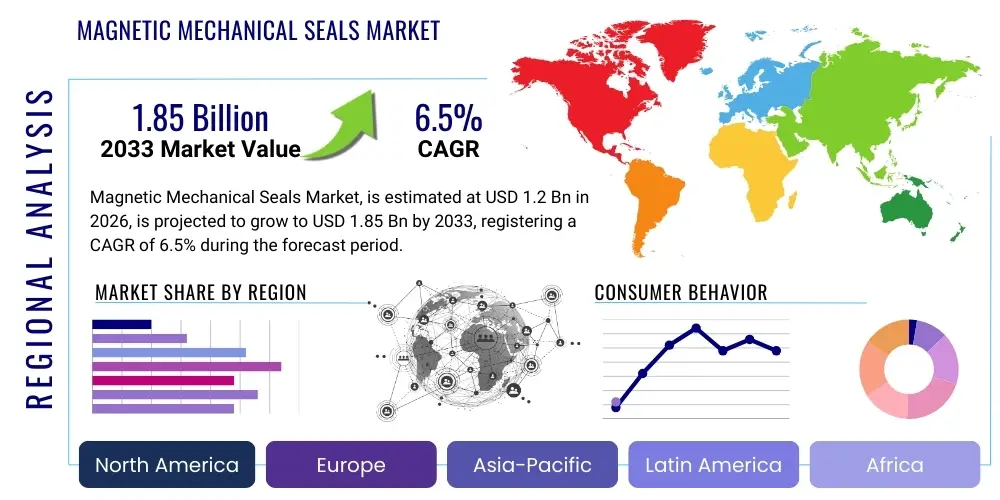

Magnetic Mechanical Seals Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438529 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Magnetic Mechanical Seals Market Size

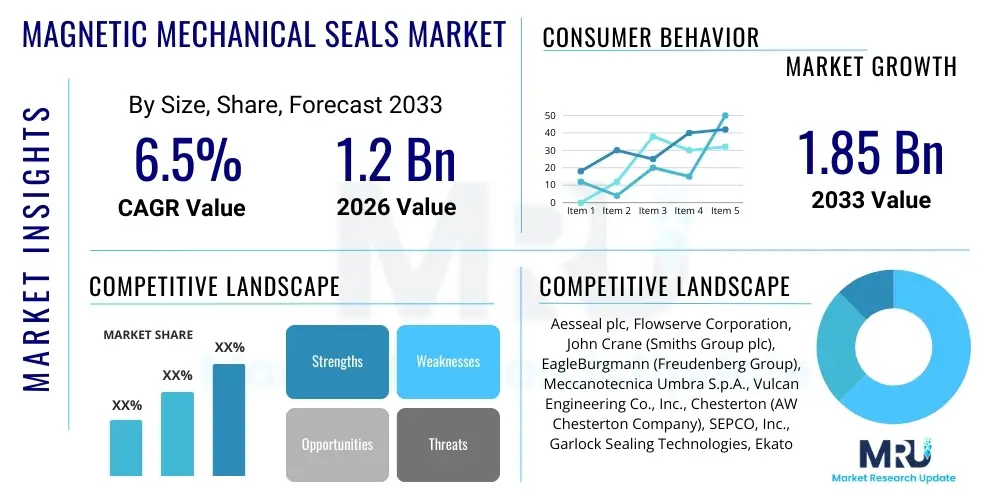

The Magnetic Mechanical Seals Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.85 Billion by the end of the forecast period in 2033.

Magnetic Mechanical Seals Market introduction

The Magnetic Mechanical Seals Market encompasses advanced sealing solutions primarily used in rotating equipment where absolute zero leakage of hazardous, corrosive, or high-purity media is mandatory. Magnetic seals operate based on the principle of magnetic coupling, which transmits torque through a containment shell, thus eliminating the need for dynamic shaft sealing mechanisms that are prone to friction and leakage. This non-contact design ensures exceptional longevity and reliability compared to traditional mechanical seals, making them indispensable in sensitive industrial processes. Key features include hermetic isolation of the process fluid, high-speed operation capability, and minimal maintenance requirements, directly addressing stringent environmental regulations and operational safety standards across global industries.

These specialized seals find major applications across various high-stakes sectors, including the chemical processing industry (CPI), pharmaceutical manufacturing, oil and gas, and nuclear power generation. In chemical plants, magnetic seals are essential for handling toxic fluids like acids and volatile organic compounds (VOCs) within pumps, mixers, and compressors, ensuring operator safety and preventing fugitive emissions. The pharmaceutical industry utilizes them extensively in sterile mixing applications and bioreactors where product integrity and contamination prevention are paramount. Furthermore, their suitability for high-pressure and high-temperature environments in petrochemical refineries reinforces their position as critical components for maximizing uptime and operational efficiency.

The primary driving factors for market growth include the escalating global focus on industrial safety and stricter environmental mandates concerning leakage and emissions, particularly in developed economies. The rising adoption of sealless pump technologies, which inherently utilize magnetic couplings or canned motor designs, further stimulates demand for integrated magnetic seal systems. Benefits derived from their implementation—such as reduced operational expenditure (OPEX) due to minimized maintenance, enhanced equipment reliability, and superior performance in extreme conditions—solidify the value proposition of magnetic mechanical seals, underpinning their sustained adoption across complex industrial landscapes globally.

Magnetic Mechanical Seals Market Executive Summary

The Magnetic Mechanical Seals Market is characterized by a persistent shift towards custom-engineered solutions that accommodate increasingly demanding operational parameters, such as ultra-high pressure, cryogenic temperatures, and exotic material compatibility required for handling highly corrosive media. Business trends indicate a strong emphasis on smart sealing solutions incorporating sensors for predictive maintenance, allowing end-users to monitor seal performance in real-time, anticipate failures, and significantly reduce unplanned downtime. Consolidation among major market players, alongside strategic acquisitions aimed at expanding technological portfolios, particularly in materials science (e.g., advanced ceramics and high-performance elastomers), defines the current competitive landscape, driving innovation in seal face designs and lubrication methods.

Regional trends highlight that Asia Pacific (APAC), driven primarily by rapid industrialization, expansion of chemical manufacturing, and burgeoning infrastructure projects in China and India, represents the fastest-growing market for magnetic mechanical seals. North America and Europe, while mature, maintain dominant positions in terms of technology adoption and high-value applications, largely owing to stringent regulatory frameworks (like EPA and REACH guidelines) that necessitate zero-leakage sealing technology, particularly in the oil and gas and specialty chemicals sectors. The Middle East and Africa (MEA) exhibit steady growth fueled by significant investments in the downstream oil and gas industry and desalination plants, where magnetic seals offer robust performance in harsh operating environments.

Segment trends underscore the dominance of the double-seal configuration segment due to its inherent redundancy and enhanced safety features, particularly preferred in applications involving volatile or toxic fluids. Material segmentation shows increasing preference for specialized materials like silicon carbide and high-density carbon graphites which offer superior wear resistance and thermal stability. End-user analysis confirms the Chemical Processing Industry (CPI) and Oil & Gas sectors as the largest consumers, although the pharmaceutical segment is experiencing accelerated demand, specifically for hermetically sealed magnetic agitators and mixers required for sterile processing environments.

AI Impact Analysis on Magnetic Mechanical Seals Market

User queries regarding AI’s influence primarily revolve around three areas: predictive maintenance capabilities, optimization of manufacturing processes, and design phase integration. Users seek clarity on how AI algorithms can leverage sensor data (temperature, vibration, pressure) gathered from magnetic seals to predict wear patterns and failure points long before conventional monitoring systems, thereby maximizing operational uptime. Concerns also focus on the cost-effectiveness and complexity of integrating sophisticated AI models with existing industrial control systems (ICS). The expectation is that AI will streamline material selection for complex chemical compatibility and optimize seal geometry design parameters for maximum energy efficiency and reliability, pushing the boundaries of current engineering limitations through rapid simulation and iteration.

- AI-driven predictive maintenance modeling minimizes seal failure and extends Mean Time Between Failures (MTBF).

- Machine learning algorithms optimize manufacturing parameters, improving the precision and quality control of seal components (e.g., magnet alignment and material sintering).

- AI assists in complex material compatibility analysis, accelerating the selection of specialized alloys and ceramics for extreme fluid environments.

- Generative design tools, powered by AI, optimize hydraulic balance and thermal management within the magnetic seal configuration, reducing energy consumption.

- Real-time anomaly detection using AI processing of vibration and temperature data enhances operational safety and compliance.

- Automated quality inspection systems using computer vision improve the efficiency of defect detection during the seal assembly phase.

- Enhanced inventory management and demand forecasting for replacement parts driven by AI predictions of installed base component lifecycles.

DRO & Impact Forces Of Magnetic Mechanical Seals Market

The market dynamics are fundamentally driven by the confluence of increasing regulatory pressure and the technological superiority of magnetic seals over traditional alternatives. Drivers include the global mandate for controlling fugitive emissions (VOCs and hazardous air pollutants) set by environmental bodies, which directly necessitates the use of zero-leakage sealing solutions in critical rotating machinery. Furthermore, the operational cost benefits derived from reduced downtime and lower consumption of barrier fluids associated with magnetic seals significantly incentivize their adoption across capital-intensive industries. The growing complexity of process fluids—requiring high-pressure, high-temperature, and corrosive media handling—further pushes manufacturers towards the robust and non-contact operation intrinsic to magnetic technology.

Restraints primarily revolve around the high initial capital expenditure (CapEx) associated with magnetic mechanical seal systems, which are significantly more expensive than standard packing or conventional single mechanical seals. The complexity of installation and specialized maintenance requirements also pose hurdles, particularly for smaller facilities or regions lacking highly trained technical personnel capable of handling precision magnetic components. Another constraint is the inherent limitation on axial movement tolerance; if significant shaft misalignment or excessive vibration occurs, the magnetic coupling gap can be compromised, leading to demagnetization or contact failure, thus requiring extremely precise equipment alignment.

Opportunities in the market are abundant, particularly in emerging applications such as hydrogen compression and carbon capture and storage (CCS) technologies, where maintaining system integrity and preventing leakage of high-pressure gases is paramount. The expansion of utility-scale solar and wind energy production requires specialized sealing for cooling pumps and lubrication systems operating in remote environments, favoring the low-maintenance profile of magnetic seals. Furthermore, technological advancements focused on developing higher-strength magnetic materials (like rare-earth magnets) capable of operating effectively at higher temperatures, alongside the integration of condition monitoring systems (sensors and IoT), represent key avenues for future market expansion and value addition. These factors create a powerful impact force pushing the market towards sustained double-digit growth in specialized segments.

Segmentation Analysis

The Magnetic Mechanical Seals market is systematically analyzed based on type, material, application, and end-use industry. Segmentation by type differentiates between single-stage and multi-stage configurations, while material segmentation highlights the dependence on specialized alloys, ceramics, and graphites essential for performance longevity in corrosive environments. Application segmentation focuses on the specific machinery where the seals are deployed, such as pumps, compressors, and agitators. Analyzing these segments provides strategic insights into the technological preferences and consumption patterns across various industrial verticals, reflecting the specialized requirements of each sector.

- By Type:

- Single-Stage Magnetic Seals

- Multi-Stage Magnetic Seals

- Custom-Engineered Seals

- By Material:

- Stainless Steel

- Exotic Alloys (e.g., Hastelloy, Inconel)

- Ceramics (e.g., Silicon Carbide, Alumina)

- Carbon Graphite

- Rare-Earth Magnets (Neodymium, Samarium-Cobalt)

- By Application:

- Pumps (Centrifugal, Gear, Positive Displacement)

- Compressors and Blowers

- Mixers and Agitators

- Reactors and Vessels

- By End-Use Industry:

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical Processing Industry (CPI)

- Pharmaceutical and Biotechnology

- Food and Beverage

- Power Generation (Nuclear, Thermal)

- Water and Wastewater Treatment

Value Chain Analysis For Magnetic Mechanical Seals Market

The value chain for the Magnetic Mechanical Seals market begins with the upstream segment, dominated by specialized raw material suppliers. This segment involves the meticulous sourcing and processing of high-pgrade materials, including advanced ceramics (like reaction-bonded silicon carbide), high-performance elastomers, specialized metallic alloys (for seal housings), and critical rare-earth elements necessary for manufacturing the high-strength permanent magnets. Suppliers in this phase require high metallurgical expertise and adherence to strict quality controls, as the integrity and longevity of the final seal product are directly dependent on the purity and homogeneity of these base materials. Fluctuations in the cost and supply chain stability of rare-earth magnets, particularly Neodymium, significantly impact the overall manufacturing cost and pricing strategy downstream.

The central segment involves the core manufacturing, assembly, and R&D activities conducted by the key market players. This phase includes precision machining of seal faces and housings, magnetic assembly design, and the integration of auxiliary components like containment shells and bearing systems. Manufacturers invest heavily in sophisticated testing and simulation facilities to ensure seals meet rigorous API and ISO standards for pressure, temperature, and chemical resistance. Customization is a key driver here, as many applications require seals tailored to unique equipment dimensions and fluid characteristics. The ability to innovate seal geometries and develop robust material pairings provides a significant competitive advantage in this complex manufacturing stage.

The distribution channel facilitates the connection between manufacturers and end-users, operating through a combination of direct sales and specialized indirect distribution networks. For highly technical and custom solutions, direct sales and engineering support are essential, ensuring correct selection, installation, and commissioning. Indirect channels, comprising authorized distributors and service partners, are crucial for aftermarket support, offering regional inventory of standard seals and crucial repair services. The downstream segment involves installation, monitoring, and ongoing maintenance services. Given the complexity and criticality of magnetic seals, comprehensive aftermarket support, including rapid replacement seal delivery and specialized field service expertise, is vital for retaining customer loyalty and maximizing the lifespan of the installed base.

Magnetic Mechanical Seals Market Potential Customers

The primary end-users and buyers of magnetic mechanical seals are large industrial entities operating in sectors characterized by high operational risk, stringent regulatory requirements, and the handling of hazardous or high-value fluids. The Chemical Processing Industry (CPI) remains a cornerstone customer base, purchasing seals for use in petrochemical reactors, solvent handling pumps, and high-pressure chemical mixers. These buyers prioritize zero-leakage capabilities to comply with environmental laws and ensure worker safety, often procuring high-specification, double-containment magnetic seals rated for extremely corrosive service and demanding P&T (pressure and temperature) profiles, necessitating custom engineering and extensive material validation.

The Oil and Gas industry, particularly the downstream refining and midstream pipeline sectors, represents another significant cohort of potential customers. Refineries utilize magnetic seals extensively in process pumps and compressors handling volatile hydrocarbons, ensuring minimal loss of product and preventing environmental contamination. Procurement decisions in this sector are heavily influenced by adherence to standards such as API 682, focusing on reliability, MTBF, and the supplier's capacity for global field service support. The continuous need for equipment upgrades and maintenance turnarounds in existing infrastructure ensures a steady demand for both new installations and replacement seals.

Beyond the core heavy industries, the Pharmaceutical and Biotechnology sectors are emerging as high-growth customers. In these industries, the primary driver is sterility and prevention of contamination during the production of drugs, vaccines, and sterile media. Customers in Pharma require magnetic seals for fermenters, high-shear mixers, and clean-in-place (CIP) systems, demanding materials certified for bio-compatibility and designs that eliminate crevices where microbial growth could occur. Their purchasing criteria are focused on validation documentation, compliance with Good Manufacturing Practices (GMP), and the highest level of product purity assurance achievable through hermetically sealed systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.85 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aesseal plc, Flowserve Corporation, John Crane (Smiths Group plc), EagleBurgmann (Freudenberg Group), Meccanotecnica Umbra S.p.A., Vulcan Engineering Co., Inc., Chesterton (AW Chesterton Company), SEPCO, Inc., Garlock Sealing Technologies, Ekato Group, Sulzer Ltd., Timken Company, Rotork plc, SKF Group, Parker Hannifin Corporation, Trelleborg AB, Burgmann Industries, Stein Seal Company, Teikoku Electric Mfg. Co., Ltd., KSB Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetic Mechanical Seals Market Key Technology Landscape

The core technology driving the Magnetic Mechanical Seals market is the sophisticated integration of permanent magnetism and precision engineering to achieve non-contact torque transmission. The primary focus remains on optimizing the magnetic coupling mechanism, particularly through the use of high-energy rare-earth magnets, such as Neodymium Iron Boron (NdFeB) and Samarium Cobalt (SmCo). SmCo is preferred in high-temperature applications due to its superior resistance to demagnetization compared to NdFeB, despite the latter offering higher magnetic strength at ambient temperatures. Ongoing technological development centers on enhancing the eddy current losses within the containment shell—which generates heat—through innovative material selection (often specialized non-magnetic, high-resistivity metals like Hastelloy C or certain composites) to minimize thermal stress and maximize operating speeds.

A crucial area of technological advancement involves tribology and material science pertaining to the backup bearings and seal faces used in the event of magnetic coupling failure or dry running conditions. Manufacturers are increasingly utilizing advanced composite materials and hard-facing technologies, such as plasma-sprayed ceramics or tungsten carbide coatings, to maximize the lifespan and minimize friction during transitional contact. Furthermore, research into ferrofluidic sealing technology, while distinct, often influences design choices in magnetic seals, leading to hybrid systems that utilize magnetic principles to stabilize the primary seal interface or provide an auxiliary barrier. The development of standardized modular designs capable of fitting a wider range of existing pump and mixer infrastructure is also a strong technological focus, aiming to reduce customization costs and lead times.

The integration of digital technology is rapidly becoming a fundamental part of the seal landscape, transitioning seals from passive components to active, monitored systems. Key technologies include embedding miniaturized sensors (IoT integration) within the seal housing to continuously measure vital parameters such as temperature, shaft vibration, and pressure differential across the containment shell. This data is processed locally and transmitted wirelessly, enabling sophisticated Condition Monitoring Systems (CMS). The use of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) software allows engineers to precisely model thermal gradients and stress distributions before physical prototyping, significantly accelerating product development and ensuring seals are robust enough for supercritical applications like nuclear reactor cooling loops or high-pressure gas compressors.

Regional Highlights

- Asia Pacific (APAC): Leading the market growth due to expansive industrial development, especially in China, India, and Southeast Asia. Heavy investments in chemical plants, oil and gas infrastructure, and pharmaceutical manufacturing drive demand for zero-leakage sealing solutions to meet rapidly evolving environmental standards and increase production capacity.

- North America: A mature market characterized by stringent regulatory environments (EPA mandates) and high technology adoption rates. Dominance is observed in the high-value oil and gas sector (shale operations) and advanced manufacturing, demanding highly reliable, API-certified magnetic seals for critical rotating equipment.

- Europe: Exhibits steady growth, primarily driven by the robust chemical and pharmaceutical industries in Germany, France, and the UK. Emphasis is placed on energy efficiency, compliance with REACH regulations, and the integration of smart, IoT-enabled seals for predictive maintenance strategies across heavy industries.

- Middle East and Africa (MEA): Growth is tied directly to large-scale investment in the downstream refining and petrochemical processing capacity, particularly in Saudi Arabia and the UAE. Demand is high for magnetic seals capable of withstanding the region's harsh operating conditions (high temperature, abrasive media) in desalination and hydrocarbon extraction projects.

- Latin America: Showing gradual uptake, supported by the modernization of existing chemical and oil and gas infrastructure, particularly in Brazil and Mexico. Economic stabilization and renewed investment in manufacturing capabilities are boosting the requirement for reliable, maintenance-free sealing solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Mechanical Seals Market.- Aesseal plc

- Flowserve Corporation

- John Crane (Smiths Group plc)

- EagleBurgmann (Freudenberg Group)

- Meccanotecnica Umbra S.p.A.

- Vulcan Engineering Co., Inc.

- Chesterton (AW Chesterton Company)

- SEPCO, Inc.

- Garlock Sealing Technologies

- Ekato Group

- Sulzer Ltd.

- Timken Company

- Rotork plc

- SKF Group

- Parker Hannifin Corporation

- Trelleborg AB

- Burgmann Industries

- Stein Seal Company

- Teikoku Electric Mfg. Co., Ltd.

- KSB Group

Frequently Asked Questions

Analyze common user questions about the Magnetic Mechanical Seals market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of magnetic mechanical seals over conventional seals?

The chief advantage is the guaranteed zero-leakage operation achieved through non-contact torque transmission via a magnetic coupling, which hermetically isolates the process fluid. This eliminates fugitive emissions, drastically reduces maintenance, and enhances operational safety, especially when handling hazardous or toxic media.

In which industries are magnetic mechanical seals most critically utilized?

Magnetic mechanical seals are most critically utilized in the Chemical Processing Industry (CPI), Oil and Gas (refining and processing), and Pharmaceutical/Biotechnology sectors where zero contamination, high reliability, and stringent environmental compliance regarding emissions are absolute requirements for pumps, mixers, and reactors.

What are the main restraints impacting the growth of the magnetic mechanical seals market?

The primary restraints include the significantly higher initial capital investment compared to standard sealing solutions, and the need for specialized technical expertise for installation, alignment, and maintenance, limiting adoption in cost-sensitive or less technologically mature operational environments.

How does the material composition of the containment shell affect seal performance?

The containment shell material is crucial as it separates the inner and outer magnets. It must be non-magnetic and highly resistant to eddy current losses which generate heat. Materials like Hastelloy or special polymers are used to maintain high efficiency and prevent thermal degradation and demagnetization of the coupling, particularly at high operating speeds.

What role does predictive maintenance play in the future of magnetic seals?

Predictive maintenance, enabled by integrating IoT sensors and AI analytics, is pivotal. It allows for the continuous monitoring of key parameters (vibration, temperature), predicting component wear and potential failure modes, thereby shifting maintenance from reactive to proactive, maximizing equipment uptime, and reducing lifecycle costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager