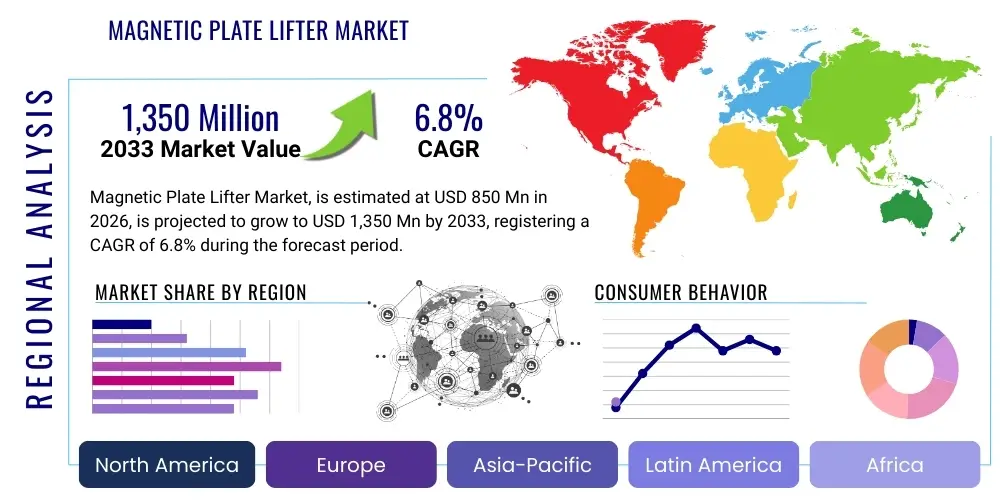

Magnetic Plate Lifter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438085 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Magnetic Plate Lifter Market Size

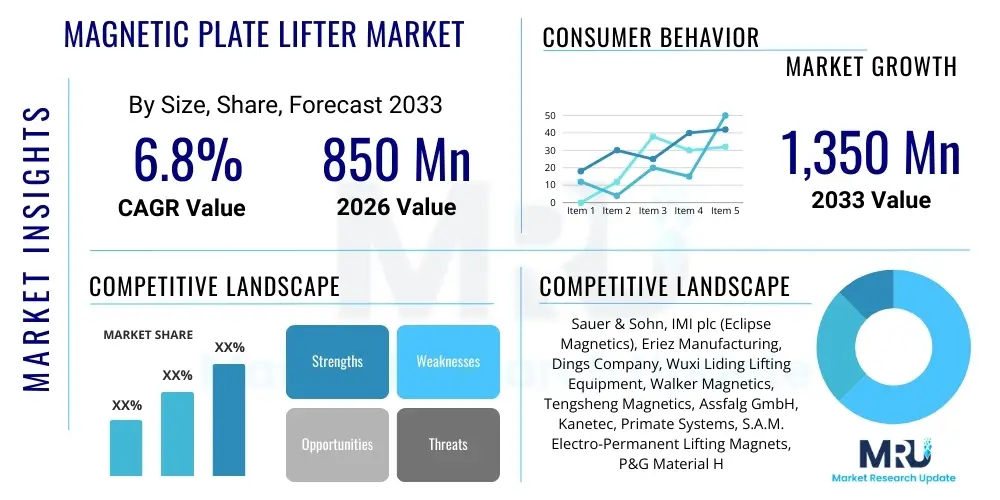

The Magnetic Plate Lifter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $850 Million in 2026 and is projected to reach $1,350 Million by the end of the forecast period in 2033.

Magnetic Plate Lifter Market introduction

The Magnetic Plate Lifter Market encompasses the global trade of material handling equipment designed to safely and efficiently lift, move, and position ferromagnetic materials, such as steel plates, blocks, and cylindrical objects, without the need for slings, clamps, or external power sources (in the case of permanent magnets). These devices are integral to modern industrial operations, significantly enhancing workplace safety by minimizing manual handling risks and improving throughput velocity in complex environments. The core product range includes permanent magnetic lifters, electro-magnetic lifters, and the increasingly popular electro-permanent magnetic lifters, each catering to specific operational requirements regarding lifting capacity, duty cycle, and frequency of use.

Major applications of magnetic plate lifters span across critical industrial sectors, including metal fabrication shops, steel mills, shipbuilding yards, foundries, and large-scale construction sites where heavy metal sheets or components must be relocated rapidly and precisely. The fundamental benefit these systems offer is the elimination of direct contact between the operator and the load, reducing the potential for accidents associated with traditional rigging methods. Furthermore, the quick engagement and disengagement mechanism dramatically cuts down operational time, making material transfer processes more streamlined and economical. These lifters are particularly valued for their ability to handle flat or round objects with varying surface conditions, provided the material is ferrous.

The market expansion is principally driven by stringent occupational safety regulations enforced globally, pushing industries toward safer material handling practices. Additionally, the continuous growth in global infrastructure development, particularly in Asia Pacific, demands high volumes of fabricated metal components, consequently boosting the need for efficient lifting solutions. Technological advancements, such as the integration of remote controls and superior magnetic materials like Neodymium (NdFeB), are further driving market adoption by increasing the power-to-weight ratio and reliability of the lifters. The demand for automation and optimization within manufacturing processes solidifies the Magnetic Plate Lifter Market's sustained growth trajectory over the forecast period.

Magnetic Plate Lifter Market Executive Summary

The Magnetic Plate Lifter Market is characterized by a significant shift towards high-performance and safety-integrated lifting solutions, primarily driven by industrial modernization efforts and regulatory compliance mandates across developed and emerging economies. Key business trends indicate a strong preference for electro-permanent magnetic lifters, which combine the safety features of permanent magnets (no drop risk during power failure) with the convenience of electrical control, offering optimal performance for high-duty cycle applications. Market competitors are focusing heavily on developing smart lifters equipped with integrated sensors for load measurement, proximity detection, and battery life monitoring, positioning product reliability and operational data accessibility as crucial differentiators in a competitive landscape.

Regionally, the Asia Pacific (APAC) stands as the dominant market, fueled by robust activity in construction, automotive manufacturing, and shipbuilding industries, particularly in China, India, and South Korea. This dominance is augmented by rapid industrialization and substantial government investment in infrastructure projects, generating massive demand for precision metal handling equipment. Conversely, North America and Europe demonstrate a mature market environment characterized by replacement cycles and high adoption of premium, automated lifting systems focusing on superior safety features and adherence to strict regional quality standards. Emerging markets in Latin America and the Middle East and Africa (MEA) are also showing promising growth, albeit from a smaller base, driven by expanding oil and gas infrastructure and general manufacturing setup.

Segment trends reveal that the high capacity segment (lifters capable of handling over 5,000 kg) is exhibiting the fastest growth rate, directly correlated with the increasing size of steel components used in mega-projects like large ships, wind turbine manufacturing, and heavy machinery production. Furthermore, the end-user preference is leaning toward customized solutions, requiring manufacturers to maintain flexible production capabilities. The Permanent Magnetic Lifter segment maintains a substantial market share due to its low operating cost and simplicity, especially for intermittent use in smaller fabrication shops. The primary challenge remains educating end-users on proper lifting techniques and ensuring regular maintenance to prevent performance degradation due to air gaps or surface contamination.

AI Impact Analysis on Magnetic Plate Lifter Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Magnetic Plate Lifter Market frequently center on themes of predictive maintenance, automated safety protocols, and optimization of handling logistics. Users often question how AI can prevent catastrophic failures, estimate the remaining useful life (RUL) of magnet assemblies, and integrate seamlessly with robotic material handling systems. Concerns also arise regarding the complexity and cost associated with integrating sophisticated AI infrastructure into traditional heavy industrial equipment, seeking validation on the return on investment (ROI) derived from such advanced systems. The overarching expectation is that AI will transform magnetic lifting from a manual, reactive process into a highly automated, proactive component of the smart factory ecosystem.

The influence of AI is most profound in enhancing operational efficiency and bolstering safety standards across industrial applications. AI algorithms, leveraging data collected from integrated sensors (load cells, temperature gauges, vibration monitors), can continuously analyze the magnet’s performance envelope. This analysis moves beyond simple fault detection, enabling predictive maintenance schedules that anticipate demagnetization or mechanical wear before performance degrades below acceptable safety margins. For instance, Machine Learning (ML) models can correlate environmental factors (humidity, temperature fluctuations) with operational parameters to fine-tune lifting capacity estimations, providing real-time, dynamic safety warnings to operators, thereby optimizing the safe working load (SWL) for varied material surface conditions.

Furthermore, AI plays a pivotal role in the automation of complex logistical movements within large warehouses or production facilities. By integrating magnetic lifters with autonomous guided vehicles (AGVs) or gantry robots, AI scheduling systems can determine the most efficient path and timing for material transfer, minimizing idle time and maximizing throughput. AI-driven vision systems can accurately identify the precise center of gravity and surface characteristics of irregularly shaped plates, optimizing the magnetic field distribution for secure lifting and placement. This integration facilitates the realization of fully automated material handling cells, significantly reducing human error and boosting overall manufacturing productivity and material traceability.

- AI-driven Predictive Maintenance: Forecasts magnetic performance decay and schedules preventative servicing, maximizing uptime.

- Automated Safety Monitoring: Real-time ML analysis of load stability and environmental factors to prevent load drops.

- Robotics and AGV Integration: AI manages coordination between magnetic lifters and autonomous handling systems for optimized logistics.

- Dynamic Load Optimization: Algorithms adjust magnetic strength based on detected material properties and surface quality.

- Operational Data Analytics: Provides deep insights into usage patterns and performance bottlenecks across the fleet of lifters.

DRO & Impact Forces Of Magnetic Plate Lifter Market

The dynamics of the Magnetic Plate Lifter Market are shaped by a strong combination of industrial necessity and regulatory impetus. Key drivers include the global expansion of manufacturing and construction sectors, particularly in emerging economies where large-scale steel consumption is rising dramatically. Crucially, the increasing global emphasis on worker safety standards, mandated by organizations like OSHA and various regional safety bodies, forces companies to replace outdated or hazardous rigging methods with certified magnetic lifting systems. Opportunities arise from technological proliferation, especially the development of battery-powered electro-permanent systems that offer versatility and mobility, opening up new applications in remote sites and temporary workshops. These magnetic lifters provide substantial long-term efficiency gains by reducing labor hours and speeding up operational cycles, acting as a potent cost-saving measure that encourages long-term investment by end-users.

However, the market faces notable restraints that temper its potential growth rate. One primary challenge is the high initial capital investment required for advanced electro-permanent lifters and integrated smart systems, which can be prohibitive for small and medium-sized enterprises (SMEs). Technical restraints include the inherent risk of performance degradation, such as demagnetization due to external factors like excessive heat or severe impact, and the substantial loss of lifting capacity when handling materials with uneven or dirty surfaces, which requires strict adherence to operational guidelines. Furthermore, the market is constrained by the necessity of trained personnel; improper selection or usage of the lifter for non-ferromagnetic materials or overloading presents significant safety risks, necessitating continuous user education and adherence to published lift tables.

The competitive intensity, coupled with the need for continuous technological refinement, acts as a pivotal force. The threat of substitutes, particularly traditional rigging equipment or vacuum lifting systems in specific applications, remains a factor, although magnetic lifters often prove superior for heavy, solid plates. The bargaining power of buyers is moderate to high, as the product is somewhat standardized, leading to price pressure. Suppliers of key magnetic materials, like Neodymium and Samarium Cobalt, hold moderate power, as geopolitical stability can impact the supply chain and pricing of these essential rare-earth elements. Overall, the market remains highly driven by technological innovation aimed at enhancing safety, reliability, and ease of use, ensuring that advanced products maintain a competitive edge over commodity offerings.

Segmentation Analysis

The Magnetic Plate Lifter Market is comprehensively segmented based on technology type, material capacity, and the specific industrial application or end-user sector. This structural breakdown provides critical insights into purchasing behaviors, regional demand profiles, and technological maturity across various sub-markets. Analyzing these segments helps stakeholders tailor product development and marketing strategies to meet diverse operational needs, ranging from low-capacity manual handling in small workshops to heavy-duty, automated lifting operations in large steel processing plants. The segmentation highlights the growing shift from purely permanent systems towards electrically assisted and digitally controlled lifters that offer greater precision and enhanced safety features required by modern industry standards.

- By Type:

- Permanent Magnetic Lifters (PML)

- Electro-Magnetic Lifters (EML)

- Electro-Permanent Magnetic Lifters (EPML)

- Battery-Powered Magnetic Lifters

- By Lifting Capacity:

- Up to 500 kg (Light Duty)

- 501 kg – 2,000 kg (Medium Duty)

- 2,001 kg – 5,000 kg (Heavy Duty)

- Above 5,000 kg (Very Heavy Duty)

- By End-User Industry:

- Metal Fabrication and Machining

- Steel Mills and Processing Centers

- Shipbuilding and Maritime Industry

- Automotive and Aerospace Manufacturing

- Construction and Infrastructure

- Warehousing and Logistics

- Foundries and Casting Operations

- By Sales Channel:

- Direct Sales (OEMs, Large Industrial Contracts)

- Indirect Sales (Distributors, Third-Party Resellers, E-commerce)

Value Chain Analysis For Magnetic Plate Lifter Market

The value chain for the Magnetic Plate Lifter Market begins with the upstream procurement of essential raw materials, most critically rare-earth magnets, primarily Neodymium-Iron-Boron (NdFeB) or Samarium Cobalt (SmCo), alongside high-grade steel and specialized polymers for casing and housing components. Suppliers of these rare-earth elements exert significant influence due to concentrated geographical mining and processing capabilities, making supply chain stability and pricing a critical upstream challenge. Efficient sourcing strategies, including long-term supply agreements and geographical diversification of component procurement, are essential for maintaining competitive manufacturing costs and consistent product quality in the midstream production phase.

The midstream stage involves the design, precision machining, assembly, and rigorous quality testing of the magnetic lifting devices. Manufacturing activities require specialized engineering expertise to ensure optimal magnetic circuit design, precision assembly to minimize air gaps, and integration of control electronics and safety features, particularly for electro-permanent models. Key activities here include magnet block alignment, housing fabrication, system calibration, and adherence to international safety standards (e.g., ASME B30.20 and various EN standards). Manufacturers that invest in automated assembly lines and advanced material handling simulation software gain a substantial advantage in terms of production efficiency and product reliability.

The downstream segment focuses on distribution, sales, and aftermarket support. Products reach the end-user through a mix of direct sales channels, especially for large, custom-built, heavy-duty lifters sold to major industrial enterprises (steel producers, shipyards), and extensive indirect channels utilizing authorized distributors and specialized industrial equipment resellers. The indirect channel relies heavily on robust logistical networks and technical sales support provided by distributors who can offer immediate local service and application consulting. Aftermarket services, including maintenance, repair, and recertification of lifting equipment, constitute a vital revenue stream and contribute significantly to customer retention and brand loyalty throughout the operational life cycle of the lifters.

Magnetic Plate Lifter Market Potential Customers

The primary customers for Magnetic Plate Lifters are enterprises engaged in handling massive volumes of ferrous metals as raw material, intermediate products, or finished goods requiring relocation within a manufacturing environment. Metal fabrication shops represent a cornerstone customer base, utilizing these lifters extensively for cutting, welding, and assembling steel plates used in structures, machinery, and various industrial components. Their requirements typically focus on versatility, ease of use, and ensuring that the magnetic force is consistent to prevent plate deformation during critical operations. The shift toward higher-capacity, quick-release systems is noticeable within this segment as fabricators aim to maximize hourly throughput.

Another major end-user category is the heavy industry sector, encompassing steel mills, shipbuilding yards, and large infrastructure construction firms. These customers demand very heavy-duty, often customized magnetic lifters, particularly electro-permanent units, capable of handling loads exceeding 10 tons. In steel production and warehousing, magnetic lifters are indispensable for moving billets, slabs, and coils safely across the production line and into storage areas. The purchasing decision in this sector is heavily weighted toward safety certification, operational longevity, and the availability of responsive, comprehensive technical support and maintenance agreements, given the high consequences of equipment failure.

Furthermore, the automotive and aerospace industries, alongside logistics and specialized warehousing operations, are increasingly integrating magnetic lifters, especially the smaller capacity, precise handling units, into their automated manufacturing cells. In automotive stamping plants, lifters assist in quickly loading sheet metal blanks onto presses, enhancing process speed and reducing operator risk. For warehousing focused on inventory of metal components, these lifters integrated with overhead cranes ensure high-density storage and retrieval efficiency. These end-users prioritize integration capabilities with existing automation systems, requiring lifters to feature digital control interfaces compatible with Industry 4.0 protocols and robust data reporting capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850 Million |

| Market Forecast in 2033 | $1,350 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sauer & Sohn, IMI plc (Eclipse Magnetics), Eriez Manufacturing, Dings Company, Wuxi Liding Lifting Equipment, Walker Magnetics, Tengsheng Magnetics, Assfalg GmbH, Kanetec, Primate Systems, S.A.M. Electro-Permanent Lifting Magnets, P&G Material Handling, Hunan Wingo, Tecnomagnete SpA, Star Trace Pvt. Ltd., Magnets USA, Shandong Finer Lifting Equipment, Kosei Magnet, Zaozhuang Rongsheng Magnet, Aichi Steel Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetic Plate Lifter Market Key Technology Landscape

The technological evolution within the Magnetic Plate Lifter Market is primarily centered on enhancing power density, improving operational safety, and integrating smart controls. The foundational technology remains the permanent magnet material, with Neodymium Iron Boron (NdFeB) being the dominant choice due to its superior residual induction and coercivity, providing high lifting capacity relative to the magnet's size and weight. Continuous research focuses on developing high-temperature resistant NdFeB alloys and improving manufacturing processes to achieve uniformity and longevity of the magnetic field. This focus ensures that permanent lifters remain lightweight, cost-effective, and highly reliable for applications where power failure is an absolute risk, as their lifting force does not require electricity.

A significant technological advancement is the widespread adoption of Electro-Permanent Magnetic Lifters (EPMLs). These systems utilize a combination of permanent magnets and strategically placed electromagnets. The lift and release functions are achieved by momentarily passing a current through the coil to switch the magnetic poles of a soft iron section, thereby activating or deactivating the external magnetic field. Crucially, once activated, the permanent magnets hold the load securely without continuous power consumption, drastically improving energy efficiency and eliminating the critical safety hazard associated with power loss in traditional electromagnets. This technology is becoming the standard for heavy-duty, high-cycle applications where precision control is mandatory.

Further innovation involves the integration of advanced electronics, sensor technology, and remote control systems. Modern lifters incorporate battery backup systems for control circuits, ensuring seamless operation, and include load cells and proximity sensors to monitor the load’s weight, dimensions, and proximity to the lifter head in real-time. Wireless remote control systems enhance operator safety by allowing activation/deactivation from a secure distance, reducing exposure to moving machinery and heavy loads. The next generation of lifters is expected to feature IoT connectivity, enabling condition monitoring, utilization tracking, and remote diagnostics, moving the technology fully into the realm of smart industrial equipment compliant with Industry 4.0 paradigms.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and adoption patterns of Magnetic Plate Lifters, driven by varying levels of industrialization, regulatory maturity, and investment in infrastructure. Asia Pacific (APAC) leads the market in terms of volume and growth potential, primarily due to the massive scale of manufacturing operations in China, India, and Southeast Asian nations. These countries are undergoing rapid urbanization and heavy infrastructure development, spurring exceptional demand for steel and fabricated metal products, thereby necessitating high-capacity magnetic handling solutions. The region's competitive advantage lies in its cost-effective manufacturing base, although there is a parallel increase in demand for premium, high-safety European and North American lifters.

North America (NA) and Europe represent mature markets characterized by stringent safety regulations and a strong emphasis on automation and operational efficiency. In these regions, the demand is often driven by replacement cycles, technology upgrades (moving from older manual systems to EPMLs and smart lifters), and regulatory mandates requiring certified lifting equipment. High labor costs encourage the adoption of automated systems that integrate magnetic lifters with robotic arms or AGVs. European markets, particularly Germany, Italy, and the UK, exhibit high standards for product quality and longevity, favoring manufacturers that offer extensive certifications and integrated safety features like remote diagnostics and condition monitoring systems.

The Latin America (LATAM) and Middle East & Africa (MEA) regions are emerging markets showing accelerated growth, primarily linked to expansion in the oil and gas sector, mining, and foundational infrastructure projects. Brazil, Saudi Arabia, and the UAE are significant contributors, with increasing demand for mid-to-heavy duty permanent and electro-magnetic lifters utilized in port handling, metal workshops supporting energy exploration, and large construction sites. While price sensitivity is generally higher in these regions, the growing imperative for imported safety standards is steadily pushing customers toward higher quality, certified lifting solutions, creating long-term opportunities for global market players specializing in robust, durable equipment.

- Asia Pacific (APAC): Dominant region driven by immense manufacturing activity (China, India), shipbuilding, and high demand for heavy-duty lifters.

- North America (NA): Focus on automation, regulatory compliance (OSHA), and technological replacement cycles favoring electro-permanent systems and smart integration.

- Europe: High adoption of premium, certified lifting technology; emphasis on precision, operational safety, and adherence to EN standards in fabrication and automotive sectors.

- Latin America (LATAM): Growth tied to infrastructure development and raw material processing (mining, oil & gas); increasing preference for cost-effective yet reliable permanent magnetic solutions.

- Middle East and Africa (MEA): Market expansion driven by energy sector projects and construction boom (especially in GCC countries), increasing demand for robust, durable lifting equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetic Plate Lifter Market.- Sauer & Sohn

- IMI plc (Eclipse Magnetics)

- Eriez Manufacturing

- Dings Company

- Wuxi Liding Lifting Equipment

- Walker Magnetics

- Tengsheng Magnetics

- Assfalg GmbH

- Kanetec

- Primate Systems

- S.A.M. Electro-Permanent Lifting Magnets

- P&G Material Handling

- Hunan Wingo

- Tecnomagnete SpA

- Star Trace Pvt. Ltd.

- Magnets USA

- Shandong Finer Lifting Equipment

- Kosei Magnet

- Zaozhuang Rongsheng Magnet

- Aichi Steel Corporation

Frequently Asked Questions

Analyze common user questions about the Magnetic Plate Lifter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the key difference between Permanent, Electro-Magnetic, and Electro-Permanent Lifters?

Permanent Magnetic Lifters (PMLs) require no external power, relying solely on rare-earth magnets; their lift/release is manual. Electro-Magnetic Lifters (EMLs) require continuous power to maintain the lift, posing a risk during power failure. Electro-Permanent Magnetic Lifters (EPMLs) use a brief electric pulse to switch the magnetic field but hold the load securely without continuous power, offering the highest safety rating and energy efficiency for critical lifts.

How do safety regulations, such as ASME B30.20, influence the Magnetic Plate Lifter Market?

Safety standards mandate specific design factors, testing protocols, and operational guidelines for magnetic lifters, driving market demand toward certified, high-quality products. Compliance with standards like ASME B30.20 ensures that lifters meet minimum rated load safety requirements (typically 3:1 safety factor) and encourages manufacturers to integrate advanced safety features like electronic lock-outs and audible warnings, accelerating the obsolescence of non-compliant equipment.

Which end-user industry is driving the highest demand for Magnetic Plate Lifters currently?

The Metal Fabrication and Steel Processing industry remains the largest consumer, requiring magnetic lifters for efficient loading, cutting, and stacking of steel plates and profiles. However, the Shipbuilding sector is currently exhibiting the fastest growth in demand for very heavy-duty, customized magnetic systems due to the increasing size and complexity of modern vessel construction projects.

What factors most significantly impact the maximum lifting capacity of a magnetic plate lifter?

The primary factors are the material grade and thickness of the load, the size and power of the permanent magnets used, and critically, the air gap between the magnet surface and the load. Even minimal air gaps, caused by paint, rust, or dirt, can significantly diminish the effective lifting capacity, necessitating clean surfaces for optimal performance and safety compliance.

How is Industry 4.0 influencing the future development of Magnetic Plate Lifters?

Industry 4.0 is pushing the development of smart magnetic lifters that integrate IoT sensors, remote diagnostics, and wireless connectivity. This allows for real-time performance monitoring, predictive maintenance scheduling, and seamless communication with automated guided vehicles (AGVs) and central manufacturing execution systems (MES), optimizing overall plant logistics and material traceability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager