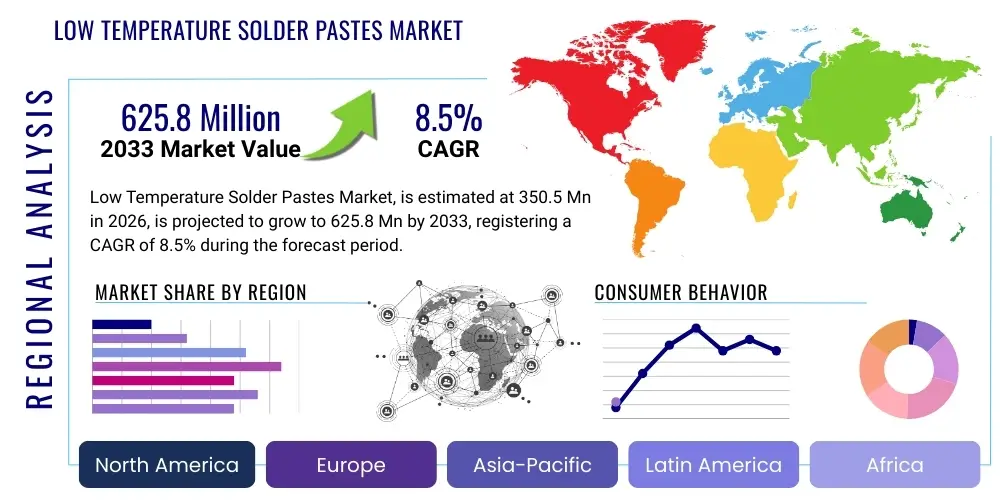

Low Temperature Solder Pastes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439737 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Low Temperature Solder Pastes Market Size

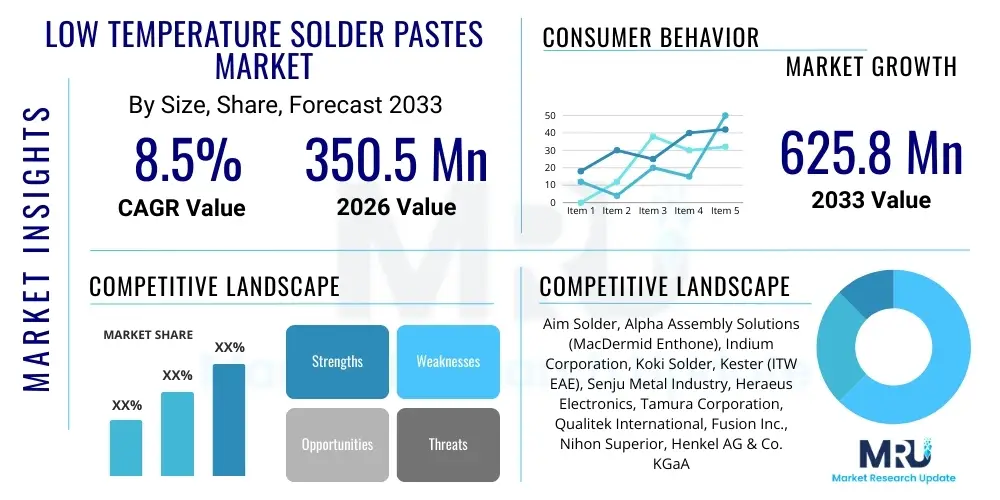

The Low Temperature Solder Pastes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 350.5 million in 2026 and is projected to reach USD 625.8 million by the end of the forecast period in 2033. This substantial growth is primarily propelled by the escalating demand for miniaturized and complex electronic devices, the increasing integration of heat-sensitive components, and the imperative for more energy-efficient manufacturing processes across a diverse range of industries. The market expansion is further underpinned by stringent environmental regulations advocating for lead-free solder solutions and the continuous advancements in material science enabling the development of high-performance low-temperature alloys.

Low Temperature Solder Pastes Market introduction

The Low Temperature Solder Pastes Market encompasses a critical segment within the broader electronics manufacturing industry, offering specialized soldering solutions designed to operate effectively at significantly lower reflow temperatures compared to traditional lead-free or tin-lead solders. These innovative pastes are typically formulated with bismuth (Bi) or indium (In) alloys, often in combination with tin (Sn) and other minor elements, to achieve melting points generally below 180°C. This unique property is instrumental in protecting delicate electronic components, such as microcontrollers, sensors, and optical devices, which are susceptible to thermal damage during conventional high-temperature soldering processes, thereby preserving their functionality and extending their operational lifespan in advanced electronic assemblies.

The product, low temperature solder paste, is a homogeneous mixture of fine metal solder powder, flux, and a rheological vehicle, meticulously engineered to facilitate precise deposition and controlled melting. Major applications span a wide array of high-growth sectors, including consumer electronics (smartphones, wearables, tablets), automotive electronics (ADAS, infotainment systems), LED lighting modules, medical devices, Internet of Things (IoT) devices, and various industrial control systems. The primary benefits derived from the adoption of these pastes include a significant reduction in thermal stress on sensitive components, substantial energy savings during the manufacturing process, improved compatibility with diverse substrate materials, and an enhanced ability to rework heat-sensitive assemblies without compromise. These advantages collectively contribute to higher production yields and improved product reliability in an era of increasing miniaturization and complexity.

Key driving factors for the market's robust expansion include the relentless global trend towards miniaturization in electronic devices, which necessitates the integration of increasingly delicate components on smaller footprints. The burgeoning proliferation of IoT devices and flexible electronics further fuels demand for low-temperature processing capabilities. Moreover, the worldwide push for sustainable manufacturing practices, driven by stringent environmental regulations mandating lead-free soldering, has accelerated the transition to alternative, lower-temperature solutions. The ongoing innovations in advanced packaging technologies, such as system-in-package (SiP) and package-on-package (PoP), which often involve multiple reflow cycles, also amplify the need for gentle, low-thermal-budget soldering solutions, positioning low temperature solder pastes as an indispensable material in the contemporary electronics ecosystem.

Low Temperature Solder Pastes Market Executive Summary

The Low Temperature Solder Pastes Market is experiencing dynamic shifts, driven by persistent innovation in electronic device manufacturing and evolving global regulatory landscapes. Current business trends indicate a strong impetus towards the development of ultra-fine pitch formulations capable of handling the increasing density of components on printed circuit boards, alongside a heightened focus on void reduction technologies to enhance solder joint reliability. Manufacturers are increasingly investing in research and development to create novel alloy compositions and flux chemistries that offer superior performance characteristics, such as enhanced printability, extended stencil life, and improved electrical conductivity, while adhering to environmental compliance standards. Furthermore, strategic collaborations and mergers and acquisitions are becoming more common as companies seek to expand their product portfolios, strengthen their market reach, and consolidate technological expertise in a highly competitive environment, reflecting a maturation of the market while still presenting opportunities for specialized players.

Regional trends reveal Asia-Pacific as the undisputed global manufacturing hub, particularly for consumer electronics and automotive components, which consequently drives the largest demand and innovation in low temperature solder pastes. Countries such as China, South Korea, Japan, and Taiwan are at the forefront of adopting and developing advanced soldering solutions to support their extensive electronics ecosystems. North America and Europe, while representing mature markets, demonstrate a strong focus on high-value, specialized applications such as aerospace and defense, medical devices, and advanced research and development, emphasizing reliability, compliance, and custom formulations. These regions are also significant drivers for new technological advancements and sustainable practices, often setting benchmarks for global industry standards, which then cascade into other emerging markets, influencing product development and adoption cycles.

Segment trends within the low temperature solder pastes market are characterized by the increasing adoption of these materials across various applications, with consumer electronics and automotive remaining the largest and fastest-growing end-user industries. The miniaturization of devices in consumer electronics, coupled with the escalating electronic content in modern vehicles for advanced driver-assistance systems (ADAS) and electric powertrains, creates a sustained demand for thermally sensitive component assembly. Technologically, there is a pronounced shift towards sophisticated paste jetting and printing technologies, enabling precise deposition for ultra-fine pitch and complex geometries, which is crucial for high-density packaging. The market is also witnessing a growing interest in low-temperature solder preforms and wires for specific applications requiring targeted thermal management and improved mechanical strength, indicating a diversification of product forms to cater to a broader spectrum of manufacturing requirements.

AI Impact Analysis on Low Temperature Solder Pastes Market

User questions regarding the impact of Artificial Intelligence on the Low Temperature Solder Pastes Market frequently revolve around how AI can enhance manufacturing efficiency, improve product quality, optimize material science, and streamline supply chains. There is significant interest in AI's potential to automate complex processes, predict material behaviors under varying conditions, and accelerate the development of next-generation solder paste formulations. Concerns often include the initial investment required for AI integration, the need for skilled personnel to manage AI systems, and the implications for data security and intellectual property. Overall, users expect AI to usher in a new era of precision, predictability, and sustainability within the low-temperature soldering ecosystem, addressing current challenges related to yield, reliability, and material discovery with intelligent solutions.

- Predictive Quality Control: AI algorithms analyze real-time data from solder paste printing and reflow processes to predict and prevent defects, ensuring optimal solder joint quality and reducing rework, thereby improving overall manufacturing yield for low temperature applications.

- Optimized Material Formulation: Machine learning models can expedite the discovery and optimization of new low-temperature solder alloys and flux chemistries by simulating material properties and performance characteristics, significantly shortening development cycles and enhancing specific attributes like mechanical strength or electrical conductivity.

- Automated Process Control: AI-powered systems can autonomously monitor and adjust parameters of solder paste dispensing and reflow ovens, ensuring precise temperature profiles and optimal environmental conditions for low-temperature processes, minimizing variability and maximizing efficiency.

- Supply Chain Optimization: AI improves inventory management, demand forecasting, and logistics for raw materials (e.g., bismuth, indium, tin powders) and finished solder pastes, reducing waste, mitigating supply disruptions, and ensuring timely delivery to manufacturers.

- Robotic Process Automation (RPA): Integration of AI with robotic systems enables more precise and consistent handling, dispensing, and inspection of low-temperature solder pastes in highly automated assembly lines, leading to higher throughput and reduced human error.

- Failure Analysis and Diagnostics: AI-driven image recognition and data analysis tools can rapidly identify the root causes of solder joint failures specific to low-temperature processes, offering faster diagnostics and facilitating targeted process improvements.

DRO & Impact Forces Of Low Temperature Solder Pastes Market

The Low Temperature Solder Pastes Market is propelled by a confluence of powerful drivers, notably the relentless pursuit of miniaturization in electronic devices, which necessitates the use of components sensitive to high temperatures. The explosive growth of the Internet of Things (IoT) and wearable technology, along with the burgeoning electric vehicle market, demands high-density packaging and robust assembly of heat-sensitive sensors and processors, making low-temperature soldering an indispensable technology. Furthermore, the global shift towards lead-free soldering, enforced by environmental directives like RoHS, continues to expand the addressable market for these pastes, as they offer a viable, often superior, alternative to traditional high-temperature lead-free options, reducing thermal stress on components and minimizing energy consumption during manufacturing. This alignment with both technological advancement and regulatory compliance creates a compelling demand ecosystem for these specialized materials.

Despite significant growth, the market faces several inherent restraints that temper its expansion. One primary challenge is the typically narrower reflow process window associated with low-temperature solder pastes, requiring highly precise thermal control during assembly to avoid defects. Concerns regarding the mechanical strength and long-term reliability of solder joints created with some low-temperature alloys, particularly in harsh environmental conditions or high-stress applications like aerospace and defense, persist among some manufacturers. The specialized formulations and often complex alloy compositions of these pastes can also lead to a cost premium compared to conventional solders, which might deter adoption in highly cost-sensitive sectors. Moreover, the lack of widespread standardization across all low-temperature alloy types can complicate adoption and integration into existing manufacturing lines, demanding specific equipment adjustments and rigorous qualification processes.

Nevertheless, substantial opportunities abound for the Low Temperature Solder Pastes Market, particularly in emerging technological frontiers. The ongoing build-out of 5G infrastructure, with its demand for advanced radio frequency modules and base station components, offers a significant growth avenue. The continued evolution of advanced packaging technologies, such as system-in-package (SiP) and heterogeneous integration, which require multiple delicate soldering steps, will increasingly rely on low-temperature solutions. Moreover, the expansion into flexible electronics, medical implants, and sophisticated aerospace and defense applications, where component integrity under minimal thermal exposure is paramount, presents lucrative niche markets. The development of novel, ultra-low-temperature formulations and those with enhanced mechanical properties and improved reliability profiles through advanced material science and manufacturing techniques will unlock new application possibilities and solidify their position as a cornerstone of future electronics manufacturing.

Segmentation Analysis

The Low Temperature Solder Pastes Market is intricately segmented across various dimensions, reflecting the diverse technological requirements and application landscapes within the electronics manufacturing industry. This segmentation provides a granular view of market dynamics, enabling a comprehensive understanding of specific product categories, end-user preferences, and regional consumption patterns. Analyzing these segments is crucial for identifying growth hotspots, strategic investment areas, and tailoring product development initiatives to meet precise industry demands, ranging from high-volume consumer electronics production to specialized, high-reliability applications in demanding sectors like medical and aerospace. Understanding these segment interactions illuminates the complex interplay of technological innovation, market demand, and regulatory pressures that collectively shape the industry's trajectory, offering valuable insights for stakeholders across the entire value chain.

- By Alloy Type:

- Tin-Bismuth (Sn-Bi): Widely adopted due to its low melting point, ideal for heat-sensitive components, and often lead-free compliant.

- Tin-Bismuth-Silver (Sn-Bi-Ag): Offers enhanced mechanical strength and improved reliability compared to basic Sn-Bi, suitable for more demanding applications.

- Indium (In)-based: Known for extremely low melting points and superior ductility, often used in specialized applications like medical devices and cryogenics.

- Others: Includes proprietary blends and specific alloys tailored for unique performance characteristics, such as improved fatigue resistance or ultra-fine pitch capabilities.

- By Form:

- Solder Paste: The most common form, used for screen printing, stencil printing, and dispensing onto PCBs.

- Solder Wire: Utilized for manual soldering, rework, and robotic soldering applications.

- Solder Bar: Primarily used in wave soldering processes, though less common for low-temperature applications given component sensitivity.

- Solder Preforms: Precisely cut shapes of solder alloy, used for targeted soldering in specific component attachment or thermal management applications.

- By Application:

- Surface Mount Technology (SMT): Dominant application for automated assembly of components onto PCBs, requiring high precision and throughput.

- Wafer Level Packaging (WLP): Critical for advanced semiconductor packaging, involving very fine pitch and high-density interconnections.

- Die Attach: Used for securing semiconductor dies to substrates or leadframes, where thermal management and low stress are crucial.

- Others: Includes various niche applications such as flexible circuit assembly, LED module assembly, and specialized component bonding.

- By End-User Industry:

- Consumer Electronics: Smartphones, tablets, wearables, IoT devices, laptops, gaming consoles, demanding miniaturization and cost-effectiveness.

- Automotive: Advanced Driver-Assistance Systems (ADAS), infotainment, engine control units (ECUs), LED lighting, requiring high reliability and performance under harsh conditions.

- LED Lighting: Manufacturing of LED modules and luminaires, where heat sensitivity of LED chips necessitates low-temperature processing.

- Medical Devices: Implants, diagnostic equipment, portable health monitors, demanding biocompatibility, reliability, and precision for delicate components.

- Telecommunications: 5G infrastructure, network equipment, optical modules, requiring high-frequency performance and signal integrity.

- Industrial Electronics: Control systems, power modules, automation equipment, needing robust and long-lasting connections.

- Aerospace & Defense: Avionics, guidance systems, military communications, demanding extreme reliability and performance in critical applications.

- Others: Includes smart home devices, renewable energy systems, and various research & development applications.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Low Temperature Solder Pastes Market

The value chain for the Low Temperature Solder Pastes Market begins with the upstream segment, which is dominated by the extraction, refining, and processing of critical raw materials. This includes primary metals such as tin, bismuth, indium, and silver, alongside specialized chemicals for flux components, rheological agents, and other additives. Suppliers in this stage focus on ensuring high purity, consistent quality, and reliable supply of these materials, as any fluctuations in pricing or availability directly impact the cost and performance of the final solder paste product. Powder manufacturers then process these metals into ultra-fine spherical particles with precise size distributions, which is a highly specialized and technically demanding step, directly influencing the solder paste's printability, reflow characteristics, and overall joint quality. Innovation in this upstream segment focuses on developing sustainable sourcing methods, improving powder atomization techniques, and formulating advanced flux chemistries.

Further down the value chain, the intermediate stage involves the sophisticated blending and manufacturing of the solder pastes themselves. Solder paste manufacturers combine the metal powders with various fluxes and vehicles, employing rigorous quality control to ensure homogeneity, stability, and optimal rheological properties. These manufacturers invest heavily in research and development to tailor pastes for specific applications, focusing on attributes like no-clean formulations, void reduction, extended stencil life, and compatibility with diverse reflow profiles. The distribution channel then bridges the gap between manufacturers and end-users, encompassing both direct sales forces that handle large OEM accounts and an extensive network of distributors. These distributors often provide localized support, technical expertise, and inventory management services, playing a crucial role in reaching a wide array of customers, from small contract manufacturers to large multinational electronics companies, ensuring product availability and technical assistance across various geographical regions.

The downstream segment of the value chain consists of the end-users, primarily electronics manufacturing service (EMS) providers, Original Equipment Manufacturers (OEMs), and specialized component manufacturers. These entities integrate the low temperature solder pastes into their assembly processes for a vast array of electronic devices. Direct customers typically include large-scale EMS providers and OEMs who purchase in bulk and often have long-term supply agreements, frequently working closely with solder paste manufacturers for custom formulations and technical support. Indirect customers are generally smaller manufacturers or those with lower volume requirements, procuring pastes through distributors. The successful utilization of low temperature solder pastes in this stage relies on the seamless integration with advanced printing and reflow equipment, requiring significant technical expertise and process optimization to achieve desired yields and reliability. Post-assembly, the products undergo rigorous testing and quality assurance, before being integrated into final products and reaching the ultimate consumer market, completing the full lifecycle of the value chain.

Low Temperature Solder Pastes Market Potential Customers

The Low Temperature Solder Pastes Market primarily serves a broad and sophisticated customer base consisting of various entities within the electronics manufacturing ecosystem, all of whom share a common need for precise, reliable, and thermally sensitive assembly solutions. Foremost among these are Electronics Manufacturing Service (EMS) providers, who are contractually engaged by Original Equipment Manufacturers (OEMs) to design, manufacture, and test electronic components and assemblies. EMS firms represent a significant portion of the demand, as they process high volumes of diverse products, from consumer gadgets to industrial controls, where the efficiency and reliability offered by low-temperature solder pastes are critical for meeting demanding production schedules and stringent quality standards for their numerous clients. Their need spans a variety of paste formulations to accommodate different component types and substrate materials, making them a cornerstone customer segment.

Original Equipment Manufacturers (OEMs) themselves also constitute a vital segment of potential customers, especially those with in-house manufacturing capabilities or those requiring highly specialized solutions for their proprietary products. This includes major players in sectors such as consumer electronics (e.g., smartphone and wearable device manufacturers), automotive electronics suppliers developing advanced driver-assistance systems (ADAS) and electric vehicle components, and medical device companies manufacturing sensitive diagnostic or implantable technologies. These OEMs often engage directly with solder paste manufacturers for tailored formulations that meet their specific product requirements for performance, miniaturization, and long-term reliability in often mission-critical applications. Their purchasing decisions are driven not only by cost but also by factors such as technical support, supply chain security, and the ability to integrate cutting-edge soldering solutions into their innovative product roadmaps.

Beyond these large-scale manufacturers, other key potential customers include LED lighting manufacturers, who rely on low-temperature solder pastes to assemble heat-sensitive LED chips without degradation, ensuring product longevity and consistent luminosity. Telecommunication equipment makers are increasingly adopting these pastes for 5G infrastructure components, where signal integrity and component protection are paramount. Furthermore, companies specializing in industrial automation, aerospace and defense, and even academic and research institutions developing advanced prototypes or experimental electronic circuits, represent significant niche markets. These diverse end-users and buyers are consistently seeking solder paste solutions that offer superior processing characteristics, enhanced reliability for delicate components, and compliance with evolving environmental standards, thereby driving continuous innovation and demand across the entire spectrum of the low-temperature solder paste market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 million |

| Market Forecast in 2033 | USD 625.8 million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aim Solder, Alpha Assembly Solutions (MacDermid Enthone), Indium Corporation, Koki Solder, Kester (ITW EAE), Senju Metal Industry, Heraeus Electronics, Tamura Corporation, Qualitek International, Fusion Inc., Nihon Superior, Henkel AG & Co. KGaA, SMT-Wertheim, Yong An Technology, Dongguan Shengding Industrial, Shenzhen Selida Technology |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Low Temperature Solder Pastes Market Key Technology Landscape

The Low Temperature Solder Pastes Market is underpinned by a sophisticated array of technologies that are continuously evolving to meet the demands of advanced electronics manufacturing. A cornerstone of this landscape is advanced powder metallurgy, which focuses on producing ultra-fine, highly spherical metal powders with tightly controlled particle size distributions. This precision in powder characteristics is crucial for achieving optimal printability for fine-pitch applications, preventing issues like bridging and slumping, and ensuring consistent reflow performance. Innovations in atomization techniques and surface treatment of these metal powders are constantly pushing the boundaries of miniaturization and reliability, directly impacting the final solder joint quality and the ability to process more complex and smaller components efficiently and consistently across high-volume production lines.

Another critical technological domain is sophisticated flux chemistry, which is integral to the performance and long-term reliability of low temperature solder pastes. Modern fluxes are designed to be highly active at lower temperatures, effectively removing oxides from both solder powder and component pads while minimizing residue post-reflow. The development of low-residue and no-clean fluxes is particularly significant, as it eliminates the need for post-soldering cleaning processes, thereby reducing manufacturing steps, environmental impact, and overall production costs. Advancements in rheology control are equally important, ensuring that the solder paste maintains its viscosity and thixotropy during printing and dispensing, preventing issues such as slumping or poor release from the stencil, which are paramount for high-yield, fine-pitch soldering operations, especially with delicate substrates.

Furthermore, the technological landscape includes the continuous innovation in solder paste dispensing and printing technologies, such as advanced stencil printing, jetting, and precise syringe dispensing systems. These technologies are continually refined to handle the unique rheological properties of low-temperature pastes, enabling accurate deposition for ultra-fine pitch components and complex geometries. Complementary technologies like vacuum reflow ovens are gaining traction, as they help to minimize voids in solder joints, which is particularly beneficial for low-temperature solders that might be more susceptible to voiding. Coupled with advanced packaging techniques like system-in-package (SiP) and heterogeneous integration, which often involve multiple delicate soldering steps, these technological advancements collectively drive the adoption and successful implementation of low temperature solder pastes, enhancing both the performance and manufacturability of next-generation electronic devices.

Regional Highlights

- Asia Pacific (APAC): This region dominates the Low Temperature Solder Pastes Market, primarily due to the presence of an extensive electronics manufacturing ecosystem across countries like China, Taiwan, South Korea, and Japan. The high concentration of consumer electronics, automotive electronics, and LED manufacturing hubs drives immense demand for these pastes, coupled with continuous investment in advanced assembly technologies and a strong focus on cost-effective, high-volume production.

- North America: Characterized by a strong emphasis on research and development, North America represents a mature market with significant demand from high-reliability applications in aerospace and defense, medical devices, and advanced computing. The region is a key innovator in developing new material formulations and process technologies, focusing on niche, high-performance applications where product reliability and thermal stress reduction are paramount, often driving premium pricing.

- Europe: Driven by stringent environmental regulations, particularly the Restriction of Hazardous Substances (RoHS) directive, Europe has been an early adopter of lead-free and low-temperature soldering solutions. The robust automotive electronics sector, industrial control systems, and renewable energy segments in countries like Germany, France, and the UK fuel demand, with a focus on sustainable manufacturing processes and high-quality, reliable electronic assemblies.

- Latin America: This region is an emerging market for low temperature solder pastes, experiencing growth driven by increasing foreign investments in electronics manufacturing, particularly in consumer electronics assembly and automotive components. Countries like Mexico and Brazil are expanding their manufacturing capacities, leading to a rising adoption of advanced soldering materials and processes to enhance local production capabilities and competitiveness.

- Middle East & Africa (MEA): While currently a smaller market, the MEA region shows nascent growth, propelled by developing infrastructure projects, increasing industrialization, and a growing interest in local electronics assembly. The market here is primarily driven by specific applications in telecommunications, security systems, and energy sector electronics, with a gradual shift towards more sophisticated manufacturing techniques.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Low Temperature Solder Pastes Market.- Aim Solder

- Alpha Assembly Solutions (MacDermid Enthone)

- Indium Corporation

- Koki Solder

- Kester (ITW EAE)

- Senju Metal Industry

- Heraeus Electronics

- Tamura Corporation

- Qualitek International

- Fusion Inc.

- Nihon Superior

- Henkel AG & Co. KGaA

- SMT-Wertheim

- Yong An Technology

- Dongguan Shengding Industrial

- Shenzhen Selida Technology

Frequently Asked Questions

Analyze common user questions about the Low Temperature Solder Pastes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of low-temperature solder pastes?

The primary advantages of low-temperature solder pastes include significantly reduced thermal stress on delicate electronic components, which prevents damage and improves overall device reliability. They also enable substantial energy savings during the manufacturing reflow process, contributing to lower operational costs and enhanced sustainability. Furthermore, their lower processing temperatures facilitate compatibility with a wider range of heat-sensitive substrates and components, expanding design flexibility for advanced electronics.

How do low-temperature solder pastes contribute to environmental sustainability?

Low-temperature solder pastes significantly contribute to environmental sustainability by allowing for lower energy consumption during the reflow soldering process, thereby reducing carbon emissions associated with electronics manufacturing. Crucially, most modern low-temperature formulations are lead-free, directly complying with global environmental directives like RoHS and mitigating the use of hazardous substances. Their ability to reduce thermal stress also leads to fewer component failures and less electronic waste, fostering a more circular economy.

What are the main challenges associated with using low-temperature solder pastes?

The main challenges associated with low-temperature solder pastes include a typically narrower reflow process window, which demands precise thermal control to prevent defects. Some formulations may exhibit lower mechanical strength or reliability compared to conventional solders in harsh environments, necessitating careful material selection. Additionally, the specialized nature of these pastes can lead to a higher initial cost, and their integration may require specific equipment adjustments and rigorous qualification processes to ensure optimal performance and yield.

In which key industries are low-temperature solder pastes most predominantly utilized?

Low-temperature solder pastes are most predominantly utilized across several key industries driven by miniaturization and thermal sensitivity. These include consumer electronics (e.g., smartphones, wearables), automotive electronics (for ADAS and infotainment), LED lighting manufacturing due to the heat sensitivity of LED chips, and medical devices where delicate components require precise and gentle assembly. The telecommunications and industrial electronics sectors are also significant users, driven by the demand for advanced packaging and high-reliability systems.

How is the evolution of electronic miniaturization impacting the demand for low-temperature solder pastes?

The relentless evolution of electronic miniaturization profoundly impacts the demand for low-temperature solder pastes by necessitating the integration of increasingly smaller, more densely packed, and often heat-sensitive components onto compact printed circuit boards. As components become more delicate and designs more intricate, conventional high-temperature soldering poses a greater risk of thermal damage. Low-temperature solder pastes provide the essential solution, enabling robust interconnections without compromising component integrity, thereby becoming indispensable for the continued advancement of compact and powerful electronic devices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager