Magnetic Coupled Mixers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438265 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Magnetic Coupled Mixers Market Size

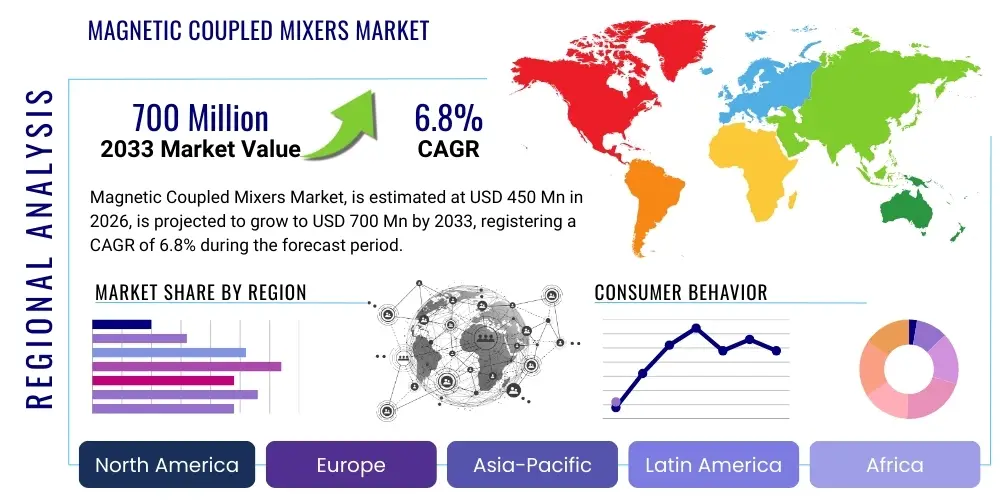

The Magnetic Coupled Mixers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 700 Million by the end of the forecast period in 2033.

Magnetic Coupled Mixers Market introduction

Magnetic Coupled Mixers, also known as mag mixers, are specialized industrial mixing devices designed to provide hermetic sealing, preventing contamination and leakage. These systems utilize magnetic forces to transmit torque from the external motor drive to the internal impeller, eliminating the need for dynamic seals found in conventional mixers. This seal-less design is critical for maintaining sterility, particularly in high-purity applications such as pharmaceutical and biotechnology manufacturing, where cross-contamination is strictly prohibited. The intrinsic safety and reliability offered by these mixers are driving their adoption across various critical processes, including hydrogenation, polymerization, crystallization, and fermentation, establishing them as essential equipment for high-specification processing environments globally.

Magnetic Coupled Mixers Market Executive Summary

The global Magnetic Coupled Mixers Market is experiencing robust expansion driven by stringent regulatory frameworks mandating sterile and contamination-free processing, particularly within the biopharmaceutical sector. Business trends emphasize the adoption of advanced materials like Hastelloy and exotic alloys to enhance chemical compatibility and durability, addressing complex mixing challenges in corrosive environments. Regionally, North America and Europe dominate the market due to established pharmaceutical and chemical industries and high investment in R&D, while the Asia Pacific region is demonstrating the highest growth trajectory, spurred by rapid expansion of localized biotech manufacturing capabilities in China and India. Segment-wise, the high-purity and high-pressure segments are exhibiting significant growth, reflecting the increasing complexity and scale of modern chemical and life science synthesis processes, demanding mixers capable of operating under extreme conditions with impeccable reliability and minimal maintenance requirements.

AI Impact Analysis on Magnetic Coupled Mixers Market

User questions regarding AI's influence center on predictive maintenance, optimization of mixing parameters, and integration into continuous manufacturing systems (CM). Users are keen to understand how AI algorithms can monitor magnetic drive integrity, predict bearing wear, and optimize energy consumption based on real-time rheological data. The consensus expects AI to shift maintenance from reactive to predictive models, significantly enhancing operational uptime and batch consistency. Furthermore, integrating machine learning into process analytical technology (PAT) surrounding the mixing vessel allows for automatic adjustment of mixing speeds and patterns, ensuring critical quality attributes (CQAs) are consistently met across diverse fluid dynamics, thereby streamlining complex formulations and maximizing yield in sensitive processes.

- Enhanced predictive maintenance using sensor data to forecast magnetic coupling or bearing failure.

- Optimization of mixing parameters (speed, duration, direction) based on real-time viscosity and fluid dynamics models.

- Integration with Process Analytical Technology (PAT) for automated feedback control and quality assurance in continuous processing.

- Reduced energy consumption through intelligent motor control algorithms adapting to load variation.

- Improved process development via simulation and digital twins utilizing AI-analyzed operational data.

- Facilitation of complex scale-up procedures by translating small-scale data into optimized large-scale mixing protocols.

DRO & Impact Forces Of Magnetic Coupled Mixers Market

The growth of the Magnetic Coupled Mixers Market is fundamentally driven by the escalating demand for high-purity processing in the pharmaceutical and biotechnology sectors, coupled with increasingly strict regulatory requirements such as FDA and EMA guidelines demanding zero-leakage equipment. However, the market faces restraints primarily due to the significantly higher initial capital expenditure required for magnetic coupled systems compared to conventional mechanically sealed mixers, alongside the technical complexity associated with handling very high viscosity fluids which can sometimes lead to magnetic decoupling. Opportunities lie in the development of advanced magnetic materials and sensor integration for real-time monitoring, catering to the growing trend of continuous manufacturing and customized small-batch production. These forces interact to push manufacturers toward higher efficiency, greater reliability, and specialized design capabilities, particularly in the realm of aseptic processing and high-pressure chemical synthesis where reliability is non-negotiable.

Segmentation Analysis

The Magnetic Coupled Mixers Market is segmented based on the critical design and application parameters that determine the functionality and end-use environment of the mixing apparatus. Segmentation by Type focuses on the configuration of the drive system and impeller, while Application differentiates between the core industries utilizing these specialized mixers. Understanding these segments is crucial for strategic market positioning and product development, allowing suppliers to tailor solutions that meet the demanding specifications of high-purity, high-pressure, and high-temperature processes across global industries.

- By Type:

- Bottom-Entry Mixers

- Top-Entry Mixers

- Side-Entry Mixers

- By Mixing Capacity:

- Pilot Scale (Below 100 Liters)

- Small Scale (100–500 Liters)

- Medium Scale (500–5,000 Liters)

- Large Scale (Above 5,000 Liters)

- By Application:

- Pharmaceutical and Biotechnology

- Chemical Processing

- Food and Beverage

- Cosmetics and Personal Care

- Water and Wastewater Treatment

- By End-User:

- Manufacturing Facilities

- Research and Development Labs

- Contract Manufacturing Organizations (CMOs)

Value Chain Analysis For Magnetic Coupled Mixers Market

The value chain for the Magnetic Coupled Mixers Market commences with upstream suppliers providing specialized components, progresses through highly technical manufacturing and assembly, and concludes with downstream distribution, installation, and essential after-sales services. Upstream analysis highlights the reliance on critical material suppliers, including high-grade stainless steel (316L, duplex), exotic alloys (e.g., Hastelloy for wetted parts), and rare-earth magnet producers (Neodymium, Samarium-Cobalt) which form the core torque transmission mechanism. The quality and availability of these specialized materials directly impact the performance, chemical resistance, and lifespan of the final product, necessitating robust quality control protocols at the procurement stage.

The core manufacturing stage involves precision engineering, machining, and cleanroom assembly, particularly for mixers destined for aseptic environments. Due to the precision required for coupling alignment and hermetic sealing, specialized fabrication techniques are employed. This stage is dominated by established players possessing the requisite expertise in fluid dynamics modeling (CFD) and magnetic circuit design. Efficiency in manufacturing relies heavily on minimizing material waste and ensuring compliance with strict global standards like ASME BPE and relevant ISO certifications, confirming the sterility and integrity of the finished equipment.

Downstream activities focus on distribution, installation, and maintenance. Direct distribution channels are often favored for large-scale, customized industrial projects where technical consultancy and direct vendor support are critical. Indirect channels, utilizing specialized distributors and system integrators, handle standard product lines and regional market penetration. Aftermarket service, including scheduled maintenance, calibration, and replacement of consumable wear parts (like bearings), constitutes a significant revenue stream and a crucial differentiator for manufacturers, ensuring the sustained high performance and regulatory compliance of the installed base throughout the mixer's operational lifecycle.

Magnetic Coupled Mixers Market Potential Customers

The primary consumers and end-users of Magnetic Coupled Mixers are large-scale manufacturing facilities and specialized research laboratories operating in environments where contamination control, reliability, and precision are paramount. The Pharmaceutical and Biotechnology sectors represent the most crucial customer base, requiring mag mixers for the formulation of active pharmaceutical ingredients (APIs), vaccine production, and sterile media preparation, where the seal-less design is mandatory for maintaining aseptic conditions and preventing biological contamination, particularly in bioreactors and fermenters.

In the Chemical Processing Industry, potential customers include manufacturers dealing with highly corrosive, toxic, or volatile substances, such as specialty chemical producers, petrochemical companies, and polymer manufacturers. For these applications, the hermetic sealing capability ensures operator safety and prevents the release of hazardous materials into the atmosphere. Magnetic coupled mixers are frequently utilized in high-pressure reactors and hydrogenation processes where mechanical seals would rapidly degrade under extreme operational parameters, making mag mixers the preferred, and often mandated, solution for reliability and environmental compliance.

Furthermore, Contract Manufacturing Organizations (CMOs) and Contract Development and Manufacturing Organizations (CDMOs) are rapidly emerging potential customers. As outsourcing of pharmaceutical and biopharmaceutical production increases globally, CMOs require flexible, reliable, and multi-functional mixing equipment capable of handling diverse product lines and meeting varying regulatory demands. These organizations invest heavily in state-of-the-art magnetic mixers to guarantee batch consistency and accelerate time-to-market for their clients, solidifying their role as significant purchasers of high-end mixing technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 700 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | EKATO Group, Pfaudler Group, Flowserve Corporation, Sulzer Ltd., SPX FLOW Inc., Dover Corporation (Mixer Systems), Steridose (Novartis), ADMIX Inc., GMM Pfaudler, Bibus AG, Hi-Mixer, BCI Acrylics Inc., Sennics, Simatek A/S, Pro-C-Tiv Co., Magnetic Technologies Inc., Dynamix Agitators, Charles Ross & Son Company, Primix Corporation, De Dietrich Process Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetic Coupled Mixers Market Key Technology Landscape

The technological landscape of the Magnetic Coupled Mixers Market is characterized by continuous innovation focused on enhancing magnet strength, improving bearing materials, and optimizing impeller design for specific fluid dynamics challenges. A crucial development involves the adoption of high-energy rare-earth magnets, such as advanced grades of Neodymium-Iron-Boron (NdFeB) or Samarium-Cobalt (SmCo), which enable higher torque transmission across larger pressure boundaries. This allows manufacturers to design larger vessels and handle higher viscosity fluids without the risk of magnetic decoupling, significantly expanding the applicability of these mixers into heavy-duty chemical synthesis and demanding polymerization processes.

Furthermore, advancements in non-metallic, inert bearing materials are paramount for maintaining product purity and extending service life. Materials like Silicon Carbide (SiC) and specialized ceramics are increasingly utilized for internal bearings, offering superior resistance to chemical attack, abrasion, and high temperatures compared to traditional materials. This technological evolution minimizes particle generation—a critical factor in high-ppurity applications—and reduces the frequency of costly maintenance cycles. The optimization of these internal components is central to the value proposition, ensuring long-term reliability in aggressive operational environments.

The integration of advanced monitoring and sensor technology represents another key trend. Modern magnetic coupled mixers often incorporate sophisticated Process Analytical Technology (PAT) sensors, including vibration analysis and temperature monitoring, capable of detecting minute changes in the mixer's operational state. This connectivity facilitates predictive maintenance schedules and aids in real-time process validation. The shift toward digitally integrated systems is crucial for supporting Industry 4.0 initiatives, enabling seamless data logging, remote diagnostics, and automated process control, which is increasingly demanded by large pharmaceutical and biotech firms for compliance and efficiency gains.

Regional Highlights

North America maintains a dominant position in the Magnetic Coupled Mixers Market, primarily due to the presence of a mature and highly regulated pharmaceutical and biotechnology sector, particularly in the United States. High levels of R&D investment, coupled with stringent FDA regulations necessitating aseptic processing capabilities, drive the continuous demand for high-specification, reliable magnetic coupled mixers. Key market drivers include the rapid development of novel biologics and gene therapies, which require precision mixing in sterile, closed systems, making mag mixers a fundamental infrastructural investment.

Europe also holds a significant market share, characterized by robust chemical and specialty pharmaceutical industries in countries like Germany, Switzerland, and Ireland. European regulatory bodies, similar to their North American counterparts, enforce demanding quality and environmental standards, which naturally favors the adoption of seal-less mixing technology to mitigate leakage and contamination risks. Furthermore, the region’s strong focus on sustainable chemical manufacturing encourages the use of highly efficient and reliable processing equipment that minimizes operational downtime.

The Asia Pacific (APAC) region is projected to register the fastest growth rate during the forecast period. This rapid expansion is attributed to increasing foreign direct investment (FDI) in localized manufacturing hubs in China and India, the expansion of generics and biosimilars production, and improving regulatory standards. As APAC countries modernize their processing infrastructure to meet international export standards, the demand for high-purity equipment like magnetic coupled mixers is surging. This growth is further fueled by expanding domestic pharmaceutical consumption and the increasing establishment of contract manufacturing facilities in the region.

- North America: Dominant market share driven by established biotech infrastructure and stringent FDA regulations for sterile processing. Focus on advanced materials and integration into sophisticated bioreactors.

- Europe: High adoption rates due to mature specialty chemical and pharmaceutical industries; strong emphasis on environmental safety and occupational health standards.

- Asia Pacific (APAC): Highest projected CAGR, powered by massive growth in contract manufacturing (CMOs) and the expansion of domestic pharmaceutical production in major economies like China, India, and South Korea.

- Latin America (LATAM): Growing market driven by infrastructure modernization in countries like Brazil and Mexico, focusing on optimizing local chemical and food processing capabilities.

- Middle East and Africa (MEA): Emerging market concentrated in the Gulf Cooperation Council (GCC) nations, primarily investing in petrochemical and nascent pharmaceutical manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Coupled Mixers Market.- EKATO Group

- Pfaudler Group

- Flowserve Corporation

- Sulzer Ltd.

- SPX FLOW Inc.

- Dover Corporation (Mixer Systems)

- Steridose (Novartis)

- ADMIX Inc.

- GMM Pfaudler

- Bibus AG

- Hi-Mixer

- BCI Acrylics Inc.

- Sennics

- Simatek A/S

- Pro-C-Tiv Co.

- Magnetic Technologies Inc.

- Dynamix Agitators

- Charles Ross & Son Company

- Primix Corporation

- De Dietrich Process Systems

Frequently Asked Questions

What is the primary advantage of a Magnetic Coupled Mixer over a conventional mixer?

The primary advantage is the hermetic, seal-less design, which completely eliminates mechanical seals and prevents leakage, contamination, and the ingress of airborne particles. This is essential for maintaining sterility and purity in aseptic and high-containment processes, particularly in biopharmaceutical manufacturing.

Which industries are the largest end-users of Magnetic Coupled Mixers?

The Pharmaceutical and Biotechnology industries are the largest end-users. They rely on these mixers extensively for critical processes such as fermentation, sterile media preparation, and the handling of sensitive Active Pharmaceutical Ingredients (APIs) where zero contamination is a regulatory prerequisite.

What is the projected growth rate (CAGR) for the Magnetic Coupled Mixers Market?

The market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. This growth is driven by increasing global investments in sterile manufacturing capacity and the expansion of the high-pressure chemical processing sector.

How does AI impact the operational efficiency of magnetic coupled mixers?

AI significantly enhances operational efficiency through predictive maintenance, monitoring bearing wear and coupling alignment in real time. It also optimizes mixing parameters by utilizing real-time rheological data, ensuring superior batch consistency and reducing unexpected downtime.

What technological advancements are shaping the Magnetic Coupled Mixers Market?

Key technological advancements include the use of higher-strength rare-earth magnets for increased torque capacity, the adoption of advanced inert ceramic materials (like Silicon Carbide) for internal bearings, and the integration of sophisticated sensors for real-time monitoring and process validation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager