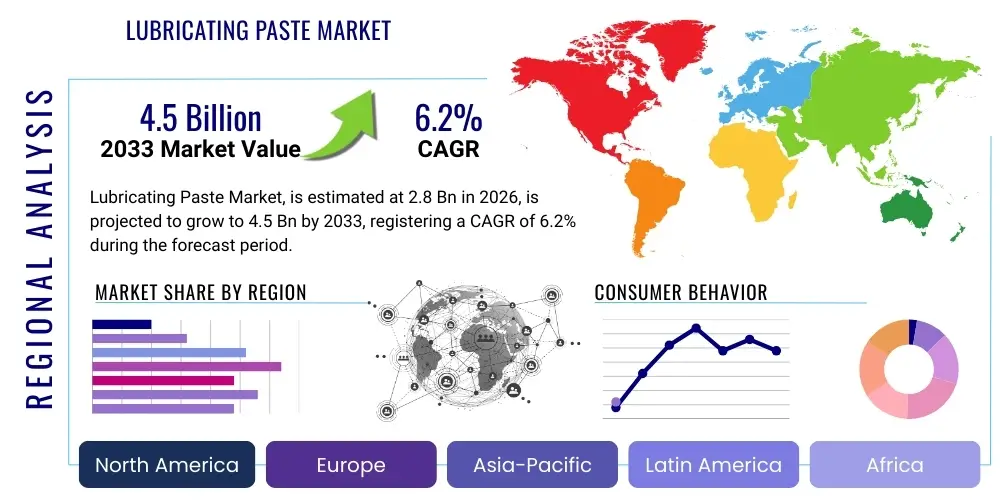

Lubricating Paste Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439300 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Lubricating Paste Market Size

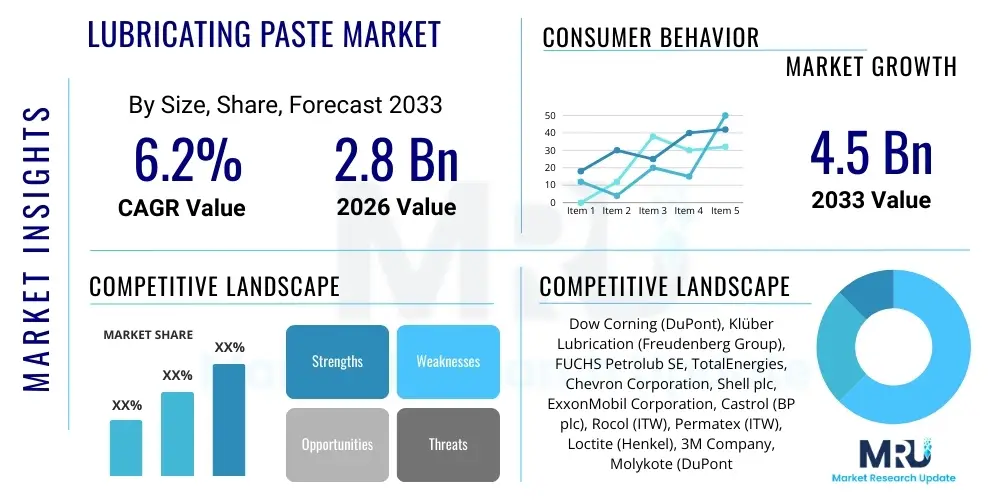

The Lubricating Paste Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 2.8 Billion in 2026 and is projected to reach USD 4.5 Billion by the end of the forecast period in 2033.

Lubricating Paste Market introduction

The lubricating paste market encompasses a specialized segment within the broader lubricants industry, focusing on formulations designed for extreme conditions where conventional oils and greases may fall short. These pastes are typically composed of a high concentration of solid lubricants, such as molybdenum disulfide (MoS2), graphite, PTFE, or ceramic particles, suspended in a base oil and thickened for optimal consistency. The primary function of lubricating pastes is to reduce friction, prevent galling, seizing, and fretting corrosion, and provide long-term lubrication under high loads, slow speeds, or extreme temperatures, ensuring the integrity and longevity of mechanical components.

Major applications of lubricating pastes span across a diverse range of industrial and automotive sectors. In the automotive industry, they are critical for engine assembly, exhaust systems, brake calipers, and threaded connections, offering anti-seize properties and ensuring smooth operation. Industrially, these pastes are indispensable in heavy machinery, manufacturing equipment, gears, bearings, and processing plants operating in harsh environments, from chemical processing to mining. The benefits extend beyond mere lubrication, including enhanced component life, reduced maintenance downtime, improved operational efficiency, and protection against corrosive elements.

Key driving factors for the market include the increasing demand for high-performance machinery across various industries, the growing emphasis on preventive maintenance practices to optimize asset lifespan, and the continuous innovation in material science leading to new, more effective paste formulations. Additionally, the expansion of manufacturing capabilities, particularly in emerging economies, coupled with stringent performance and safety standards, further fuels the adoption of advanced lubricating pastes. The market's growth is also supported by the rising complexity of mechanical systems that require specialized lubrication solutions to operate reliably.

Lubricating Paste Market Executive Summary

The global lubricating paste market is characterized by robust growth, propelled by the escalating demand for high-performance industrial and automotive solutions. Business trends indicate a strong focus on developing specialized formulations, including eco-friendly and bio-based pastes, alongside a push towards digitalization in supply chain management and customer service. Manufacturers are increasingly investing in research and development to create products that can withstand more extreme operating conditions, such as higher temperatures, heavier loads, and more corrosive environments, catering to the evolving needs of modern machinery and equipment. The market also witnesses strategic collaborations and mergers aimed at expanding product portfolios and geographical reach.

From a regional perspective, Asia Pacific continues to emerge as the dominant and fastest-growing market, primarily due to rapid industrialization, booming manufacturing sectors, and increasing automotive production in countries like China, India, and Southeast Asian nations. North America and Europe, while mature, remain significant markets driven by technological advancements, stringent regulatory frameworks promoting high-quality and environmentally compliant products, and a strong presence of key automotive and aerospace industries. Latin America and the Middle East & Africa regions are also showing promising growth, fueled by infrastructure development, expanding oil and gas sectors, and industrial modernization efforts.

Segment trends highlight a significant shift towards synthetic and ceramic-based lubricating pastes, favored for their superior performance under extreme conditions compared to traditional mineral-based counterparts. The anti-seize and assembly lubrication applications continue to be critical segments, with increasing demand from both original equipment manufacturers (OEMs) and the aftermarket. End-use industries such as automotive, general manufacturing, and heavy equipment are expected to drive the largest shares, while emerging applications in electric vehicles (EVs) and renewable energy sectors present substantial growth opportunities, demanding specialized pastes tailored for new material combinations and operating characteristics.

AI Impact Analysis on Lubricating Paste Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the lubricating paste market, particularly concerning product development, application efficiency, and operational intelligence. Common questions revolve around AI's capability to optimize paste formulations for specific demanding environments, enhance predictive maintenance strategies by analyzing lubrication data, streamline supply chain logistics, and improve quality control throughout the manufacturing process. There is significant interest in how AI can lead to more efficient product usage, reduce waste, and identify novel material combinations for next-generation pastes, ultimately driving innovation and sustainability within the industry.

- AI-driven formulation optimization: Utilizes machine learning algorithms to analyze vast datasets of material properties and performance characteristics, accelerating the development of novel lubricating paste compositions with enhanced properties for specific applications, reducing trial-and-error in R&D.

- Predictive maintenance and smart lubrication: AI analyzes sensor data from machinery (temperature, vibration, pressure) to predict wear patterns and optimal lubrication intervals, ensuring timely application of lubricating pastes, preventing unscheduled downtime, and extending component life.

- Supply chain optimization: AI algorithms can forecast demand, manage inventory more efficiently, optimize logistics routes for raw materials and finished products, and enhance supply chain resilience, reducing operational costs and improving delivery times.

- Enhanced quality control: AI-powered vision systems and data analytics can detect imperfections or inconsistencies in paste manufacturing, ensuring product quality and adherence to specifications, minimizing defects and waste.

- Personalized product recommendations: AI can analyze customer usage data and machinery requirements to recommend the most suitable lubricating paste products, improving customer satisfaction and driving targeted sales strategies.

- Market trend analysis and competitive intelligence: AI processes market data, competitor activities, and regulatory changes to provide insights into emerging trends, allowing companies to strategically position their products and adapt to market shifts.

DRO & Impact Forces Of Lubricating Paste Market

The lubricating paste market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. A primary driver is the accelerating industrialization across developing economies, coupled with the global expansion of manufacturing sectors, particularly in automotive, heavy machinery, and general engineering. The increasing complexity and sophistication of industrial equipment demand advanced lubrication solutions capable of performing under extreme conditions of temperature, pressure, and corrosive environments, thereby bolstering the adoption of high-performance lubricating pastes. Furthermore, a rising focus on preventive maintenance and operational efficiency across industries to minimize downtime and extend the lifespan of costly assets consistently fuels demand for reliable and specialized lubrication products. Stringent regulatory standards for equipment performance and safety also push manufacturers towards using superior lubricating solutions.

However, the market faces notable restraints that can impede its expansion. Volatility in the prices of raw materials, such as base oils, solid lubricants (e.g., molybdenum disulfide, graphite), and various additives, presents a significant challenge, impacting production costs and profit margins for manufacturers. Environmental concerns surrounding certain chemical additives and the disposal of used lubricants also pose a restraint, leading to increased scrutiny and demand for more eco-friendly and bio-degradable alternatives. Additionally, intense competition from alternative lubrication methods, including self-lubricating materials and advanced surface coatings, can limit the market penetration of traditional pastes. Economic slowdowns or global recessions, which can reduce industrial output and capital expenditure, also act as a significant dampener on market growth.

Despite these challenges, substantial opportunities exist for market participants. The growing demand for specialized lubricating pastes in emerging applications, such as electric vehicles (EVs), renewable energy infrastructure (wind turbines, solar panel tracking systems), and advanced robotics, presents new avenues for innovation and market expansion. The development of bio-based and sustainable lubricating pastes aligns with global environmental initiatives and can unlock new customer segments, particularly in environmentally conscious industries. Furthermore, geographical expansion into untapped or rapidly industrializing markets offers significant growth potential. Technological advancements in material science, including nanotechnology and smart lubricants, provide opportunities to develop next-generation pastes with superior performance characteristics, customized for highly specific industrial requirements and pushing the boundaries of what lubrication can achieve. These impact forces necessitate continuous innovation and strategic adaptation from market players to capitalize on emerging trends and overcome existing barriers.

Segmentation Analysis

The lubricating paste market is extensively segmented to address the diverse needs of various industrial and automotive applications. This segmentation allows for a granular understanding of market dynamics, enabling manufacturers to tailor products and marketing strategies to specific end-user requirements. The market is typically analyzed across several key dimensions including Type, Base Oil, Application, and End-Use Industry, each representing distinct categories with unique demand drivers and performance expectations. The comprehensive breakdown helps in identifying niche markets, competitive landscapes, and future growth opportunities within the highly specialized lubrication sector.

Each segment holds critical relevance in defining product specifications and market positioning. For instance, the choice of solid lubricant type directly impacts the paste's performance under different load and temperature conditions, while the base oil selection determines its thermal stability and compatibility with various materials. Application-specific segments, such as anti-seize or assembly lubrication, cater to particular functional needs, preventing galling or ensuring smooth component installation. Furthermore, understanding demand across different end-use industries like automotive, manufacturing, or aerospace allows for targeted product development and sales efforts, ensuring that the right lubrication solution reaches the right consumer effectively.

- By Type:

- Metal-based (e.g., Copper, Nickel, Aluminum)

- Ceramic-based (e.g., Boron Nitride, Zirconium Dioxide)

- Synthetic (e.g., PTFE, Silicone)

- Graphite-based

- Molybdenum Disulfide (MoS2)

- Others (e.g., Calcium Sulfonate, Polyurea)

- By Base Oil:

- Mineral Oil

- Synthetic Oil (e.g., PAO, Esters)

- Semi-Synthetic Oil

- By Application:

- Anti-Seize

- Assembly Lubrication

- Heavy Load Lubrication

- High Temperature Lubrication

- Corrosion Protection

- Thread Lubrication

- Others

- By End-Use Industry:

- Automotive (OEM, Aftermarket)

- Manufacturing (Machinery, Heavy Equipment)

- Aerospace & Defense

- Marine

- Construction

- Mining

- Power Generation

- Chemical & Petrochemical

- Electrical & Electronics

- Others

Value Chain Analysis For Lubricating Paste Market

The value chain for the lubricating paste market begins with the upstream activities centered around the sourcing and processing of critical raw materials. This segment involves suppliers of base oils, which can be mineral, synthetic (like PAOs or esters), or semi-synthetic, along with providers of various solid lubricants such as molybdenum disulfide, graphite, PTFE, and ceramic particles. Additionally, a crucial part of the upstream segment includes suppliers of performance-enhancing additives like extreme pressure (EP) agents, anti-wear compounds, corrosion inhibitors, and thickeners that provide the paste with its unique rheological properties. Research and development also plays a significant upstream role, continuously innovating new formulations and improving existing ones to meet evolving industrial demands and regulatory standards.

Moving further along the value chain, these raw materials are then acquired by the manufacturers of lubricating pastes. These companies undertake complex blending and processing operations, combining the base oils, solid lubricants, and additives in precise ratios under controlled conditions to produce the final range of lubricating paste products. Quality control and assurance are paramount at this stage to ensure product consistency, performance, and adherence to industry specifications. Manufacturers also invest in packaging and branding to differentiate their offerings in a competitive market, catering to various product sizes and industrial requirements. The downstream segment of the value chain involves the distribution and ultimate consumption of these products.

The distribution channel plays a pivotal role in connecting manufacturers with end-users. This typically involves a mix of direct and indirect channels. Direct distribution might include sales teams catering to large industrial clients or original equipment manufacturers (OEMs), providing specialized technical support and customized solutions. Indirect channels are more common and include a network of industrial distributors, specialized chemical suppliers, automotive aftermarket retailers, and increasingly, online e-commerce platforms. These distributors often maintain inventories, provide logistical support, and offer local technical expertise to a broader customer base. Ultimately, the end-users—ranging from manufacturing plants, automotive workshops, construction sites, and marine operators—receive and utilize the lubricating pastes, completing the value chain. Aftermarket services, technical support, and product training also form an essential part of the downstream activities, ensuring proper application and maximizing product effectiveness.

Lubricating Paste Market Potential Customers

The lubricating paste market caters to a broad spectrum of potential customers across diverse industrial and commercial sectors, all seeking to optimize mechanical performance, extend equipment life, and reduce maintenance costs. A primary segment includes various manufacturing industries, such as automotive, heavy machinery, and general engineering, where these pastes are crucial for assembly, anti-seize applications, and the lubrication of components subjected to high loads and temperatures. This encompasses both original equipment manufacturers (OEMs) who integrate these pastes into their production lines and the aftermarket segment, comprising repair shops and service centers that use them for maintenance and overhaul operations.

Beyond traditional manufacturing, potential customers also include the Maintenance, Repair, and Operations (MRO) departments of industrial facilities spanning power generation, chemical and petrochemical processing, mining, and construction. In these environments, lubricating pastes are indispensable for the upkeep of heavy equipment, complex machinery, and critical infrastructure components that operate under harsh conditions, including exposure to extreme temperatures, corrosive chemicals, and high moisture. The marine industry, with its unique challenges of saltwater corrosion and heavy loads, also represents a significant customer base for specialized lubricating pastes.

Furthermore, emerging sectors like renewable energy (wind turbines, solar panel installations) and advanced robotics are increasingly becoming vital customers, requiring high-performance pastes tailored for new material combinations and long-life cycle expectations. Even individual mechanics, engineers, and DIY enthusiasts constitute a market segment for smaller quantities of specialized pastes used in precision applications or demanding hobbyist projects. The demand is driven by the need for enhanced reliability, reduced downtime, improved operational safety, and overall cost efficiency in mechanical systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.8 Billion |

| Market Forecast in 2033 | USD 4.5 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dow Corning (DuPont), Klüber Lubrication (Freudenberg Group), FUCHS Petrolub SE, TotalEnergies, Chevron Corporation, Shell plc, ExxonMobil Corporation, Castrol (BP plc), Rocol (ITW), Permatex (ITW), Loctite (Henkel), 3M Company, Molykote (DuPont), Chesterton, SKF, Liqui Moly, Wurth Group, NYE Lubricants, Valvoline Inc., Whitmore Manufacturing |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lubricating Paste Market Key Technology Landscape

The lubricating paste market is at the forefront of material science and engineering, constantly integrating advanced technologies to meet the escalating demands of modern industrial and automotive applications. A significant aspect of this technological landscape involves the development of nano-lubricants, where nanoparticles of materials like graphene, hexagonal boron nitride (hBN), or specific metal oxides are incorporated into paste formulations. These nanomaterials offer superior friction reduction, enhanced wear resistance, and improved load-carrying capacity at lower concentrations, leading to more efficient and durable lubrication solutions. The precise dispersion and stabilization of these nanoparticles within the base oil and thickener matrix are critical technological challenges that drive innovation.

Another crucial technological trend is the proliferation of smart lubricants and adaptive paste formulations. These advanced pastes are designed to respond dynamically to changes in operating conditions, such as temperature, pressure, or shear. This can involve materials that release additional solid lubricants upon reaching a certain temperature, or self-healing properties that can repair minor wear surfaces. The integration of advanced polymeric thickeners and sophisticated additive packages, including extreme pressure (EP) additives and anti-wear agents, allows pastes to maintain performance under increasingly severe conditions, preventing metal-to-metal contact and extending component life. These innovations are particularly vital for critical applications in aerospace, high-speed machinery, and heavy industrial equipment where failure is not an option.

Furthermore, there is a growing emphasis on developing sustainable and bio-based lubricating paste technologies. This involves utilizing renewable base oils (e.g., vegetable oils, synthetic esters derived from biomass) and environmentally benign solid lubricants and additives. The challenge lies in ensuring that these eco-friendly formulations can match or surpass the performance of traditional petroleum-based pastes, especially in terms of thermal stability, oxidation resistance, and load-bearing capabilities. Innovations in surface engineering, such as the use of advanced ceramic particles that form protective layers on metal surfaces, also contribute to the technological evolution, offering enhanced corrosion protection and extended lubrication intervals. The continuous pursuit of pastes with extended service life and reduced environmental footprint is a key driver in the current technological landscape.

Regional Highlights

- North America: A mature market characterized by high demand for specialty and high-performance lubricating pastes, particularly in the automotive, aerospace, and general manufacturing sectors. The region benefits from robust R&D activities and stringent regulatory standards driving innovation towards advanced, environmentally compliant formulations. Companies here often focus on precision applications and solutions for complex machinery, emphasizing product reliability and extended service life.

- Europe: This region is a significant consumer and innovator in the lubricating paste market, strongly influenced by strict environmental regulations and a focus on sustainability. Demand is high for bio-based and eco-friendly products, especially within its strong automotive, industrial machinery, and energy sectors. Germany, France, and the UK are key markets, driving technological advancements and specialized solutions for high-end applications and preventive maintenance strategies.

- Asia Pacific (APAC): The fastest-growing and largest market for lubricating pastes, propelled by rapid industrialization, massive automotive production (especially in China, India, and Japan), and expanding manufacturing bases across various industries. Increased infrastructure development and a growing focus on improving industrial efficiency contribute to sustained demand. The region offers significant opportunities for both domestic and international players due to its large industrial base and increasing adoption of advanced machinery.

- Latin America: An emerging market for lubricating pastes, driven by growth in industrial sectors such as mining, agriculture, automotive, and infrastructure development. Brazil and Mexico are key contributors, experiencing increasing demand for robust lubrication solutions to support their expanding industrial activities. The market here is growing as industries modernize and seek to improve operational efficiency and equipment longevity.

- Middle East & Africa (MEA): This region is experiencing steady growth, primarily fueled by investments in the oil and gas sector, mining, and large-scale infrastructure projects. Demand for high-temperature and anti-corrosion lubricating pastes is significant due to the challenging operating environments. Countries like Saudi Arabia, UAE, and South Africa are leading the adoption of advanced lubrication solutions to protect valuable industrial assets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lubricating Paste Market.- Dow Corning (DuPont)

- Klüber Lubrication (Freudenberg Group)

- FUCHS Petrolub SE

- TotalEnergies

- Chevron Corporation

- Shell plc

- ExxonMobil Corporation

- Castrol (BP plc)

- Rocol (ITW)

- Permatex (ITW)

- Loctite (Henkel)

- 3M Company

- Molykote (DuPont)

- Chesterton

- SKF

- Liqui Moly

- Wurth Group

- NYE Lubricants

- Valvoline Inc.

- Whitmore Manufacturing

Frequently Asked Questions

What are lubricating pastes used for?

Lubricating pastes are specialized formulations designed to reduce friction, prevent wear, galling, seizing, and corrosion in mechanical components, especially under high loads, slow speeds, or extreme temperatures. They are commonly used for assembly, anti-seize applications, and heavy-duty lubrication in industrial and automotive settings.

How do lubricating pastes differ from greases?

While both are semi-solid lubricants, lubricating pastes contain a significantly higher concentration of solid lubricants (like MoS2 or graphite) compared to greases. This higher solid content allows pastes to provide superior protection and anti-seize properties in extreme conditions where the base oil film might break down, unlike greases which rely more on a thickened oil film.

What are the key benefits of using lubricating paste?

Key benefits include preventing metal-to-metal contact, reducing friction and wear, protecting against corrosion and fretting, extending the lifespan of components, simplifying assembly and disassembly, and ensuring reliable operation under severe conditions such as high temperatures, heavy loads, and aggressive environments.

Are there environmentally friendly lubricating pastes?

Yes, the market is seeing a growing trend towards environmentally friendly lubricating pastes. These formulations often utilize bio-based or synthetic base oils that are biodegradable, along with non-toxic solid lubricants and additives, meeting stricter environmental regulations and catering to industries with sustainability goals.

How does temperature affect lubricating paste performance?

Temperature significantly impacts paste performance. High temperatures can degrade base oils and additives, while very low temperatures can increase viscosity, affecting pumpability and flow. Specialized pastes are formulated with high-performance base oils and solid lubricants to maintain stability and effectiveness across a wide temperature range, ensuring consistent lubrication in extreme thermal conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager