Masonry Chisels Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434522 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Masonry Chisels Market Size

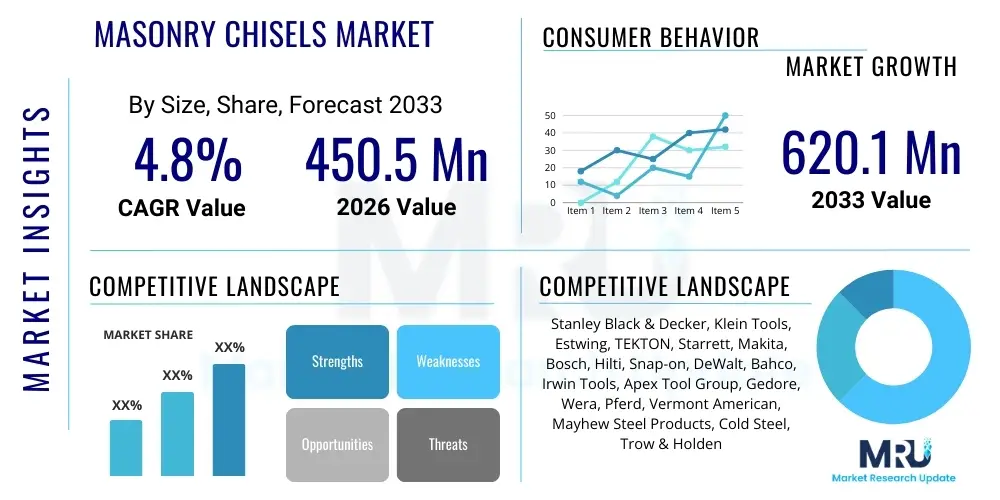

The Masonry Chisels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 620.1 Million by the end of the forecast period in 2033.

Masonry Chisels Market introduction

The Masonry Chisels Market encompasses specialized hand and power tools designed for cutting, shaping, and removing materials such as brick, concrete, stone, mortar, and tile. These tools are fundamental in construction, demolition, renovation, and artistic stone carving sectors, providing precision and force necessary for tasks where larger power tools are impractical or excessive. Key products include cold chisels, brick sets, bolster chisels, and specialized jointing and pointing chisels, manufactured predominantly from high-grade hardened steel alloys, often incorporating tungsten carbide tips for enhanced longevity and performance against dense aggregates. The primary function revolves around controlled material removal, crucial for tasks such as breaking down old mortar joints, cutting bricks cleanly to size, or preparing surfaces for repair.

The widespread adoption of masonry chisels is directly linked to the robust growth observed in global infrastructure development and the increasing focus on refurbishment and retrofitting projects, particularly in mature economies. These tools offer distinct advantages, including portability, independence from power sources (for manual variants), and unparalleled control over the cutting process, minimizing structural damage to surrounding areas. Major applications span residential building, large-scale commercial construction, road infrastructure maintenance, and heritage restoration, where precision is paramount. Furthermore, the rising popularity of DIY home improvement projects contributes significantly to the demand, particularly for consumer-grade, ergonomic, and safer tool variants.

Driving factors for sustained market growth include technological advancements in metallurgy leading to more durable and efficient chisel designs, improvements in ergonomic handles to reduce user fatigue and injury risk, and the regulatory push towards safer manual tool usage in occupational settings. The transition toward high-strength, lightweight construction materials necessitates corresponding improvements in tool performance, propelling innovation in manufacturing processes like forging and heat treatment. The versatility of masonry chisels, coupled with their relatively low maintenance requirements compared to mechanized alternatives, positions them as indispensable instruments in the global construction tool inventory, ensuring consistent market expansion throughout the forecast period.

Masonry Chisels Market Executive Summary

The Masonry Chisels Market is characterized by stable demand driven primarily by the cyclical nature of the global construction industry and increasing investment in refurbishment projects. Current business trends indicate a strong focus on premiumization, where manufacturers are competing less on price and more on material quality, ergonomic design, and specialized application utility. There is a noticeable shift towards adopting tools featuring anti-vibration technology and composite handles, responding to stringent occupational health standards and professional user preferences for reduced long-term strain. Supply chain dynamics are critical, with sourcing high-grade steel and ensuring consistent thermal processing being core competitive advantages for major industry players, enabling them to offer superior guarantees on tool life and impact resistance.

Regionally, the Asia Pacific (APAC) market is projected to exhibit the highest growth rate, fueled by rapid urbanization, massive government infrastructure spending in emerging economies like India and Southeast Asia, and escalating residential construction activities. North America and Europe, while being mature markets, maintain significant market share, driven by demand for high-end, specialized tools utilized in complex restoration and demolition projects, alongside stringent safety regulations promoting tool replacement cycles. The growth in these regions is also sustained by the DIY segment, which increasingly seeks out professional-quality tools. Conversely, markets in Latin America and MEA are experiencing gradual expansion linked to commodity price stability and localized infrastructure development initiatives, though adoption rates may vary based on local construction practices and available capital investment.

Segment-wise, the professional-grade segment, particularly carbide-tipped and specialized pneumatic chisels, dominates revenue generation due to their application in high-frequency, heavy-duty industrial environments. However, the manual handheld chisel segment retains the largest volume share, benefiting from its ubiquity across all project sizes and strong adoption in emerging markets. Within materials, high-carbon steel remains the standard, but the market is seeing increased penetration of tungsten carbide inserts, specifically beneficial for prolonged use against extremely hard aggregates like granite and reinforced concrete. Distribution channels are evolving, with e-commerce platforms increasingly capturing market share, offering enhanced product visibility and direct-to-consumer opportunities, although traditional specialty hardware stores maintain their dominance for professional tradespeople seeking immediate availability and expert consultation.

AI Impact Analysis on Masonry Chisels Market

User inquiries regarding AI's impact on the Masonry Chisels Market predominantly focus on how automation and smart construction will influence manual tool usage, the integration of AI into construction robotics that may eventually replace traditional chiseling tasks, and the potential for AI to optimize material science and tool design. Users are concerned about whether AI-driven construction methodologies (such as advanced additive manufacturing or highly precise robotic demolition) will render traditional handheld masonry tools obsolete. Furthermore, there is significant interest in how predictive maintenance algorithms could extend the life of powered masonry tools (like pneumatic or electric chipping hammers) and optimize replacement cycles for chisels based on actual usage wear, detected through integrated sensors.

While AI will not directly replace the simple function of a manual chisel in the immediate future, its influence is profound in supporting industries and indirectly optimizing the chisel market. AI is being utilized in materials research to develop superior, harder, and longer-lasting alloys for chisel tips, predicting stress points and failure modes before manufacturing, thereby drastically improving product durability and efficiency. In the construction domain, AI-powered construction management software is optimizing workflow, leading to more precise material cutting requirements, which could subtly shift demand towards specialized, dimensionally accurate chisels. Furthermore, AI helps in predictive quality control on the manufacturing line, ensuring tighter tolerances and higher reliability for professional-grade tools.

The greatest long-term impact of AI is likely to be felt through the rise of automated masonry robots and advanced demolition technology. These systems, utilizing computer vision and machine learning for precise material handling and cutting, may reduce the overall volume demand for manual bulk-removal chisels. However, specialized cleanup, delicate restoration, and access-restricted fine work will still necessitate human intervention supported by traditional tools. Ultimately, AI serves as an optimization layer, driving demand for technologically superior, sensor-ready, and ultra-durable chisels that fit within smart construction ecosystems, rather than eliminating the tool class entirely.

- Optimization of Chisel Metallurgy: AI used for predictive modeling of alloy performance and wear characteristics.

- Advanced Manufacturing Quality Control: Machine learning ensuring high tolerance and consistency in heat treatment and forging processes.

- Integration with Smart Tools: Potential for sensor integration in powered chisels for usage monitoring, stress analysis, and predictive maintenance.

- Robotic Construction Interface: AI-guided construction robots requiring highly specialized, precise cutting and shaping inserts (potentially chisel derivatives).

- Demand Forecasting: AI-driven supply chain management optimizing inventory based on real-time construction activity data.

DRO & Impact Forces Of Masonry Chisels Market

The dynamics of the Masonry Chisels Market are governed by a robust interplay of Drivers (D), Restraints (R), Opportunities (O), and potent Impact Forces. Key drivers include the global resurgence in infrastructural investment, particularly in transportation networks and utility modernization, which mandates continuous masonry cutting and repair work. Coupled with this is the accelerating demand for residential renovation and refurbishment projects, especially in developed economies where aging structures require constant maintenance. Restraints primarily involve the cyclical volatility of the construction sector, often influenced by macroeconomic factors like interest rates and geopolitical instability, which can lead to temporary market contractions. Additionally, competition from technologically advanced powered alternatives, such as rotary hammers with chiseling functions, poses a continuous challenge to the manual segment's market share.

Significant opportunities exist in emerging markets, characterized by rapid urbanization and relatively lower labor costs, favoring the widespread use of durable, cost-effective manual tools. Furthermore, the specialized tools segment offers high-margin growth potential, focusing on ergonomic and application-specific chisels (e.g., for delicate historical restoration or specialized tile removal), catering to professional niche users. The development and adoption of new, ultra-hard materials like specialized ceramic composites or enhanced carbide tips present a substantial opportunity for product differentiation and premium pricing, directly addressing the industry's need for tools that can handle modern, higher-strength concrete mixtures effectively. Sustainability concerns also provide an opportunity for manufacturers focusing on tools with longer lifecycles and using recyclable materials.

The collective Impact Forces amplify these elements, driving market shifts. Regulatory forces, particularly occupational safety standards (e.g., EU directives on hand-arm vibration syndrome, or HAVS), compel manufacturers to invest heavily in anti-vibration design for both manual and powered chisels, elevating product specifications and pricing. Economic impact forces dictate that in periods of high labor costs, the efficiency and speed provided by high-quality, specialized chisels are favored, justifying higher investment by contractors. Technological impact forces, particularly advancements in metal forming and cryogenic treatment, ensure that chisel performance continuously improves, maintaining the relevancy of these tools even as construction methodologies evolve. The balance between necessary construction activity (Driver) and the challenge posed by competing power tools (Restraint) dictates the overall market trajectory towards specialized, high-durability solutions (Opportunity).

Segmentation Analysis

The Masonry Chisels Market is segmented primarily based on Product Type, Application, Material Type, and Distribution Channel, reflecting the diverse requirements of various end-user groups, from professional stone masons to DIY enthusiasts. Understanding these segmentations is crucial for manufacturers to tailor their product offerings, marketing strategies, and distribution networks effectively. Segmentation by type differentiates between manually operated chisels, which emphasize control and precision, and powered chisels (like pneumatic or electric variants), which prioritize speed and bulk material removal, thereby addressing fundamentally different operational needs on a construction site. The selection process often hinges on the frequency of use and the hardness of the material being worked upon.

Segmentation by application provides insights into where the greatest demand volume and highest value transactions occur. Commercial and infrastructure construction segments typically drive demand for heavy-duty and highly durable tools (often carbide-tipped), justifying premium pricing due to intensive usage. Conversely, the residential and DIY segments drive volume for mid-range and general-purpose tools. Material segmentation, covering specialized high-carbon steel, chrome vanadium steel, and tools enhanced with tungsten carbide, reflects performance capabilities and cost structures. Tungsten carbide segments are rapidly growing due to the increasing use of harder aggregates in modern concrete and stone construction, demanding superior edge retention.

Finally, segmentation by distribution channel highlights the critical routes through which products reach the end consumer. Traditional channels, such as specialized tool wholesalers and large hardware chains, remain vital for professional contractors who require immediate access and often rely on established brand relationships. However, the rapidly expanding e-commerce channel offers manufacturers direct access to global markets and is particularly attractive to the DIY and smaller contracting segments due to convenience and competitive pricing. Successful market penetration requires a multi-channel approach, optimizing logistics and inventory management based on the specific requirements of each segment.

- Product Type:

- Handheld Chisels (Cold Chisels, Brick Sets, Bolster Chisels, Pointing Chisels)

- Powered Chisels (Pneumatic Chisels, Electric Chisels/Attachments)

- Material Type:

- High-Carbon Steel

- Chrome Vanadium Steel

- Tungsten Carbide Tipped Chisels

- Specialized Alloy Steel

- Application:

- Residential Construction and Renovation

- Commercial Construction

- Infrastructure and Utility Projects

- Demolition and Salvage Operations

- Stone Carving and Restoration

- Distribution Channel:

- Online Retail (E-commerce Platforms)

- Offline Retail (Hardware Stores, Specialty Tool Suppliers)

- Direct Sales to Large Contractors

Value Chain Analysis For Masonry Chisels Market

The Value Chain for the Masonry Chisels Market begins with Upstream activities, centered heavily on raw material procurement and initial processing. This phase is dominated by suppliers of high-grade steel alloys, specifically high-carbon and chrome vanadium steels, which form the core material for nearly all masonry chisels. The quality and purity of these raw inputs are critical determinants of the final tool's durability and performance. Manufacturers focus on securing stable supply contracts and implementing stringent quality control over input materials, including specific metallurgical specifications required for forging and subsequent heat treatment. The cost of raw materials, which is subject to global commodity price fluctuations (especially iron ore and specialty metals like chromium and vanadium), represents a major cost component in the final product.

Midstream activities involve core manufacturing processes: forging, machining, heat treatment, tip sharpening (especially for carbide inserts), and handle assembly. This stage is where value addition is maximized through precision engineering and technological innovation, such as cryogenic tempering to enhance hardness and toughness. Specialized manufacturers often own proprietary heat treatment processes that distinguish their product performance. Downstream activities involve logistics, warehousing, marketing, and distribution. Given the often bulky and heavy nature of professional tools, efficient logistics management is vital to maintain cost competitiveness. Marketing efforts focus heavily on communicating durability guarantees, ergonomic benefits, and performance metrics relevant to professional tradespeople.

Distribution channels are broadly categorized into Direct and Indirect sales. Direct sales are typically reserved for large-volume contracts with major construction firms or infrastructure project procurement agencies, allowing manufacturers greater control over pricing and customer relationship management. Indirect channels, which dominate the market, include a complex network of regional distributors, large retail hardware chains (like Home Depot or Lowe’s), and increasingly, specialized e-commerce platforms (like Amazon or dedicated tool websites). The efficiency of this indirect network is paramount, as professional users demand immediate accessibility to replacement tools. Maintaining strong partnerships with these distributors ensures broad market reach and effective inventory positioning, catering to both the professional and DIY segments simultaneously.

Masonry Chisels Market Potential Customers

The primary End-User/Buyers of masonry chisels constitute a wide spectrum, fundamentally divided into professional tradespeople, institutional users, and the vast DIY segment. Professional users include specialized stone masons, bricklayers, concrete workers, demolition experts, and general contractors. These customers prioritize performance, measured by material durability, impact absorption characteristics (ergonomics), and the tool’s ability to maintain a sharp edge under continuous, rigorous use. Their purchasing decisions are heavily influenced by brand reputation, professional recommendations, and warranty terms, leading them to consistently invest in premium, high-specification tools, often carbide-tipped or forged from specialized alloys designed for industrial environments.

Institutional customers include governmental bodies responsible for public works maintenance, military engineering divisions, historical preservation trusts, and utility companies performing road and pipeline repairs. These entities often procure tools in bulk through tender processes, placing high importance on standardized quality, compliance with occupational health and safety regulations (especially concerning anti-vibration features), and long-term cost of ownership. For these large buyers, the ability of a manufacturer to supply a complete range of supporting tools and provide consistent, reliable delivery globally is a significant purchasing factor. Specialized chisels for infrastructure maintenance, such as those used for concrete pavement breaking or utility access, form a critical part of this segment.

The DIY (Do-It-Yourself) segment and small general maintenance professionals represent the volume market for masonry chisels. These users typically seek versatile, easy-to-use, mid-range tools that offer a good balance between cost and sufficient durability for intermittent use, such as minor home repairs, patio laying, or decorative stone work. Sales in this segment are heavily influenced by retail merchandising, promotional activities, and ease of access through large retail hardware chains and online marketplaces. While their average spend per unit is lower than professional counterparts, their sheer number ensures that this segment contributes substantially to overall market consumption, particularly for basic cold chisels and brick sets used for general masonry tasks.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 620.1 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, Klein Tools, Estwing, TEKTON, Starrett, Makita, Bosch, Hilti, Snap-on, DeWalt, Bahco, Irwin Tools, Apex Tool Group, Gedore, Wera, Pferd, Vermont American, Mayhew Steel Products, Cold Steel, Trow & Holden |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Masonry Chisels Market Key Technology Landscape

The technology landscape in the Masonry Chisels Market is primarily focused on three core areas: advanced metallurgy, optimized forging techniques, and ergonomic design innovation. Metallurgy constitutes the most critical technological battleground, where manufacturers continuously seek superior steel alloys, such as specific formulations of chrome-molybdenum or high-carbon tool steel, capable of withstanding extreme percussive forces without fracturing or deforming. A major innovation is the increased use of tungsten carbide tips, which are brazed or welded onto the chisel body. These tips offer significantly superior abrasion resistance and edge retention compared to traditional steel, making them essential for working with highly abrasive materials like high-strength concrete or granite, thus directly improving tool lifespan and user efficiency.

Precision forging and advanced heat treatment technologies represent the manufacturing innovations that distinguish premium products. Modern forging processes utilize computer-controlled machinery to ensure optimal grain structure alignment, maximizing the strength and toughness of the steel. This is often complemented by sophisticated heat treatment regimes, including differential hardening (where the striking end is softer to resist mushrooming, while the cutting edge is extremely hard) and, increasingly, cryogenic treatment. Cryogenic tempering involves chilling the steel to extremely low temperatures, which alters the microstructure to reduce retained austenite, resulting in enhanced wear resistance and reduced brittleness, thereby extending the practical life of the chisel dramatically under professional use conditions.

Ergonomic and safety technologies are rapidly gaining importance, driven by increasing regulatory scrutiny on occupational health. Anti-vibration and shock-absorbing handles, typically made from high-density polymers or specialized rubber composites, are essential for compliance with standards aimed at mitigating Hand-Arm Vibration Syndrome (HAVS). These designs focus on dissipating impact energy before it reaches the user's hands, making powered chisels safer and manual use less fatiguing over long periods. Furthermore, safety enhancements include integrated guards or widened handles (like bolster chisels) to protect hands from glancing blows from hammers, ensuring that technological progress is aligned not just with performance but also with long-term user safety and comfort on site.

Regional Highlights

Regional dynamics are highly correlated with localized construction booms, infrastructure age, and economic development cycles. Investment patterns, regulatory environments, and labor practices heavily influence the type and volume of masonry chisels consumed across major geographies.

- North America (NA): This region is characterized by high demand for specialized, premium, and ergonomically advanced chisels. The market is mature, driven primarily by residential and commercial renovation, high-value infrastructure maintenance (bridges, highways), and strict occupational safety standards that favor anti-vibration tools. Key markets include the United States and Canada, where professional contractors prefer branded, high-performance tools offering excellent warranties. The DIY segment is also robust, supporting strong sales through major retail chains.

- Europe: Europe is defined by stringent safety regulations (e.g., concerning HAVS), which compels manufacturers to invest in highly engineered, low-vibration tools. The market is stable, with significant demand stemming from the preservation and restoration of historic buildings and complex infrastructure projects. Germany, the UK, and France are critical markets, emphasizing tools designed for precision masonry work and high durability. Eastern European markets show increasing growth linked to modernization efforts.

- Asia Pacific (APAC): APAC is the fastest-growing region globally, fueled by massive urbanization, rapid expansion of public infrastructure (rail, housing, power plants), and manufacturing growth. Countries like China, India, and Indonesia represent enormous volume markets, often favoring cost-effective, durable manual tools, although the adoption of powered and specialized carbide-tipped chisels is rapidly increasing, driven by international construction standards implemented in mega-projects.

- Latin America (LATAM): Market growth in LATAM is moderate but steady, tied closely to local economic stability and investment in housing and energy infrastructure. Demand is mixed, spanning from basic high-carbon steel chisels for general construction to increasingly sophisticated tools required by foreign contractors operating in major urban centers. Brazil and Mexico are the primary demand hubs, where distribution efficiency remains a key competitive factor.

- Middle East and Africa (MEA): The MEA market is largely influenced by large-scale oil and gas infrastructure projects and ambitious real estate developments (e.g., in the GCC states). This drives substantial demand for heavy-duty, industrial-grade masonry chisels and attachments for demolition and site preparation. Africa’s growth is nascent but accelerating, particularly in regions investing heavily in foundational infrastructure development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Masonry Chisels Market.- Stanley Black & Decker

- Klein Tools

- Estwing

- TEKTON

- Starrett

- Makita

- Bosch

- Hilti

- Snap-on

- DeWalt

- Bahco

- Irwin Tools

- Apex Tool Group

- Gedore

- Wera

- Pferd

- Vermont American

- Mayhew Steel Products

- Cold Steel

- Trow & Holden

Frequently Asked Questions

Analyze common user questions about the Masonry Chisels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Masonry Chisels Market?

Market growth is primarily driven by global infrastructure development, especially in emerging economies, combined with significant demand from the mature markets for renovation, repair, and historical restoration projects. Technological improvements in chisel durability, such as carbide tipping and advanced metallurgy, also sustain growth by improving efficiency and reducing replacement cycles for professional users.

How does the type of material affect the performance and cost of masonry chisels?

The material type, typically high-carbon steel, Chrome Vanadium steel, or tungsten carbide, significantly impacts performance and cost. Carbide-tipped chisels offer superior hardness and edge retention for cutting high-strength concrete or granite but are significantly more expensive than standard steel chisels. The material choice is dictated by the frequency of use and the hardness of the masonry material being worked on.

Which regional market holds the highest growth potential for masonry chisels?

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to extensive urbanization, massive governmental infrastructure investments, and rapidly expanding residential construction sectors across key countries like China, India, and Southeast Asia, driving high volume demand for both manual and specialized powered masonry tools.

What are the major restraints impacting the Masonry Chisels Market?

Key restraints include the intense competition posed by sophisticated powered alternatives, such as demolition hammers with chisel attachments, which often offer higher efficiency for bulk removal. Additionally, the market remains sensitive to the cyclical nature and macroeconomic volatility of the global construction industry, leading to fluctuating demand and investment levels.

What technological innovations are shaping the future of masonry chisel design?

Future chisel design is centered on integrating advanced metallurgy, specifically through cryogenic treatment to enhance steel toughness and the increased use of robust tungsten carbide inserts. Furthermore, innovation is heavily focused on ergonomic features, particularly anti-vibration technology in handles, to comply with stringent occupational health and safety regulations, improving user safety and reducing fatigue.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager