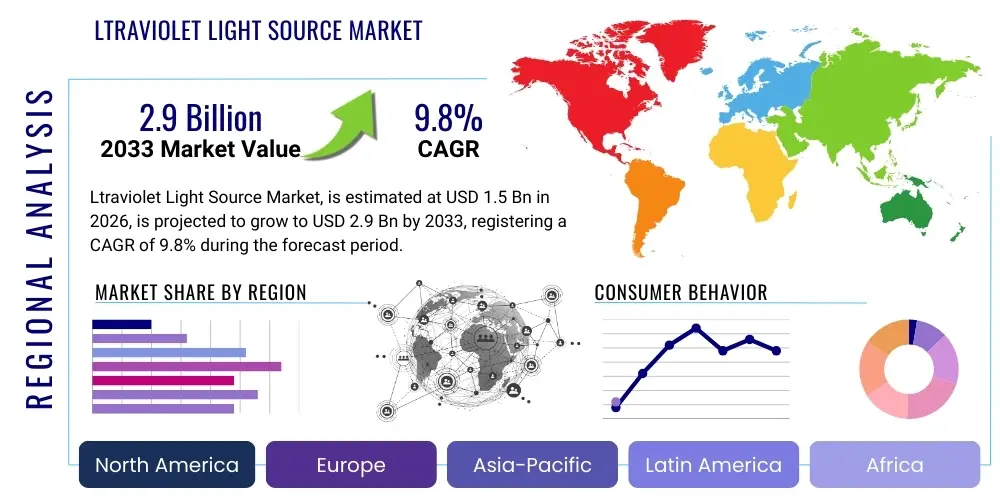

Ltraviolet Light Source Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437907 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Ltraviolet Light Source Market Size

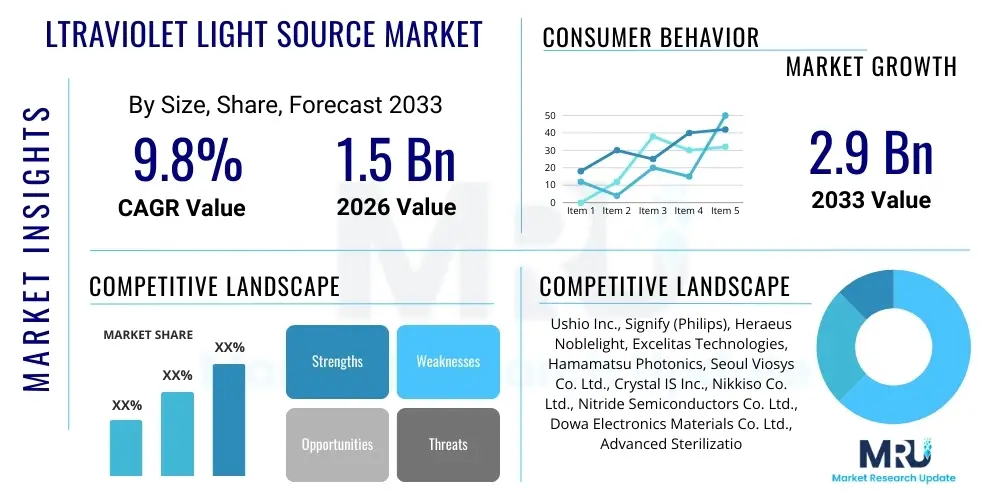

The Ltraviolet Light Source Market, more accurately referred to as the Ultraviolet (UV) Light Source Market, is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.9 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the escalating demand for advanced disinfection technologies across various end-use sectors, particularly healthcare, water treatment, and air purification, where UVC sources play a critical role in mitigating pathogenic contamination. Furthermore, industrial applications, such as UV curing in printing, coatings, and adhesives, continue to provide significant momentum, benefiting from the operational efficiencies and environmental advantages offered by UV technologies over traditional heat-based methods.

The market valuation reflects a significant technological transition, specifically the shift from traditional mercury vapor lamps to solid-state solutions like Ultraviolet Light Emitting Diodes (UV LEDs). While conventional lamps maintain a strong presence in high-power applications due to their cost-effectiveness and maturity, UV LEDs are rapidly gaining traction across low-to-medium power segments. This growth is fueled by their distinct advantages, including compact size, instant on/off capabilities, longer lifespan, lower power consumption, and the absence of hazardous materials like mercury, aligning with stringent environmental regulations such as the Minamata Convention. Investment in deep UV-C LED technology, focused on efficient germicidal capabilities, is a core driver of market revenue increase.

Geographic market expansion is concentrated in the Asia Pacific region, attributed to rapid industrialization, high population density necessitating improved water and air quality infrastructure, and robust manufacturing activities utilizing UV curing processes. North America and Europe, characterized by sophisticated healthcare standards and early adoption of regulatory-compliant, mercury-free technologies, also hold substantial market shares. The overall forecast indicates that persistent global focus on public health safety and the imperative for sustainable manufacturing processes will solidify the trajectory of strong, sustained growth across all primary application domains throughout the forecast period.

Ltraviolet Light Source Market introduction

The Ultraviolet (UV) Light Source Market encompasses a diverse range of devices designed to generate electromagnetic radiation within the UV spectrum, typically spanning wavelengths from 10 nm to 400 nm. These sources are fundamentally categorized into two main technologies: traditional UV lamps (such as low-pressure mercury vapor lamps, medium-pressure lamps, and excimer lamps) and modern solid-state UV Light Emitting Diodes (UV LEDs). Product descriptions vary based on the specific wavelength output: UVA (320–400 nm) is predominantly used for curing, forensic analysis, and tanning; UVB (280–320 nm) is utilized in medical phototherapy; and UVC (100–280 nm), known as germicidal UV, is vital for sterilization and disinfection applications. The core mechanism involves the emission of photons that interact with materials, causing photochemical reactions, fluorescence, or microbial DNA/RNA damage, depending on the spectral output.

Major applications of UV light sources are vast and critical to modern infrastructure. Industrial applications heavily rely on UV curing for surface coatings, inks, and adhesives in manufacturing sectors like automotive, electronics assembly, and graphic arts, offering rapid processing times and reduced Volatile Organic Compound (VOC) emissions. The largest growth driver remains sterilization and disinfection, encompassing water treatment plants, municipal and commercial air purification systems, and surface sanitation in healthcare settings and consumer appliances. Other significant areas include analytical instrumentation, where UV light is integral to spectroscopy and chromatography; semiconductor manufacturing for photolithography; and specialized lighting for horticultural enhancement and insect control. The versatility and efficiency of UV technology underpin its pervasive integration across various industries demanding precision and hygiene.

The primary benefits driving market adoption include enhanced public health safety through effective pathogen inactivation, significant operational cost savings due to longer source lifespans (especially LEDs) and rapid processing speeds (in curing), and improved environmental compliance by eliminating mercury and reducing energy consumption. Key driving factors involve increasingly strict global regulations on water and air quality, heightened consumer awareness regarding hygiene post-pandemic events, and continuous technological advancements resulting in higher output power, improved efficiency, and reduced manufacturing costs for UV LEDs. Furthermore, the push towards miniaturization and portability across medical and consumer electronics sectors favors the adoption of compact, durable UV LED solutions, ensuring market resilience and continuous innovation.

Ltraviolet Light Source Market Executive Summary

The Ultraviolet Light Source Market is experiencing dynamic growth defined by a pronounced shift towards solid-state technologies, driven by global mandates for environmental sustainability and enhanced public health infrastructure. Key business trends highlight aggressive investment in deep UVC LED manufacturing capabilities, aimed at improving germicidal efficiency and reducing overall system costs, allowing UV disinfection solutions to penetrate residential and point-of-use markets more effectively. Strategic collaborations between LED manufacturers and system integrators are focusing on developing smart UV-based solutions integrated with IoT functionalities for real-time monitoring and optimization in water and air purification systems. The business landscape is also characterized by intense merger and acquisition activity as established lamp manufacturers seek to acquire specialized UV LED expertise, consolidating technological platforms and expanding product portfolios to maintain competitive edge in the evolving market.

Regionally, the Asia Pacific (APAC) market leads in terms of manufacturing capacity and overall application volume, primarily due to the expansive electronics and automotive sectors utilizing UV curing, coupled with massive infrastructure projects requiring advanced water treatment. North America and Europe dominate the high-value, stringent regulatory segments, particularly medical device sterilization and certified public water systems, emphasizing energy efficiency and mercury-free solutions. Regional trends are also shaped by regulatory divergence; while Europe pushes strongly for complete mercury phase-out, certain developing economies still heavily rely on cost-effective, high-power conventional lamps for industrial curing and large-scale disinfection. The Middle East and Africa (MEA) region shows significant potential growth, particularly in arid zones where water recycling and purification technologies are becoming paramount to resource management and food security initiatives.

Segmentation trends reveal that the UV LED segment is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR), reflecting rapid technology maturity and cost reduction. Within applications, the disinfection and sterilization segment holds the largest market share and is expected to maintain its dominance due to continuous health and safety investments globally. Specifically, water disinfection remains the single largest application sub-segment, critical for both municipal and industrial water reuse. In terms of wavelength, UVC technology is the fastest-growing segment, directly capitalizing on the demand for germicidal irradiation across all end-user sectors, including the integration of far-UVC (207–222 nm) research which holds promise for safer continuous occupancy disinfection systems.

AI Impact Analysis on Ltraviolet Light Source Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Ultraviolet Light Source Market frequently center on how AI can optimize the performance, efficiency, and maintenance of UV systems, especially within large-scale industrial and germicidal applications. Common themes include concerns about predictive failure, the optimal dosing of UV light in dynamic environments (like municipal water flows or air handling units), and the integration of machine learning for process control in complex UV curing lines. Users are keenly interested in understanding if AI can significantly extend the lifespan of expensive UV emitters by managing operational parameters, reducing energy waste, and ensuring validated disinfection efficacy in real-time. The general expectation is that AI will move UV technology beyond simple 'on/off' operation toward intelligent, responsive, and resource-efficient illumination management.

The key themes emerging from user analysis highlight the desire for intelligent UV systems that can adapt to changing environmental inputs, such as varying water turbidity or microbial load, to administer precise UV doses, thereby maximizing efficacy while minimizing energy expenditure. Concerns often relate to the computational complexity and initial investment required to implement sophisticated AI algorithms into existing UV infrastructure. Furthermore, questions arise concerning data security and the standardization of protocols for collecting performance data from a network of UV light sources. Expectations are high that AI will facilitate predictive maintenance schedules, analyzing slight variations in emitter output or electrical characteristics to forecast imminent component failure, significantly reducing unplanned downtime, particularly in mission-critical applications like semiconductor fabrication or clinical sterilization.

In essence, the core function of AI in this market segment is optimization and decision support. AI algorithms can process vast amounts of sensor data—including UV intensity readings, flow rates, temperature, and historical operational data—to fine-tune the power supply and operational cycles of the UV source. This optimization ensures that regulatory compliance for disinfection is consistently met, while also extending the economic lifespan of the light sources. Moreover, AI-driven fault detection is becoming crucial for quality control in UV curing applications, where real-time analysis of coating adhesion or ink density can immediately trigger adjustments to exposure time or intensity, leading to unparalleled consistency and waste reduction in high-speed manufacturing environments.

- AI enables predictive maintenance, forecasting emitter degradation and failure in advance.

- Machine learning optimizes UV dosing based on real-time environmental variables (e.g., water quality, flow rate), ensuring compliance and energy efficiency.

- AI enhances quality control in industrial UV curing by adjusting exposure parameters dynamically to ensure consistent material properties.

- Integration of smart sensors and AI facilitates automated regulatory reporting and validation of disinfection efficacy.

- AI algorithms assist in spectrum tailoring and calibration for customized phototherapy and analytical applications.

DRO & Impact Forces Of Ltraviolet Light Source Market

The Ultraviolet Light Source Market is significantly shaped by a confluence of accelerating drivers and persistent restraints, counterbalanced by emerging opportunities, all of which define the long-term impact forces governing market direction. Key drivers include rigorous public health initiatives demanding effective sterilization solutions, the rapid proliferation of UV LED technology offering superior longevity and environmental benefits, and stringent governmental regulations enforcing the phase-out of traditional mercury-containing lamps under international agreements like the Minamata Convention. These forces collectively push the market toward innovation and adoption of mercury-free, energy-efficient solutions. Simultaneously, the market faces restraints such as the relatively high initial capital expenditure associated with high-power UV LED systems compared to conventional lamps, concerns regarding the long-term stability and efficiency droop of deep UVC LEDs, and inherent safety challenges related to direct UV exposure, necessitating complex shielding and monitoring systems. These constraints slightly impede widespread adoption, particularly in cost-sensitive industrial sectors.

However, the opportunities present substantial avenues for expansion. The global shortage of clean water necessitates increased investment in advanced UV water reuse and ballast water treatment systems, providing a massive commercial opportunity for high-throughput UVC sources. Furthermore, the development of Far-UVC sources (207-222 nm), which demonstrate germicidal efficacy without damaging human skin or eyes, promises revolutionary applications in continuously occupied public spaces, opening entirely new market segments in air and surface disinfection. The increasing application of UV curing in 3D printing, advanced composite manufacturing, and specialized electronics packaging offers diversification opportunities away from traditional printing and coating markets. Exploiting these emerging sectors requires sustained research into next-generation emitter materials, particularly aluminum nitride (AlN) and gallium nitride (GaN) substrates, to overcome current efficiency limitations.

The primary impact forces driving competitive advantage center on innovation in efficiency and longevity. Companies able to drastically increase the Wall Plug Efficiency (WPE) and lifespan of UVC LEDs will capture substantial market share, particularly as the cost per milliwatt continues to decrease, making LED solutions competitive across all power ranges. Regulatory pressure acts as a powerful external force, compelling the market to transition away from legacy technologies, favoring those companies positioned with robust, certified mercury-free alternatives. Additionally, the increasing convergence of UV technology with smart sensing and AI platforms transforms UV light sources from mere components into intelligent sanitation or curing systems, creating a significant competitive differentiation based on integrated system performance rather than just emitter cost. This confluence of technological push and regulatory pull dictates the competitive landscape and investment priorities across the forecast period.

- Drivers: Growing global demand for advanced disinfection solutions in water and air purification; regulatory pressure to phase out mercury lamps; increasing adoption of UV curing in high-speed manufacturing; performance improvements and cost reduction of UV LEDs.

- Restraints: High initial investment cost of high-power UV LED systems; efficiency limitations (Wall Plug Efficiency) of deep UVC LEDs; technological challenges related to thermal management and long-term lifespan degradation; safety concerns related to UV exposure requiring specialized training and protective measures.

- Opportunities: Emergence of Far-UVC technology for safe, continuous disinfection; increasing application in ballast water treatment and water reuse infrastructure; integration with IoT and AI for smart, optimized UV systems; expansion of UV curing into 3D printing and advanced electronics encapsulation.

- Impact Forces: Intense technological competition focused on UVC LED efficiency and lifespan (WPE); strong regulatory enforcement driving mercury-free transition; market consolidation through strategic acquisitions of specialized LED technology firms; shift towards solution-based selling incorporating intelligent control systems.

Segmentation Analysis

The Ultraviolet Light Source Market is meticulously segmented based on product type, application, and geographic region, reflecting the diverse technological options and widespread industrial uses of UV radiation. The segmentation by product type is critical, delineating between traditional UV Lamps (including medium and low-pressure mercury, xenon excimer, and metal halide lamps) and UV LEDs, which represent the future growth vector of the industry. This distinction is crucial for understanding current market dynamics, where lamps still dominate high-power curing and large-scale water treatment due to established cost structures, while LEDs aggressively penetrate disinfection, analytical, and handheld consumer markets due to size and efficiency advantages. Application segmentation separates the market into core functional areas, such as sterilization and disinfection, industrial curing, medical phototherapy, and analytical instruments, each requiring specific wavelength outputs and power characteristics.

Detailed analysis across the primary segments highlights differing growth trajectories. The UVC LED sub-segment, particularly those targeting the 250 nm to 280 nm range, is poised for explosive growth as infrastructure upgrades worldwide prioritize advanced pathogen control. Conversely, the mercury lamp segment faces secular decline, though it maintains a strong revenue base in replacement sales and specific high-power industrial installations where LEDs have yet to fully achieve cost parity and required power output. Application-wise, the disinfection segment, spurred by governmental and commercial investments in pandemic-proofing and public health maintenance, significantly outweighs industrial curing, though curing remains a vital, high-value component within the manufacturing sector, particularly in electronics where precision and low thermal impact are critical.

Furthermore, segmentation by wavelength is increasingly relevant, distinguishing UVA (primarily curing and forensic), UVB (phototherapy), and UVC (germicidal). This segmentation dictates end-user industry adoption, as UVA sources are essential for coatings and printing, while UVC sources are mandatory for water and air treatment. Regional segmentation underscores differential growth rates and technology adoption curves; mature markets like North America and Europe focus on compliance and high-efficiency replacement technologies, whereas rapidly industrializing nations in Asia Pacific focus on capacity expansion and infrastructure deployment, utilizing a mix of both cost-effective lamps and emerging LED technology. This granular segmentation provides essential clarity for strategic investment and market forecasting across the UV ecosystem.

- By Product Type:

- UV Lamps (Mercury Vapor Lamps, Xenon Excimer Lamps, Metal Halide Lamps)

- UV LEDs (UVA LED, UVB LED, UVC LED)

- By Application:

- Sterilization and Disinfection (Water Treatment, Air Purification, Surface Disinfection, Medical Device Sterilization)

- Industrial Curing (Coatings, Adhesives, Printing Inks)

- Medical and Phototherapy (Psoriasis, Vitiligo Treatment)

- Analytical Instruments (Spectroscopy, Chromatography)

- Sensing and Monitoring

- By Wavelength:

- UVA (320 nm – 400 nm)

- UVB (280 nm – 320 nm)

- UVC (100 nm – 280 nm, including Far-UVC)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Ltraviolet Light Source Market

The value chain for the Ultraviolet Light Source Market is complex, involving highly specialized technological expertise across multiple stages, from raw material procurement to final system integration and deployment. The upstream segment is critical, dominated by suppliers of specialized semiconductor materials (e.g., GaN and AlN substrates for LEDs, high-purity quartz glass for lamps) and key components (electrodes, phosphors, gas mixtures, and optical components). The quality and availability of these materials, especially the expensive, high-quality crystalline substrates required for deep UVC LEDs, directly influence the cost structure and performance of the final light source. Technological barriers to entry are highest at this foundational level, requiring significant intellectual property and capital investment in epitaxy and wafer fabrication facilities.

The midstream involves the core manufacturing of the light sources themselves, categorized primarily into traditional lamp production and advanced LED packaging. Lamp manufacturers focus on precise gas filling and electrode assembly, while LED manufacturers perform complex chip fabrication, packaging (e.g., flip-chip technology), and thermal management integration. Direct distribution often occurs for standard replacement lamps sold through specialized industrial distributors. However, for advanced systems, the midstream often involves original equipment manufacturers (OEMs) who purchase the bare chips or emitters and integrate them into proprietary modules with power supplies, heat sinks, and optics. This module assembly stage is crucial for optimizing system efficiency and ensuring regulatory compliance, particularly in germicidal applications.

Downstream analysis focuses on system integration and end-user deployment. System integrators specialize in incorporating UV modules into large-scale applications such as municipal water reactors, HVAC systems, or industrial curing chambers. These integrators provide necessary peripherals, control electronics, and regulatory certification, forming the primary interface with end-users. Distribution channels are varied: large industrial systems often use direct sales or specialized engineering firms; replacement lamps are handled by industrial and electrical supply distributors; and consumer-grade UV products are increasingly sold through e-commerce and retail channels. The shift toward UV LEDs emphasizes indirect channels via system integrators, leveraging their expertise in specialized application engineering and installation, which is crucial for achieving validated disinfection or curing outcomes.

Ltraviolet Light Source Market Potential Customers

The Ultraviolet Light Source Market serves an exceptionally broad and diversified customer base, reflecting the fundamental utility of UV radiation across industrial, medical, and environmental safety domains. Key end-users include governmental bodies and municipal water authorities that mandate large-scale disinfection systems for public health and resource management, representing a stable, high-volume customer segment. Industrial manufacturing firms, particularly those in automotive coatings, electronics assembly, printing, and packaging, are vital consumers of UVA and medium-pressure lamps for rapid curing processes, seeking sources that maximize throughput and minimize environmental impact. The semiconductor industry forms a high-value customer group, relying on highly specialized deep UV excimer lasers and lithography equipment for microchip fabrication, where cleanliness and precision are paramount.

The healthcare and life sciences sectors constitute another major segment. Hospitals, clinics, and pharmaceutical manufacturing facilities require high-efficacy UVC sources for surgical instrument sterilization, HVAC system disinfection, and cleanroom sanitization, increasingly adopting UV LED solutions for smaller, mobile disinfection units. Additionally, medical professionals utilize UVB sources for dermatological phototherapy treatments, driving demand for specific spectral outputs. Research institutions and analytical laboratories purchase UV sources for integration into spectrophotometers, HPLC detectors, and other forensic and scientific instruments, requiring stable and reliable performance across specific wavelengths for accurate analysis.

Furthermore, the consumer and commercial sectors are rapidly emerging as significant buyers. Commercial enterprises, including hotels, offices, and airlines, are integrating UVC air and surface disinfection systems into their operations to reassure customers and employees regarding safety protocols. Consumer demand for point-of-use water purifiers, portable sanitization wands, and specialized lighting (e.g., bug zappers utilizing UVA) is bolstering the market for low-power, compact UV LED modules. These customers prioritize ease of use, safety features, and durability, often procuring products through retail or e-commerce channels, indicating a shift toward decentralized, accessible UV applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.9 Billion |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ushio Inc., Signify (Philips), Heraeus Noblelight, Excelitas Technologies, Hamamatsu Photonics, Seoul Viosys Co. Ltd., Crystal IS Inc., Nikkiso Co. Ltd., Nitride Semiconductors Co. Ltd., Dowa Electronics Materials Co. Ltd., Advanced Sterilization Products (ASP), Honle UV, IST Metz GmbH, Nordson Corporation, Lumileds, Semileds Corporation, Luminus Devices, San'an Optoelectronics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ltraviolet Light Source Market Key Technology Landscape

The technology landscape of the Ultraviolet Light Source Market is defined by a dichotomy between mature, high-power conventional lamp technologies and rapidly evolving, precise solid-state solutions. Conventional technology, predominantly centered around low- and medium-pressure mercury vapor lamps, utilizes electric discharge through mercury gas to generate UVC radiation, specifically the 254 nm wavelength for germicidal applications. While established, cost-effective for large flows, and offering high instantaneous power, this technology is constrained by warm-up time, bulb fragility, and the environmental liability associated with mercury content. Excimer lamps, leveraging noble gas mixtures (e.g., Xenon Chloride at 308 nm or Krypton Chloride at 222 nm), represent a cleaner alternative, offering monochromatic output and instant power but currently require higher operational complexity and cost compared to mercury lamps, especially Far-UVC excimers which hold immense promise for safety.

The primary disruptive technology is the Ultraviolet Light Emitting Diode (UV LED), fabricated using gallium nitride (GaN) and aluminum nitride (AlN) based semiconductor materials. UV LEDs offer distinct technological advantages, including compact form factors, directional output, significantly longer operational lifespans (often exceeding 10,000 hours), mercury-free composition, and high energy efficiency under pulsed operation. The technology landscape is heavily focused on overcoming the current limitations of deep UVC LEDs, specifically improving Wall Plug Efficiency (WPE) and tackling thermal management issues which cause efficiency degradation (droop) at high currents. Breakthroughs in epitaxy, particularly the use of high-quality, native AlN substrates rather than sapphire, are critical for minimizing crystalline defects and substantially boosting internal quantum efficiency, thereby enhancing overall light output and lifespan for germicidal applications.

Further technological advancements are centered on smart integration and miniaturization. The development of sophisticated driver circuitry and advanced optics allows UV LED systems to deliver highly specific irradiance patterns, crucial for applications like micro-curing in electronics and targeted phototherapy. Integration with Internet of Things (IoT) sensors and Artificial Intelligence (AI) algorithms is transforming UV sources into intelligent systems capable of real-time monitoring of microbial load or curing depth, optimizing performance and reducing power consumption. Research into next-generation light sources, including microplasma UV emitters and advanced material deposition techniques, seeks to bridge the power output gap between traditional lamps and high-efficiency solid-state devices, solidifying the market’s transition toward safer, smarter, and environmentally sustainable light emission technologies across all segments.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, technology adoption, and regulatory compliance within the Ultraviolet Light Source Market. Each major region exhibits unique consumption patterns driven by disparate industrial bases, public health infrastructure, and environmental mandates. North America, characterized by sophisticated regulatory frameworks, high capital expenditure in healthcare, and robust investment in water treatment infrastructure, shows strong demand for high-end, certified UV disinfection systems and advanced UV LED curing solutions, particularly in aerospace and high-precision electronics manufacturing. The region prioritizes mercury-free solutions and is often at the forefront of adopting new technologies like Far-UVC for research and pilot projects, leading in the development of validated germicidal systems.

Europe mirrors North America in its focus on environmental compliance, driven specifically by the RoHS directive and the Minamata Convention, accelerating the replacement of traditional mercury lamps with UV LED alternatives across industrial and medical sectors. The region’s strong pharmaceutical and food and beverage industries create persistent demand for UVC sterilization solutions to meet stringent hygiene standards. Furthermore, Europe is a leader in industrial printing and coatings, ensuring a steady, albeit increasingly LED-focused, demand for high-power UVA curing systems. Investment is concentrated in improving the energy efficiency of existing UV installations and integrating smart monitoring systems to meet evolving sustainability targets.

Asia Pacific (APAC) stands out as the highest growth region globally, fueled by rapid urbanization, massive infrastructure development, and substantial electronics manufacturing output. China, Japan, and South Korea are key players, both as major consumers and as global manufacturing hubs for UV LED emitters and components. Demand is driven by massive municipal water and wastewater treatment projects, the booming electronics curing market, and rapidly increasing consumer awareness regarding air purification in densely populated urban centers. While adoption of cost-effective conventional lamps remains high in some industrial segments, significant government backing for domestic LED technology development (particularly in China and South Korea) is quickly accelerating the transition toward solid-state UV solutions across the region.

Latin America and the Middle East & Africa (MEA) represent emerging markets with high potential, albeit starting from a lower adoption base. In LATAM, growing industrialization and the need for improved public health infrastructure are slowly driving the adoption of UV disinfection systems, particularly in regional water facilities. The MEA region, especially the Gulf Cooperation Council (GCC) countries, exhibits robust demand linked to large-scale water recycling and desalination projects necessary for managing scarce water resources. These projects require reliable, high-power UV light sources. While price sensitivity remains a factor, the critical need for advanced water management positions UVC technology as a necessary investment, driving moderate but consistent growth in these regions, often relying on imported technology and localized system integrators.

- North America: Leader in regulatory compliance and early adoption of Far-UVC research; strong demand in high-precision manufacturing and specialized medical disinfection.

- Europe: Driven by environmental mandates (Minamata, RoHS); high focus on energy efficiency and smart UV integration in industrial curing and pharmaceutical production.

- Asia Pacific (APAC): Highest growth market due to massive infrastructure projects (water treatment), dominance in electronics manufacturing, and significant domestic UV LED production capacity.

- Latin America (LATAM): Emerging demand driven by urbanization and improving industrial safety standards; gradual shift toward modern disinfection technologies.

- Middle East and Africa (MEA): Key market for large-scale water treatment and reuse projects (desalination and recycling); increasing investment in sustainable water management solutions using high-power UV sources.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ltraviolet Light Source Market.- Ushio Inc.

- Signify (Philips Lighting)

- Heraeus Noblelight GmbH

- Excelitas Technologies Corp.

- Hamamatsu Photonics K.K.

- Seoul Viosys Co. Ltd.

- Crystal IS Inc. (subsidiary of Asahi Kasei)

- Nikkiso Co. Ltd.

- Nitride Semiconductors Co. Ltd.

- Dowa Electronics Materials Co. Ltd.

- Advanced Sterilization Products (ASP)

- Honle UV America Inc.

- IST Metz GmbH

- Nordson Corporation

- Lumileds Holding B.V.

- Semileds Corporation

- Luminus Devices Inc.

- San'an Optoelectronics Co. Ltd.

- LG Innotek

- Phoseon Technology

Frequently Asked Questions

Analyze common user questions about the Ltraviolet Light Source market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between UV lamps and UV LEDs in terms of germicidal efficacy and lifespan?

UV lamps, specifically low-pressure mercury vapor lamps, typically deliver high germicidal output at the fixed 254 nm wavelength but contain mercury and have shorter operational lifespans. UV LEDs are mercury-free, offer highly customizable wavelengths (including UVC), possess much longer lifespans (10,000+ hours), are more energy-efficient for specific applications, and provide instant on/off capability, though high-power UVC LEDs still face challenges in Wall Plug Efficiency compared to established lamps.

How is the global regulatory environment impacting the adoption of new UV light sources?

Global regulations, particularly the Minamata Convention on Mercury, are the chief drivers pushing the market away from traditional mercury vapor lamps. This regulatory pressure is accelerating the development and adoption of mercury-free alternatives, predominantly UV LEDs, across all application sectors, forcing manufacturers to prioritize sustainable and compliant solid-state technologies for new installations.

Which application segment holds the largest market share and why is it experiencing strong growth?

The Sterilization and Disinfection application segment currently holds the largest market share. This dominance is driven by persistent global investments in public health infrastructure, including large-scale municipal water treatment, wastewater reuse, air purification in commercial buildings, and surface sterilization in healthcare, amplified by heightened pathogen mitigation concerns post-pandemic events.

What is Far-UVC technology and how does it promise to change disinfection practices?

Far-UVC technology uses specific wavelengths, typically around 222 nm, which have demonstrated the ability to effectively inactivate airborne and surface pathogens without penetrating the human skin or eye tear layer significantly. This breakthrough promises to enable safe, continuous overhead disinfection in occupied public spaces (like schools and transportation hubs), moving beyond intermittent, high-dose UVC treatments currently requiring vacant rooms.

How does the integration of AI and IoT benefit industrial UV curing processes?

AI and IoT integration significantly enhance industrial UV curing by enabling real-time process optimization and quality control. IoT sensors monitor critical parameters (temperature, irradiance), while AI algorithms dynamically adjust UV dose and exposure time based on coating material, substrate, and production speed, ensuring consistent curing results, minimizing material waste, and facilitating predictive maintenance for the UV system components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager