Manual Riveter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440146 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Manual Riveter Market Size

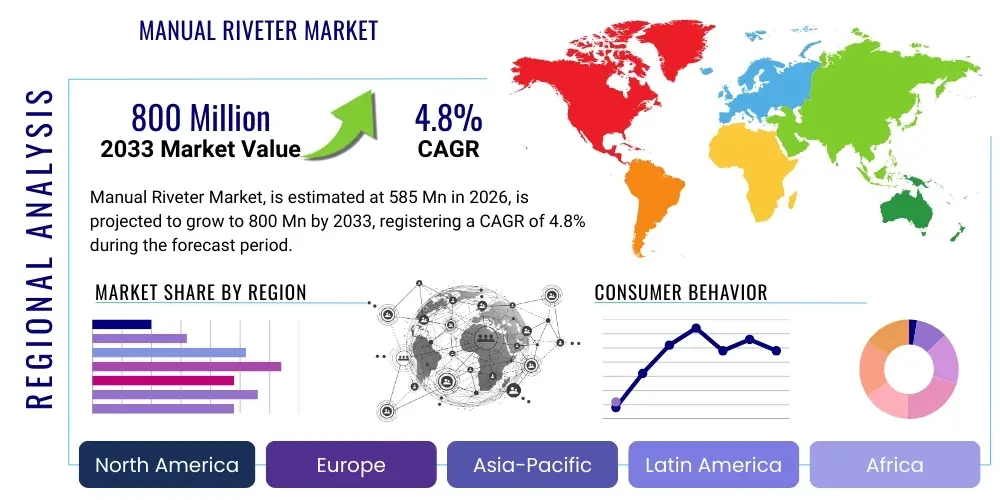

The Manual Riveter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 585 Million in 2026 and is projected to reach USD 800 Million by the end of the forecast period in 2033. This growth trajectory is underpinned by sustained demand across various industrial and commercial sectors, alongside an expanding interest in DIY and home improvement projects globally. The inherent advantages of manual riveting, such as its cost-effectiveness, portability, and versatility in diverse applications, continue to ensure its relevance even amidst advancements in fastening technologies.

Manual Riveter Market introduction

The Manual Riveter Market encompasses the global sales and distribution of hand-operated tools designed for permanently joining two or more materials by deforming a rivet. These tools are essential for creating strong, durable, and vibration-resistant mechanical fasteners across a myriad of applications without the need for an external power source. Manual riveters, ranging from simple hand squeeze types to more robust lever-action models, are valued for their reliability and precision in scenarios where access to power is limited or where delicate control is paramount. The fundamental principle involves inserting a rivet through pre-drilled holes in the materials to be joined and then using the riveter to expand the rivet's tail, creating a secure joint.

Major applications for manual riveters span critical sectors such as automotive repair and aftermarket, where they are indispensable for bodywork and component assembly; construction, including HVAC ductwork, roofing, and general sheet metal fabrication; and electronics, for securing chassis and internal components. Beyond industrial uses, manual riveters are widely adopted in consumer goods manufacturing, marine applications for boat and dock repairs, and perhaps most significantly, in the burgeoning do-it-yourself (DIY) market for various home repair, craft, and hobby projects. Their adaptability to different rivet types and material thicknesses further enhances their utility, making them a staple tool in workshops and field service kits.

The key benefits driving the sustained demand for manual riveters include their low initial cost, ease of operation requiring minimal training, and exceptional portability, allowing for use in remote or constrained environments. They offer a highly secure and tamper-resistant fastening solution that is often superior to screws in terms of vibration resistance and structural integrity, and more accessible than welding for certain materials or skill levels. Furthermore, the market is driven by the consistent growth in global manufacturing output, expanding infrastructure development projects, and a noticeable increase in consumer engagement with DIY activities, all of which contribute to a steady demand for reliable and efficient manual fastening tools.

Manual Riveter Market Executive Summary

The Executive Summary of the Manual Riveter Market highlights a landscape characterized by resilience and strategic adaptation. Business trends indicate a persistent demand for ergonomic and durable manual riveters, driven by end-users seeking enhanced operational comfort and tool longevity. While automated riveting systems continue to advance, manual riveters maintain a crucial niche due to their cost-effectiveness, versatility for low-volume or repair tasks, and suitability for environments without power access. Manufacturers are increasingly focusing on incorporating high-strength materials, precision engineering, and user-friendly designs to cater to a diverse clientele ranging from professional tradespersons to hobbyists. Innovation in rivet material compatibility and ease of rivet loading mechanisms are also notable trends shaping product development.

Regionally, the market exhibits varied dynamics. Asia-Pacific stands out as a significant growth engine, fueled by rapid industrialization, expanding manufacturing bases, and extensive infrastructure development across countries like China, India, and Southeast Asian nations. This region sees substantial demand for both basic and advanced manual riveting solutions. North America and Europe, while representing more mature markets, demonstrate stable demand, particularly in the automotive aftermarket, construction, and a thriving DIY sector. In these regions, the emphasis is often on premium quality, specialized tools, and compliance with stringent safety and ergonomic standards. Latin America and the Middle East & Africa are emerging markets, with increasing investments in construction and industrial sectors driving a steady uptick in demand for manual riveting tools.

Segmentation trends within the Manual Riveter Market underscore the increasing prevalence of blind riveters due to their single-sided access requirement, making them highly versatile for various applications. There is also a growing demand for multi-material compatible riveters, capable of handling aluminum, steel, and stainless steel rivets with ease, reflecting the diverse material usage in modern manufacturing and repair. The end-user segment reveals strong contributions from industrial applications, alongside a robust and continuously expanding commercial and DIY segment, highlighting the broad appeal of these tools. Specialized riveters for heavy-duty tasks or specific rivet types, such as structural rivets, are also experiencing tailored growth, addressing niche requirements for high-strength fastening.

AI Impact Analysis on Manual Riveter Market

Common user questions regarding AI's impact on the Manual Riveter Market often revolve around concerns about job displacement, the future relevance of manual tools in increasingly automated factories, and how smart technologies might enhance or render obsolete traditional methods. Users seek to understand if AI will directly integrate into manual tools, or if its influence will be more peripheral, affecting the broader ecosystem in which these tools operate. There is a general expectation that while AI may not directly transform the physical operation of a manual riveter, it will undoubtedly reshape demand patterns, operational efficiencies, and the skill sets required in related fields.

Based on this analysis, the key themes indicate that AI's influence on the Manual Riveter Market will be predominantly indirect, acting as an enabler for optimized processes rather than a direct technological upgrade to the tools themselves. Concerns about obsolescence are largely mitigated by the distinct advantages of manual riveting in specific scenarios, such as repair work, low-volume production, or field applications where portability and independence from power are critical. Expectations are geared towards AI enhancing the manufacturing, distribution, and utilization contexts of manual riveters, rather than embedded intelligence within the tools themselves. For instance, AI can optimize supply chains for rivets and riveters, predict maintenance needs for accompanying automated machinery, and improve training for manual assembly tasks.

- AI-driven supply chain optimization enhances the availability and cost-efficiency of manual riveters and associated rivets, ensuring timely delivery to diverse markets.

- Predictive analytics, powered by AI, can forecast demand for manual riveters based on construction trends, automotive aftermarket activity, and DIY market growth.

- AI in manufacturing can optimize production lines for riveter components, improving quality control and reducing waste, even for conventionally manufactured tools.

- Smart inventory management systems, utilizing AI, can ensure distributors maintain optimal stock levels of various manual riveter types and rivet assortments.

- AI-enhanced training platforms, leveraging augmented reality (AR) or virtual reality (VR), can provide immersive and efficient instruction for technicians and DIY users on proper manual riveting techniques.

- Indirectly, AI's role in advancing material science could lead to lighter, stronger, or more specialized rivets, influencing the design and material compatibility requirements of manual riveters.

DRO & Impact Forces Of Manual Riveter Market

The Manual Riveter Market is shaped by a confluence of critical drivers, restraints, and opportunities, collectively known as DRO & Impact Forces. A primary driver is the continuous expansion of global manufacturing sectors, particularly in automotive, construction, and HVAC industries, which rely heavily on durable and cost-effective fastening solutions. The escalating trend of do-it-yourself (DIY) activities and home improvement projects among consumers further boosts demand for accessible and easy-to-use riveting tools. Additionally, the inherent benefits of rivets, such as their superior vibration resistance, high shear and tensile strength, and suitability for joining dissimilar materials, position manual riveters as indispensable tools where permanent and robust joints are required, often at a lower initial investment compared to welding or complex automated systems. The versatility and portability of these tools also make them ideal for field repairs and remote applications.

Despite these drivers, several restraints impact market growth. The most significant is the increasing adoption of automated riveting systems in large-scale industrial manufacturing, which offer higher speeds, greater precision, and reduced labor costs for repetitive tasks. Competition from alternative fastening methods, such as advanced adhesives, self-piercing rivets (SPR), and specialized screws, also presents a challenge, particularly in applications where material integrity or assembly time is a critical factor. Furthermore, the manual nature of these tools means they can be prone to ergonomic issues for operators performing repetitive tasks over extended periods, potentially leading to lower productivity and increased labor costs compared to automated solutions. The potential lack of skilled labor capable of consistently achieving high-quality manual rivet installations in some regions also acts as a constraint.

Opportunities for growth in the Manual Riveter Market primarily lie in emerging economies, where industrialization and infrastructure development are creating a burgeoning demand for fundamental fastening tools. These regions often prioritize cost-effectiveness and ease of use, characteristics inherent to manual riveters. Niche applications requiring precision control, on-site repairs, or customization for specialized projects, such as those in aerospace maintenance or bespoke fabrication, continue to provide strong avenues for market penetration. Moreover, advancements in ergonomic tool design, the development of lighter yet more robust materials for riveter construction, and the ongoing innovation in rivet types (e.g., multi-grip, sealed, or structural rivets) present significant opportunities for manufacturers to differentiate their products and cater to evolving user needs, enhancing both comfort and application versatility.

Segmentation Analysis

The Manual Riveter Market is comprehensively segmented to provide granular insights into its diverse operational landscape. This segmentation allows for a detailed understanding of market dynamics based on the characteristics of the tool, its intended applications, the type of end-user, and the specific rivet materials and types it is designed to handle. Such categorization is crucial for manufacturers to tailor product development, for distributors to optimize inventory, and for end-users to select the most appropriate tools for their specific requirements, reflecting the varied demands and preferences across different industrial, commercial, and consumer contexts. The market's structure is thus analyzed through multiple lenses to reveal underlying trends and growth areas.

- By Type:

- Hand Riveters: Compact, single-hand operated tools, suitable for light-duty and occasional use.

- Lever Riveters: Two-hand operated, providing increased leverage for larger rivets and tougher materials, ideal for medium to heavy-duty applications.

- Accordion Riveters: Characterized by their scissor-like action, offering ergonomic advantages and mechanical force multiplication for sustained use.

- Heavy-Duty Riveters: Designed for industrial-grade applications, capable of setting large diameter and high-strength rivets.

- By Application:

- Automotive (Repair & Aftermarket): Used for vehicle body repair, accessory installation, and component fastening.

- Construction: Essential for HVAC ductwork, roofing, general sheet metal assembly, and non-structural fastening.

- HVAC: Specifically for joining sheet metal in heating, ventilation, and air conditioning systems.

- Electronics: Utilized for securing components within chassis, enclosures, and circuit boards where welding is unsuitable.

- Consumer Goods: Applied in the assembly of appliances, furniture, and various household items.

- Marine: Employed for boat repair, dock maintenance, and marine fabrication due to corrosion resistance benefits of rivets.

- DIY & Hobby: Popular among individual users for home repairs, crafting, and personal projects.

- Others: Includes aerospace repair (non-critical), signage, and general fabrication workshops.

- By End-User:

- Industrial: Large-scale manufacturing plants, assembly lines, and heavy fabrication workshops.

- Commercial: Professional trade persons, small and medium-sized enterprises (SMEs), automotive repair shops, and construction contractors.

- DIY/Residential: Individual consumers, hobbyists, and homeowners for personal projects and repairs.

- By Rivet Material Compatibility:

- Aluminum Riveters: Designed to work primarily with softer aluminum rivets.

- Steel Riveters: Capable of setting steel and stainless steel rivets, requiring more force.

- Multi-Material Riveters: Versatile tools capable of handling various rivet materials with interchangeable nosepieces.

- By Rivet Type:

- Blind Rivet Tools: Used for blind rivets, which can be installed when access is only available from one side of the workpiece.

- Solid Rivet Tools: Employed for solid rivets, requiring access to both sides for installation.

- Drive Rivet Tools: Specific tools for drive rivets, which are installed by striking a pin.

Value Chain Analysis For Manual Riveter Market

The value chain for the Manual Riveter Market begins with comprehensive upstream analysis, focusing on the sourcing and processing of raw materials and the manufacturing of essential components. This initial stage involves suppliers of high-grade steel alloys for tool bodies and jaws, aluminum for lighter models, and various plastics and rubbers for ergonomic handles and grips. These raw materials undergo rigorous processing, including forging, machining, heat treatment, and precision stamping, to create durable and precisely engineered internal mechanisms and external casings. Component manufacturers specialize in producing springs, mandrels, nosepieces, and other intricate parts that determine the riveter's functionality, lifespan, and compatibility with different rivet types. The quality and cost-effectiveness at this upstream stage are critical, directly influencing the final product's performance and market competitiveness.

Moving downstream, the value chain encompasses the assembly, branding, and distribution of the finished manual riveters. Manufacturers assemble the components, conduct quality control checks, and package the tools for market. The distribution channel is multifaceted, comprising both direct and indirect routes. Direct distribution involves manufacturers selling directly to large industrial clients, specialized fabrication shops, or government entities through dedicated sales teams or online platforms. This approach often allows for customized orders, bulk pricing, and direct technical support, fostering strong client relationships. It is typically favored for large-volume purchases or specialized industrial-grade tools where specific requirements must be met.

Indirect distribution forms the broader and more common pathway to market, involving a network of wholesalers, regional distributors, and various retailers. Wholesalers purchase in large volumes from manufacturers and then supply smaller quantities to a diverse array of retailers. These retailers include major hardware store chains, specialized tool shops, automotive parts stores, building material suppliers, and an increasingly significant segment of e-commerce platforms. This extensive network ensures wide market penetration, reaching individual tradespersons, small businesses, and the vast DIY consumer base. E-commerce platforms, in particular, have revolutionized the indirect channel by offering unparalleled reach, competitive pricing, and convenience, making manual riveters accessible to a global audience and often serving as a primary point of purchase for hobbyists and professionals alike.

Manual Riveter Market Potential Customers

The Manual Riveter Market serves a broad and diverse spectrum of potential customers, spanning multiple industries and individual user segments. At the core, end-users are typically organizations or individuals requiring a reliable, permanent, and often portable fastening solution for joining various materials. This includes a significant portion of the manufacturing sector where manual processes remain cost-effective or necessary for specific assembly steps, as well as an extensive network of repair and maintenance service providers. The critical attributes of manual riveters—namely, their cost-efficiency, ease of use, and robust fastening capabilities—make them attractive to a wide array of buyers seeking practical and durable mechanical joining solutions for their projects and operations.

Key segments of potential customers include automotive repair shops and body shops, which frequently use manual riveters for vehicle panel replacement, interior component fastening, and various aftermarket installations. The construction industry, encompassing HVAC installers, roofers, sheet metal fabricators, and general contractors, relies on these tools for ductwork, flashing, roofing applications, and non-structural assemblies. Manufacturers of consumer goods, ranging from appliances to small electronics and furniture, also utilize manual riveters for specific assembly stages where precision and permanent attachment are crucial without the need for power-intensive equipment. These professional and commercial entities prioritize tool durability, reliability, and ergonomic design to ensure efficient and high-quality work.

Beyond industrial and commercial users, the burgeoning do-it-yourself (DIY) and hobbyist market represents a substantial and growing customer base. Homeowners engaging in renovation projects, individuals pursuing craft and art projects, and hobbyists involved in model making or small-scale repairs frequently turn to manual riveters for their simplicity and effectiveness. Educational institutions and vocational training centers also constitute an important segment, acquiring these tools for teaching fundamental fabrication and assembly skills. The versatility of manual riveters allows them to cater to both the demanding needs of professional tradespersons and the occasional requirements of casual users, solidifying their position as a fundamental tool across numerous applications and skill levels.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 585 Million |

| Market Forecast in 2033 | USD 800 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, POP Avdel, Gesipa, Marson (Howmet Aerospace), RivetKing, DeWalt, Astro Pneumatic Tool, Surebonder, Chicago Pneumatic, ATD Tools, Capri Tools, Klauke (Textron), Makita, Milwaukee Tool, Wera, Knipex, Facom, IRWIN, Proto, Apex Tool Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Manual Riveter Market Key Technology Landscape

The technology landscape for the Manual Riveter Market, while seemingly conventional, is underpinned by continuous advancements aimed at enhancing user experience, durability, and versatility. A primary focus is on ergonomic design, where research and development efforts are directed towards creating tools that minimize user fatigue and maximize comfort during prolonged use. This includes optimizing handle shapes, incorporating anti-slip and shock-absorbing grip materials, and balancing tool weight to reduce strain. The application of advanced material science is critical, with manufacturers utilizing high-strength steel alloys for critical components like jaws and mandrels, often coupled with specialized heat treatments to increase wear resistance and extend the tool's lifespan. Lighter, yet robust, materials such as aluminum composites are also being explored for tool bodies to improve portability without compromising strength.

Precision manufacturing techniques play a vital role in ensuring the consistent quality and reliable performance of manual riveters. Computer Numerical Control (CNC) machining is extensively used to produce components with tight tolerances, ensuring smooth mechanical action and accurate rivet setting every time. This precision is essential for tools that must operate flawlessly across various rivet sizes and material types. Furthermore, the technological evolution of rivets themselves directly influences the design of manual riveters. The development of multi-grip rivets, sealed rivets for waterproof applications, and high-strength structural rivets necessitates corresponding advancements in tool jaw design, pulling mechanisms, and interchangeable nosepiece systems to accommodate these specialized fasteners effectively. These innovations ensure that manual riveters remain compatible with the latest rivet technologies, expanding their range of applications.

Beyond the core mechanical aspects, the technology landscape also includes innovations that enhance the overall efficiency and longevity of manual riveters. This involves applying corrosion-resistant coatings to metal components, improving lubrication systems for moving parts, and designing mechanisms that simplify the loading and ejection of mandrels. Some advanced models may incorporate features like adjustable stroke settings for precise rivet deformation or built-in spent mandrel collectors for cleaner workspaces. While manual riveters typically do not contain complex electronic components, the underlying technological advancements in materials, manufacturing processes, and ergonomic principles ensure that these traditional tools continue to evolve, offering improved performance, greater user comfort, and extended service life to meet the rigorous demands of modern industrial, commercial, and DIY environments.

Regional Highlights

- North America: This region represents a mature and stable market for manual riveters, characterized by a strong emphasis on quality, durability, and ergonomic design. The robust automotive aftermarket, steady construction industry, and a deeply entrenched DIY culture drive consistent demand. Key countries like the United States and Canada are significant consumers, with professionals valuing brand reputation and performance, and the retail sector thriving through large hardware chains and e-commerce platforms.

- Europe: Similar to North America, Europe is a well-established market with high demand for premium and specialized manual riveters. Countries such as Germany, the UK, France, and Italy exhibit strong industrial bases, particularly in manufacturing, automotive repair, and construction, where precision and adherence to strict safety standards are paramount. The European market also benefits from a vibrant professional trades sector and a growing interest in sustainable and long-lasting tools.

- Asia Pacific (APAC): This region is identified as the fastest-growing market for manual riveters globally, primarily due to rapid industrialization, extensive infrastructure development, and burgeoning manufacturing activities in countries like China, India, Japan, South Korea, and Southeast Asian nations. The region's large population also fuels a significant and expanding DIY segment. The demand here spans from cost-effective basic models to more advanced, high-performance tools, reflecting diverse economic landscapes.

- Latin America: The Manual Riveter Market in Latin America is experiencing steady growth, driven by increasing investments in construction, infrastructure projects, and developing industrial sectors, particularly in Brazil, Mexico, and Argentina. Cost-effectiveness and versatility are key purchasing criteria in this region, as businesses seek reliable fastening solutions that are accessible and easy to deploy across various applications.

- Middle East and Africa (MEA): This emerging market shows promising growth potential, stimulated by ongoing infrastructure development, urbanization, and expansion in the oil and gas sector, which necessitates robust repair and maintenance tools. Countries like Saudi Arabia, UAE, and South Africa are leading the demand, prioritizing durable tools that can withstand challenging environmental conditions and support various construction and industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Manual Riveter Market.- Stanley Black & Decker

- POP Avdel

- Gesipa

- Marson (Howmet Aerospace)

- RivetKing

- DeWalt

- Astro Pneumatic Tool

- Surebonder

- Chicago Pneumatic

- ATD Tools

- Capri Tools

- Klauke (Textron)

- Makita

- Milwaukee Tool

- Wera

- Knipex

- Facom

- IRWIN

- Proto

- Apex Tool Group

Frequently Asked Questions

Analyze common user questions about the Manual Riveter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of manual riveters?

Manual riveters are primarily used in automotive repair, construction (especially HVAC and sheet metal work), electronics assembly, consumer goods manufacturing, marine applications, and a wide range of DIY and hobby projects. They excel in scenarios requiring permanent, vibration-resistant fastening where power access is limited or precise manual control is preferred.

How do manual riveters compare to automated riveting systems?

Manual riveters offer cost-effectiveness, portability, and versatility for low-volume production, repair work, or field applications without requiring external power. Automated systems, conversely, provide higher speed, greater precision, and reduced labor for large-scale, repetitive industrial tasks, but come with a higher initial investment and less flexibility for varied job sites.

What types of rivets can manual riveters install?

Manual riveters are compatible with various rivet types including blind rivets, solid rivets, and drive rivets. Their compatibility often depends on the specific tool's design and interchangeable nosepiece attachments, allowing them to set rivets made from materials like aluminum, steel, stainless steel, and copper.

What factors should be considered when choosing a manual riveter?

Key factors include the types and sizes of rivets to be installed, the materials being joined, the frequency of use, ergonomic design for user comfort, durability, the availability of interchangeable nosepieces, and the overall cost. Heavy-duty applications typically require lever or accordion-style riveters for increased force.

Is the manual riveter market growing, and what drives this growth?

Yes, the manual riveter market is experiencing steady growth, projected at a 4.8% CAGR between 2026 and 2033. This growth is driven by expanding manufacturing sectors, particularly in emerging economies, increasing participation in DIY activities, the demand for durable and cost-effective fastening solutions, and the inherent portability and versatility of manual tools.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager