Macromolecule Hydrogel Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435295 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Macromolecule Hydrogel Market Size

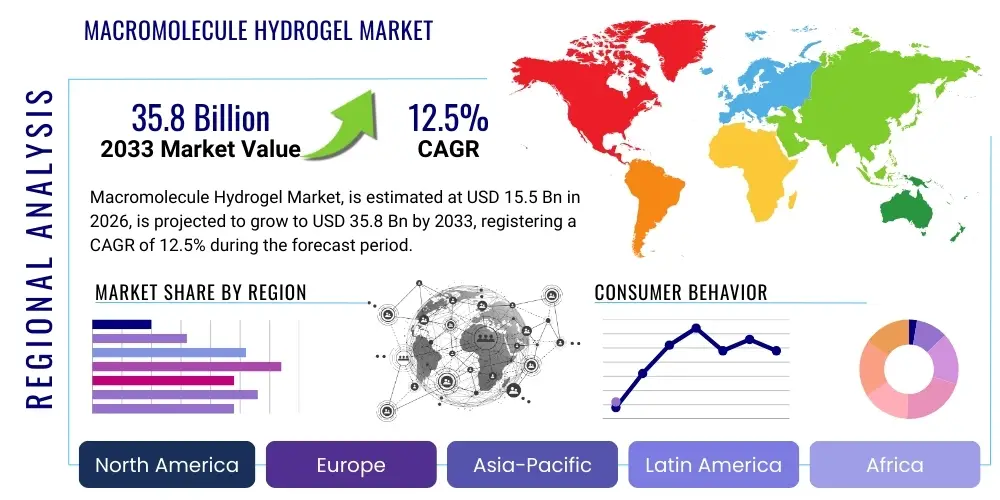

The Macromolecule Hydrogel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at $15.5 Billion in 2026 and is projected to reach $35.8 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for advanced biomedical materials, particularly in high-precision fields such as targeted drug delivery and regenerative medicine. The inherent biocompatibility, adjustable mechanical properties, and high water content of macromolecular hydrogels position them as indispensable components in next-generation medical devices and therapeutic platforms.

Macromolecule Hydrogel Market introduction

The Macromolecule Hydrogel Market encompasses materials formed from long-chain polymeric molecules (both natural and synthetic) cross-linked to form a three-dimensional network capable of retaining large amounts of water without dissolving. These unique polymer networks mimic the structure of biological tissues, making them supremely suitable for biological applications. Key products include hydrogels based on polysaccharides (like alginate and chitosan), proteins (like gelatin and collagen), and synthetic polymers (like polyethylene glycol (PEG) and poly(vinyl alcohol) (PVA)). These materials are pivotal in creating controlled release systems and scaffolds for cell culture and tissue repair, offering a superior alternative to traditional materials due to their responsive properties to environmental stimuli such as pH, temperature, or electric fields. The global shift toward non-invasive and highly localized therapies significantly bolsters market growth.

Major applications of macromolecule hydrogels span across the healthcare spectrum, including advanced wound care dressings that facilitate faster healing, ophthalmic products like contact lenses and intraocular implants, and complex systems designed for drug encapsulation and sustained release, particularly for sensitive biological drugs. Furthermore, the market benefits profoundly from their use in cosmetic formulations, hygiene products, and specialized industrial filters. The versatility derived from customizing the polymer backbone, crosslinking density, and functional groups allows manufacturers to fine-tune material performance for specific application requirements, ensuring high efficacy and low immunogenicity in biomedical contexts. Continuous research in smart hydrogels that exhibit on-demand release mechanisms is further expanding the application base beyond conventional boundaries.

The core benefits driving market acceptance include exceptional biocompatibility, minimizing adverse reactions within the body; high biodegradability, ensuring safe degradation post-treatment; and superior mechanical tunability, allowing the creation of materials ranging from soft gels to stiff matrices tailored for specific tissue engineering needs. Driving factors include the aging global population requiring more sophisticated medical interventions, significant funding for regenerative medicine research, and technological advancements in 3D printing utilizing bio-inks based on macromolecule hydrogels. These factors converge to create a robust demand landscape, particularly in developed economies emphasizing personalized medicine approaches and high-quality patient care standards.

Macromolecule Hydrogel Market Executive Summary

The Macromolecule Hydrogel Market demonstrates robust growth propelled by synergistic advancements in materials science and biotechnology. Key business trends indicate a strong focus on strategic collaborations between academic institutions and commercial enterprises aimed at accelerating the commercialization of novel, stimulus-responsive hydrogels, particularly those capable of targeted therapeutic delivery. Regional trends highlight North America and Europe as dominant forces owing to established healthcare infrastructures and high R&D spending, while the Asia Pacific region is emerging as the fastest-growing market, driven by expanding healthcare access, rising prevalence of chronic diseases, and increased governmental investment in biopharma manufacturing capabilities. Segment trends show that the application segment of Tissue Engineering and Regeneration is experiencing the highest CAGR, reflective of breakthroughs in scaffold design and cell proliferation techniques, while synthetic polymer hydrogels maintain the largest market share due to their reliable consistency and ease of large-scale production, offering cost-effective solutions for widespread applications like wound dressings and contact lenses. Overall, the market trajectory is highly positive, conditioned by continuous innovation in material design and expanded clinical adoption across multiple therapeutic areas.

AI Impact Analysis on Macromolecule Hydrogel Market

Users frequently inquire about how Artificial Intelligence (AI) and machine learning (ML) are transforming the research and development pipeline for macromolecule hydrogels, specifically focusing on optimizing material synthesis, predicting performance characteristics, and personalizing drug delivery systems. Common questions revolve around the efficiency gains provided by AI in screening novel polymer combinations for desired mechanical and biological properties, assessing the long-term stability and biodegradability of new hydrogel formulations, and designing complex multi-component systems for enhanced therapeutic efficacy. Users are concerned with the speed of data analysis needed to sift through high-throughput screening results and how AI can accelerate the transition from lab-scale prototypes to scalable manufacturing processes. The consensus expectation is that AI will minimize costly trial-and-error experiments, enabling researchers to predict optimal crosslinking agents and concentrations required for specific therapeutic outcomes, thereby significantly shortening the time-to-market for advanced hydrogel products, particularly in personalized medicine and biomaterial engineering. This technological integration is viewed as crucial for unlocking the full potential of smart hydrogels.

- AI-driven simulation predicts optimal polymer structures, crosslinking ratios, and responsive behavior (e.g., pH/temperature sensitivity) for tailored hydrogel fabrication.

- Machine learning algorithms analyze large datasets from high-throughput screening to identify novel biocompatible hydrogel compositions, reducing experimental time by up to 50%.

- AI optimizes manufacturing parameters, ensuring batch-to-batch consistency and scalability in the production of complex hydrogel structures, such as bio-inks for 3D bioprinting.

- Predictive modeling enhances clinical trial design by simulating the interaction between the hydrogel drug delivery system and physiological environments, improving efficacy prediction.

- Integration of AI in smart hydrogel sensors allows for real-time monitoring and dynamic adjustment of drug release rates based on patient physiological feedback (closed-loop systems).

DRO & Impact Forces Of Macromolecule Hydrogel Market

The Macromolecule Hydrogel Market is powerfully influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the key Impact Forces shaping its competitive landscape and growth trajectory. Primary drivers include the massive global demand generated by the medical industry, especially the accelerating need for advanced biomaterials in treating chronic wounds, neurological disorders, and cardiovascular conditions. The unique ability of these hydrogels to facilitate cell growth and mimic native extracellular matrices positions them at the forefront of regenerative medicine innovation. Simultaneously, technological breakthroughs in crosslinking techniques, such as click chemistry and photopolymerization, are enabling the fabrication of highly precise and mechanically robust hydrogels, overcoming previous limitations related to structural integrity in vivo. These drivers underscore a market transitioning toward high-value, specialized medical applications, where material performance directly translates to improved patient outcomes and reduced recovery times, thus justifying premium pricing and sustained investment.

Restraints, however, pose significant challenges to widespread adoption. The foremost restraint is the stringent regulatory pathway required for biomaterials, particularly those intended for implantable or long-term internal use, leading to protracted and expensive clinical trials. Furthermore, issues related to scaling up production of highly customized, complex hydrogels while maintaining homogeneity and purity standards present technical and economic hurdles for smaller manufacturers. Cost constraints, particularly in developing nations, and concerns regarding the long-term toxicity or degradation byproducts of certain synthetic polymers also act as limitations. Overcoming these restraints necessitates global harmonization of regulatory standards and the development of more sustainable and cost-effective synthesis methods that do not compromise biocompatibility or mechanical performance, ensuring that advanced hydrogel technologies are accessible across different economic strata.

Opportunities for market expansion are abundant, centered around the untapped potential of smart hydrogels and 3D bioprinting. The development of hydrogels responsive to specific biomarkers or external stimuli (e.g., light, ultrasound) promises highly localized and personalized drug delivery, minimizing systemic side effects. Moreover, the integration of hydrogels as bio-inks in 3D bioprinting is revolutionizing tissue engineering, allowing for the precise construction of complex organs and tissue models for drug testing and eventual transplantation. Beyond biomedicine, emerging applications in agriculture (as superabsorbent materials for water retention and nutrient release) and environmental remediation (as specialized filters for pollutants) represent significant growth avenues. The proactive pursuit of these opportunities, coupled with strategic partnerships focused on intellectual property development, will be crucial for sustained market leadership and capturing new revenue streams outside traditional medical uses.

Segmentation Analysis

The Macromolecule Hydrogel Market is comprehensively segmented based on its structural composition (Type), its intended function (Application), and its geographic consumption patterns (Region). The segmentation by type typically separates the market into Natural, Synthetic, and Hybrid categories, reflecting the source and properties of the base polymer used. Natural hydrogels, derived from materials like hyaluronic acid and collagen, dominate specific medical niches due to their inherent biocompatibility, while synthetic hydrogels, such as those made from PEG and PVA, lead in volume due to their enhanced stability and tunable mechanical properties. Hybrid hydrogels combine the best attributes of both, offering specialized performance for advanced applications. This foundational segmentation allows manufacturers to tailor their production strategies and marketing efforts toward end-user specific requirements, ensuring optimal material-application matching.

Application-based segmentation is the most dynamic category, reflecting the diverse utility of hydrogels across multiple industries. Key applications include Drug Delivery Systems, Tissue Engineering and Regeneration, Wound Dressings, Contact Lenses, Diagnostics, and Agriculture. The rapid advancement in personalized medicine has positioned Drug Delivery and Tissue Engineering segments for explosive growth, demanding materials capable of sustained release and structural support for new tissue formation. Meanwhile, established applications like Wound Dressings and Contact Lenses provide a stable revenue base, driven by continuous product refinement and increasing consumer preference for high-comfort biomaterials. Understanding the nuances within each application segment is crucial for competitive positioning and targeted investment in capacity expansion and specialized R&D programs.

Geographically, the market analysis divides consumption into major regions: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. This regional segmentation is vital as regulatory environments, healthcare expenditure levels, and technological adoption rates vary significantly across these areas. North America currently leads the market due to its robust biomedical research infrastructure and high adoption of advanced materials. However, the Asia Pacific region is forecast to exhibit the fastest growth rate, fueled by improving healthcare access, large patient pools, and supportive government initiatives promoting domestic biotechnology sectors. Strategic market entry and expansion decisions must be informed by these regional dynamics, considering factors such as local manufacturing costs, intellectual property protection, and established distribution networks, to maximize global reach and profitability.

- By Type: Natural Macromolecule Hydrogels, Synthetic Macromolecule Hydrogels, Hybrid Macromolecule Hydrogels.

- By Composition: Polysaccharide-based Hydrogels, Protein-based Hydrogels, Synthetic Polymer-based Hydrogels (e.g., Polyethylene Glycol (PEG), Poly(vinyl alcohol) (PVA), Poly(acrylic acid)).

- By Application: Drug Delivery Systems, Tissue Engineering and Regeneration, Wound Care Dressings, Contact Lenses, Diagnostics and Sensing, Agriculture and Horticulture, Cosmetics and Hygiene Products.

- By Region: North America, Europe, Asia Pacific (APAC), Latin America (LATAM), Middle East and Africa (MEA).

Value Chain Analysis For Macromolecule Hydrogel Market

The value chain for the Macromolecule Hydrogel Market begins with the sourcing and synthesis of fundamental raw materials, which include specialized monomers, polymers, and crosslinking agents. The upstream segment is dominated by chemical and biopolymer suppliers who must adhere to rigorous quality standards, especially for biomedical-grade inputs. Key activities here involve R&D for novel, high-purity precursors and efficient polymerization techniques. The quality and cost of these raw materials directly impact the final product performance and manufacturing scalability. Strong partnerships between raw material suppliers and hydrogel producers are crucial to ensure a steady supply of innovative and regulatory-compliant base components, driving efficiencies in the initial stages of production. Continuous innovation in biopolymer extraction and synthetic material purification remains a major competitive focus upstream.

The midstream component involves the complex manufacturing and formulation process, where the base polymers are crosslinked and processed into the final hydrogel forms, such as sheets, films, microparticles, or injectable gels. This stage includes specialized processes like sterilization, packaging, and quality control, which must comply with Good Manufacturing Practices (GMP). Advanced manufacturers often invest heavily in patented crosslinking technologies (e.g., photo-polymerization, thermal crosslinking) to achieve precise control over the material's mechanical and biological properties. The efficiency of the manufacturing step is critical, determining the final production cost and the capability to scale production volumes to meet rapidly rising global demand, particularly in the mass-market segments like wound care.

The downstream segment focuses on distribution channels and end-user adoption. Products are distributed both directly and indirectly. Direct distribution is common for highly specialized products, such as customized tissue engineering scaffolds and novel drug delivery systems, often requiring direct consultation between the manufacturer and clinical researchers or pharmaceutical companies. Indirect distribution utilizes established networks of medical distributors, wholesalers, and pharmacies for high-volume products like contact lenses and standard wound dressings. Successful downstream operations require robust logistics, effective inventory management for temperature-sensitive products, and extensive sales teams knowledgeable about clinical applications. The penetration of products into diverse geographic regions depends significantly on established regulatory approvals and localized sales expertise.

Macromolecule Hydrogel Market Potential Customers

Potential customers for the Macromolecule Hydrogel Market are diverse and primarily concentrated within the biomedical and pharmaceutical sectors, reflecting the high-value clinical applications of these materials. Pharmaceutical and biotechnology companies are major buyers, utilizing hydrogels as advanced drug encapsulation and controlled release vehicles, particularly for delicate protein therapeutics and vaccine delivery systems where protection and sustained release are critical performance requirements. These customers prioritize high biocompatibility, predictable release kinetics, and manufacturing scalability that integrates seamlessly into existing drug product lines. Academic and private research institutions constitute another significant customer base, procuring hydrogels for developing complex 3D cell culture models, researching regenerative therapies, and screening new drug candidates, emphasizing customizability and high purity grades suitable for in vitro and in vivo studies.

Furthermore, the medical device industry, encompassing wound care manufacturers, ophthalmic product developers (contact lenses and intraocular devices), and aesthetic product developers (dermal fillers), represents a vast and stable customer segment. Wound care companies seek hydrogels that provide moist healing environments and deliver antimicrobial agents, while ophthalmic customers require materials with high transparency, oxygen permeability, and mechanical resilience for long-term wear. These customers often require high-volume supply contracts and robust quality assurance protocols. Lastly, emerging customers in the agricultural sector are purchasing hydrogel materials as soil amendments and seed coatings to enhance water retention and optimize nutrient delivery in challenging arid environments, demonstrating the market’s expanding reach beyond traditional healthcare confines and into sustainability solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $15.5 Billion |

| Market Forecast in 2033 | $35.8 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ashland Inc., Johnson & Johnson, 3M Company, The Cooper Companies, Royal DSM, Bausch Health Companies Inc., Lonza Group, BASF SE, Evonik Industries, Gelita AG, Advanced Medical Solutions Group plc, AMAG Pharmaceuticals, Chemence Medical, Coloplast A/S, ConvaTec Group Plc, Halyard Health, Momentive Performance Materials, Nippon Gohsei, Cosmotec, Medtronic Plc |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Macromolecule Hydrogel Market Key Technology Landscape

The technology landscape for the Macromolecule Hydrogel Market is defined by a rapid evolution toward precision engineering and stimuli-responsive capabilities. A foundational technology remains traditional chemical crosslinking, utilizing chemical agents to form covalent bonds between polymer chains, but this is increasingly being superseded by advanced techniques. Photopolymerization, which uses light (UV or visible) to rapidly and spatially control the crosslinking process, is critical for bio-inks used in 3D bioprinting, allowing for the fabrication of complex microstructures with high cell viability. Thermal and pH-responsive crosslinking technologies enable the creation of "smart hydrogels" that undergo reversible volume changes or structural collapse in response to physiological shifts, making them ideal for injectable formulations that solidify in situ or release drugs triggered by localized inflammation.

A major technological focus is the development of injectable and self-healing hydrogels. Injectable systems, often using shear-thinning or supramolecular assembly mechanisms, allow for minimally invasive surgical procedures, reducing patient recovery time. Self-healing hydrogels possess the capacity to autonomously repair mechanical damage, significantly extending their functional lifespan, which is crucial for implantable devices like cartilage replacements or long-term therapeutic implants. These technologies leverage dynamic bonds, such as hydrogen bonds or host-guest interactions, providing robust performance without sacrificing flexibility. The integration of nanotechnology, including incorporating nanoparticles or carbon nanotubes within the hydrogel matrix, is also emerging, aimed at enhancing mechanical strength, conductivity, and imaging capabilities, transforming hydrogels into truly multifunctional biomaterials for complex medical challenges.

Furthermore, the ongoing development of 3D bioprinting techniques, utilizing hydrogels as bio-inks, represents a paradigm shift. Technologies like extrusion-based, inkjet-based, and laser-assisted bioprinting require hydrogel formulations—the bio-inks—that meet specific rheological (flow) and biological criteria to support cell viability and tissue maturation post-printing. Successful bio-ink development hinges on adjusting factors like viscosity, crosslinking speed, and biological cues embedded within the macromolecular structure. The synergy between materials science and advanced manufacturing techniques, such supported by AI and computational fluid dynamics, is essential for designing hydrogel constructs that accurately mimic the mechanical and biochemical environment of native tissues, thus accelerating progress in regenerative medicine and pharmaceutical testing models.

Regional Highlights

- North America: Market Dominance Driven by R&D and Healthcare Spending

- Europe: Focus on Regulatory Excellence and Aging Population Needs

- Asia Pacific (APAC): Fastest Growth Driven by Healthcare Expansion

North America, encompassing the United States and Canada, holds the dominant share in the Macromolecule Hydrogel Market, primarily due to an exceptionally robust biomedical research ecosystem and high levels of public and private healthcare expenditure. The presence of numerous leading pharmaceutical, biotechnology, and medical device companies, coupled with significant governmental funding from bodies like the NIH, fuels continuous innovation in hydrogel applications, particularly in advanced drug delivery systems and cutting-edge tissue engineering scaffolds. The regulatory environment, although stringent, is predictable and supports the rapid adoption of clinically validated novel materials. Key market drivers in this region include a high prevalence of chronic diseases requiring advanced wound management and orthopedic repairs, alongside early and enthusiastic adoption of personalized medicine approaches. The demand for sophisticated materials in high-value segments, such as diagnostics and aesthetic medicine, ensures North America maintains its market leadership, driven by a consumer base willing to pay a premium for high-quality medical outcomes.

The United States serves as the epicenter for hydrogel research, benefiting from world-class universities and research centers actively collaborating with industry partners to translate laboratory discoveries into commercial products. The market here is characterized by intense competition and a focus on developing smart hydrogels that respond to specific biological stimuli, enhancing therapeutic efficacy and reducing side effects. Furthermore, the substantial investment in 3D bioprinting technologies, leveraging hydrogel bio-inks, positions the region at the forefront of regenerative medicine. Canada also contributes significantly, particularly in areas like biomaterials science and orthopedic applications. The maturity of the healthcare infrastructure ensures efficient integration and widespread commercial uptake of innovative hydrogel-based products, confirming the region's strong influence on global market trends and technological standards.

Europe represents the second-largest market for macromolecule hydrogels, characterized by a strong emphasis on regulatory compliance (e.g., MDR compliance) and high-quality manufacturing standards. Countries like Germany, Switzerland, and the UK are major hubs for biomedical material production and R&D. The European market is significantly driven by the needs of an aging population, which generates high demand for orthopedic implants, chronic wound care products, and minimally invasive surgical aids utilizing hydrogel technology. Government initiatives supporting research into novel materials for chronic disease management and regenerative therapies, such as those funded by the European Union’s Horizon Europe program, accelerate market growth and technological diffusion across the continent.

The competitive landscape in Europe is marked by the presence of established chemical and life science companies, like BASF and Evonik, who leverage their expertise in polymer synthesis to produce high-grade hydrogel precursors. A key trend involves developing sustainable and biodegradable hydrogel solutions, aligning with the EU’s strong environmental policy goals. Furthermore, the high concentration of specialized medical device manufacturers ensures a continuous pipeline of new hydrogel-based products reaching the clinical stage. Market penetration is high for applications like contact lenses and sophisticated wound dressings, while the region is steadily increasing its adoption of hydrogels in advanced drug eluting stents and localized pain management systems, further solidifying its prominent position globally.

The Asia Pacific region is projected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period, making it the most dynamic market globally. This exponential growth is fueled by rapidly improving healthcare infrastructure in key emerging economies such as China, India, South Korea, and Japan, alongside significantly increasing per capita healthcare spending. The large, expanding patient population suffering from diabetes (driving wound care demand) and other lifestyle-related diseases provides a massive addressable market for hydrogel-based therapeutics. Governmental support for domestic manufacturing and biotechnology R&D, often through favorable tax incentives and subsidized research parks, is attracting both foreign direct investment and fostering local innovation, particularly in areas like traditional Chinese medicine (TCM) integration with modern delivery systems.

China is a pivotal growth engine within APAC, demonstrating unparalleled capacity for large-scale production of hydrogel raw materials and finished goods, often providing cost advantages globally. Japan and South Korea, on the other hand, lead in technological sophistication, focusing heavily on advanced applications like regenerative scaffolds and high-precision diagnostic hydrogels, driven by their established consumer electronics and advanced material science sectors. Market accessibility is increasing across Southeast Asia, driven by rising awareness of advanced wound care techniques and expanding insurance coverage. While regulatory processes can vary across nations, the overall upward trend in biomedical material adoption ensures that APAC will be the primary source of volume growth and competitive manufacturing innovation in the coming decade, profoundly impacting the global supply chain dynamics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Macromolecule Hydrogel Market.- Ashland Inc.

- Johnson & Johnson

- 3M Company

- The Cooper Companies

- Royal DSM

- Bausch Health Companies Inc.

- Lonza Group

- BASF SE

- Evonik Industries

- Gelita AG

- Advanced Medical Solutions Group plc

- AMAG Pharmaceuticals

- Chemence Medical

- Coloplast A/S

- ConvaTec Group Plc

- Halyard Health

- Momentive Performance Materials

- Nippon Gohsei

- Cosmotec

- Medtronic Plc

Frequently Asked Questions

Analyze common user questions about the Macromolecule Hydrogel market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between natural and synthetic macromolecule hydrogels?

Natural hydrogels (e.g., collagen, hyaluronic acid) exhibit high biocompatibility and biodegradability, making them excellent for tissue engineering, but often suffer from poor mechanical strength. Synthetic hydrogels (e.g., PEG, PVA) offer tunable mechanical stability, low batch-to-batch variability, and enhanced chemical control, primarily utilized for long-term implants and contact lenses where durability is essential.

How are smart hydrogels contributing to targeted drug delivery?

Smart or stimulus-responsive hydrogels are designed to alter their structure or release encapsulated therapeutics in response to specific environmental cues, such as temperature fluctuations, changes in pH (indicative of tumor sites or inflammation), or exposure to light. This targeted release mechanism maximizes drug concentration at the diseased site while minimizing systemic exposure and side effects, significantly enhancing therapeutic efficacy.

Which application segment shows the highest growth potential in the market?

The Tissue Engineering and Regeneration segment is forecasted to exhibit the highest growth rate (CAGR). This is driven by rapid advancements in 3D bioprinting technologies utilizing hydrogel bio-inks to create complex, functional tissue constructs and scaffolds for research, drug screening, and potential organ transplantation, addressing major unmet clinical needs.

What regulatory challenges face new macromolecule hydrogel products?

New hydrogel products, particularly implantable or degradable materials, face significant regulatory scrutiny requiring extensive biocompatibility and toxicology testing. Challenges include demonstrating predictable degradation rates, ensuring non-toxic degradation byproducts, and navigating varying global regulatory requirements (e.g., FDA in the US, EMA in Europe) which can substantially lengthen the time and cost associated with commercialization.

How does 3D bioprinting specifically rely on macromolecule hydrogels?

Macromolecule hydrogels serve as essential bio-inks in 3D bioprinting because they provide the necessary structural support (scaffold) and a biocompatible microenvironment for seeded cells to survive, proliferate, and differentiate. Their high water content mimics native tissue, and their rheological properties allow for controlled extrusion and precise structuring during the printing process necessary to create functional complex biological constructs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager