Magnetorheological Fluid Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434820 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Magnetorheological Fluid Market Size

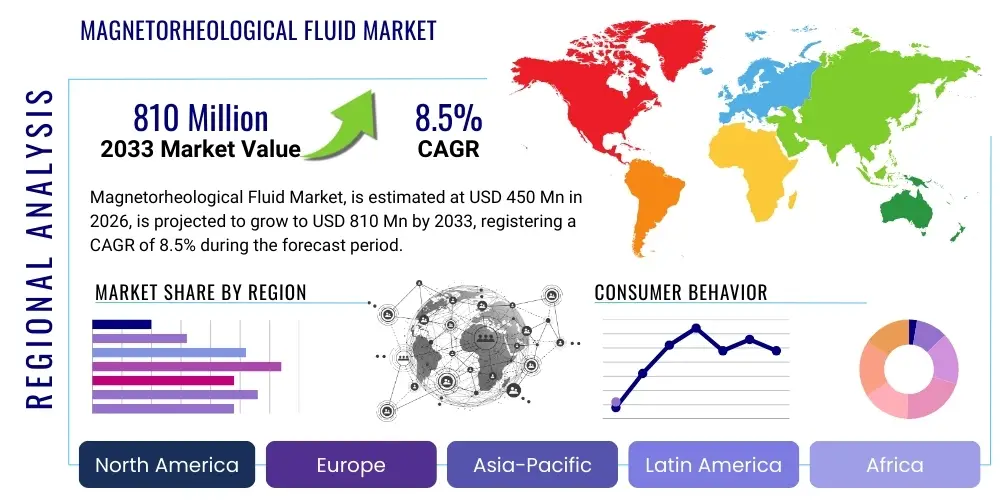

The Magnetorheological Fluid Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 810 Million by the end of the forecast period in 2033.

Magnetorheological Fluid Market introduction

The Magnetorheological (MR) Fluid market encompasses specialized smart materials whose rheological properties, specifically viscosity, can be rapidly and reversibly changed by applying a magnetic field. These fluids typically consist of micro- or nano-sized magnetically polarizable particles suspended in a non-magnetic carrier fluid, such as mineral oil, silicone oil, or synthetic hydrocarbons. The fundamental mechanism relies on the magnetic particles aligning themselves into chain-like structures when subjected to a magnetic field, thereby increasing the fluid's yield stress and apparent viscosity within milliseconds. This rapid and controllable transition from a liquid state to a semi-solid state makes MR fluids highly desirable for advanced motion control and damping applications requiring instantaneous responsiveness and high precision.

Major applications of MR fluids span across high-performance industries, including automotive suspension systems, where they enable adaptive damping, and defense sectors, used in tactical equipment and specialized protective gear. They are also crucial in the design of sophisticated hydraulic systems, vibration mitigation devices in civil engineering structures, and high-fidelity haptic feedback devices. The unique benefit offered by MR fluids is their ability to provide controllable energy dissipation and stiffness without complex mechanical valves or high-pressure hydraulics, leading to simplified designs, reduced power consumption, and improved overall system reliability and performance across various operational environments.

The market growth is primarily driven by the increasing integration of smart materials in the automotive industry, particularly in luxury and electric vehicles, to enhance ride comfort and safety through active suspension and braking systems. Furthermore, the rising demand for efficient seismic dampers in earthquake-prone regions and the miniaturization trend in robotics and medical devices, where precise fluid control is essential, significantly propel market expansion. Continuous research focused on improving particle stability, reducing sedimentation, and developing fluids with higher yield stress at lower magnetic field strengths remains a key factor fueling technological advancement and commercial uptake in demanding applications.

Magnetorheological Fluid Market Executive Summary

The global Magnetorheological Fluid Market is characterized by strong upward momentum, driven by transformative advancements in automotive and industrial automation sectors. Business trends show a significant push towards developing high-stability and low-sedimentation MR formulations to overcome historical reliability issues, leading to higher adoption rates in critical applications like prosthetics and aerospace flight control surfaces. Key players are heavily investing in vertical integration, securing raw material supply chains (particularly carbonyl iron powder), and forging strategic alliances with Tier 1 automotive suppliers to capitalize on the burgeoning demand for adaptive damping technologies. The competitive landscape is moderately fragmented, with specialized chemical companies dominating the supply of advanced fluid compounds, while downstream integrators focus on designing sophisticated MR devices.

Regional trends indicate that North America and Europe currently hold significant market shares due due to high defense spending, established automotive manufacturing bases, and stringent regulatory requirements promoting vehicle safety and performance standards. However, the Asia Pacific region, led by China, Japan, and South Korea, is poised for the highest CAGR throughout the forecast period. This rapid growth is underpinned by massive infrastructural development requiring vibration control systems, coupled with the exponential expansion of the electric vehicle (EV) market and increased governmental focus on smart manufacturing and precision robotics. Latin America and the Middle East & Africa are still nascent markets, primarily driven by localized oil and gas exploration equipment and smaller-scale civil engineering projects requiring specialized damping solutions.

Segment trends reveal that the Carbonyl Iron-based MR fluids segment maintains market dominance owing to their superior magnetic responsiveness and cost-effectiveness compared to alternatives. The application segment is heavily skewed towards transportation and mobility, with automotive dampers constituting the largest revenue share. However, non-traditional applications, such as haptic devices and biomedical systems, are projected to exhibit the fastest growth rates, signaling diversification in end-user demand. The market is fundamentally shifting towards customized fluid specifications, where suppliers must offer fluids tailored for specific temperature ranges, shear stability requirements, and long operational life cycles demanded by complex industrial and medical machinery.

AI Impact Analysis on Magnetorheological Fluid Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Magnetorheological Fluid Market frequently center around three core themes: optimization of fluid formulation, enhancement of device control systems, and predictive maintenance capabilities. Users are keen to understand how AI algorithms can accelerate the discovery of novel particle coatings and carrier fluids to reduce sedimentation and improve temperature stability—long-standing challenges in MR technology. A significant area of interest is the deployment of machine learning (ML) models within MR fluid devices, such as smart dampers, to instantly analyze external stimuli (road conditions, seismic activity) and precisely adjust the magnetic field for optimal rheological response, achieving performance levels unattainable by traditional PID controllers. Furthermore, users anticipate that AI will facilitate predictive failure analysis in MR systems by monitoring fluid degradation indicators in real-time, thereby extending the service life of high-value industrial assets and reducing unscheduled downtime.

- AI-driven material informatics accelerate the discovery and optimization of stable MR fluid compositions.

- Machine Learning enhances the real-time control algorithms for MR dampers, optimizing performance based on sensor input.

- Predictive maintenance analytics, powered by AI, monitor fluid quality and predict system failure, extending device longevity.

- AI simulation tools reduce the cost and time required for designing and testing new MR fluid-based devices.

- Enhanced quality control systems utilize computer vision and AI for detecting micro-defects in particle manufacturing.

DRO & Impact Forces Of Magnetorheological Fluid Market

The Magnetorheological Fluid Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively determine its growth trajectory and competitive intensity. The primary drivers are rooted in the growing global demand for high-performance vibration control systems in vehicles and infrastructure, coupled with technological advancements that have improved the reliability and yield stress of modern MR formulations. The ability of MR fluids to offer instantaneous, controllable damping is unparalleled, making them indispensable in applications where adaptability and speed are crucial. However, the market faces notable restraints, chiefly concerning the high cost of raw materials, particularly highly refined carbonyl iron powders, and persistent issues related to particle sedimentation and sealing difficulties within operational devices. These technical challenges currently limit widespread adoption in cost-sensitive, high-volume consumer applications, requiring continued material science innovation to address.

Opportunities for exponential growth are concentrated in emerging fields such as haptics, prosthetics, and soft robotics, where the precise control offered by MR fluids enables groundbreaking user interaction and functional capabilities. Furthermore, the necessity for robust seismic mitigation technologies in construction and infrastructure offers a significant untapped segment, positioning MR fluids as a superior alternative to traditional passive dampers. The transition towards electrification in the automotive sector presents a dual opportunity: using MR fluids not only in suspension but also potentially in novel braking or clutch mechanisms designed specifically for EV architecture, capitalizing on their smooth torque transmission capabilities and fast response times, particularly in regenerative systems.

The market operates under substantial impact forces, including supplier power, buyer power, threat of substitutes, threat of new entrants, and competitive rivalry. Supplier power is moderate to high, as the specialized nature of carbonyl iron production limits the number of qualified raw material vendors. Buyer power is increasing, particularly from large automotive original equipment manufacturers (OEMs), who demand customized specifications and rigorous quality control, exerting downward pressure on fluid prices. The threat of substitutes, primarily sophisticated electro-hydraulic and pneumatic systems, remains a constant challenge, forcing MR fluid developers to continually enhance performance metrics. However, high entry barriers related to material science expertise and intellectual property protections maintain the dominance of established, technologically advanced players.

Segmentation Analysis

The Magnetorheological Fluid Market is systematically segmented based on the type of magnetic particle utilized, the application area where the fluid is deployed, and the specific end-use industry utilizing the technology. This multi-dimensional segmentation is crucial for understanding specific growth pockets and tailoring product development to meet distinct performance requirements across various sectors. Analyzing these segments helps in distinguishing between high-volume, cost-sensitive segments like automotive and low-volume, high-value segments like aerospace or medical devices, allowing market participants to strategically allocate R&D and marketing resources. The core segmentation rests on defining the composition of the fluid, as particle stability and material cost directly influence commercial viability.

By focusing on particle type, the market acknowledges the material science hurdles and cost differences inherent in MR fluid manufacturing. Carbonyl iron-based fluids dominate due to their optimal magnetic properties and relatively mature production processes. However, research into alternative magnetic materials, often nano-sized, is gaining traction to improve dispersion stability and reduce the overall device size. Application-wise, the market structure is heavily defined by devices that require variable damping or torque transmission, which are foundational to mobility and industrial control. Dampers (for shock absorption and vibration isolation) and brakes/clutches are the traditional application pillars, although specialized machinery and niche haptic systems are rapidly increasing their market share, signifying diversification beyond core automotive uses.

The end-use segmentation underscores the ultimate consumers and the stringent regulatory environments governing product performance. The Automotive Industry remains the single largest consumer due to mass adoption in luxury and high-performance vehicles, where advanced suspension systems are a competitive differentiator. Aerospace and Defense demands extremely high reliability and performance under severe conditions, justifying higher material costs. Conversely, the growth of MR fluids in Building & Construction, particularly for seismic dampers, represents a long-term opportunity driven by global urbanization and increased focus on resilient infrastructure, further solidifying the necessity for robust, specialized fluid formulations tailored to large-scale structural requirements and long lifespan expectations.

- By Type:

- Carbonyl Iron Based MR Fluid

- Ferrous Based MR Fluid (Other Magnetic Particles)

- Hybrid MR Fluid

- By Application:

- Dampers and Shock Absorbers

- Brakes and Clutches

- Seismic Dampers and Structural Control

- Polishing and Finishing

- Actuators, Valves, and Pumps

- Haptic Devices and Prosthetics

- By End-use Industry:

- Automotive (Passenger Cars, Commercial Vehicles, Heavy Equipment)

- Aerospace and Defense

- Building and Construction (Civil Engineering)

- Industrial Machinery and Robotics

- Medical and Healthcare

- Consumer Electronics

Value Chain Analysis For Magnetorheological Fluid Market

The value chain for the Magnetorheological Fluid Market starts with the rigorous sourcing and refining of highly specialized raw materials, primarily ultrafine magnetic particles (carbonyl iron powder being the most common) and high-purity carrier fluids (silicone or mineral oils). This upstream analysis highlights the criticality of material purity and particle size uniformity, which directly dictates the MR fluid’s ultimate performance characteristics, such as yield stress and responsiveness. Key suppliers in this stage are concentrated and possess significant technological expertise, often commanding higher margins due to the complex chemical processes involved in synthesizing high-quality magnetic powders. Securing stable, cost-effective access to these specialized inputs is a critical determinant of competitive advantage for MR fluid manufacturers, who then blend and stabilize these components using specialized additives and surfactants to prevent sedimentation and oxidation, thereby creating the marketable fluid.

Moving downstream, the distribution channel is primarily bifurcated into direct sales to large Original Equipment Manufacturers (OEMs) and indirect sales through specialized distributors focusing on smaller industrial clients and research institutions. Large automotive and aerospace companies often engage in direct procurement or highly customized contracts with MR fluid manufacturers, allowing for specific fluid tuning and integration support. This direct model ensures rigorous quality control and technical alignment. Conversely, indirect channels are vital for penetrating smaller niche markets like laboratory equipment suppliers or specialized robotics firms, utilizing technical distributors who can provide localized inventory, technical support, and smaller batch sizes, broadening the market reach beyond major industrial hubs.

The final stage involves the integration of the MR fluid into proprietary devices, marking the transition from fluid supply to system component delivery. Device manufacturers, such as those producing automotive active suspension systems or specialized prosthetic joints, purchase the fluid and incorporate it into their closed systems. This integration process requires specialized engineering expertise to design magnetic coils, durable sealing mechanisms, and appropriate fluid reservoirs. The ultimate consumer—be it a car buyer, a civil engineering firm, or a defense contractor—values the performance of the final device, not just the fluid itself. Therefore, innovation downstream focuses heavily on miniaturization, long-term durability, and seamless electronic control integration, often driving the need for continuous collaborative R&D between fluid suppliers and device manufacturers to optimize system performance.

Magnetorheological Fluid Market Potential Customers

Potential customers for Magnetorheological Fluids are concentrated primarily in sectors demanding superior, controllable force and vibration management capabilities, where the fluid acts as a key enabler of advanced system functionality. The largest segment of end-users is the Automotive Industry, encompassing global manufacturers of high-end passenger vehicles and heavy-duty commercial trucks who utilize MR fluids in adaptive chassis control systems, including semi-active and active suspension systems, providing real-time adjustment of ride stiffness and handling. These OEMs are highly sensitive to fluid stability and long-term performance guarantees, as the fluid is a non-serviceable component intended to last the vehicle's lifespan, establishing rigorous qualification standards for potential suppliers.

Beyond transportation, the second major group of customers includes specialized engineering firms in the Aerospace and Defense sectors, and civil infrastructure companies focused on resilience. Defense applications involve the deployment of MR fluids in tactical vehicle suspension, blast mitigation seats, and specialized weapon recoil mechanisms, requiring fluids that operate reliably under extreme temperature and dynamic stress conditions. Civil engineers utilize large-scale MR dampers in bridges and high-rise buildings situated in seismic zones, focusing on providing controllable energy dissipation to mitigate earthquake damage. These customers prioritize robustness, high yield stress, and reliability over decades, requiring substantial technical support and certified testing data from their MR fluid providers.

Emerging segments include manufacturers of advanced medical devices and industrial robotics, categorized by their need for precision and miniaturization. Prosthetic limb manufacturers use MR fluids to achieve highly realistic and adaptive knee or ankle joint damping, offering enhanced mobility and comfort to users. Similarly, robotics firms leverage MR fluid actuators and clutches for haptic feedback systems, specialized grippers, and high-precision polishing machinery. These customers seek extremely small particle sizes, stable dispersion, and high repeatability in performance, emphasizing suppliers who can deliver fluids customized for low-volume, high-precision applications, highlighting the segmentation of the market into both large industrial volume consumers and specialized technological integrators.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 810 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LORD Corporation (Parker Hannifin), BASF SE, QED Chemicals, Arusyn LLC, MRF Engineering, Industrial Rheology Applications Ltd., Liquids Research Limited, Wacker Chemie AG, SKF Group, KKR Corporation, Pioneer Solutions, CK Materials, AK Scientific, Extrude Hone Corporation, Eutectic Fluids, Inc., Nikkiso Co., Ltd., Advanced Fluid Technologies |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetorheological Fluid Market Key Technology Landscape

The technological landscape of the Magnetorheological Fluid market is predominantly defined by advancements in three key areas: particle synthesis and surface modification, carrier fluid stability, and the design of magnetic circuits within MR devices. Current technology heavily relies on advanced chemical engineering techniques to produce highly spherical, uniform-sized carbonyl iron particles, which are the backbone of high-performance MR fluids. Recent breakthroughs involve applying sophisticated polymeric or inorganic coatings to these particles. These surface treatments are crucial for minimizing particle-particle attraction in the absence of a magnetic field, drastically improving dispersion stability, reducing sedimentation rates, and extending the operational lifespan of the fluid, thereby addressing one of the major historical barriers to widespread adoption.

Furthermore, technology development is rapidly progressing in optimizing the carrier fluid matrix itself. Traditional mineral oils are being substituted or enhanced by synthetic hydrocarbon oils and specialized silicone fluids which offer superior thermal stability, wider operational temperature ranges, and compatibility with advanced sealing materials. Researchers are also exploring novel additives, including rheological modifiers and anti-wear agents, that ensure the fluid maintains its performance characteristics under high shear rates and prolonged use typical of automotive shock absorbers or heavy industrial machinery. The optimization of the fluid’s zero-field viscosity is also paramount, aiming to reduce inherent resistance and improve efficiency when the damping system is inactive or operating in low-force modes.

In parallel to fluid composition, device design technology, particularly the geometry of the magnetic coils and the flux path, is continuously evolving. Modern MR devices leverage finite element analysis (FEA) and advanced electromagnetic simulation software to maximize the magnetic field strength reaching the fluid while minimizing power consumption and overall device weight. Innovations include the use of advanced laminated core materials to reduce eddy current losses and the integration of highly sensitive sensors and microprocessors. These integrated technologies enable precise, instantaneous control over the fluid's state, linking the physical fluid properties directly to sophisticated electronic control units (ECUs), facilitating adaptive performance tailored to specific application demands in real-time, such as in high-speed rail damping or precision surgical tools.

Regional Highlights

The global Magnetorheological Fluid Market demonstrates varied growth patterns influenced by regional industrial maturity, regulatory frameworks, and technological adoption rates across key geographies. North America is characterized by robust demand, primarily driven by a strong presence of aerospace and defense contractors, who require high-performance, MIL-SPEC certified MR components. Furthermore, the region’s established automotive industry and significant investment in smart infrastructure projects, particularly seismic mitigation in states like California, ensure continuous high-value consumption. Regulatory emphasis on safety and performance acts as a strong driver for adopting advanced MR technology in vehicles and structures, supporting market leadership.

Europe represents a mature market, heavily reliant on the advanced automotive manufacturing sector, especially in Germany and the UK, where MR fluids are standard components in luxury and performance vehicles for premium suspension systems. The region is also a hub for sophisticated industrial machinery and precision engineering, leading to steady demand for MR technology in specialized industrial clutches, brakes, and robotic end-effectors. European research institutions play a crucial role, often leading advancements in material science for improved fluid stability and durability, which feeds directly into industrial applications and maintains competitive intensity.

Asia Pacific (APAC) is projected to be the fastest-growing market globally, fueled by rapid urbanization, massive infrastructure development, and the explosive growth of the domestic electric vehicle (EV) market, particularly in China and South Korea. The need for earthquake-resistant infrastructure in countries like Japan further accelerates the adoption of structural MR dampers. Furthermore, APAC serves as a global manufacturing base for industrial machinery and consumer electronics, leading to increasing integration of MR technology in polishing equipment, factory automation, and specialized consumer feedback devices, positioning it as the key growth engine for the forecast period.

- North America: Market leader in defense and aerospace applications; strong governmental and private investment in advanced vehicle technologies and seismic retrofitting.

- Europe: Dominated by the premium automotive sector; high R&D activity focused on fluid stability and industrial machinery precision.

- Asia Pacific (APAC): Highest projected growth rate; driven by EV manufacturing, infrastructure construction (seismic mitigation), and expansion of the robotics industry, especially in China and Japan.

- Latin America: Emerging market; growth tied mainly to localized heavy machinery, mining equipment, and smaller-scale civil engineering projects.

- Middle East and Africa (MEA): Nascent demand; usage primarily restricted to specialized high-value oil and gas exploration equipment and localized defense spending.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetorheological Fluid Market.- LORD Corporation (Parker Hannifin)

- BASF SE

- QED Chemicals

- Arusyn LLC

- MRF Engineering

- Industrial Rheology Applications Ltd.

- Liquids Research Limited

- Wacker Chemie AG

- SKF Group

- Pioneer Solutions

- CK Materials

- AK Scientific

- Extrude Hone Corporation

- Eutectic Fluids, Inc.

- Nikkiso Co., Ltd.

- Advanced Fluid Technologies

- General Rheology Systems

- Fluid Technologies Inc.

- Hubei Honyar New Material Co., Ltd.

- Shenzhen Yuda New Material Technology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Magnetorheological Fluid market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Magnetorheological Fluids?

The primary factor driving demand is the increasing need for high-performance, instantaneous, and controllable vibration damping systems, particularly within the luxury and electric vehicle sectors for adaptive suspension and enhanced safety features. Furthermore, civil engineering applications requiring effective seismic protection are significant demand drivers.

What are the main technical challenges facing the widespread adoption of MR Fluids?

The main challenges are the high production cost of specialized carbonyl iron powders, along with technical issues such as particle sedimentation over prolonged periods, which can affect long-term stability and performance, and the necessity for robust sealing mechanisms to contain the fluid.

Which end-use industry holds the largest share in the Magnetorheological Fluid Market?

The Automotive industry currently holds the largest market share. MR fluids are extensively used in semi-active suspension systems, engine mounts, and braking systems to optimize vehicle handling, stability, and overall ride comfort under variable conditions.

How does the performance of MR Fluids compare to traditional hydraulic fluids?

MR Fluids offer a distinct advantage over traditional hydraulic fluids by allowing their viscosity and yield stress to be modulated electronically in milliseconds using a magnetic field. This enables instantaneous, precise, and infinitely variable control, which is impossible with passive hydraulic systems reliant on mechanical valves.

What role does Asia Pacific play in the future growth of the MR Fluid Market?

Asia Pacific is projected to be the fastest-growing region due to explosive growth in the electric vehicle manufacturing base, massive investments in large-scale infrastructure projects requiring seismic damping technology, and increasing adoption in precision industrial robotics and automation across major economies like China and Japan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager