Material Jetting (MJ) Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436086 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Material Jetting (MJ) Equipment Market Size

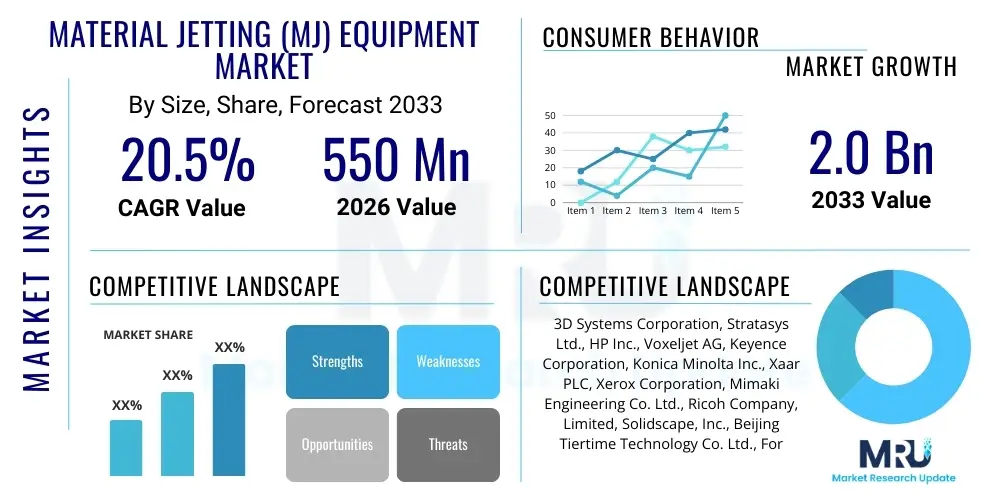

The Material Jetting (MJ) Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 20.5% between 2026 and 2033. The market is estimated at $550 Million in 2026 and is projected to reach $2.0 Billion by the end of the forecast period in 2033.

Material Jetting (MJ) Equipment Market introduction

Material Jetting (MJ) is a sophisticated additive manufacturing technology characterized by the process of selectively depositing droplets of building material, such as photopolymers or wax, onto a build platform and then curing them using UV light. This method, often likened to 3D printing with an inkjet mechanism, allows for exceptionally high resolution, smooth surface finishes, and the unique capability to simultaneously jet multiple materials or colors within a single print job. This multi-material capacity is a significant differentiator, enabling the creation of complex parts with varying mechanical properties, flexibility, and aesthetic characteristics, which is highly valued across diverse industries requiring rapid prototyping and functional parts.

The core product in this market is the MJ equipment itself, encompassing high-precision print heads, UV curing systems, advanced software for droplet control and material management, and robust platform mechanics. Major applications span conceptual modeling, creating jigs and fixtures, producing detailed anatomical models for medical training, and manufacturing injection mold tooling. Key industrial sectors adopting MJ include aerospace, automotive for detailed interior components and fluid dynamics testing models, consumer electronics for complex enclosures and prototypes, and most notably, the healthcare sector for customized prosthetics, surgical guides, and patient-specific medical devices.

The market expansion is fundamentally driven by the increasing demand for rapid, high-fidelity prototypes and end-use parts that require smooth surfaces and intricate details, minimizing the need for extensive post-processing. Furthermore, the continuous improvement in material science, particularly the development of high-performance engineering-grade photopolymers, is broadening the functional scope of MJ technology. The superior resolution and speed offered by next-generation MJ systems, coupled with their ability to simulate overmolding and produce flexible/rigid combinations, solidify Material Jetting’s position as a crucial technology in the transition toward industrialized additive manufacturing workflows.

Material Jetting (MJ) Equipment Market Executive Summary

The Material Jetting (MJ) Equipment Market is experiencing robust expansion, primarily fueled by advancements in multi-material capabilities and the growing industrial requirement for high-accuracy, aesthetically superior parts. Key business trends include strategic acquisitions focused on consolidating specialized photopolymer expertise and the emergence of subscription-based service models for MJ equipment and material supply, enhancing accessibility for small to medium enterprises. Manufacturers are intensely focused on integrating advanced sensing and control systems to ensure droplet consistency and optimize print yield, moving MJ from primarily a prototyping tool to a legitimate production technology, especially in customized medical and specialized consumer goods sectors. The competitive environment is defined by innovation in print head technology and the development of materials capable of enduring higher thermal and mechanical stresses.

Regionally, North America and Europe maintain dominance, driven by significant R&D spending in aerospace and medical device manufacturing, coupled with established industrial infrastructure supportive of additive processes. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, propelled by rapid industrialization, increasing adoption of 3D printing in the electronics and automotive supply chains in countries like China, Japan, and South Korea, and supportive government initiatives promoting localized manufacturing technologies. Emerging markets in Latin America and the Middle East are beginning to adopt MJ technology, initially focused on architectural modeling and academic research, indicating future diversification opportunities.

Segment trends reveal that the equipment market is segmented by material type (polymers, ceramics), application (prototyping, tooling, manufacturing), and end-use industry. The polymer segment, particularly photopolymers, commands the largest market share due to its versatility and established use in visual and functional prototyping. The manufacturing application segment is poised for the fastest growth as companies leverage MJ for direct digital manufacturing of low-volume, highly complex end-use parts. Furthermore, the specialized medical and dental subsegments continue to drive demand for ultra-high-resolution systems capable of producing biocompatible and complex geometrical structures necessary for surgical planning and personalized treatments.

AI Impact Analysis on Material Jetting (MJ) Equipment Market

User inquiries regarding the integration of Artificial Intelligence (AI) and Material Jetting commonly center on optimizing print quality, predicting equipment maintenance needs, and accelerating material development cycles. Key concerns revolve around how AI can minimize print errors resulting from inconsistent droplet formation or material viscosity fluctuations, thereby reducing material waste and production time. Users are highly interested in AI-driven generative design tools that automatically suggest optimal part geometries specific to the constraints of the MJ process, maximizing part strength while minimizing material consumption. Furthermore, there is significant expectation that AI will be leveraged to manage complex multi-material printing schedules and predict the long-term performance characteristics of jetted materials under various environmental conditions, bridging the gap between digital design intent and physical part reality.

The integration of machine learning algorithms is transforming the MJ workflow, particularly in closed-loop process monitoring. Sensors embedded in the MJ equipment collect vast amounts of data regarding temperature, droplet velocity, UV intensity, and material flow. AI analyzes this data in real-time, identifying subtle deviations that human operators might miss, allowing for immediate corrective adjustments during the print process. This capability drastically improves first-time-right yield rates, which is crucial for reducing the operational costs associated with high-precision additive manufacturing. By ensuring consistent quality control across batches, AI enhances the repeatability and reliability necessary for industrial-scale production applications.

Moreover, AI is playing a pivotal role in accelerating the discovery and formulation of new photopolymer and ceramic inkjet materials. Machine learning models can predict the resultant properties of material compositions based on existing datasets, significantly reducing the laborious and time-consuming process of traditional trial-and-error experimentation in the lab. This speeds up time-to-market for specialized materials—such as those with tailored refractive indices, electrical conductivity, or specific biocompatibility requirements—further expanding the range of applications where Material Jetting is viable. AI not only optimizes the machine performance but fundamentally accelerates the innovation curve of the materials ecosystem supporting MJ.

- AI-driven real-time print monitoring and fault detection for quality control assurance.

- Machine learning optimization of droplet deposition parameters (e.g., jetting frequency, voltage) to ensure geometric accuracy.

- Predictive maintenance schedules for print heads, minimizing downtime and replacement costs.

- Generative Design algorithms tailored to maximize performance characteristics achievable through multi-material MJ capabilities.

- Accelerated material informatics for rapid development and qualification of novel photopolymers and composites.

- Automated post-processing simulation and optimization based on AI analysis of part geometry and support structure density.

DRO & Impact Forces Of Material Jetting (MJ) Equipment Market

The Material Jetting market dynamics are shaped by strong drivers focusing on precision and multi-functionality, moderate restraints related to material costs and throughput limitations for large parts, and compelling opportunities in highly specialized niche applications. The primary drivers include the accelerating demand for high-resolution prototypes and aesthetic models across design and medical industries, coupled with MJ's unique ability to incorporate multi-color and multi-material elements seamlessly within a single build. This technological advantage for producing complex assemblies without post-assembly steps provides significant impetus for adoption, especially in fields requiring variable rigidity and transparency. The market's potential growth hinges on the continued reduction of equipment and material costs, making the technology accessible to a wider industrial base.

Conversely, significant restraints limit broader market penetration. The cost of proprietary photopolymer resins remains notably high compared to materials used in other additive manufacturing processes like Fused Deposition Modeling (FDM) or Stereolithography (SLA). Furthermore, while MJ excels in detail and smoothness, the speed of production for very large volumes or very large parts can be restrictive compared to mass manufacturing methods. The limited portfolio of highly durable, engineering-grade materials capable of withstanding extreme environmental conditions (high heat, mechanical stress) also restricts adoption in critical end-use applications in sectors like primary aerospace components, though material research is continuously addressing this gap.

Opportunities are abundant in the personalized medicine and custom tooling sectors. Material Jetting is perfectly positioned to capture the growing demand for customized dental aligners, patient-specific surgical tools, and highly detailed anatomical models for pre-operative planning. The opportunity for direct digital manufacturing of consumer goods, particularly in cosmetics, eyewear, and jewelry, capitalizing on MJ's surface finish and color capabilities, is vast. Impact forces such as rapid technological obsolescence and intense intellectual property competition among equipment manufacturers necessitate continuous innovation. The bargaining power of suppliers is moderate but increasing due to reliance on specialized, proprietary photopolymer materials, while the bargaining power of buyers remains strong, pressuring manufacturers to offer versatile and cost-effective solutions.

Segmentation Analysis

The Material Jetting (MJ) Equipment Market is comprehensively segmented based on the components that make up the system, the types of materials processed, the range of applications, and the primary industries utilizing the technology. This granular segmentation allows for precise market analysis, identifying high-growth niches such as the manufacturing and medical applications which demand the highest resolution and material variability. Understanding these segments is crucial for manufacturers to tailor their equipment design and material portfolios to specific industrial needs, ranging from rapid design verification to the final production of complex end-use parts, especially in custom tooling and fixtures.

- By Component:

- Equipment (3D Printers)

- Materials (Photopolymers, Wax, Ceramics)

- Software and Services

- By Material:

- Polymers (Acrylics, Epoxies)

- Wax

- Others (Metals, Ceramics - niche applications)

- By Application:

- Prototyping and Conceptual Modeling

- Tooling and Fixtures

- Manufacturing of End-use Parts

- Casting and Molding

- By End-use Industry:

- Automotive

- Aerospace and Defense

- Healthcare (Dental and Medical Devices)

- Consumer Goods and Electronics

- Architecture and Construction

- Education and Research

Value Chain Analysis For Material Jetting (MJ) Equipment Market

The value chain for the Material Jetting (MJ) Equipment Market begins with upstream activities dominated by specialized chemical and hardware suppliers. Upstream analysis focuses on the manufacturers of key components, including specialized piezoelectric print heads (often supplied by a few dominant players), high-performance UV light sources, and, critically, the chemical companies that formulate and produce the proprietary photopolymer resins. These resin manufacturers hold significant power due to the strict physical and chemical requirements for jettable materials, including viscosity control, cure speed, and resulting mechanical properties. Successful MJ equipment providers often form close, proprietary partnerships with these material developers to ensure system compatibility and performance, which affects standardization and pricing across the market.

Moving through the midstream, the value chain encompasses the MJ equipment Original Equipment Manufacturers (OEMs). These companies focus on integrating the hardware (print heads, motion systems) with sophisticated proprietary software and control systems necessary for precise droplet deposition and curing sequences. OEMs invest heavily in R&D to enhance speed, resolution, multi-material handling capabilities, and build envelope size. Distribution channels are typically a combination of direct sales for large industrial clients (ensuring detailed service contracts and training) and indirect distribution through value-added resellers (VARs) and distributors who provide localized sales, technical support, and consumables stocking, particularly in geographically diverse markets like APAC.

Downstream analysis centers on the end-users and the service providers utilizing MJ technology. End-users fall into two categories: in-house production departments (aerospace, automotive) that purchase equipment directly for large-scale prototyping and specialized manufacturing, and 3D printing service bureaus (job shops) that offer MJ capabilities on demand. The latter group acts as a key market accelerator, providing access to the technology without the high capital investment required for equipment purchase. The increasing specialization of applications, especially in medical and dental fields, requires tailored post-processing and certification services, adding further value downstream. Direct channels are critical for complex, high-cost equipment, ensuring immediate feedback for product refinement, while indirect channels via VARs are crucial for market penetration into smaller organizations.

Material Jetting (MJ) Equipment Market Potential Customers

Potential customers for Material Jetting (MJ) equipment are organizations requiring extremely high geometric accuracy, smooth surface finishes, and the ability to produce parts incorporating multiple materials or colors simultaneously. End-user demand is heavily concentrated in sectors where visualization, fit-and-function prototyping, and custom, low-volume production are paramount. Key buyers include design and engineering firms in the consumer electronics sector looking to create visually stunning and functionally representative prototypes quickly before moving to injection molding. These firms utilize MJ for complex casing designs, detailed buttons, and internal components that require strict tolerances.

Another major demographic consists of specialized medical and dental laboratories. These facilities use MJ systems for producing highly precise, biocompatible surgical guides, transparent dental aligner molds, and patient-specific anatomical models used for surgical planning and education. The high resolution of MJ is critical here, ensuring the fine details necessary for accurate medical intervention. Furthermore, industrial manufacturers, particularly in automotive and aerospace, invest in MJ for non-critical tooling, jigs, fixtures, and customized internal components that require aesthetic quality alongside mechanical performance, serving as effective replacements for costly traditional machining processes for low-run parts.

Finally, academic institutions and research organizations represent consistent buyers, utilizing MJ equipment for fundamental material science research, educational purposes, and the development of new functional devices like microfluidics or sensors. These customers prioritize system flexibility and the ability to experiment with novel material inks. Overall, the ideal customer is one whose business model values rapid iteration, complex geometry, multi-material functionality, and superior visual aesthetics over the bulk throughput typically offered by powder-based or filament-based 3D printing technologies, justifying the premium associated with MJ materials and equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million |

| Market Forecast in 2033 | $2.0 Billion |

| Growth Rate | 20.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3D Systems Corporation, Stratasys Ltd., HP Inc., Voxeljet AG, Keyence Corporation, Konica Minolta Inc., Xaar PLC, Xerox Corporation, Mimaki Engineering Co. Ltd., Ricoh Company, Limited, Solidscape, Inc., Beijing Tiertime Technology Co. Ltd., Formlabs, Inc., Desktop Metal, Inc., Materialise NV, EnvisionTEC GmbH, Nexa3D, Inc., Quantica, Roboze S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Material Jetting (MJ) Equipment Market Key Technology Landscape

The Material Jetting technology landscape is defined by continuous innovation in four primary areas: print head technology, material flexibility, curing mechanisms, and integrated software controls. The core technology relies on industrial piezoelectric inkjet heads, which are essential for ejecting high-viscosity photopolymer droplets with extreme precision and speed. Key players are aggressively developing print heads with higher nozzle density and smaller droplet volumes (picoliter scale), allowing for micron-level resolution and significantly finer surface texture, which is highly sought after in demanding applications like microfluidics and jewelry casting. This drive for precision necessitates superior temperature control mechanisms within the print head to maintain consistent material viscosity throughout the printing process, ensuring uniform droplet size and trajectory.

A critical trend is the shift towards multi-jetting and multi-material capabilities. Modern MJ systems are designed to simultaneously jet dozens of unique materials, including varying colors, rigid polymers, flexible elastomers, and transparent resins, within the same print layer. This enables the creation of gradient materials and functional parts that mimic complex assemblies or biological tissues, accelerating the adoption of MJ in advanced research and medical simulation. The subsequent step involves instantaneous curing, predominantly achieved through high-intensity UV LED arrays. Recent advancements focus on dynamic curing techniques, where the intensity or wavelength of the UV light is adjusted layer-by-layer based on the material being jetted, optimizing mechanical properties and reducing internal stresses in the final part.

Software and networking capabilities are also paramount to maintaining competitiveness. Advanced algorithms are used for print preparation, optimizing part orientation to minimize support structure requirements and calculating complex multi-material blending ratios. Furthermore, the incorporation of closed-loop feedback systems, often utilizing AI and optical sensors, monitors the deposition process in real-time, detecting and correcting errors such as clogged nozzles or inaccurate droplet placement immediately. This technological convergence ensures that Material Jetting remains at the forefront of additive manufacturing for applications where surface finish and heterogeneous material properties are non-negotiable requirements.

Regional Highlights

Regional dynamics significantly influence the adoption rates and technological focus within the Material Jetting (MJ) Equipment Market, driven by industrial concentration and government investment in advanced manufacturing.

- North America: Dominates the market, driven by high R&D expenditure in the aerospace, defense, and healthcare sectors. The presence of major market leaders and a robust ecosystem for rapid prototyping services ensure continuous demand. The focus here is on high-performance materials and mission-critical applications, particularly in customizing medical implants and optimizing aircraft components.

- Europe: A mature market with strong adoption in automotive design, specialized machinery, and dental applications, particularly in Germany and the UK. European manufacturers emphasize precision, sustainability, and integrating MJ into Industry 4.0 initiatives. Standardization and process certification for end-use parts are key focus areas.

- Asia Pacific (APAC): Expected to register the highest CAGR due to rapid industrial growth and increasing investment in localized manufacturing capabilities, particularly in China and India. Demand is surging in consumer electronics, tooling, and education. Market penetration is accelerating due to competitive pricing strategies by regional and international equipment manufacturers.

- Latin America (LATAM): A developing market primarily focused on initial prototyping, architectural modeling, and education. Growth is steady but constrained by capital expenditure limitations, relying heavily on imported equipment and materials. Key growth is concentrated in industrial hubs like Brazil and Mexico.

- Middle East and Africa (MEA): Represents the smallest but fastest-growing regional segment, driven by investments in large-scale construction, infrastructure projects (necessitating large-format modeling), and specialized medical infrastructure, particularly in the Gulf Cooperation Council (GCC) countries focusing on diversifying their economies away from oil.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Material Jetting (MJ) Equipment Market.- 3D Systems Corporation

- Stratasys Ltd.

- HP Inc.

- Voxeljet AG

- Keyence Corporation

- Konica Minolta Inc.

- Xaar PLC

- Xerox Corporation

- Mimaki Engineering Co. Ltd.

- Ricoh Company, Limited

- Solidscape, Inc.

- Beijing Tiertime Technology Co. Ltd.

- Formlabs, Inc.

- Desktop Metal, Inc.

- Materialise NV

- EnvisionTEC GmbH (part of Desktop Metal)

- Nexa3D, Inc.

- Quantica

- Roboze S.p.A.

- Nano Dimension Ltd.

Frequently Asked Questions

Analyze common user questions about the Material Jetting (MJ) Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Material Jetting (MJ) over other 3D printing technologies?

MJ offers superior resolution and dimensional accuracy, extremely smooth surface finishes requiring minimal post-processing, and the unique capability to simultaneously print with multiple materials, colors, or varying durometers (rigid and flexible combinations) in a single build cycle.

Which industries are the major adopters of Material Jetting equipment for end-use parts?

The primary industries adopting MJ for functional end-use parts include healthcare (custom surgical guides, detailed anatomical models, dental aligner molds), consumer electronics (complex enclosures, gaskets), and specialized low-volume tooling and fixtures for manufacturing lines.

What is the main restraining factor affecting the widespread industrial adoption of MJ technology?

The primary restraint is the high operating cost, largely due to the expensive, proprietary nature of the photopolymer resins required for the jetting process, alongside the relatively high capital investment for advanced multi-material MJ systems.

How is AI integrating with and optimizing the Material Jetting workflow?

AI is used for real-time process monitoring, predicting and correcting droplet inconsistencies to improve yield rates, optimizing complex multi-material structures through generative design, and accelerating the R&D cycle for new printable materials.

Which regional market is projected to demonstrate the fastest growth rate for MJ equipment?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth, driven by rapid industrial expansion, increased adoption of additive manufacturing in consumer goods and electronics supply chains, and greater regional investment in manufacturing technology.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager