Manhole Cover Hooks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436216 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Manhole Cover Hooks Market Size

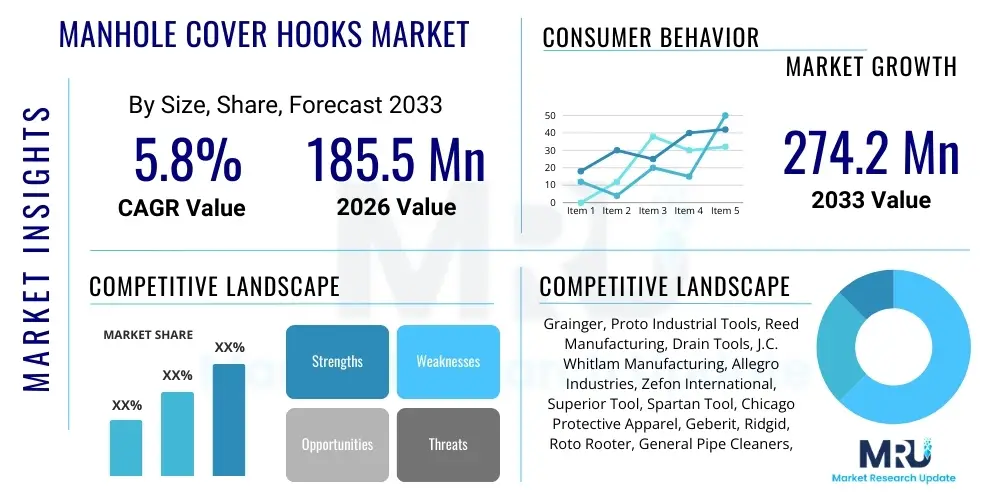

The Manhole Cover Hooks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $185.5 million USD in 2026 and is projected to reach $274.2 million USD by the end of the forecast period in 2033.

Manhole Cover Hooks Market introduction

The Manhole Cover Hooks Market encompasses the manufacturing and distribution of specialized tools designed for the safe and efficient lifting and maneuvering of heavy manhole covers used in urban, municipal, and industrial infrastructure. These essential tools are crucial for maintenance, inspection, and repair activities within underground utility networks, including sewer lines, storm drains, and telecommunication conduits. The core products range from standard steel hooks to advanced ergonomic and multi-functional lifting systems, addressing diverse weight and design specifications of manhole covers globally. The continuous need for infrastructure maintenance, coupled with stringent occupational safety standards, serves as a fundamental market driver.

Manhole cover hooks are integral components within the workflow of utility companies, public works departments, and construction contractors. Major applications include accessing wastewater systems for blockage removal, inspecting subsurface cables and fiber optics, and performing routine environmental monitoring of underground flow. The primary benefit derived from these tools is the mitigation of back injuries and strains associated with manual lifting of extremely heavy, often rusted or stuck, metal or composite covers. Furthermore, modern hooks incorporate features such as adjustable lengths, leverage-enhancing designs, and magnetic capabilities, optimizing operational efficiency and reducing task completion time.

Key driving factors accelerating market expansion include rapid urbanization leading to increased underground infrastructure development, particularly in emerging economies, and the continuous necessity to replace aging infrastructure in developed regions. Additionally, governmental mandates emphasizing worker safety, such as those imposed by OSHA and similar international bodies, necessitate the use of specialized lifting tools, pushing traditional methods out of favor. Innovations in materials, particularly the shift toward lighter, high-strength composite hooks and telescopic designs, also contribute significantly to the market's positive trajectory by offering superior portability and durability.

Manhole Cover Hooks Market Executive Summary

The Manhole Cover Hooks Market is currently characterized by robust business trends centered on safety standardization and ergonomic innovation. Market growth is underpinned by sustained public and private investment in water, sewage, and telecommunications infrastructure upgrades globally. Manufacturers are increasingly focusing on developing specialized tools for composite and fiberglass covers, moving beyond traditional heavy cast iron designs. Key business priorities involve minimizing physical strain on operators, leading to the rapid adoption of telescoping and folding hook designs which enhance portability and storage efficiency. Furthermore, market competition is intensifying through the introduction of premium, corrosion-resistant materials such as stainless steel and specialized alloys tailored for harsh underground environments, ensuring longevity and reliability under frequent heavy use conditions.

Regionally, North America and Europe maintain dominance due to established infrastructure networks and strict enforcement of occupational health and safety regulations, necessitating continuous replacement and upgrade of older manual lifting equipment. However, the Asia Pacific (APAC) region is poised for the highest growth rate, fueled by unprecedented urbanization, massive government-led smart city projects, and the associated construction boom in utilities infrastructure, particularly in China, India, and Southeast Asia. Latin America and MEA show steady, increasing demand driven by expansion of municipal sewage systems and growing foreign investment in basic utility provision, focusing primarily on cost-effective, durable steel hook solutions.

Segmentation trends indicate a strong preference for high-strength steel hooks based on material, owing to their proven durability and cost-effectiveness, although composite and aluminum variants are gaining traction due to lightweight properties beneficial for single-operator tasks. Application-wise, the Municipal Infrastructure segment, encompassing water and wastewater utilities, remains the dominant revenue generator, necessitating specialized magnetic and multi-point lifting tools. Within product type, non-folding hooks hold the largest volume share due to their robust simplicity, but telescopic hooks are forecast to exhibit the fastest growth, aligning with the industry's shift toward highly adaptable and space-saving tools that cater to varied manhole depths and access constraints.

AI Impact Analysis on Manhole Cover Hooks Market

User inquiries regarding the influence of Artificial Intelligence on the Manhole Cover Hooks market primarily revolve around automation, safety integration, and predictive maintenance. Common questions focus on whether AI will completely replace manual lifting (leading to reduced hook demand), how sensor technology paired with AI can improve hook usage safety, and if AI-driven infrastructure monitoring will predict when and where manual intervention (using hooks) is required. The consensus emerging from this analysis suggests that while AI will not eliminate the immediate need for physical lifting tools, it will fundamentally transform the context and frequency of their deployment. AI-powered diagnostic and inspection tools, such as subterranean drones and smart sensors, are minimizing unnecessary human entries, thereby optimizing the deployment of manhole cover hooks strictly for necessary maintenance or emergency access, rather than routine inspections. This shift focuses demand away from basic, high-volume tools towards precision-engineered, safety-enhanced, and potentially RFID/sensor-integrated lifting equipment designed for high-stakes, planned interventions. Furthermore, AI analytics can optimize tool inventory management, ensuring the right type of hook is available based on predicted regional cover requirements and operational scheduling.

- AI-enhanced infrastructure monitoring reduces routine manual inspections, shifting demand for hooks towards critical, predicted maintenance events.

- Integration of smart sensors (RFID, Bluetooth) into hooks enables AI systems to track tool utilization, location, and maintenance needs, optimizing inventory.

- AI algorithms analyze ergonomic data gathered during lifting operations, informing manufacturers on future hook designs that minimize operator strain and comply with safety standards.

- Predictive maintenance analytics, driven by AI monitoring of subterranean assets, dictates the specific timing and location where manhole cover hooks will be required for access.

- Automation (e.g., robotic cover lifters) handles repetitive tasks, but specialized, heavy-duty hooks remain essential for unique or jammed covers inaccessible to robotics.

DRO & Impact Forces Of Manhole Cover Hooks Market

The Manhole Cover Hooks Market is primarily driven by escalating global investments in urban infrastructure modernization and the strict enforcement of worker safety regulations, demanding specialized, ergonomic lifting equipment. Conversely, the market faces restraints from the rising adoption of sophisticated remote inspection technologies, such as underground cameras and autonomous vehicles, which reduce the frequency of physical manhole entry. Significant opportunities exist in the development of lightweight, highly durable composite materials and integration with smart city infrastructure, allowing for tool tracking and operational data logging. These forces collectively shape the market's trajectory, emphasizing innovation in safety and efficiency while navigating technological substitution pressures.

Drivers: A paramount driver is the increasing regulatory scrutiny on workplace safety, particularly concerning manual material handling. Regulatory bodies mandate tools that minimize strain and prevent musculoskeletal injuries associated with lifting heavy municipal infrastructure elements. This pressure compels utilities and contractors to replace outdated or makeshift lifting methods with professionally designed manhole cover hooks. Furthermore, the global trend toward urban densification necessitates continuous expansion and maintenance of sewer, water, and power infrastructure, directly increasing the operational scope for these tools. High-frequency maintenance cycles in aging urban centers across North America and Europe also ensure consistent demand for replacement and specialized hooks designed for various cover sizes and materials.

Restraints: The market faces significant headwinds from the growing penetration of non-invasive inspection technologies. High-resolution sewer cameras, sonic leak detection equipment, and drone-based inspection systems allow utility providers to monitor and diagnose subterranean issues without physically removing the manhole cover. This reduction in mandatory physical access diminishes the overall volume demand for lifting tools. Another restraint is the initial high capital investment required for ergonomic, multi-function hook systems compared to basic, conventional steel bars, which can deter smaller municipal departments or independent contractors operating under tight budget constraints. The standardization challenges posed by the sheer variety of manhole cover designs (size, weight, locking mechanism) across different regions also complicate universal tool adoption.

Opportunity: Key opportunities lie in the development of advanced materials, specifically lightweight composites and high-grade aluminum alloys, which appeal to operators requiring highly portable and easily maneuverable tools without compromising strength. The emerging market for smart city integration presents a chance to incorporate RFID tags or GPS trackers into hooks, facilitating efficient inventory management and geo-location tracking, crucial for large-scale utility operations. Additionally, the development of specialty hooks designed specifically for the rapidly increasing number of composite manhole covers (used in low-traffic areas) and specialized sewer access points opens up niche, high-margin product lines. Penetrating the rapidly growing infrastructure markets in APAC and optimizing distribution channels remain key strategic growth opportunities.

Impact Forces: The impact forces of safety regulations and infrastructure investment are powerful positive influences, guaranteeing a stable baseline demand for essential tools. However, the rapidly advancing technological substitution forces, particularly driven by remote sensing and robotics, serve as a medium-to-long-term disruptive threat, pushing manufacturers towards higher value, specialized tools rather than high-volume commodity items. The evolving material science impact force facilitates product differentiation and ergonomic improvement, maintaining the competitive edge of professional tools over improvised lifting solutions.

Segmentation Analysis

The Manhole Cover Hooks market is comprehensively segmented based on the critical attributes of the product, including material composition, functionality type, and the ultimate end-user application. Analyzing these segments provides a clear delineation of market dynamics, revealing where innovation is focused and which end-user categories drive the highest demand. The Material segment is crucial as it dictates durability, weight, and corrosion resistance, essential factors given the harsh operational environments. The Application segmentation identifies the primary consumers—municipalities being the largest—and allows for tailored product development addressing specific regulatory and infrastructure needs in diverse sectors like telecommunications and industrial complexes. Product Type segmentation reflects the ongoing drive for ergonomic improvement and operational efficiency, favoring designs that offer portability and enhanced lifting leverage over simple static hooks.

The predominant segmentation involves Material, differentiating products into traditional heavy-duty steel, lighter aluminum variants, and modern, corrosion-resistant composite materials. Steel hooks dominate volume sales due to cost-efficiency and strength, essential for heavy cast iron covers. Conversely, the fastest growth is observed in composite and aluminum segments, catering to operator safety and mobility requirements. Application segmentation reveals that the Municipal Infrastructure sector, including water, sewage, and public utility access, generates the bulk of revenue, followed by Construction & Utilities segments which require tools for temporary access during site development. Understanding these segments is vital for manufacturers to allocate R&D resources effectively, particularly towards developing multi-functional tools capable of handling varied cover types found across all end-user groups, thus maximizing market penetration and cross-sector applicability.

- Type:

- Folding Hooks

- Non-Folding Hooks (Fixed)

- Telescopic Hooks (Adjustable)

- Multi-Functional Lifting Systems (Magnetic/Leverage Enhanced)

- Material:

- Steel (Carbon Steel, Stainless Steel)

- Aluminum (High-Strength Alloys)

- Composite Materials (Fiberglass, Reinforced Polymers)

- Application:

- Municipal Infrastructure (Water/Wastewater)

- Construction & Utilities

- Industrial Facilities

- Telecommunication and Data Networks

Value Chain Analysis For Manhole Cover Hooks Market

The value chain for the Manhole Cover Hooks Market starts with the sourcing of raw materials, primarily high-grade steel, aluminum alloys, or specialized composite resins. This upstream activity involves material suppliers providing standardized and certified inputs. The manufacturing stage then encompasses forging, machining, welding, and surface treatments (like galvanization or powder coating) to produce the final tools, focusing heavily on quality control and ergonomic design features. Efficiency in this stage dictates final product cost and durability. Downstream activities involve distribution, sales, and end-user deployment. Given the specialized nature of the tool, adherence to strict safety standards throughout the manufacturing and quality assurance processes is a non-negotiable requirement that heavily influences the value added at each stage.

Upstream analysis highlights the dependence on stable pricing and supply of base metals like steel and aluminum. Manufacturers must strategically manage commodity price volatility, often through long-term contracts, to maintain competitive pricing for the final tool. The rise of composite materials introduces new upstream complexities related to sourcing specialized resins and fiber reinforcement, requiring closer collaboration with chemical suppliers. Midstream, the manufacturing process is increasingly sophisticated, incorporating advanced CAD design for optimal leverage and weight balance, and robotic welding for structural integrity. Value is maximized by achieving certifications (e.g., ISO, ANSI standards) that validate the tool's load-bearing capacity and safety compliance, directly appealing to risk-averse municipal buyers.

Distribution channels are critical in the downstream phase. Direct sales are often utilized for large municipal contracts or bespoke orders, allowing manufacturers to maintain high margins and direct relationships with key stakeholders. However, the majority of sales flow through indirect channels, primarily industrial distributors, specialized safety equipment retailers, and large construction supply wholesalers (like Grainger or specialized utility suppliers). These intermediaries provide regional access, logistical support, and bundling opportunities with related safety and maintenance gear. The choice between direct and indirect distribution hinges on market penetration goals and the size of the target customer, with indirect channels essential for reaching small to medium-sized contractors and maintenance teams efficiently across broad geographical areas.

Manhole Cover Hooks Market Potential Customers

The primary consumers of manhole cover hooks are entities responsible for the construction, maintenance, and inspection of subterranean public and private utilities. These potential customers possess operational requirements centered on safety compliance, reliability, and ergonomic efficiency. Municipal Public Works Departments form the largest customer base, necessitating bulk procurement of heavy-duty, certified tools for routine access to water mains, sewage systems, and storm drains. Beyond the governmental sector, private utility companies—including telecommunications providers, electricity distributors, and natural gas operators—represent a significant, often higher-value customer segment, requiring specialized, non-conductive, or high-security access tools tailored for their proprietary infrastructure components.

A second major customer category includes civil engineering firms and specialized construction contractors involved in large-scale infrastructure projects. During new road construction, utility installation, or rehabilitation projects, these contractors require durable, portable hooks for temporary access and rapid site setup. Their procurement decisions are often project-based and driven by immediate compliance needs and tool portability, favoring telescopic or folding models. Furthermore, industrial facilities, such as manufacturing plants or processing sites with complex internal drainage and utility systems, constitute a specialized customer group demanding hooks for confined space entry procedures, where safety and reliable retrieval mechanisms are paramount.

Finally, safety and environmental service providers, including companies specializing in hazard cleanup, waste management, and environmental monitoring, frequently purchase manhole cover hooks. These customers require tools that ensure swift, safe access under varied conditions, often incorporating magnetic or highly specialized tips to handle seized or unusual covers. The purchasing process across all segments is highly regulated, often involving public tenders or mandated safety checks, meaning manufacturers must provide comprehensive documentation, load testing certifications, and compliance assurances to successfully capture market share among these diverse but safety-conscious buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185.5 Million USD |

| Market Forecast in 2033 | $274.2 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Grainger, Proto Industrial Tools, Reed Manufacturing, Drain Tools, J.C. Whitlam Manufacturing, Allegro Industries, Zefon International, Superior Tool, Spartan Tool, Chicago Protective Apparel, Geberit, Ridgid, Roto Rooter, General Pipe Cleaners, Electric Eel Manufacturing, Ken-Tool, Norva Plastics, Sani-Flow, QSP Supply, Custom Cover Hooks Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Manhole Cover Hooks Market Key Technology Landscape

The technology landscape within the Manhole Cover Hooks market is focused less on radical digital transformation and more on advanced material science, ergonomic engineering, and multi-functional integration. Key technological advancements involve the sophisticated utilization of specialized alloys, such particularly high-tensile strength stainless steels and aviation-grade aluminum, which provide maximum strength-to-weight ratios essential for compliance with single-operator lifting limits. Surface treatment technologies, such as advanced galvanization, powder coating, and specialized ceramic coatings, are crucial for enhancing corrosion resistance, thereby extending the service life of tools exposed to highly caustic sewage and storm drain environments. These material and treatment innovations directly address the fundamental requirements for tool longevity and safety under extreme operational stress.

Ergonomic engineering is another critical technological focus area. Modern hook designs utilize principles of mechanical advantage and leverage optimization to minimize the force required by the operator to initially break the seal of a stuck manhole cover and subsequently lift and maneuver the cover. This includes the development of adjustable-length telescopic shafts that accommodate different operator heights and access depths, mitigating awkward postures and reducing back injury risks. Advanced hook tip designs often incorporate replaceable tungsten carbide inserts or hardened steel points optimized for gripping various cover types (e.g., slotted, keyway, or magnetic), ensuring secure engagement and preventing slippage, which is a significant safety risk during lifting operations, especially on uneven surfaces.

The integration of digital technology, while subtle, is increasing. This involves the use of permanent magnets embedded in specialized hook systems, often utilizing rare-earth magnets, providing hands-free attachment capabilities for specific cast-iron covers, improving both safety and speed. Furthermore, some high-end manufacturers are embedding passive technologies such as Radio Frequency Identification (RFID) chips or NFC tags directly into the tool handle. This integration facilitates automated asset tracking, inventory management, and operational data logging when the tool is checked out or used in conjunction with a utility company's digital maintenance management system (CMMS), marking a significant step towards optimizing tool deployment and ensuring mandatory safety checks are performed before use.

Regional Highlights

- North America (United States, Canada, and Mexico): This region dominates the Manhole Cover Hooks Market, primarily driven by substantial regulatory emphasis on worker safety, particularly OSHA standards, which mandate the use of certified lifting tools. The expansive and aging infrastructure across major U.S. cities requires constant maintenance and upgrades, ensuring steady demand. The market here is characterized by a strong preference for high-end, ergonomic, and multi-functional tools, including specialized magnetic lifters and telescoping hooks, reflecting high labor costs and the priority placed on minimizing injury liability. Demand is stable for replacement tools and innovative composite materials suitable for new utility installations.

- Europe (Germany, UK, France, Italy, Spain, Russia): Europe represents a mature and technologically advanced market. Stringent EU safety directives and high environmental standards necessitate frequent sewer and utility inspections, sustaining the demand for high-quality, durable hooks. Germany and the UK are key markets, characterized by sophisticated utility management and a high adoption rate of non-folding stainless steel hooks known for their corrosion resistance and longevity. The focus remains on tools that offer maximum leverage and certified load capacity, often requiring regional-specific certifications to handle diverse municipal cover designs prevalent across different member states.

- Asia Pacific (APAC) (China, Japan, South Korea, India, Southeast Asia): APAC is the fastest-growing region, fueled by unprecedented rates of urbanization and massive government investments in new public infrastructure and smart city development. China and India are the core engines of growth, driven by volume demand for basic, robust steel hooks used in rapid construction and expansion projects. While cost-sensitivity is higher, there is emerging demand in countries like Japan and South Korea for advanced ergonomic hooks and composite materials, mirroring Western safety standards, particularly within highly regulated urban maintenance sectors. The market here focuses heavily on establishing scalable and cost-effective supply chains.

- Latin America (Brazil, Argentina, Colombia): This market exhibits steady growth, primarily influenced by ongoing efforts to modernize and extend basic sanitation and utility infrastructure. Demand is typically concentrated in urban centers and is highly price-sensitive, leading to a dominance of basic, cost-effective carbon steel hooks. Brazil, with its large infrastructure projects, is the regional leader. Market penetration requires navigating complex local distribution networks and addressing varied infrastructural quality levels, often necessitating tools that can handle severely degraded or rusted covers.

- Middle East and Africa (MEA): The MEA market is experiencing moderate but accelerating growth, heavily correlated with large-scale development projects in the Gulf Cooperation Council (GCC) states (Saudi Arabia, UAE) and increasing basic utility access in parts of Africa. Demand in the GCC is characterized by a need for durable tools capable of handling extreme heat and sandy conditions, often sourced through international contracts. The market is highly influenced by government infrastructure spending, focusing on quality and robust construction to withstand harsh environmental conditions and prolonged operational cycles in rapidly expanding utility networks.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Manhole Cover Hooks Market.- Grainger

- Proto Industrial Tools

- Reed Manufacturing

- Drain Tools

- J.C. Whitlam Manufacturing

- Allegro Industries

- Zefon International

- Superior Tool

- Spartan Tool

- Chicago Protective Apparel

- Geberit

- Ridgid

- Roto Rooter

- General Pipe Cleaners

- Electric Eel Manufacturing

- Ken-Tool

- Norva Plastics

- Sani-Flow

- QSP Supply

- Custom Cover Hooks Inc.

Frequently Asked Questions

Analyze common user questions about the Manhole Cover Hooks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for ergonomic manhole cover hooks?

The primary driver is the stringent enforcement of occupational health and safety regulations (such as those established by OSHA and equivalent bodies globally) which necessitate the use of specialized lifting tools to mitigate serious musculoskeletal injuries, particularly back strains, resulting from manually moving heavy manhole covers. Ergonomic design is paramount to ensuring worker compliance and reducing employer liability.

How is the proliferation of non-invasive inspection technology impacting the market?

Non-invasive technologies, including high-definition subterranean cameras and robotic inspection systems, are reducing the overall frequency of mandatory physical manhole entry for routine checks. This trend restrains volume sales of basic hooks but simultaneously drives demand for specialized, higher-value hooks required only for critical, planned maintenance, emergency access, or repair tasks that robots cannot yet perform.

Which material segment is expected to show the fastest growth rate in the forecast period?

The Composite Materials segment (including reinforced polymers and fiberglass) is projected to exhibit the fastest growth. This acceleration is due to the inherent lightweight properties of composites, enhancing portability and operator safety, combined with their superior resistance to corrosion and chemical exposure commonly found in wastewater environments, offering an extended lifespan compared to standard carbon steel.

What role does Smart City infrastructure development play in the future of the manhole cover hooks market?

Smart City initiatives drive demand for advanced tools by requiring efficient management and tracking of all utility assets. This includes the potential integration of RFID or GPS tracking into manhole cover hooks to optimize utility maintenance workflows, monitor tool usage, and ensure the right equipment is deployed rapidly for AI-predicted infrastructure failures or maintenance events.

What are the key technical specifications potential customers prioritize when selecting a manhole cover hook?

Potential customers, particularly municipal departments, prioritize certified load capacity and lifting strength, corrosion resistance (especially for hooks used near coastal or industrial areas), ergonomic handle design to reduce physical strain, and multi-functionality, ensuring the hook can effectively engage with various cover types (e.g., lift, drag, and break seals) commonly found within their jurisdiction.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager