Manufacturing Consulting Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439218 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Manufacturing Consulting Market Size

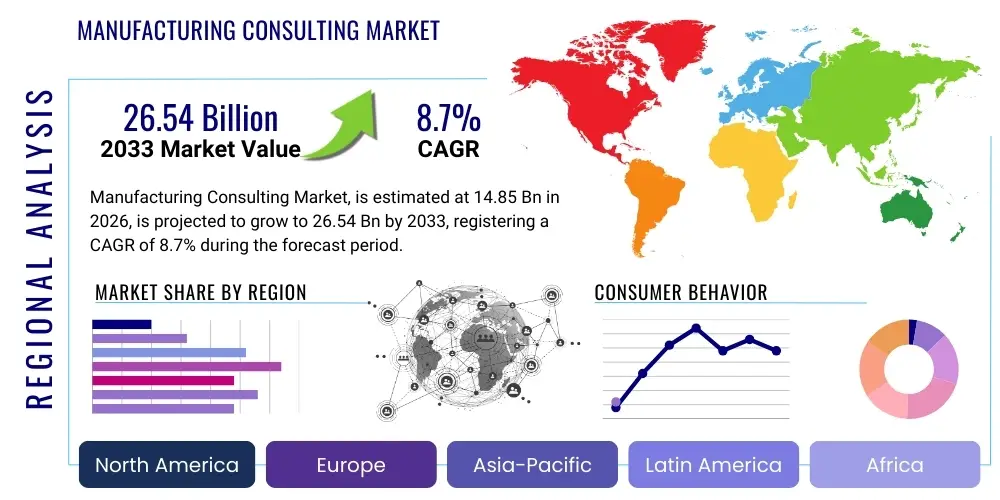

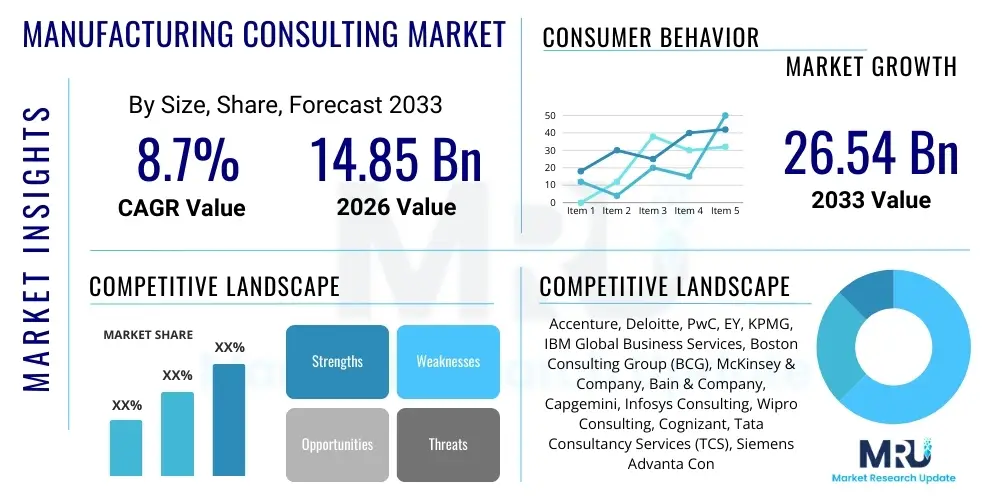

The Manufacturing Consulting Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2026 and 2033. The market is estimated at USD 14.85 Billion in 2026 and is projected to reach USD 26.54 Billion by the end of the forecast period in 2033.

Manufacturing Consulting Market introduction

The manufacturing consulting market encompasses a wide array of professional services designed to assist manufacturing companies in optimizing their operations, improving efficiency, enhancing productivity, and fostering innovation. These services span strategic planning, operational excellence, supply chain management, technology implementation, digital transformation, and sustainable practices. The primary objective is to help manufacturers navigate complex market dynamics, technological advancements, and regulatory landscapes to achieve competitive advantage and sustainable growth. Consultants bring specialized expertise, methodologies, and an external perspective to identify challenges, develop tailored solutions, and facilitate their successful implementation.

Product descriptions within this market vary significantly, ranging from broad enterprise-level strategic overhauls to highly specialized technical optimizations in areas like lean manufacturing, Industry 4.0 adoption, or factory automation. Major applications include enhancing production processes, reducing waste, optimizing inventory, improving product quality, managing global supply chains, integrating advanced technologies like AI and IoT, and ensuring regulatory compliance. The consulting services are not merely advisory; they often involve hands-on support in change management, training, and performance monitoring to ensure long-term impact and value realization for the client.

The benefits derived from engaging manufacturing consultants are multifaceted. These include significant cost reductions through operational efficiencies, increased revenue from improved product quality and faster time-to-market, enhanced agility and responsiveness to market shifts, and a stronger competitive position through innovation and digital capabilities. Driving factors for market growth include the increasing complexity of global supply chains, the imperative for digital transformation, the need for sustainable and resilient operations, the rising demand for personalized products, and intense competition compelling manufacturers to continuously seek operational excellence and technological integration to maintain their edge.

Manufacturing Consulting Market Executive Summary

The manufacturing consulting market is experiencing robust growth, primarily driven by transformative business trends such as the widespread adoption of Industry 4.0 technologies, the increasing focus on supply chain resilience, and the relentless pursuit of operational efficiency. Manufacturers are grappling with challenges ranging from geopolitical uncertainties and labor shortages to escalating production costs and the urgent need for sustainable practices. Consulting firms are instrumental in guiding these businesses through digital transformation journeys, helping them leverage advanced analytics, artificial intelligence, and automation to create smart factories and agile production systems. This strategic partnership enables clients to not only address immediate operational hurdles but also to build long-term capabilities for innovation and market leadership.

Regionally, the market exhibits dynamic trends, with established industrial hubs in North America and Europe demonstrating a strong demand for advanced manufacturing consulting services, particularly in areas like sustainable manufacturing and advanced robotics. Meanwhile, the Asia Pacific region is emerging as a significant growth engine, fueled by rapid industrialization, expanding manufacturing bases, and increasing foreign direct investment. Countries like China, India, and Southeast Asian nations are investing heavily in upgrading their manufacturing infrastructure and adopting digital technologies, thereby creating substantial opportunities for consulting firms. Latin America, the Middle East, and Africa are also showing promising growth, albeit at a slower pace, driven by infrastructure development projects and efforts to diversify industrial capabilities.

Segmentation trends reveal a shift towards specialized consulting services tailored to specific industry verticals and technological needs. Operational consulting, IT consulting, and supply chain consulting remain dominant segments, but there is a notable surge in demand for digital transformation consulting, including services focused on AI, IoT, cloud integration, and cybersecurity within manufacturing environments. Furthermore, large enterprises continue to be major clients, yet small and medium-sized enterprises (SMEs) are increasingly seeking consulting expertise to scale their operations, improve competitiveness, and adopt new technologies, often facilitated by more flexible and modular consulting engagement models. This evolution underscores the market's adaptability and its critical role in supporting the global manufacturing ecosystem's continuous evolution.

AI Impact Analysis on Manufacturing Consulting Market

Common user questions regarding AI's impact on the manufacturing consulting market often revolve around how AI can enhance efficiency, reduce costs, and drive innovation, alongside concerns about data privacy, integration complexity, and the need for specialized AI expertise. Users frequently inquire about practical applications, such as predictive maintenance, quality control, and supply chain optimization, and the tangible ROI consultants can deliver through AI implementations. There is also significant interest in understanding the role of AI in shaping future manufacturing strategies and how consulting firms are adapting their service offerings to meet these evolving demands, particularly in terms of workforce upskilling and ethical AI deployment. Key themes include the fear of being left behind without AI adoption, the challenge of justifying initial investment, and the quest for clear, actionable AI roadmaps.

- Enhanced data-driven decision-making for operations and strategy.

- Optimization of supply chains through predictive analytics and demand forecasting.

- Implementation of predictive maintenance to reduce downtime and costs.

- Automation of quality control processes, leading to fewer defects and higher product standards.

- Personalization of manufacturing processes to meet bespoke customer demands.

- Development of smart factories through AI-powered automation and robotics integration.

- Improvement in energy efficiency and sustainability through AI-managed resource allocation.

- Creation of digital twins for simulation, testing, and process optimization.

- Facilitation of faster product design and development cycles.

- Enabling more agile and responsive manufacturing systems.

- Guiding clients on ethical AI deployment and data governance.

- Training and upskilling of workforce for AI-driven manufacturing environments.

- Identification of new revenue streams through AI-enabled product and service innovation.

- Risk assessment and mitigation strategies for AI system integration.

- Benchmarking AI adoption against industry best practices.

DRO & Impact Forces Of Manufacturing Consulting Market

The manufacturing consulting market is significantly shaped by a confluence of drivers, restraints, opportunities, and external impact forces. Key drivers include the escalating global competition, which compels manufacturers to continuously seek operational excellence and cost reductions. The rapid pace of technological advancements, particularly in Industry 4.0, automation, and artificial intelligence, creates an urgent need for specialized guidance in digital transformation and technology adoption. Furthermore, the increasing complexity of global supply chains and the growing demand for sustainable and resilient manufacturing practices are strong forces pushing companies to seek external expertise for strategic optimization and risk management. Regulatory pressures and the need for compliance across diverse geographies also contribute to the demand for consulting services.

However, the market also faces several restraints. High consulting fees can be a significant barrier for small and medium-sized enterprises (SMEs), potentially limiting their access to crucial expertise. Data security and intellectual property concerns often make manufacturers hesitant to share sensitive operational data with external consultants. Moreover, the difficulty in accurately measuring the return on investment (ROI) from consulting engagements can lead to skepticism and reluctance from potential clients. The scarcity of highly specialized consultants with deep expertise in emerging technologies combined with practical manufacturing experience also poses a challenge, sometimes leading to a mismatch between client needs and consultant capabilities. Internal resistance to change within client organizations can also hinder the successful implementation of consulting recommendations.

Opportunities within the manufacturing consulting market are abundant, particularly in the realm of digital transformation, where consultants can guide manufacturers in implementing IoT, AI, machine learning, and blockchain for enhanced efficiency and transparency. The growing emphasis on environmental, social, and governance (ESG) criteria presents a substantial opportunity for consulting firms to advise on sustainable manufacturing practices, circular economy models, and energy efficiency. Furthermore, the expanding manufacturing base in emerging economies, coupled with their drive for industrial modernization, offers new geographical markets for consulting services. The development of more flexible, outcome-based, and modular consulting models can also help overcome cost barriers and expand the client base, especially among SMEs. Impact forces such as geopolitical shifts, trade policies, and global economic volatility frequently alter market dynamics, requiring manufacturers to adapt swiftly, thereby increasing their reliance on expert consulting advice for resilience and strategic navigation.

Segmentation Analysis

The manufacturing consulting market is systematically segmented to reflect the diverse needs and operational structures of its client base, allowing for targeted service offerings and strategic market analysis. This segmentation typically categorizes services based on the type of expertise provided, the industries served, the size of the client enterprise, and the engagement model adopted. This granular approach helps consulting firms to specialize and position themselves effectively, while also enabling clients to identify the most suitable partners for their specific challenges. Understanding these segments is crucial for competitive analysis and strategic planning within the consulting landscape.

The breakdown by service type covers a broad spectrum, from high-level strategic guidance to detailed operational improvements and technological implementations. Industry vertical segmentation acknowledges the unique operational complexities and regulatory environments present in sectors like automotive, aerospace, pharmaceuticals, and consumer goods. Enterprise size distinction helps address the varying resource capacities and strategic priorities of large corporations versus small and medium-sized businesses. These segmentation frameworks allow for a comprehensive understanding of market demand and supply dynamics, facilitating more precise market sizing and forecasting, and ultimately, more effective delivery of value to manufacturing clients globally.

- By Service Type:

- Operations Consulting

- Strategy Consulting

- IT Consulting & Digital Transformation

- Supply Chain & Logistics Consulting

- Human Resources & Organization Consulting

- Financial & Risk Consulting

- Sustainability & ESG Consulting

- By Industry Vertical:

- Automotive

- Aerospace & Defense

- Pharmaceuticals & Healthcare

- Food & Beverage

- Chemicals & Materials

- Electronics & High-Tech

- Industrial Machinery & Equipment

- Consumer Goods

- Metals & Mining

- By Enterprise Size:

- Large Enterprises

- Small & Medium-sized Enterprises (SMEs)

- By Delivery Model:

- On-site Consulting

- Remote/Hybrid Consulting

Value Chain Analysis For Manufacturing Consulting Market

The value chain for the manufacturing consulting market begins with upstream activities focused on talent acquisition, knowledge development, and intellectual property creation. This involves recruiting highly skilled professionals with specialized expertise in various manufacturing domains, investing in continuous training and development, and conducting extensive research to build proprietary methodologies, frameworks, and technological tools. Strong internal research and development capabilities, coupled with partnerships with academic institutions and technology providers, are critical at this stage to ensure consultants are equipped with the latest insights and solutions. Effective knowledge management systems are essential to capture, categorize, and disseminate expertise across the firm, forming the foundational assets that consulting firms leverage downstream.

Midstream activities primarily involve project delivery, which encompasses client engagement, problem diagnosis, solution design, and implementation support. This stage requires robust project management capabilities, effective communication, and a collaborative approach with the client's internal teams. Consultants analyze operational data, conduct interviews, perform site visits, and utilize diagnostic tools to identify root causes of inefficiencies or challenges. Based on this analysis, tailored solutions are designed, ranging from process re-engineering and technology integration to strategic realignment. The implementation phase often involves change management, training, and ongoing monitoring to ensure the proposed solutions are effectively integrated and sustained within the client's operations, requiring adaptability and strong interpersonal skills.

Downstream activities center on distribution channels and client relationship management, which are crucial for market reach and sustained growth. Direct distribution channels involve consultants directly engaging with clients through existing networks, referrals, and proactive outreach. Indirect channels can include partnerships with technology vendors, industry associations, or government agencies that refer manufacturing clients. Post-engagement, ongoing relationship management, including follow-up assessments, value realization tracking, and identification of future consulting needs, is vital for fostering long-term partnerships and securing repeat business. Effective marketing and thought leadership — such as publishing whitepapers, hosting webinars, and speaking at industry conferences — also serve as powerful indirect channels to attract potential clients and establish credibility within the manufacturing sector.

Manufacturing Consulting Market Potential Customers

The potential customers for manufacturing consulting services span a broad spectrum of industries and enterprise sizes, all unified by a common need to enhance operational performance, embrace innovation, and navigate complex market dynamics. At its core, any organization involved in the production of goods, from raw material processing to final product assembly, represents a potential client. This includes established multinational corporations, large enterprises with intricate global supply chains, and increasingly, small and medium-sized enterprises (SMEs) striving for efficiency and growth in competitive landscapes. Their motivations for seeking consulting range from addressing specific operational bottlenecks and improving profitability to undertaking large-scale digital transformations and achieving sustainability goals.

Key end-users or buyers of these consulting services are typically senior management teams, including CEOs, COOs, plant managers, supply chain directors, and heads of innovation or R&D departments. These decision-makers are responsible for setting strategic direction, optimizing production, managing costs, ensuring quality, and driving technological adoption within their organizations. They often seek external expertise to gain an objective perspective, access specialized knowledge not available in-house, accelerate change, or validate internal strategies. The diversity of industries, such as automotive, aerospace, pharmaceuticals, food and beverage, electronics, and heavy machinery, each presents unique challenges and opportunities, requiring consultants to tailor their offerings to specific industry pain points and regulatory environments.

Furthermore, companies embarking on significant capital expenditures, factory expansions, new product launches, or mergers and acquisitions are prime candidates for manufacturing consulting, as they require strategic guidance and operational alignment. Organizations facing intense competitive pressure, supply chain disruptions, or regulatory non-compliance also frequently turn to consultants for urgent problem-solving and strategic interventions. The increasing imperative for sustainable manufacturing practices and the integration of environmental, social, and governance (ESG) factors into business operations are also expanding the customer base to include companies committed to responsible and resilient production models.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 14.85 Billion |

| Market Forecast in 2033 | USD 26.54 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Accenture, Deloitte, PwC, EY, KPMG, IBM Global Business Services, Boston Consulting Group (BCG), McKinsey & Company, Bain & Company, Capgemini, Infosys Consulting, Wipro Consulting, Cognizant, Tata Consultancy Services (TCS), Siemens Advanta Consulting, Rockwell Automation (Consulting Services), Dassault Systèmes (Consulting), SAP Services, Oracle Consulting, Kearney. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Manufacturing Consulting Market Key Technology Landscape

The manufacturing consulting market is heavily influenced by a dynamic technological landscape, demanding consultants to be at the forefront of innovation to effectively guide their clients. Core technologies include those underpinning Industry 4.0, such as the Internet of Things (IoT) for real-time data collection from factory floors, advanced robotics and automation for enhanced production efficiency, and artificial intelligence (AI) and machine learning (ML) for predictive analytics, quality control, and supply chain optimization. Consultants leverage these technologies to design and implement smart factories, enabling manufacturers to achieve higher levels of automation, connectivity, and data-driven decision-making, thereby transforming traditional production lines into intelligent, adaptive systems.

Furthermore, cloud computing plays a pivotal role by providing scalable infrastructure for data storage, processing, and application hosting, facilitating seamless integration across various operational systems and enabling remote access and collaboration. Digital twin technology is increasingly utilized for creating virtual replicas of physical assets, processes, or systems, allowing consultants to simulate scenarios, test modifications, and optimize performance before physical implementation. Additive manufacturing (3D printing) offers opportunities for product innovation and customized production, requiring consulting expertise to integrate these capabilities into existing manufacturing workflows. Blockchain technology is also gaining traction for enhancing supply chain transparency, traceability, and security, especially in complex global networks, presenting a new frontier for consulting services.

Data analytics platforms and business intelligence tools are fundamental for consultants to extract actionable insights from vast amounts of manufacturing data, enabling performance benchmarking, root cause analysis, and strategic forecasting. Cybersecurity solutions are paramount, as the increasing connectivity of operational technology (OT) systems exposes manufacturers to greater cyber risks, necessitating consulting services for risk assessment and implementation of robust security protocols. Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) continue to be foundational, with consultants specializing in their selection, customization, and integration to optimize enterprise-wide operations. The confluence of these technologies forms a comprehensive toolkit that manufacturing consultants utilize to drive efficiency, innovation, and resilience for their clients in an increasingly complex and digitalized industrial world.

Regional Highlights

- North America: A mature market characterized by early adoption of advanced manufacturing technologies, strong emphasis on operational excellence, and a significant demand for digital transformation consulting. The presence of large multinational corporations and a robust R&D ecosystem drives innovation. Key countries include the United States and Canada, with growing focus on reshoring and supply chain resilience.

- Europe: A diverse region with varying levels of technological maturity. Western Europe, particularly Germany, France, and the UK, leads in Industry 4.0 adoption, sustainable manufacturing practices, and advanced automation. Eastern Europe is experiencing growth due to increasing foreign investment and industrial modernization efforts. Regulatory compliance (e.g., GDPR, ESG standards) also fuels consulting demand.

- Asia Pacific (APAC): The fastest-growing market, driven by rapid industrialization, expanding manufacturing capacities (especially in China, India, Japan, South Korea, and Southeast Asian nations), and increasing adoption of automation and AI. Government initiatives to promote smart manufacturing and export-oriented production contribute significantly to market expansion.

- Latin America: An emerging market with growing investment in industrial infrastructure and technology upgrades, particularly in automotive, aerospace, and food & beverage sectors. Countries like Brazil and Mexico are key players, with a focus on improving operational efficiency and competitiveness amidst economic fluctuations.

- Middle East & Africa (MEA): Demonstrating steady growth, primarily driven by economic diversification efforts away from oil dependence, large-scale infrastructure projects, and industrial development initiatives. Countries in the GCC region (e.g., UAE, Saudi Arabia) are investing in advanced manufacturing and smart city concepts, fueling demand for consulting services.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Manufacturing Consulting Market.- Accenture

- Deloitte

- PwC

- EY

- KPMG

- IBM Global Business Services

- Boston Consulting Group (BCG)

- McKinsey & Company

- Bain & Company

- Capgemini

- Infosys Consulting

- Wipro Consulting

- Cognizant

- Tata Consultancy Services (TCS)

- Siemens Advanta Consulting

- Rockwell Automation (Consulting Services)

- Dassault Systèmes (Consulting)

- SAP Services

- Oracle Consulting

- Kearney

Frequently Asked Questions

What is manufacturing consulting and why is it important?

Manufacturing consulting involves professional services that help manufacturing companies optimize operations, enhance efficiency, reduce costs, and innovate. It is crucial because it provides specialized expertise and an objective perspective to navigate complex market dynamics, technological shifts, and competitive pressures, driving sustainable growth and strategic advantage.

How is AI impacting the manufacturing consulting market?

AI is profoundly impacting manufacturing consulting by enabling data-driven decision-making, predictive maintenance, supply chain optimization, and automation of quality control. Consultants are now guiding manufacturers in implementing AI for smart factories, digital twins, and personalized production, enhancing efficiency and creating new revenue streams.

What are the primary drivers of growth in the manufacturing consulting market?

The key drivers include intense global competition, rapid technological advancements (Industry 4.0, AI), increasing complexity of global supply chains, the imperative for sustainable manufacturing practices, and evolving regulatory landscapes, all compelling manufacturers to seek expert external guidance.

Which regions are leading the demand for manufacturing consulting services?

North America and Europe are mature markets with strong demand for advanced and digital transformation consulting. Asia Pacific, especially China and India, is the fastest-growing region due to rapid industrialization and technological adoption. Latin America, Middle East, and Africa are also showing significant growth.

What kind of technologies do manufacturing consultants typically advise on?

Manufacturing consultants advise on a broad range of technologies, including IoT, AI/ML, advanced robotics, cloud computing, digital twin, additive manufacturing, blockchain, data analytics, cybersecurity, ERP, and MES. Their expertise helps clients integrate these technologies for operational excellence and strategic innovation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager