Magnetic Cylinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432914 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Magnetic Cylinder Market Size

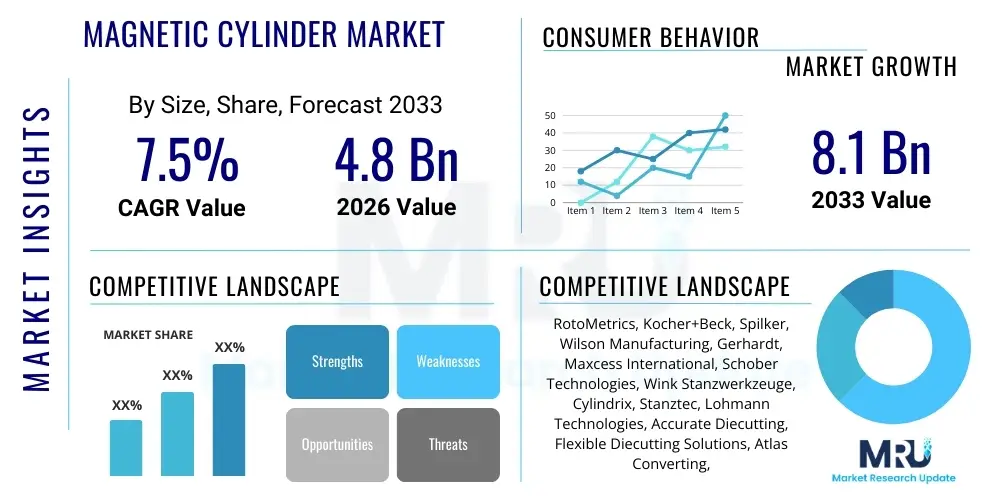

The Magnetic Cylinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 8.1 Billion by the end of the forecast period in 2033.

Magnetic Cylinder Market introduction

The Magnetic Cylinder Market encompasses the manufacturing, distribution, and utilization of precision rotary tools equipped with powerful magnetic features, primarily used in high-speed converting, printing, and die-cutting applications. These cylinders are integral components in flexible die systems, facilitating rapid and accurate mounting of thin, flexible dies (often referred to as magnetic dies). The core functionality revolves around providing precise registration and high tensile holding force necessary for demanding processes like label production, packaging perforation, and specialized converting operations. The market is defined by the critical need for operational efficiency, minimal downtime during job changeovers, and repeatable accuracy in industrial production environments where microns matter.

Magnetic cylinders typically consist of a precision-machined steel core embedded with high-energy permanent magnets, such as Neodymium Iron Boron (NdFeB), which ensure a uniformly strong magnetic field across the cylinder surface. These products are crucial for industries requiring complex geometries and high throughput, particularly the labeling and flexible packaging sectors, which are experiencing robust global expansion. Key applications span rotary die cutting for pressure-sensitive labels, converting materials such as thin films and foils, and specialized printing techniques requiring precise material registration. The consistency and reliability offered by these systems significantly enhance the overall productivity of modern converting machinery, making them essential capital expenditure items for manufacturers seeking a competitive edge.

The primary driving factors propelling this market include the relentless global demand for processed and packaged goods, which necessitates faster and more efficient label and packaging production lines. Furthermore, technological advancements leading to stronger magnetic materials and stricter manufacturing tolerances have improved cylinder lifespan and performance, thereby reducing operational costs for end-users. The transition away from traditional, less flexible die systems toward magnetic technology, offering quick set-up times and superior die alignment, underpins the positive growth trajectory. Benefits such as reduced material waste, ease of maintenance, and compatibility with high-speed presses further cement the Magnetic Cylinder Market's sustained growth potential across various industrial verticals.

Magnetic Cylinder Market Executive Summary

The Magnetic Cylinder Market is characterized by robust business trends centered on automation integration, material science innovation, and sustainability demands within the packaging and converting industries. Manufacturers are increasingly focusing on developing cylinders optimized for extreme high-speed applications and those capable of handling specialized, often thinner, sustainable substrates without compromising magnetic holding strength or cutting precision. Mergers, acquisitions, and strategic partnerships are prevalent strategies among key players aiming to expand global distribution networks and integrate vertical expertise, particularly in markets demanding intricate label designs and complex pharmaceutical packaging solutions. The shift toward shorter run lengths and increased personalization in packaging drives the necessity for flexible, fast-changeover tooling, directly boosting the demand for magnetic cylinder systems designed for versatility and quick adaptation.

Regionally, the Asia Pacific (APAC) continues to dominate the market growth landscape, driven by massive expansion in manufacturing capabilities, particularly in China and India, coupled with rapid urbanization and rising consumer spending leading to increased packaging consumption. North America and Europe, while mature, remain crucial markets characterized by high adoption of premium, technologically advanced cylinders focused on integrating smart manufacturing (Industry 4.0) principles, such as sensor integration for predictive maintenance and real-time performance monitoring. Emerging economies in Latin America and the Middle East and Africa (MEA) are also showing promising growth as local converting industries modernize their production lines to meet international quality standards and consumer demand for packaged goods.

Segment trends indicate a strong preference for high-precision, permanent magnet cylinders, particularly those utilizing rare-earth magnet technologies (NdFeB) due to their superior holding power and longevity compared to alternative electromagnetic systems. The printing and packaging application segment remains the largest revenue contributor, intrinsically linked to the global rise in e-commerce and subsequent requirements for efficient labeling and corrugated packaging production. Furthermore, the pharmaceutical and healthcare sectors represent a high-value growth niche, demanding cylinders manufactured to extremely tight tolerances for sterile and highly regulated product packaging and security labeling, focusing heavily on quality assurance and defect prevention capabilities embedded in the tooling systems.

AI Impact Analysis on Magnetic Cylinder Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Magnetic Cylinder Market primarily revolve around how AI can enhance manufacturing precision, optimize the operational lifespan of the cylinders, and integrate tooling data into smart factory ecosystems. Users are keenly interested in predictive maintenance models, asking if AI algorithms can forecast magnetic field decay or mechanical wear long before failure occurs, thereby minimizing costly unplanned downtime in high-speed rotary processes. Furthermore, there is significant inquiry into AI's role in optimizing the design phase, specifically using generative design techniques to create lighter, yet stronger, cylinder architectures with maximized magnetic uniformity. The consensus theme is the expectation that AI will transition magnetic cylinders from passive tools into active data-generating assets within the Industry 4.0 framework, improving overall equipment effectiveness (OEE) and accelerating quality control checks during production runs.

- AI-Driven Predictive Maintenance: Utilizing machine learning algorithms to analyze vibration, temperature, and run-time data from magnetic cylinders, predicting wear patterns, and scheduling preemptive replacements, thereby maximizing asset uptime and reducing maintenance costs.

- Optimized Generative Design: AI tools aid engineers in rapidly iterating cylinder designs, optimizing magnet placement, material distribution, and overall thermal stability to achieve maximum magnetic force uniformity while minimizing cylinder mass.

- Enhanced Quality Control (QC): AI-powered vision systems integrated with the converting machinery analyze the precision cutting results produced by the cylinder in real-time, instantly identifying registration errors or incomplete cuts caused by subtle cylinder defects or material inconsistencies.

- Supply Chain and Inventory Management: AI models predict future demand for specific cylinder sizes and configurations based on historical usage and forward-looking production schedules, optimizing inventory levels of raw materials (e.g., rare earth magnets) and finished goods.

- Process Parameter Optimization: Machine learning helps fine-tune the interactions between the magnetic cylinder, the flexible die, the substrate, and the machine pressure settings, ensuring optimal performance and extending the operational life of the cutting tools across different job specifications.

DRO & Impact Forces Of Magnetic Cylinder Market

The Magnetic Cylinder Market is fundamentally driven by the rising automation needs across global manufacturing sectors, particularly packaging and labeling, where speed and precision are paramount. Key drivers include the exponential growth of e-commerce, which requires massive volumes of quick-changeover labels and corrugated packaging elements, forcing manufacturers to invest in highly efficient rotary tooling. Technological advancement in magnetic materials, notably the increased availability and improved strength of Neodymium magnets, allows for the creation of cylinders with higher holding power and narrower tolerances, facilitating faster line speeds and greater cutting accuracy. Furthermore, the shift towards environmentally friendly, thinner substrates in packaging mandates the use of highly precise die-cutting tools that magnetic cylinders provide, preventing material tearing or slippage during conversion.

However, the market faces significant restraints, primarily related to the volatile pricing and supply chain complexities associated with rare earth materials used in high-performance magnets (e.g., Neodymium). Geopolitical instability surrounding these raw material sources introduces risk and cost fluctuations that can impact final product pricing. Additionally, the high initial capital investment required for magnetic cylinder systems, particularly bespoke, high-tolerance units tailored for specialized machinery, can be prohibitive for smaller converting operations. The technical expertise required for the proper setup, handling, and maintenance of precision magnetic tooling also acts as a restraint in regions with inadequate skilled labor pools, potentially leading to operational inefficiencies if not managed correctly.

Significant opportunities exist in the expansion of custom tooling services tailored for specialized sectors such as security printing (anti-counterfeiting labels), medical device manufacturing (sterile packaging), and flexible electronics. The growing trend toward personalized packaging and shorter production runs creates a continuous demand for new, flexible magnetic cylinders adaptable to diverse job specifications. The impact forces driving the market include competitive pressure among label manufacturers to reduce lead times and improve quality, technological obsolescence of older mechanical die systems, and stringent global regulatory standards for packaging safety and traceability. The interplay between these forces necessitates continuous innovation in cylinder design and manufacturing processes, focusing on maximizing efficiency and durability, thereby solidifying the magnetic cylinder's role as a mission-critical component in the modern rotary converting industry.

Segmentation Analysis

Market segmentation provides a critical framework for understanding the diverse dynamics and growth pockets within the Magnetic Cylinder Market, allowing stakeholders to target investments and product development effectively. The market is broadly categorized based on the core technology utilized (Product Type), which defines the cylinder's operational characteristics, and the specific industrial end-use (Application), which dictates design specifications and volume demand. Analyzing these segments helps reveal where the highest growth potential resides—for instance, high-strength permanent magnet cylinders dominate due to their energy efficiency and consistent magnetic field, while the packaging application segment offers the largest volume demand due to global consumer trends.

Further granularity is achieved by evaluating regional consumption patterns, where high-cost, customized solutions are prevalent in mature markets (North America, Europe), and standardized, high-volume production cylinders drive growth in rapidly industrializing regions (APAC). Understanding these segments allows manufacturers to tailor their supply chains, marketing strategies, and R&D efforts. For example, focusing on the pharmaceutical application segment requires adherence to stricter material certifications and dimensional accuracy, differentiating the required technology and pricing structure from general consumer labeling applications.

- By Product Type:

- Permanent Magnet Cylinders

- Electromagnetic Cylinders

- Flexible Magnetic Cylinders (Secondary Category)

- By Application:

- Rotary Die Cutting (Labels, Packaging)

- Flexographic Printing (Mounting plates)

- Converting Operations (Perforating, Scoring)

- Specialty Applications (Security Tags, Medical Devices)

- By Industry Vertical:

- Packaging and Labeling

- Food and Beverage

- Pharmaceuticals and Healthcare

- Automotive and Electronics

- Textile and Film Converting

- By Manufacturing Process:

- Standard Machining

- Precision CNC Machining

- Custom Engineered Solutions

Value Chain Analysis For Magnetic Cylinder Market

The value chain for the Magnetic Cylinder Market begins with upstream activities heavily reliant on the sourcing and processing of specialized raw materials. This includes high-grade alloy steels (for the cylinder body) and, most critically, rare earth magnetic materials, predominantly Neodymium, Iron, and Boron (NdFeB), which require sophisticated mining, separation, and sintering processes. The volatility of rare earth prices and supply chain concentration necessitates strategic supplier relationship management at this stage. Following material acquisition, manufacturing involves precision machining, specialized magnet embedding techniques, and rigorous quality control checks to ensure extremely tight tolerances (often within single-digit microns) crucial for high-speed operation and consistent die-cutting results. This highly specialized manufacturing phase represents a major value-add in the chain.

The distribution channel operates through a mix of direct and indirect sales models. Direct sales are common for high-volume orders or highly customized, integrated solutions where the cylinder manufacturer works closely with the original equipment manufacturers (OEMs) of rotary presses and converting machines. This partnership ensures seamless integration and optimized performance. Indirect distribution utilizes specialized industrial tooling distributors and regional agents who provide localized support, technical expertise, and quicker delivery times for standardized or replacement magnetic cylinders to end-users (converting houses and printers). Aftermarket services, including cylinder refurbishment, repair, and magnetic field recalibration, form a critical part of the downstream value proposition, ensuring product longevity and consistent performance for the customer.

Downstream activities center on the end-use application sectors, dominated by the packaging and labeling industry. The value realized downstream is defined by the cylinder's ability to maximize throughput, minimize material waste, and facilitate rapid job changeovers. Customers are increasingly focused on total cost of ownership (TCO) rather than upfront price, valuing reliability, durability, and the supplier's capacity to provide rapid, high-quality technical support. The entire value chain is therefore influenced by customer demand for greater automation and seamless integration of tooling data into factory management systems, pushing manufacturers to invest in R&D not just in magnetics, but also in digital and sensor technology embedded within the cylinders themselves.

Magnetic Cylinder Market Potential Customers

Potential customers for magnetic cylinders are primarily organizations involved in high-volume, precision rotary converting and printing operations where tooling accuracy and speed are critical determinants of profitability. The largest segment of buyers comprises commercial printing and labeling houses, particularly those specializing in pressure-sensitive labels, shrink sleeves, and flexible packaging films. These companies continually purchase new cylinders to match expanding press lines, replace worn tooling, and accommodate new product specifications or unique die designs required by brand owners and consumer goods manufacturers.

Another major segment includes Original Equipment Manufacturers (OEMs) of flexographic printing presses, rotary die cutters, and converting machinery. These OEMs are high-volume, direct buyers who integrate magnetic cylinders as standard components into their advanced machinery sold globally. Their purchasing decisions are driven by factors like magnetic force consistency, durability, compatibility with high-speed automation systems, and the ability of the cylinder to maintain performance under continuous, heavy industrial loads, forming long-term supply agreements with cylinder manufacturers.

Specialized industries, such as pharmaceuticals, healthcare, and electronics manufacturing, represent high-value, niche customers. These buyers require customized magnetic cylinders built to extremely stringent tolerances for specialized applications, including micro-cutting sterile packaging, producing medical device components, or manufacturing precise electronic film overlays. For these customers, critical purchasing criteria include certified material traceability, superior surface finishing to prevent contamination, and validation of dimensional accuracy necessary to meet strict industry regulations and quality standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 8.1 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | RotoMetrics, Kocher+Beck, Spilker, Wilson Manufacturing, Gerhardt, Maxcess International, Schober Technologies, Wink Stanzwerkzeuge, Cylindrix, Stanztec, Lohmann Technologies, Accurate Diecutting, Flexible Diecutting Solutions, Atlas Converting, Dieflex, Magna-Cylinders, Custom Rotary Tooling, Precision Tooling Systems, Cylinder Technology Inc., Rotec Cylinders |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetic Cylinder Market Key Technology Landscape

The technology landscape of the Magnetic Cylinder Market is primarily defined by advancements in three critical areas: material science, precision machining, and digital integration. In material science, the shift towards utilizing ultra-high energy density permanent magnets, specifically sintered Neodymium Iron Boron (NdFeB) grades, is paramount. These materials provide significantly higher magnetic flux density compared to traditional ferrite magnets, allowing cylinder manufacturers to achieve stronger, more consistent holding forces across larger surface areas while potentially reducing the overall weight and mass of the cylinder assembly. Research focuses on magnet coating technologies and corrosion resistance to maintain magnetic integrity and operational performance in harsh industrial environments involving inks, adhesives, and chemical cleaning agents, ensuring a longer effective lifespan for the tooling.

Precision machining techniques, particularly sophisticated CNC (Computer Numerical Control) grinding and turning, are foundational to the cylinder's function. The demand for sub-micron level manufacturing tolerances is non-negotiable, as even slight variations in cylinder geometry lead to registration errors, uneven cutting, and premature die wear, especially in high-speed, multi-color printing or complex die-cutting operations. Modern cylinder manufacturers employ advanced thermal stabilization and stress-relieving processes during manufacturing to prevent dimensional changes caused by operational heat buildup or high centrifugal forces. Furthermore, surface finishing technologies, such as specialized hard coatings (e.g., chromium or proprietary ceramic layers), are applied to enhance wear resistance and improve release characteristics when working with challenging adhesive materials.

Digital integration marks the newest frontier, aligning magnetic cylinder technology with Industry 4.0 paradigms. This includes embedding passive or active sensor technology (such as RFID tags or specialized magneto-resistive sensors) within the cylinders to monitor critical operational parameters, including temperature, vibration, and total rotational hours. This data is crucial for implementing AI-driven predictive maintenance schedules. Future developments are focused on cylinders with active magnetic adjustment capabilities, potentially allowing minor corrections to the magnetic field distribution via controlled electromagnets to compensate for substrate inconsistencies or die deflection in real-time, thereby maximizing cutting yield and further enhancing the reliability of the high-precision rotary converting process.

Regional Highlights

- Asia Pacific (APAC) Market Dominance: The APAC region is the fastest-growing market, driven by rapid industrialization, massive investments in manufacturing infrastructure, and the expansion of the middle class, fueling explosive demand for packaged goods and consumer electronics. Countries like China, India, and Southeast Asian nations are modernizing their printing and converting capabilities, leading to high adoption rates of advanced, high-speed rotary presses that require magnetic cylinders. The market here is volume-driven, with substantial domestic production capacity for both the cylinders and the machinery they operate in.

- North America (NA) Focus on Automation and Quality: The North American market is mature but highly focused on quality, automation, and technological integration. Demand is characterized by a strong emphasis on highly customized, high-tolerance cylinders used in specialized sectors like pharmaceutical labeling, medical device packaging, and intricate consumer branding. The adoption of smart factory initiatives (Industry 4.0) promotes the purchase of cylinders equipped with data-logging capabilities and designed for seamless integration with sophisticated automated material handling systems.

- Europe Market for Sustainability and Precision: Europe maintains a significant market share, characterized by stringent regulatory requirements related to packaging sustainability and food contact materials. This drives demand for magnetic cylinders capable of handling thinner, more challenging biodegradable and recycled substrates with exceptional precision. European manufacturers are leaders in developing advanced flexible dies and corresponding magnetic tooling that minimize material waste and optimize energy consumption during the conversion process. Germany and Italy, home to major converting machinery manufacturers, act as central hubs for technology development and consumption.

- Latin America (LATAM) Modernization Wave: The LATAM market, while smaller, is undergoing a substantial modernization wave, moving away from older mechanical systems toward efficient rotary converting technology. This shift is prompted by increasing local and international investment in food processing and beverage production. Brazil and Mexico are key growth centers, where demand is focused on robust, reliable magnetic cylinders that offer a good balance of cost-effectiveness and performance to upgrade aging industrial facilities.

- Middle East & Africa (MEA) Infrastructure Development: The MEA region is exhibiting emerging growth linked to ongoing infrastructure development, particularly in the UAE and Saudi Arabia, where investment in sophisticated processing and packaging plants is rising. The demand for magnetic cylinders is currently concentrated in sectors related to domestic consumer goods and regional export packaging, with a growing emphasis on durable tooling solutions suitable for continuous, high-temperature operation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Cylinder Market.- RotoMetrics

- Kocher+Beck

- Spilker GmbH

- Wilson Manufacturing

- Gerhardt GmbH

- Maxcess International

- Schober Technologies

- Wink Stanzwerkzeuge

- Cylindrix Tooling

- Stanztec GmbH

- Lohmann Technologies

- Accurate Diecutting

- Flexible Diecutting Solutions

- Atlas Converting Equipment

- Dieflex International

- Magna-Cylinders Corp.

- Custom Rotary Tooling Inc.

- Precision Tooling Systems

- Cylinder Technology Inc.

- Rotec Cylinders

Frequently Asked Questions

Analyze common user questions about the Magnetic Cylinder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the growth of the Permanent Magnet Cylinder segment?

The Permanent Magnet Cylinder segment is predominantly driven by the superior energy efficiency and operational consistency offered by rare earth magnets, such as Neodymium. These cylinders provide significantly higher, more stable magnetic holding power required for high-speed rotary die-cutting, ensuring precise registration and minimizing downtime without requiring external power, leading to lower operating costs and extended tool life.

How does magnetic cylinder manufacturing ensure high precision for critical applications?

High precision is achieved through meticulous manufacturing processes utilizing multi-axis CNC machining and precision grinding, often achieving tolerances below five microns. This is combined with specialized magnet embedding techniques and thermal stabilization treatments to prevent warping or dimensional shift, ensuring the cylinder geometry remains perfect under extreme operating temperatures and pressures common in advanced converting machinery.

Which industry vertical accounts for the largest demand for magnetic cylinders globally?

The Packaging and Labeling industry vertical accounts for the largest demand globally. The rapid expansion of e-commerce, coupled with the need for high-quality, customized labels and specialized flexible packaging (including folding cartons and security seals), necessitates the highly efficient and quick-change tooling solutions provided by magnetic cylinders.

What challenges does the market face regarding raw material supply?

The primary raw material challenge is the supply and price volatility of rare earth magnets (Neodymium). Supply chain concentration in specific geographic regions and geopolitical factors often lead to price fluctuations and potential disruptions, compelling manufacturers to seek diversified sourcing strategies and explore alternative, non-rare earth magnetic compounds for certain applications.

What role does Industry 4.0 play in the future development of magnetic cylinders?

Industry 4.0 facilitates the integration of magnetic cylinders as "smart tools." Future development focuses on embedding sensor technology (IIoT) into the cylinders to capture real-time data on performance and wear, enabling AI-driven predictive maintenance and allowing the cylinder to communicate directly with the converting press management system for automatic process optimization and quality assurance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager