Mango Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437244 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Mango Powder Market Size

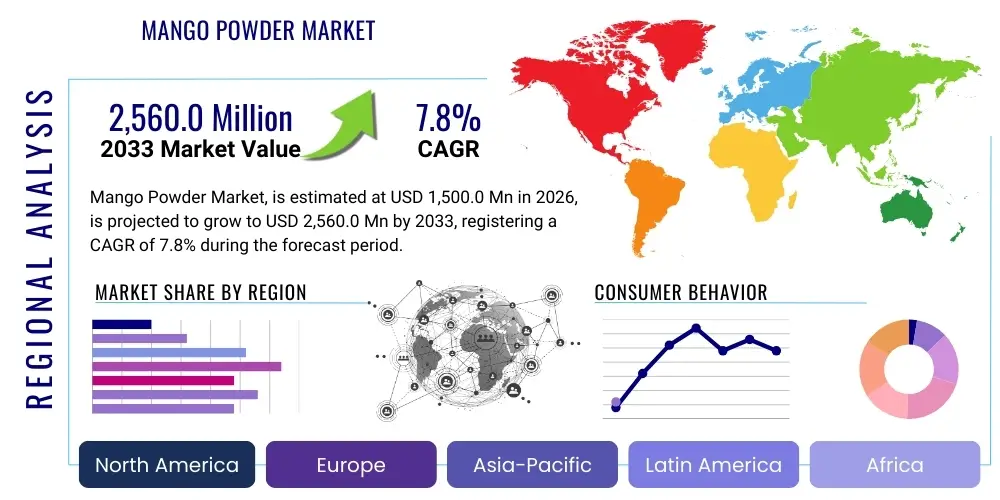

The Mango Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1,500.0 Million in 2026 and is projected to reach USD 2,560.0 Million by the end of the forecast period in 2033.

Mango Powder Market introduction

The Mango Powder Market encompasses the production, distribution, and consumption of dehydrated mango pulp processed into a fine powder. This product serves as a versatile ingredient utilized extensively across the food and beverage industry, offering concentrated flavor, natural color, and essential nutrients inherent to the fresh fruit. Key applications include flavor enhancement in beverages, incorporation into bakery and confectionery items, and use as a functional ingredient in health supplements and infant food formulas. The growing consumer preference for natural, clean-label ingredients, coupled with the increasing demand for exotic and globally inspired flavors, is fundamentally driving the market expansion across various geographic regions.

Mango powder, often categorized based on the drying technology employed—such as spray drying, freeze drying, or vacuum drying—maintains a significantly longer shelf life compared to fresh mangoes, mitigating supply chain complexity and ensuring year-round availability of mango derivatives. This long-term stability and ease of storage make it an indispensable ingredient for large-scale industrial food manufacturing. Furthermore, the inherent nutritional benefits, including high levels of Vitamin A, Vitamin C, and antioxidants, position mango powder favorably within the burgeoning health and wellness sector, where consumers are actively seeking nutrient-dense, plant-based functional ingredients to enhance dietary quality and overall well-being.

Major applications span diverse sectors, including functional beverages, yogurt and dairy products, dessert mixes, spice blends (particularly in the savory sector, such as 'amchur' derived from raw mangoes), and RTE (Ready-to-Eat) meal components. Driving factors include globalization of food supply chains, advancements in drying and encapsulation technologies that improve powder quality and solubility, and supportive governmental policies in major mango-producing regions aimed at reducing post-harvest losses by promoting value addition and processing. The market’s resilience is strongly linked to the ability of manufacturers to ensure consistent quality and flavor profiles despite the inherent variability of raw mango seasonality and varietal differences.

Mango Powder Market Executive Summary

The global Mango Powder Market is experiencing robust growth driven primarily by shifting consumer demographics favoring convenience foods fortified with natural, fruit-derived ingredients. Business trends indicate a strong move toward contract manufacturing and strategic partnerships between powder producers and large food conglomerates to secure long-term raw material supply and standardize product specifications. Manufacturers are heavily investing in specialized drying technologies, such as freeze-drying, to preserve maximal nutrient content and sensory characteristics, catering to the premium segment of the market focused on nutraceutical and high-end functional food applications. Competitive strategies focus heavily on traceability, sustainability certifications, and the development of organic and non-GMO verified mango powder variants to address ethical sourcing and clean-label demands.

Regionally, the Asia Pacific (APAC) market, spearheaded by India and Southeast Asian countries, dominates both production capacity and consumption volume, largely due to deep-rooted cultural consumption patterns and the ready availability of diverse mango varieties suitable for processing. However, North America and Europe are exhibiting the fastest growth rates, driven by the massive uptake in health supplements, dietary powders, and innovative beverage concepts that utilize mango powder for natural sweetness, coloring, and functional benefits. Regulatory environments regarding food additives and allergen labeling are becoming stricter globally, compelling manufacturers to adhere to stringent international quality standards, especially concerning heavy metal contamination and pesticide residues, which significantly influences trade flows.

Segmentation analysis highlights the increasing dominance of the Application segment, with Beverages and Functional Foods being the most lucrative areas. Within the powder type, spray-dried mango powder remains the highest volume segment due to its cost-effectiveness and excellent solubility, making it suitable for high-volume beverage and industrial processing. Conversely, freeze-dried mango powder commands a premium price point, dictated by its superior preservation of flavor, aroma, and thermo-sensitive nutrients, making it highly preferred in the high-value dietary supplement and infant nutrition sectors. Sustainability initiatives focusing on waste reduction and utilizing underutilized mango varieties for powder production are emerging as crucial differentiating factors for market leaders.

AI Impact Analysis on Mango Powder Market

User inquiries regarding AI's influence on the Mango Powder Market predominantly revolve around optimizing agricultural yields, ensuring raw material quality consistency, and enhancing supply chain predictability amidst volatile climate conditions. Key themes center on leveraging machine learning for pest and disease detection in orchards, using predictive modeling to forecast mango harvest timing and volume, and automating quality control processes during dehydration. Users are keenly interested in how AI can minimize post-harvest losses, which historically have been a significant challenge in the mango industry, ultimately stabilizing pricing and ensuring a reliable supply of high-quality feedstock for powder production. Additionally, questions often arise concerning AI's role in consumer demand forecasting, allowing manufacturers to optimize production runs and reduce inventory holding costs, thereby improving overall market efficiency and reducing wastage.

- AI-driven predictive modeling optimizes mango yield forecasting and harvest timing, minimizing post-harvest losses.

- Machine learning algorithms enhance raw material quality sorting based on ripeness, sugar content, and defect analysis prior to processing.

- Automated spectrophotometers, integrated with AI, ensure consistent color and flavor profile matching of the final mango powder batches.

- Supply chain risk management utilizes AI to analyze climate data, geopolitical stability, and shipping logistics to optimize global distribution routes.

- Advanced analytics supports demand forecasting, allowing powder manufacturers to align production schedules precisely with fluctuating seasonal buyer requirements.

- AI facilitates the traceability of mango sources from farm to final product, enhancing transparency and compliance with stringent international sourcing regulations.

DRO & Impact Forces Of Mango Powder Market

The market dynamics of mango powder are significantly shaped by a combination of strong market drivers, inherent operational restraints, and substantial future growth opportunities, which collectively exert powerful influence forces. Drivers include the global health and wellness trend, emphasizing natural and functional ingredients, and the rising consumer preference for convenience food formats that utilize dried fruit powders for flavor and fortification. Furthermore, the strong push from developing economies to commercialize post-harvest processing to reduce agricultural waste provides continuous impetus for market expansion. These drivers create a sustained high demand environment, encouraging significant capital investment in processing technology and capacity expansion, particularly in APAC and Latin America.

However, the market faces notable restraints, primarily centered around the intense seasonality of mango production, leading to inherent price volatility and supply chain inconsistencies that complicate year-round manufacturing planning. The high capital expenditure required for advanced drying technologies, such as freeze-drying, also acts as a barrier to entry for smaller market players. Moreover, regulatory scrutiny regarding residual pesticides and quality standards (e.g., moisture content, particle size) demands rigorous quality assurance processes, adding to operational costs. These restraints necessitate strong backward integration strategies, including contract farming and specialized storage infrastructure, to mitigate risks associated with raw material availability and quality fluctuations.

Opportunities are abundant in emerging applications, specifically within the nutraceutical, infant food, and pet food industries, where the nutritional profile of mango powder offers significant value addition. The development of specialized, highly soluble, and encapsulated mango powder variants tailored for specific industrial processes (e.g., acidic beverage formulations) presents a substantial avenue for premiumization and market penetration. Furthermore, expanding into previously untapped markets in Eastern Europe and Africa, coupled with a focus on sustainable and organic sourcing certifications, promises long-term profitable growth. These collective forces underscore a dynamic market environment where technological innovation and strategic resource management are critical for competitive success.

Segmentation Analysis

The Mango Powder Market segmentation provides a granular view of consumption patterns, technological preferences, and end-user requirements across the global landscape. Segmentation is primarily based on Processing Technology (Form), Application, and Distribution Channel. Analysis reveals that market choices are heavily influenced by the desired final product attributes, such as nutritional retention, solubility, shelf life, and, critically, cost-effectiveness. Spray-dried powder dominates in terms of volume due to its lower production cost and superior suitability for high-volume industrial uses like beverage flavoring and confectionery fillings, where price sensitivity is high and rapid dissolution is paramount.

Conversely, the high-value segment is predominantly driven by Freeze-Dried Mango Powder. This method, while more capital-intensive, excels at retaining the delicate volatile compounds responsible for authentic mango aroma and flavor, alongside preserving heat-sensitive micronutrients. This makes freeze-dried variants the preferred choice for premium functional food manufacturers, dietary supplement producers, and baby food formulators, sectors that prioritize sensory excellence and maximum nutrient density. The convergence of consumer demand for functional foods and advancements in drying technology continues to refine these segmentation boundaries, leading to the introduction of hybrid drying methods designed to balance cost and quality effectively.

By Application, the market is characterized by strong demand from the Bakery and Confectionery sector, utilizing mango powder for flavor, natural color, and moisture control. However, the Beverages segment, including fortified juices, smoothies, and instant drink mixes, is projected to exhibit the fastest growth, capitalizing on the powder's excellent solubility and concentrated flavor profile. The meticulous analysis of these segments is crucial for market participants looking to tailor their product offerings, optimize production processes, and focus their marketing efforts on the most profitable end-user industries, ensuring alignment with specific industrial requirements concerning particle size, flowability, and moisture absorption characteristics.

- By Processing Technology (Form):

- Spray Dried Mango Powder

- Freeze Dried Mango Powder

- Vacuum Dried Mango Powder

- Other Drying Methods (e.g., Refractance Window Drying)

- By Application:

- Beverages (Juices, Smoothies, Instant Mixes)

- Food & Bakery Products (Cakes, Cookies, Fillings)

- Confectionery and Desserts (Ice Cream, Yogurt, Candies)

- Nutraceuticals and Functional Foods

- Infant Food and Nutrition

- Savory Applications (Spice Mixes, Sauces)

- By Distribution Channel:

- Business to Business (B2B)

- Business to Consumer (B2C)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Mango Powder Market

The Mango Powder Market value chain commences with the upstream activities of raw material sourcing, predominantly centered in tropical and subtropical regions such as India, Thailand, Mexico, and Brazil. Upstream analysis involves rigorous agricultural practices, including cultivar selection, pest control, and harvesting, which are critical for determining the final quality and yield of the powder. Strong backward integration and long-term contract farming agreements are essential components at this stage, enabling processors to secure consistent volumes of high-quality mangoes and standardize parameters like Brix level and acidity. Challenges here include seasonal volatility, climate change risks, and the high cost of transportation from farm gate to the processing facility, all of which heavily influence the ultimate cost of goods sold for the finished powder.

The core midstream activity involves processing, encompassing washing, peeling, pulping, and the critical drying phase (spray, freeze, or vacuum drying), followed by milling and packaging. The choice of drying technology is the most significant value-adding step, directly impacting the sensory profile, nutritional retention, and price of the powder. Quality control checkpoints at this stage are crucial, involving stringent testing for moisture content, microbial contamination, and heavy metal residues, ensuring compliance with global food safety standards such as HACCP and ISO 22000. Efficient energy management and waste utilization (e.g., utilizing mango peels and seeds for by-products) are increasingly important strategic focuses for optimizing operational expenses and meeting sustainability goals within the processing ecosystem.

Downstream analysis focuses on distribution and market penetration, primarily dominated by the Business-to-Business (B2B) channel, where bulk powder is sold to industrial buyers—food and beverage manufacturers, flavor houses, and nutraceutical companies—through specialized distributors and ingredient brokers. Direct distribution is common for large-volume contracts, fostering stronger relationships and customization opportunities. The indirect channel, serving the smaller B2C market (e.g., specialty food stores and e-commerce platforms selling retail-packaged mango powder), is growing rapidly due to the rising demand for DIY health foods and culinary ingredients. Effective logistics, including specialized temperature-controlled storage and handling to prevent caking and spoilage, are vital for maintaining product integrity until it reaches the final end-user.

Mango Powder Market Potential Customers

Potential customers for mango powder are highly diversified across the commercial food landscape, driven by the ingredient's utility as a natural flavorant, colorant, and nutritional fortifier. The primary customers are large-scale food and beverage manufacturing companies, including major dairy processors seeking natural fruit flavors for yogurts and ice creams, and global beverage corporations requiring concentrated, shelf-stable fruit essences for ready-to-drink formulations, instant drink mixes, and functional beverages. These customers prioritize bulk supply reliability, standardized flavor profiles, and excellent dissolution characteristics to ensure seamless integration into high-speed production lines, often demanding specific particle sizes and flowability characteristics for automated dispensing systems.

A rapidly expanding customer base resides within the nutraceutical and dietary supplement industry. These buyers leverage mango powder, particularly the freeze-dried variant, for its high antioxidant content, vitamins, and perceived health benefits, incorporating it into protein powders, meal replacements, and specialized health supplement capsules. These customers place extremely high emphasis on ingredient purity, traceability, and the verification of nutritional claims, often requiring organic certification or specific testing to confirm bioactive compound concentration. This segment often procures smaller, high-value batches compared to the mainstream food industry, but requires significantly higher documentation and quality assurance standards.

Further potential customers include specialty bakeries, confectionery producers, and Quick Service Restaurants (QSRs) that utilize mango powder in glazes, dessert toppings, or specialized limited-edition menu items. The infant food sector represents a highly regulated but lucrative segment, demanding the highest levels of safety and quality, ensuring the powder is free from contaminants and retains maximum nutritional value suitable for sensitive populations. Additionally, the growing popularity of international cuisine and the demand for authentic flavoring agents in the prepared meal and spice blend markets (where amchur powder is highly valued) ensure a broad and stable long-term customer base for the diverse range of mango powder products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,500.0 Million |

| Market Forecast in 2033 | USD 2,560.0 Million |

| Growth Rate | CAGR 7.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Archer Daniels Midland (ADM), Döhler GmbH, Sunopta Inc., NutraDry Pty Ltd., Banyan Tree Foods, Kanegrade Ltd., Aarkay Food Products, Green Valley Industries, FutureCeuticals Inc., SV Agrofood, Saipro Biotech Pvt. Ltd., Diana Group (Symrise), Iprona AG, DMH Ingredients, New Global Group, Van Drunen Farms, Paradise Fruits Solutions, Berrifine A/S, Naturex (Givaudan), Sensient Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mango Powder Market Key Technology Landscape

The technology landscape for the Mango Powder Market is defined by continuous innovation aimed at maximizing flavor retention, extending shelf life, and minimizing energy consumption during the dehydration process. The core technologies employed include Spray Drying, which remains the most cost-effective method for high-volume production, utilizing a rapid evaporation process that results in fine, highly soluble powder suitable for beverage and instant mix applications. Recent advancements in spray drying focus on using encapsulation agents, such as maltodextrin or gum arabic, to protect the volatile flavor compounds and improve powder flowability, thereby enhancing overall product stability and extending the effective shelf life of the mango essence.

Freeze Drying (Lyophilization) represents the high-end technology in the market. Although significantly more energy-intensive and time-consuming, freeze drying operates under vacuum and low temperatures, sublimating ice directly from the frozen state and avoiding exposure to high heat. This gentle process is crucial for preserving the thermosensitive vitamins, antioxidants, and the authentic, complex flavor profile of the fresh fruit, resulting in a premium powder highly valued by the nutraceutical and clean-label food industries. The ongoing development in freeze drying centers on optimizing cycle times and enhancing energy efficiency through advanced heat pump systems and intelligent process control, striving to reduce the cost premium associated with this superior preservation method.

Emerging and specialized technologies, such as Refractance Window Drying (RWD) and Vacuum Microwave Drying, are gaining traction due to their potential to offer a balance between the low operational costs of spray drying and the quality preservation of freeze drying. RWD utilizes infrared radiation through a thin film of water, allowing rapid, low-temperature drying that results in high-quality powder with superior color and nutrient retention compared to conventional methods. Beyond drying, quality assurance technologies—including near-infrared (NIR) spectroscopy for instant quality checking (e.g., moisture, sugar content) and advanced metal detection systems—are standard across modern processing facilities, ensuring regulatory compliance and maintaining the high purity standards expected by global industrial customers.

Regional Highlights

- Asia Pacific (APAC): APAC is the global hub for mango powder, dominating both production and consumption. Countries like India, China, Thailand, and the Philippines have extensive mango cultivation and processing capabilities. India, in particular, drives the supply, leveraging diverse varieties for different end-use profiles (e.g., Kesar, Alphonso). Regional consumption is deeply embedded in traditional culinary applications, alongside rapid growth in the modern industrial food sector. The market is characterized by high volume, competitive pricing, and a strong presence of both small-scale local processors and large international ingredient suppliers establishing regional hubs.

- North America: North America represents a high-value, fast-growing market driven by robust demand for functional foods, health supplements, and natural flavorings. Consumers in the US and Canada exhibit a strong preference for clean-label, exotic ingredients, fueling demand for premium, freeze-dried mango powder variants. The market growth here is strongly supported by innovative product launches in the specialized beverage and sports nutrition sectors. Strict regulatory standards related to food safety and transparency significantly influence sourcing decisions and product formulation strategies within this region.

- Europe: The European market demonstrates significant appetite for high-quality, traceable, and sustainably sourced mango powder. Key growth drivers include the booming demand for vegan and vegetarian food products and the stringent regulatory environment that favors natural coloring and flavoring agents over synthetic alternatives. Western European countries, notably Germany, the UK, and France, are major importers, using mango powder extensively in confectionery, dairy products, and specialized infant nutrition formulations. Emphasis on certifications (Fair Trade, Organic) dictates supply chain development.

- Latin America (LATAM): LATAM, particularly Mexico, Brazil, and Peru, functions as both a crucial production base and a growing consumption market. Favorable climate and extensive agricultural infrastructure support high raw mango output. The market is increasingly shifting towards value-added processing, with local manufacturers catering to the regional demand for juices, preserves, and instant mixes. Investment in advanced processing technology is increasing, aiming to capture global export opportunities, particularly targeting the North American and European functional ingredient markets.

- Middle East and Africa (MEA): The MEA region is primarily an import market for highly processed mango powder, although certain African nations are developing production capabilities. High demand is driven by the use of mango powder in luxury confectionery, specialized catering services, and reconstituted fruit beverages, aligning with regional consumer preferences for intensely flavored foods. The market growth is reliant on stable import logistics and increasing disposable incomes within the Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mango Powder Market.- Archer Daniels Midland (ADM)

- Döhler GmbH

- Sunopta Inc.

- NutraDry Pty Ltd.

- Banyan Tree Foods

- Kanegrade Ltd.

- Aarkay Food Products

- Green Valley Industries

- FutureCeuticals Inc.

- SV Agrofood

- Saipro Biotech Pvt. Ltd.

- Diana Group (Symrise)

- Iprona AG

- DMH Ingredients

- New Global Group

- Van Drunen Farms

- Paradise Fruits Solutions

- Berrifine A/S

- Naturex (Givaudan)

- Sensient Technologies

Frequently Asked Questions

Analyze common user questions about the Mango Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between spray-dried and freeze-dried mango powder?

Spray-dried mango powder is cost-effective, highly soluble, and suitable for bulk industrial applications like beverages, but it has lower nutritional retention. Freeze-dried powder is premium, retains superior flavor, color, and thermosensitive nutrients, and is preferred for nutraceuticals and high-value functional foods.

Which geographical region dominates the global supply and consumption of mango powder?

The Asia Pacific (APAC) region, spearheaded by countries such as India and Thailand, dominates the global supply chain due to extensive raw mango cultivation and established processing infrastructure, while also holding the largest share of historical consumption.

How does the seasonality of raw mangoes affect the market stability of mango powder?

Mango seasonality leads to inherent price volatility and supply inconsistencies in the raw material market. Manufacturers mitigate this through advanced preservation technologies, long-term contract farming, and maintaining significant cold storage capacity to ensure year-round product availability and stable pricing for industrial buyers.

What is the primary driver for the high growth rate observed in the mango powder market?

The primary driver is the accelerating global trend toward clean-label and functional ingredients, where consumers demand natural flavorants, colorants, and nutritional boosters derived from fruits, positioning mango powder as a preferred alternative to artificial additives.

What key application segment is projected to show the fastest market growth during the forecast period?

The Beverages segment, encompassing fortified juices, instant drink mixes, and functional smoothies, is projected to exhibit the fastest growth, capitalizing on the excellent solubility and concentrated flavor delivery offered by high-quality mango powder formulations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager