Magnetic Couplings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434238 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Magnetic Couplings Market Size

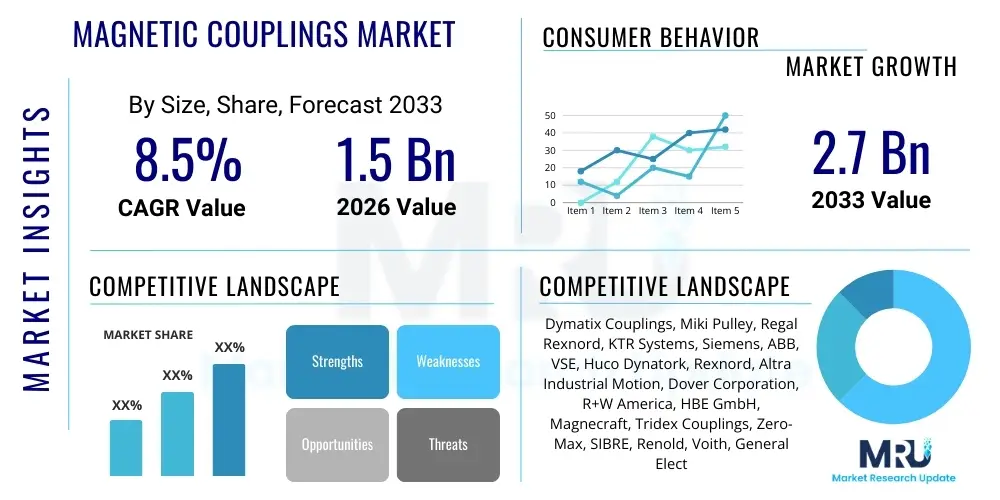

The Magnetic Couplings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.7 Billion by the end of the forecast period in 2033.

Magnetic Couplings Market introduction

The Magnetic Couplings Market involves the design, manufacture, and deployment of devices that transmit torque between two shafts without physical contact, utilizing magnetic fields. This non-contact transmission is crucial for applications requiring hermetically sealed barriers, primarily to prevent leakage of hazardous, corrosive, or high-pressure fluids. Magnetic couplings fundamentally enhance operational safety and system reliability by isolating the motor side (driving magnet assembly) from the pump/driven side (driven magnet assembly), thereby eliminating the need for traditional shaft seals, which are common points of mechanical failure and maintenance requirements.

Product Description: Magnetic couplings typically consist of two distinct assemblies—an outer rotor (driving) and an inner rotor (driven)—separated by a containment shell or barrier. These assemblies use high-strength permanent magnets, often rare-earth materials like Neodymium Iron Boron (NdFeB) or Samarium Cobalt (SmCo), arranged in a highly optimized configuration. Major applications span across industrial pumps, compressors, mixers, and specialized fluid handling systems where zero leakage is mandatory. Their inherent benefits include reduced maintenance costs, extended operational lifespan, and unparalleled system integrity in harsh environments, making them indispensable in sectors such as chemical processing, oil and gas, and pharmaceutical manufacturing.

The market growth is primarily driven by the escalating demand for advanced, leak-proof fluid handling equipment across industries focused on environmental protection and safety regulations. Increasing investments in infrastructure projects, particularly in water and wastewater treatment plants and expanding chemical production facilities in Asia Pacific, further propel the adoption of reliable magnetic coupling technology. Additionally, technological advancements focusing on improving torque density and thermal management in couplings using specialized composite materials are continually expanding their application scope into high-power and high-speed machinery.

Magnetic Couplings Market Executive Summary

The global Magnetic Couplings Market is characterized by robust growth, propelled primarily by stringent environmental regulations mandating zero-emission and zero-leakage pumping systems across process industries. Business trends indicate a strong shift towards couplings engineered with superior rare-earth magnets (Neodymium) to achieve higher torque density in smaller footprints, satisfying the industrial need for compact, efficient machinery. Strategic collaborations and mergers among key manufacturers are focused on integrating magnetic coupling technology into broader fluid dynamics solutions, offering comprehensive sealed pump and compressor packages. Furthermore, customization remains a critical differentiator, with manufacturers offering specialized designs tailored for extreme temperatures, high pressures, and highly viscous media, ensuring market resilience across diverse industrial verticals.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, driven by rapid industrialization, extensive investments in chemical and petrochemical facilities, and increased deployment of water treatment infrastructure, particularly in China and India. North America and Europe, while mature, exhibit strong demand fuelled by strict safety standards in the oil and gas sector and continuous modernization of existing industrial plants, emphasizing energy efficiency and reduced operational expenditure. Segment trends show that the coaxial magnetic coupling type dominates the market due to its ease of integration and wide range of torque capabilities, while the Neodymium magnet material segment holds the largest market share due to its superior strength-to-volume ratio, crucial for high-performance applications.

AI Impact Analysis on Magnetic Couplings Market

User queries regarding AI's influence on magnetic couplings often center on predictive maintenance, design optimization, and smart manufacturing integration. Users are keen to know if AI can preemptively identify demagnetization risks or material degradation in couplings operating under thermal stress, thus minimizing unplanned downtime. Another core theme revolves around leveraging machine learning algorithms to optimize the geometrical design of magnet arrays and containment shells, aiming for maximum torque transmission efficiency while reducing material usage. Concerns often involve the cost of integrating sensor technology and AI platforms into existing legacy systems, particularly in older industrial plants, and the security of the operational data generated by smart coupling monitoring systems.

The primary impact of Artificial Intelligence (AI) and Machine Learning (ML) on the Magnetic Couplings market lies in enhancing product lifecycle management and operational reliability. AI algorithms, fed by real-time sensor data regarding vibration, temperature, and rotational speed, enable highly accurate predictive maintenance models. These models move beyond traditional scheduled maintenance, allowing operators to intervene precisely before component failure, which is especially critical in preventing catastrophic failures related to coupling demagnetization or misalignment. This integration transforms magnetic couplings from passive components into active, data-generating assets contributing to the overall intelligence of the industrial internet of things (IIoT) ecosystem.

- AI-Driven Predictive Maintenance: Utilizing ML models to forecast demagnetization rates and potential component failure based on operational stress data.

- Optimized Coupling Design: Generative AI employed to optimize magnetic circuit layout for maximum torque density and thermal stability, accelerating R&D cycles.

- Smart Manufacturing Integration: AI controlling advanced manufacturing processes (e.g., automated magnet placement, welding) ensuring high precision and consistency in production.

- Remote Diagnostics and Monitoring: Implementing digital twins of coupling systems to simulate operational stresses and provide real-time remote diagnostic capabilities.

- Energy Efficiency Management: AI systems analyzing power consumption patterns to ensure couplings operate at optimal efficiency points relative to the driven load.

DRO & Impact Forces Of Magnetic Couplings Market

The Magnetic Couplings Market is predominantly driven by the increasing global focus on industrial safety and environmental compliance, pushing industries to adopt sealed, zero-leakage fluid handling solutions. Significant restraints include the cost associated with high-strength rare-earth magnets, which directly impacts the overall price of the coupling unit, and the technical complexity related to the potential for magnetic slippage (synchronous loss) under excessive load conditions, requiring precise system sizing. Opportunities arise from the expanding application of magnetic couplings in renewable energy sectors, such as tidal power and wind turbine pitch control, and the miniaturization trend in robotics and high-precision medical devices. These factors collectively create a dynamic competitive landscape where innovation in material science and design optimization is paramount for market penetration and sustained growth.

Impact forces are heavily influenced by regulatory bodies like the Environmental Protection Agency (EPA) and various regional health and safety organizations, which tighten mandates on fugitive emissions in chemical processing and petrochemical plants. The development of advanced composite materials for containment shells, which reduce eddy current losses and improve thermal management, acts as a significant internal force driving product innovation and performance enhancement. Furthermore, the rising demand for highly automated and maintenance-free industrial processes globally reinforces the fundamental value proposition of magnetic couplings over traditional mechanical seals, ensuring long-term market expansion despite initial high component costs.

Segmentation Analysis

The Magnetic Couplings Market is comprehensively segmented based on Type, Material, Application, and End-User, reflecting the diversity in industrial requirements and performance specifications. This segmentation helps in tailoring product offerings to specific operational needs, such as high-torque density in compressors or chemical resistance in processing pumps. Coaxial couplings currently lead the market due to their widespread suitability across general industrial and fluid dynamics applications. Material segmentation is dominated by Neodymium magnets, essential for achieving the necessary high performance and miniaturization demanded by modern machinery. Analyzing these segments provides strategic insights into areas of highest growth potential and technological focus, particularly the integration of couplings into high-pressure, high-temperature industrial environments where reliability is non-negotiable.

- By Type: Coaxial Magnetic Couplings, Parallel Magnetic Couplings, Angular Magnetic Couplings

- By Material: Neodymium (NdFeB), Samarium Cobalt (SmCo), Ceramic Ferrite, Alnico

- By Application: Pumps and Compressors, Mixers and Agitators, Blowers and Fans, Generators and Turbines, Medical Devices, Specialized Robotics

- By End-User Industry: Chemical and Petrochemical, Oil and Gas, Water and Wastewater Treatment, Power Generation (Conventional and Nuclear), Pharmaceutical and Biotechnology, General Industrial Manufacturing

Value Chain Analysis For Magnetic Couplings Market

The value chain for magnetic couplings begins with the Upstream Analysis, which is heavily reliant on the sourcing and processing of rare-earth metals, primarily Neodymium and Samarium, which are critical components determining coupling performance and cost. Key upstream activities include the mining, refining, and manufacturing of high-performance permanent magnets, along with sourcing specialized materials for the containment shell (e.g., corrosion-resistant stainless steel or high-strength composites). Fluctuations in rare-earth magnet prices and supply chain stability, particularly concerning key producing regions, significantly influence the operational costs and pricing strategies for coupling manufacturers. Efficiency in magnet manufacturing and quality control are essential for ensuring the longevity and torque capacity of the final product.

Midstream activities involve the core manufacturing and assembly processes. This includes precision machining of the coupling components, precise arrangement and bonding of the permanent magnets onto the inner and outer rotors, and the fabrication of the containment shell to meet specific pressure and temperature ratings. Quality assurance through stringent testing, including torque testing, thermal cycling, and pressure integrity checks, is crucial at this stage. Technological expertise in magnetic circuit design is a key differentiator, allowing companies to maximize torque transmission while minimizing eddy current losses. Manufacturers focus on lean processes and high automation to maintain competitive production costs.

Downstream analysis focuses on Distribution Channels and reaching the End-Users. Distribution is multifaceted, involving both Direct and Indirect channels. Direct sales are common for highly customized, large-scale projects, such as supplying specialized pumps for major oil and gas refineries or nuclear power plants. Indirect channels involve established networks of industrial distributors, certified engineering firms, and specialized equipment suppliers who provide technical support, inventory, and localized service to smaller industrial clients and general manufacturing sectors. Effective aftermarket services, including spare parts availability and technical consultation on coupling sizing and installation, are vital for maintaining customer loyalty and ensuring long-term operational success in the highly demanding industrial market.

Magnetic Couplings Market Potential Customers

Potential customers for magnetic couplings are diverse, spanning virtually all heavy and process industries where fluid transfer and mixing are essential operations, especially under conditions where leakage poses environmental or safety risks. The primary buyers are original equipment manufacturers (OEMs) of industrial pumps, compressors, and agitators, who integrate these couplings into their sealed equipment packages to meet strict performance and reliability specifications. Major end-user/buyers include large chemical processing companies (e.g., manufacturers of specialty chemicals, polymers, and fertilizers) and integrated oil and gas companies (for pipeline pumps, wellhead injection systems, and offshore platforms), where the integrity of the containment barrier is critical to process safety and regulatory compliance.

Furthermore, critical infrastructure sectors, such as the Water and Wastewater Treatment industry, represent significant potential customers, requiring robust, reliable pumping solutions to handle corrosive media and ensure continuous operation with minimal maintenance downtime. The pharmaceutical and biotechnology industries also represent a high-value segment, utilizing magnetic couplings in sensitive mixing and homogenization equipment where sterility and the prevention of cross-contamination are paramount. These end-users prioritize couplings manufactured from inert, clean materials and often require extensive documentation and validation protocols, ensuring market opportunities for suppliers specializing in high-purity applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.7 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dymatix Couplings, Miki Pulley, Regal Rexnord, KTR Systems, Siemens, ABB, VSE, Huco Dynatork, Rexnord, Altra Industrial Motion, Dover Corporation, R+W America, HBE GmbH, Magnecraft, Tridex Couplings, Zero-Max, SIBRE, Renold, Voith, General Electric. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetic Couplings Market Key Technology Landscape

The technology landscape of the Magnetic Couplings Market is focused intensely on enhancing efficiency, thermal dissipation, and reliability through advanced material science and sophisticated design methodologies. A primary technological area involves the development of high-performance rare-earth magnets, specifically optimizing Neodymium Iron Boron (NdFeB) grades to resist demagnetization at higher operating temperatures, which is critical for high-speed or high-power applications often found in large compressors and turbines. Concurrently, manufacturers are investing in specialized containment shell materials, such as non-metallic composites (e.g., carbon fiber reinforced polymers) or advanced ceramics, which significantly reduce eddy current generation and subsequent heat loss compared to traditional stainless steel barriers, thereby improving the overall system efficiency and reducing cooling requirements.

Another crucial technological frontier is the refinement of magnetic circuit design using Finite Element Analysis (FEA) software. This allows engineers to simulate complex magnetic interactions and optimize the geometry, arrangement, and pole configuration of magnets, ensuring maximum torque transmission within the smallest possible volume, leading to more compact and lighter coupling units. This design sophistication is vital for applications with strict spatial constraints, such as robotics and aerospace systems. Furthermore, integrating smart monitoring technologies, including embedded sensors for temperature and vibration, linked to IIoT platforms, is becoming standard practice, enabling real-time condition monitoring and predictive maintenance, moving the technology toward a ‘Smart Coupling’ paradigm.

The market also sees continuous innovation in specialized coupling types, such as eddy current couplings, which offer inherent overload protection and soft start capabilities, catering specifically to systems requiring controlled acceleration and shock absorption. The push for higher operational parameters (increased speed and pressure) necessitates advancements in bearing technology used within the coupling assembly, favoring robust, corrosion-resistant bearings and, in some cases, magnetic bearings for completely contact-free operation. Overall, the technological evolution is centered on improving the power density and thermal stability of the couplings, ensuring they can reliably handle the increasingly demanding operational envelope of modern industrial machinery while upholding the zero-leakage promise.

Regional Highlights

- North America: Characterized by mature industrial infrastructure and rigorous environmental and safety standards, particularly in the Oil & Gas and Chemical sectors. The region shows robust adoption driven by retrofit and modernization projects focused on operational efficiency and compliance. The U.S. leads in adopting advanced monitoring technologies (IIoT integration) for couplings.

- Europe: Driven by strong regulatory support (e.g., REACH regulations) promoting leak-free systems and heavy investment in sustainable water management and nuclear power generation. Germany and the UK are key markets, characterized by high-precision manufacturing and high demand for customized, energy-efficient coupling solutions.

- Asia Pacific (APAC): The fastest-growing region, fueled by massive industrial expansion, particularly in chemical manufacturing, wastewater infrastructure, and power generation in China, India, and Southeast Asia. Rapid urbanization and subsequent industrial safety requirements are driving the large-scale procurement of magnetic couplings for new plant setups.

- Latin America: Growth is steady, primarily concentrated in resource-extraction industries (mining and oil & gas). Market adoption is driven by the need for reliable equipment in remote and often corrosive environments, demanding highly durable and low-maintenance coupling solutions.

- Middle East and Africa (MEA): Significant demand originating from massive investments in the regional petrochemical and desalination industries. The market requires couplings capable of operating reliably under extreme heat and handling highly corrosive or high-viscosity fluids, leading to high consumption of specialized, high-temperature magnetic materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Couplings Market.- Dymatix Couplings

- Miki Pulley

- Regal Rexnord

- KTR Systems

- Siemens

- ABB

- VSE

- Huco Dynatork

- Rexnord

- Altra Industrial Motion

- Dover Corporation

- R+W America

- HBE GmbH

- Magnecraft

- Tridex Couplings

- Zero-Max

- SIBRE

- Renold

- Voith

- General Electric

Frequently Asked Questions

Analyze common user questions about the Magnetic Couplings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using a magnetic coupling over a traditional mechanical seal?

The main advantage is the creation of a hermetically sealed barrier, ensuring zero leakage of fluids (crucial for hazardous or high-pressure applications). This eliminates common maintenance issues, reduces downtime, and significantly lowers operational costs associated with seal replacement and fluid loss.

How does the material of the containment shell affect coupling performance and efficiency?

The containment shell material is critical as it separates the magnetic rotors. Non-ferrous, composite materials (like carbon fiber or specialized plastics) or thin, non-magnetic metals (like Hastelloy or Titanium) are preferred because they minimize eddy current generation. High eddy currents create heat, lowering efficiency and risking demagnetization. Therefore, selecting low-conductivity materials maximizes torque transmission and thermal stability.

Which magnetic material dominates the market, and why is it preferred?

Neodymium Iron Boron (NdFeB) dominates the market. It is preferred due to its exceptionally high energy density (powerful magnetic field per unit volume), which allows manufacturers to achieve very high torque transmission in compact coupling designs. However, SmCo (Samarium Cobalt) is used in niche, high-temperature applications where NdFeB’s heat resistance limits are exceeded.

What is the main restraint to market growth for magnetic couplings?

The primary restraint is the high initial cost, driven largely by the expense and supply volatility of rare-earth permanent magnets (Neodymium and Samarium). While magnetic couplings offer lower total cost of ownership (TCO) through reduced maintenance, the high upfront investment can be a deterrent, especially for smaller-scale industrial applications.

In which end-user industry are magnetic couplings most critical for operational safety?

Magnetic couplings are most critical in the Chemical and Petrochemical industries. These sectors routinely handle highly toxic, volatile, or explosive fluids under high pressure. The zero-leakage capability provided by magnetic couplings is mandatory to prevent fugitive emissions, ensuring strict compliance with environmental regulations and dramatically mitigating catastrophic safety risks associated with fluid escape.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager