

- Europe: Similar to North America, Europe is a well-established market with strong demand from its advanced manufacturing sectors, including automotive, medical technology, and precision engineering, particularly in Germany, Italy, and France. European manufacturers prioritize high-quality outputs, energy efficiency, and compliance with strict safety regulations. The region also benefits from a strong R&D base, fostering innovation in laser technology and driving the adoption of sophisticated handheld systems for various applications, including customized fabrication and restoration.

- Latin America: This region is an emerging market for low power handheld laser welding machines, showing promising growth as countries like Brazil, Mexico, and Argentina invest in modernizing their industrial infrastructure and expanding their manufacturing capabilities. The demand is primarily from the automotive, general fabrication, and metalworking sectors seeking to improve productivity and product quality. Economic development and increasing foreign investment are key drivers for the gradual adoption of these advanced welding technologies in the region.

- Middle East & Africa (MEA): The MEA market is still nascent but exhibits considerable potential, particularly in countries focusing on industrial diversification and infrastructure development. The growth in construction, automotive repair, and specialized manufacturing (e.g., jewelry, oil & gas maintenance) sectors is creating opportunities for advanced welding solutions. As industrial capabilities expand and awareness of laser technology benefits increases, the adoption of low power handheld laser welding machines is expected to accelerate in this region, driven by the need for efficiency and precision in new industrial setups.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Power Handheld Laser Welding Machine Market.- IPG Photonics

- Trumpf

- Coherent (II-VI)

- Han's Laser

- Raycus Laser

- Maxphotonics

- JPT Opto-Electronics

- nLight

- SPI Lasers (Trumpf Group)

- Photonics Industries

- Laserline

- O.R. Lasertechnology

- ALPHA LASER

- AMADA MIYACHI

- Jenoptik

- Prima Power

- Bystronic

- Universal Laser Systems

- Hypertherm

- Lincoln Electric

Frequently Asked Questions

What is a low power handheld laser welding machine?

A low power handheld laser welding machine is a portable and compact device, typically utilizing fiber or diode lasers below 1000W, designed for precision welding of thin metals and delicate components. It offers high speed, minimal heat input, and superior weld quality compared to traditional methods, enhancing flexibility for various industrial applications. These machines are known for ease of use, reduced post-processing needs, and excellent weld aesthetics, making them ideal for tasks requiring fine control and clean finishes.

Which industries primarily benefit from these welding machines?

Key industries benefiting from low power handheld laser welding machines include automotive repair, jewelry manufacturing, electronics assembly, medical device fabrication, and general light manufacturing. Their precision and minimal heat-affected zone are crucial for delicate materials and intricate designs in these sectors, ensuring high-quality, durable, and aesthetically pleasing welds without material distortion or discoloration. This versatility makes them indispensable for businesses aiming for efficiency and superior product output across diverse applications.

What are the main advantages of using a handheld laser welder over traditional methods?

The primary advantages include significantly higher welding speed, superior weld quality with minimal distortion, reduced heat-affected zone (HAZ), and less need for consumables and post-processing. Handheld laser welders offer enhanced precision and flexibility for intricate tasks, improved user safety through reduced fume exposure, and are often easier to operate than traditional welding equipment, leading to lower labor costs and improved operational efficiency. Their portability also allows for greater versatility in deployment across various work environments.

What are the typical power ranges for low power handheld laser welding machines?

Low power handheld laser welding machines typically operate within a power range of 100W to 1000W. This range is further segmented, with machines up to 500W ideal for very thin materials and delicate precision work, while those between 501W and 1000W cater to a broader scope of thin to medium-gauge metals, offering a balance of speed and versatility. The specific power output chosen depends on the material thickness, type of weld, and desired penetration, ensuring optimal performance for diverse industrial applications.

What is the market growth forecast for low power handheld laser welding machines?

The Low Power Handheld Laser Welding Machine Market is projected for substantial growth, with an estimated Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. This growth is driven by increasing industrial demand for high-precision, efficient, and portable welding solutions, coupled with ongoing technological advancements and expanding applications across various end-user industries. The market is anticipated to reach USD 720.5 million by 2033, up from USD 350.2 million in 2026, indicating a robust and expanding market landscape.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager