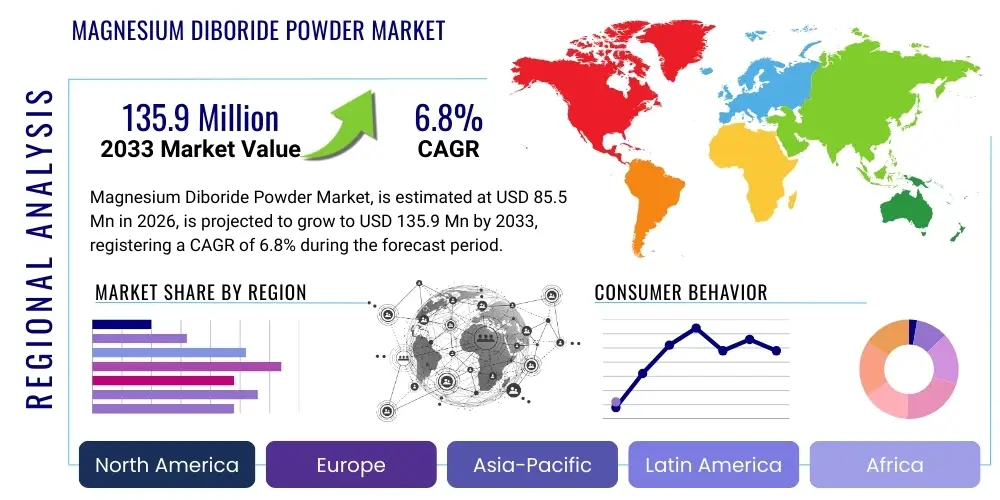

Magnesium Diboride Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435534 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Magnesium Diboride Powder Market Size

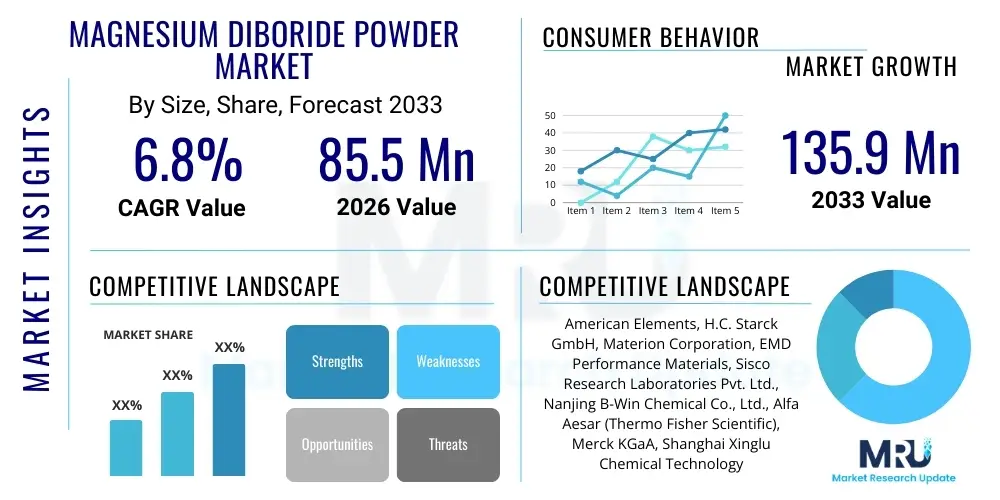

The Magnesium Diboride Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 85.5 million in 2026 and is projected to reach USD 135.9 million by the end of the forecast period in 2033.

Magnesium Diboride Powder Market introduction

Magnesium Diboride (MgB₂) powder is a critical advanced material known primarily for its extraordinary superconducting properties. Discovered in 2001 to exhibit superconductivity at a relatively high critical temperature (Tc) of 39 Kelvin, it presents a compelling low-cost, high-performance alternative to traditional Nb-based superconductors. This material's fundamental utility stems from its unique crystal structure and metallic nature, making it highly valuable in applications requiring strong magnetic fields and minimal energy loss. The powder form allows for flexible processing, including the fabrication of superconducting wires through techniques like Powder-in-Tube (PIT) and the deposition of thin films for radio-frequency cavities and sensitive detectors.

The product description encompasses ultra-high purity MgB₂ powder, typically categorized by particle size, ranging from nano-scale to micro-scale, influencing its reactivity and final superconducting performance. Key applications span high-energy physics, medical devices (such as high-field Magnetic Resonance Imaging or MRI systems), and advanced electric power systems, including superconducting transmission cables and fault current limiters. The material is inherently cost-effective compared to traditional high-temperature superconductors (HTS) or even low-temperature superconductors (LTS) like Niobium-Titanium (NbTi), driving its adoption in large-scale commercial projects that prioritize economic viability alongside performance metrics.

Driving factors for market expansion include escalating global investments in energy infrastructure modernization, particularly the development of smarter, more efficient electrical grids, and continuous advancements in magnet technology for research and medical diagnostics. The material's non-toxic nature, relative abundance of raw materials (magnesium and boron), and enhanced upper critical field capabilities when appropriately doped, position MgB₂ powder as a pivotal component in the transition toward practical, cost-efficient superconducting technology, fostering research and commercial interest across various high-tech sectors globally.

Magnesium Diboride Powder Market Executive Summary

The Magnesium Diboride Powder market is experiencing robust growth fueled by increasing commercial viability in niche high-performance sectors, moving beyond initial academic interest. Current business trends indicate a critical shift toward optimizing production methods, focusing on achieving highly stoichiometric and phase-pure material necessary for high-current applications. Manufacturers are heavily investing in advanced synthesis techniques, such as Reaction Synthesis and various chemical vapor deposition routes, to enhance powder consistency, reduce grain size for improved flux pinning, and mitigate oxidation risks that compromise superconducting performance. Geographically, Asia Pacific, particularly China and Japan, remains the epicenter of high-volume production and industrial application uptake, driven by substantial national investment in smart grid technology and scientific research infrastructure, while North America and Europe lead in high-end military and aerospace applications requiring extremely stable materials.

Segment trends highlight the dominance of the Superconducting Wire segment, which constitutes the largest volume consumer of MgB₂ powder, essential for high-field magnets used in fusion energy research and high-resolution NMR/MRI machines. Furthermore, there is a notable accelerating trend in the Thin Film segment, primarily driven by demand for advanced microelectronics, sensors, and quantum computing components where MgB₂’s gap structure offers specific advantages. Innovation in doping techniques (e.g., carbon doping) to enhance critical current density (Jc) and the upper critical field (Hc₂) is a defining trend, enabling MgB₂ to function effectively under more demanding operational conditions, thus expanding its competitive scope against conventional superconductors.

The market faces structural challenges related to the scalability of ultra-high purity synthesis processes and managing the material's susceptibility to moisture and oxygen degradation during handling and integration. However, the sheer opportunity presented by its potential replacement of costly liquid helium-cooled Niobium-based systems in specific mid-field applications ensures sustained R&D focus. Strategic partnerships between material producers and end-use system integrators (e.g., MRI manufacturers or grid component developers) are becoming crucial for standardizing material specifications and accelerating commercial deployment across key regional markets, solidifying its place in the advanced materials ecosystem.

AI Impact Analysis on Magnesium Diboride Powder Market

User inquiries regarding AI's influence in the MgB₂ market frequently center on three critical themes: accelerating new material discovery, optimizing complex synthesis processes, and ensuring rigorous quality control in production. Users are keenly interested in whether AI can drastically reduce the time and cost associated with identifying optimal doping agents or structural modifications necessary to boost the material's critical current density (Jc). A significant concern is the complexity of parameter space in synthesis—AI models are expected to correlate precursor purity, temperature profiles, and reaction atmosphere with final material performance (Tc, Hc₂, Jc), minimizing experimental trial-and-error. Furthermore, users anticipate AI-driven vision systems and predictive modeling to detect subtle defects, oxidation, or non-stoichiometry in large production batches, thereby enhancing overall product consistency and reliability for sensitive applications like high-energy colliders or advanced defense systems.

- AI algorithms significantly reduce the material discovery cycle by predicting optimal doping concentrations and synthesis parameters for enhanced superconductivity.

- Machine learning models are employed to optimize furnace temperature profiles and gas flow rates in Powder-in-Tube (PIT) processing, maximizing wire homogeneity and Jc.

- Predictive maintenance analytics, driven by AI, monitor reactor health and precursor material quality in real-time, preventing batch failures during high-purity production.

- AI-enhanced quality control systems utilize spectroscopic data analysis (e.g., XRD, SEM imaging) to rapidly assess phase purity, grain size distribution, and stoichiometry deviation.

- Computational materials science, leveraging deep learning, assists in simulating MgB₂ performance under extreme operational conditions (high magnetic fields, cryogenic temperatures).

- Intelligent supply chain management uses AI to forecast demand variability for raw materials (Boron, Magnesium) and optimize inventory levels for production efficiency.

DRO & Impact Forces Of Magnesium Diboride Powder Market

The market trajectory for Magnesium Diboride Powder is shaped by a critical interplay of drivers, restraints, and opportunities. The primary driver is the material's superior cost-effectiveness and relatively high critical temperature (39 K), enabling cooling via cryocoolers (closed-cycle refrigerators) rather than expensive liquid helium, significantly lowering operational costs in high-field magnet systems. Secondary drivers include increasing global investment in magnetically confined fusion energy research, particularly large-scale projects like ITER, and the adoption of superconducting magnets in industrial applications such as mineral separation and magnetic levitation trains. These forces collectively create a sustained, high-value demand for MgB₂ material, replacing conventional conductors in new, high-efficiency system designs that mandate minimal energy dissipation.

Restraints are prominently associated with material processing complexity and intrinsic limitations. The inherent brittle nature of bulk MgB₂ makes wire fabrication challenging, necessitating complex Powder-in-Tube or ex-situ techniques that influence final performance characteristics. Moreover, the material’s high reactivity with moisture and oxygen mandates strict handling procedures under inert atmosphere, increasing manufacturing overheads and logistical complexities. Another key restraint is the current ceiling on critical current density (Jc) compared to optimized LTS materials like Nb₃Sn in very high magnetic fields (above 10 Tesla), limiting its deployment in the most demanding applications, although continuous research aims to bridge this performance gap through advanced doping strategies.

Opportunities reside predominantly in expanding its application envelope into non-superconducting areas and next-generation energy systems. The material's high hardness and low density present niche opportunities in armor plating and structural ceramics. However, the most significant commercial opportunities lie in developing superconducting power devices, including high-efficiency transmission lines for metropolitan areas, high-power synchronous motors for electric propulsion, and advanced energy storage systems (Superconducting Magnetic Energy Storage - SMES). The ongoing effort to standardize manufacturing processes and integrate MgB₂ components into commercial products is poised to unlock substantial long-term market growth, particularly as global emphasis shifts towards energy security and decarbonization.

Segmentation Analysis

The Magnesium Diboride Powder market is structurally segmented based on crucial attributes including Purity/Grade, Particle Size, and End-Use Application, which dictates the performance requirements and pricing structure across various high-tech industries. Understanding these segmentations is vital for strategic positioning, as the stringent requirements of a high-field MRI magnet necessitate ultra-high purity, small particle size powder, distinct from the specifications required for structural ceramics or research applications. The segmentation analysis provides granular insights into demand trends, helping producers align their material synthesis capabilities (e.g., high-temperature vs. lower-temperature routes) with the specific needs of specialized end-markets, thereby maximizing yield and market penetration in high-growth areas.

- By Purity/Grade:

- High Purity Grade (99.5% - 99.99%)

- Standard Research Grade (98% - 99.5%)

- By Particle Size:

- Nanopowder (10 nm - 100 nm)

- Micron Powder (1 µm - 10 µm)

- By Application:

- Superconducting Wires and Tapes

- Thin Films and Coatings

- Research & Development (R&D)

- Defense and Aerospace Components

- Energy Storage (SMES, Supercapacitors)

- Others (Catalysis, Structural Materials)

- By End-Use Industry:

- Medical (MRI, NMR)

- Energy and Power Transmission

- Scientific Research (Particle Accelerators, Fusion Reactors)

- Industrial Manufacturing

Value Chain Analysis For Magnesium Diboride Powder Market

The Magnesium Diboride Powder value chain begins with the procurement of highly refined precursor materials in the upstream segment. This stage involves sourcing high-purity elemental Magnesium (Mg) and Boron (B) powder or their compounds (e.g., boric acid, magnesium hydride). The purity of these raw materials is paramount, as impurities directly impact the critical temperature (Tc) and critical current density (Jc) of the final MgB₂ product. Strategic relationships with specialized chemical suppliers are necessary to ensure a consistent feed of contamination-free precursors, often subjecting the materials to stringent quality checks before entering the synthesis phase. Price volatility in the global elemental Boron market can significantly influence the production cost of MgB₂, making robust supplier management a critical component of cost control.

The midstream process involves the complex chemical synthesis of the MgB₂ powder itself. Key synthesis methods include direct reaction between Mg and B under controlled high-temperature, inert atmosphere conditions (Solid-State Reaction, PVD/CVD) or alternative routes like precursor decomposition. Producers often specialize in specific particle sizes (nano vs. micro) and purity levels required by different applications. The successful outcome depends heavily on precise control over reaction kinetics, pressure, and temperature to ensure high phase purity and desirable morphology. Following synthesis, the powder undergoes rigorous testing (XRD, SEM, elemental analysis) and subsequent processing steps, such as milling or surface stabilization treatments, necessary to prepare it for integration into end products like superconducting wires or sputter targets.

The downstream segment encompasses the distribution and utilization of the finalized MgB₂ powder. Distribution channels are highly specialized, often involving direct sales to Original Equipment Manufacturers (OEMs) in the medical imaging (MRI) and energy sectors, or specialized distributors catering to academic and government research laboratories. For superconducting wire manufacturers, the powder is typically sold in bulk to be processed using the Powder-in-Tube (PIT) method. The channel structure leans heavily toward indirect distribution for research-grade materials sold globally, while direct sales are favored for high-volume, customized industrial grades, ensuring close collaboration between the producer and the system integrator regarding material specifications and long-term supply agreements.

Magnesium Diboride Powder Market Potential Customers

Potential customers for Magnesium Diboride Powder are highly technical entities operating within sectors that demand superior energy efficiency and high-field magnetic performance, often under cryogenic conditions. The primary end-users are large-scale manufacturers of medical imaging equipment, specifically those developing next-generation high-field MRI and Nuclear Magnetic Resonance (NMR) spectroscopy systems, where the reliability and low operational cost of MgB₂ magnets offer a distinct competitive edge. These buyers require consistent supply of high-purity, standardized powder suitable for predictable processing into robust superconducting coils and tapes, prioritizing material longevity and stability under repeated thermal cycling. Furthermore, major governmental and academic research institutions involved in fundamental physics and fusion energy experiments represent significant, high-volume purchasers of specialized MgB₂ products.

Another major customer segment includes companies and consortia focused on electric power infrastructure modernization. This encompasses manufacturers developing superconducting power cables (SC power lines) designed for high current capacity with zero resistive loss, which are ideal for dense urban environments or long-distance transmission. Additionally, manufacturers of fault current limiters (FCLs) and superconducting magnetic energy storage (SMES) systems are key buyers, utilizing MgB₂ for its fast response time and robust performance in managing grid disturbances and storing energy efficiently. These industrial buyers prioritize scalability, material cost-effectiveness, and predictable performance metrics necessary for deployment in utility-scale operations, often requiring direct, long-term supply contracts.

Finally, niche but crucial segments include aerospace and defense contractors and advanced sensor manufacturers. These customers leverage the unique properties of MgB₂ not just for high-field magnets but also for sensitive infrared detectors, radiation detectors, and specialized electronic components operating in extreme environments. Although volumes in these segments may be lower compared to the medical or energy sectors, the demand for ultra-high purity and nano-sized MgB₂ powder is often non-negotiable, commanding premium pricing. These buyers look for suppliers capable of providing highly tailored and stable materials that meet stringent military or space-grade specifications and regulatory compliance standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85.5 Million |

| Market Forecast in 2033 | USD 135.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | American Elements, H.C. Starck GmbH, Materion Corporation, EMD Performance Materials, Sisco Research Laboratories Pvt. Ltd., Nanjing B-Win Chemical Co., Ltd., Alfa Aesar (Thermo Fisher Scientific), Merck KGaA, Shanghai Xinglu Chemical Technology Co., Ltd., Stanford Advanced Materials, Beijing Zhongyantai Science and Technology Co., Ltd., LTS Research Laboratories, Advanced Technology & Materials Co., Ltd. (AT&M), Reade International Corp., Cerac Inc., XFNANO, A-Star Nanomaterials, Strem Chemicals, Graphene Supermarket, Nanografi Nanotechnology. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnesium Diboride Powder Market Key Technology Landscape

The technological landscape of the Magnesium Diboride Powder market is dominated by advancements in synthesis methods aimed at controlling stoichiometry, crystal structure, and particle morphology to maximize superconducting performance (Tc, Jc). The most widely utilized synthesis technology is the Solid-State Reaction (SSR) method, where Mg and B precursors are reacted at high temperatures (typically 650°C to 950°C) under an inert atmosphere (often Argon). Refinements in SSR focus on techniques like the Powder-in-Tube (PIT) route, which is crucial for manufacturing flexible superconducting wires, requiring uniform powder packing density and optimized annealing protocols to enhance grain connectivity and flux pinning mechanisms necessary for achieving high critical currents in industrial conductors.

Beyond traditional SSR, advanced processing technologies are increasingly employed, especially for high-end research and thin-film applications. These include Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) techniques, which offer superior control over film thickness and crystal orientation, critical for microelectronic devices and high-frequency RF applications. Furthermore, plasma synthesis methods are gaining traction as they allow for the production of highly reactive, nano-sized MgB₂ powders at relatively lower temperatures, leading to finer grain structures that can significantly improve the critical current density (Jc) by increasing the number of effective flux pinning centers within the material matrix. Technological competitiveness is centered on achieving high levels of carbon doping uniformity, which is empirically proven to elevate the material’s upper critical magnetic field (Hc₂).

A crucial technological focus involves surface passivation and encapsulation technologies. Given MgB₂'s inherent susceptibility to hydrolysis and oxidation, methods utilizing inert coatings, specialized polymers, or vacuum packaging are essential for maintaining material stability during storage, transportation, and subsequent processing into end-use components. Innovations in particle engineering, specifically controlling particle size distribution and aggregation state, are continuously being integrated to improve the material’s handleability and its effective density when used in sintering or wire-drawing operations. These combined technological efforts aim to transition MgB₂ from a laboratory novelty to a robust, scalable, and commercially reliable superconductor component, thereby lowering entry barriers for widespread industrial adoption in demanding applications like large-scale power transmission and advanced particle physics experimentation.

Regional Highlights

The global Magnesium Diboride Powder market exhibits distinct regional dynamics driven by varying levels of investment in scientific infrastructure, energy grid modernization, and industrial manufacturing capacity. Asia Pacific (APAC) holds the largest market share, predominantly propelled by China's extensive investment in state-sponsored research projects, particularly in fusion energy (e.g., EAST reactor) and large-scale industrial production capabilities. Japan and South Korea also contribute significantly through robust electronics manufacturing and advanced medical imaging development. The region benefits from lower manufacturing costs and readily available raw material sourcing, making it a critical hub for high-volume, cost-effective MgB₂ powder production destined for global supply chains.

North America, led by the United States, represents a major market in terms of high-value, specialized demand, focusing heavily on defense applications, high-energy physics research (Fermilab, Brookhaven), and cutting-edge medical device technology. The region emphasizes the development of high-performance, carbon-doped MgB₂ for applications requiring superior magnetic field stability and critical current density. Procurement here is often characterized by stringent quality controls and demands for domestically sourced or trusted international suppliers, reflecting the strategic importance of superconducting materials in sensitive technological areas.

Europe maintains a strong position driven by foundational scientific research (CERN, ITER participation) and sophisticated energy system development. European countries, including Germany, the UK, and France, are actively researching MgB₂ use in superconducting cables and fault current limiters as part of the broader EU energy transition goals. The regional market is characterized by strong academic-industrial partnerships focused on optimizing wire fabrication techniques and standardizing material specifications to ensure interoperability and reliable long-term performance in complex utility-scale superconducting installations.

- Asia Pacific (APAC): Dominates in volume and manufacturing capacity; driven by China's investment in fusion energy and smart grid projects; focus on cost-effective, scalable production.

- North America: Leading region for high-value applications; emphasis on defense, advanced MRI technology, and fundamental particle accelerator research; high demand for ultra-high purity, custom-doped materials.

- Europe: Strong R&D focus linked to large international projects (ITER, CERN); significant market penetration in energy efficiency and power transmission infrastructure (SC cables, FCLs).

- Latin America (LATAM) & Middle East & Africa (MEA): Emerging markets with current demand focused primarily on university research and small-scale industrial adoption; potential growth tied to future infrastructure spending and scientific collaborations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnesium Diboride Powder Market.- American Elements

- H.C. Starck GmbH

- Materion Corporation

- EMD Performance Materials

- Sisco Research Laboratories Pvt. Ltd.

- Nanjing B-Win Chemical Co., Ltd.

- Alfa Aesar (Thermo Fisher Scientific)

- Merck KGaA

- Shanghai Xinglu Chemical Technology Co., Ltd.

- Stanford Advanced Materials

- Beijing Zhongyantai Science and Technology Co., Ltd.

- LTS Research Laboratories

- Advanced Technology & Materials Co., Ltd. (AT&M)

- Reade International Corp.

- Cerac Inc.

- XFNANO

- A-Star Nanomaterials

- Strem Chemicals

- Graphene Supermarket

- Nanografi Nanotechnology

Frequently Asked Questions

Analyze common user questions about the Magnesium Diboride Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary commercial advantage of Magnesium Diboride over other superconductors?

The primary commercial advantage of MgB₂ is its cost-effectiveness, high critical temperature (39 K), and low operating costs. Unlike Niobium-based superconductors that require cooling with expensive liquid helium (4.2 K), MgB₂ can be effectively cooled using closed-cycle cryocoolers, dramatically simplifying logistics and reducing long-term operational expenditure in applications like MRI and power transmission.

How is the critical current density (Jc) of MgB₂ powder enhanced for high-power applications?

The critical current density (Jc) is primarily enhanced through impurity control and advanced doping techniques. Incorporating carbon-containing compounds (like SiC) during synthesis creates flux pinning centers within the material microstructure. This optimized grain structure helps anchor magnetic flux lines, significantly increasing the material's ability to carry high currents in strong magnetic fields.

Which end-use industry contributes the most to the demand for Magnesium Diboride powder?

The Medical sector, specifically the manufacturing of high-field Magnetic Resonance Imaging (MRI) systems, contributes significantly to demand. The Energy sector, encompassing superconducting magnetic energy storage (SMES) and advanced power cables, represents the largest potential growth area due to global grid modernization efforts and the push for high-efficiency power devices.

What synthesis method is most commonly used for producing high-purity MgB₂ powder commercially?

The most common commercial synthesis method is the Solid-State Reaction (SSR) route, which involves heating elemental magnesium and boron powders under carefully controlled temperature and inert atmosphere conditions. This method is preferred for its scalability and ability to produce the volume necessary for large industrial applications, especially for subsequent Powder-in-Tube (PIT) wire fabrication.

What are the main regional drivers of market growth for MgB₂?

In Asia Pacific, growth is driven by state-funded scientific infrastructure projects (fusion energy, accelerators) and industrial manufacturing scale. In North America and Europe, growth is propelled by high-tech defense applications, advanced medical technology development, and significant investment in developing next-generation, high-efficiency electrical power grid components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager