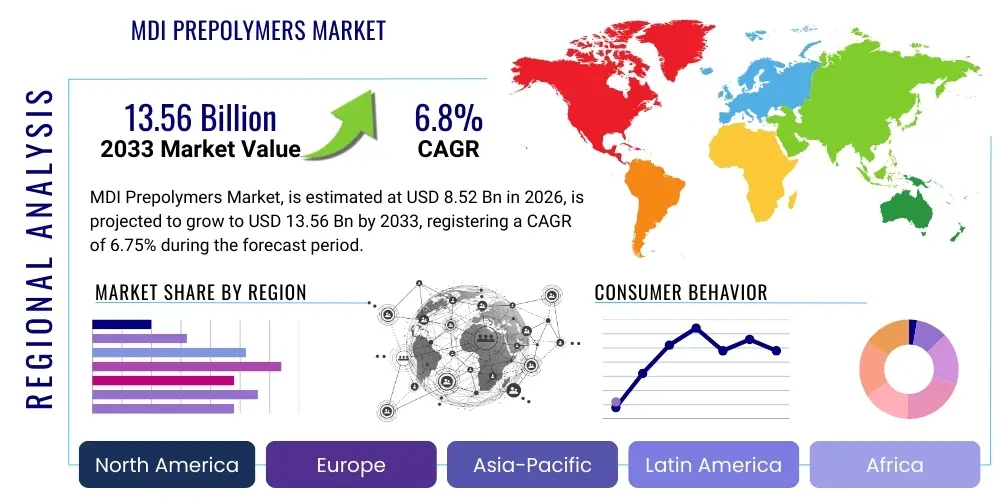

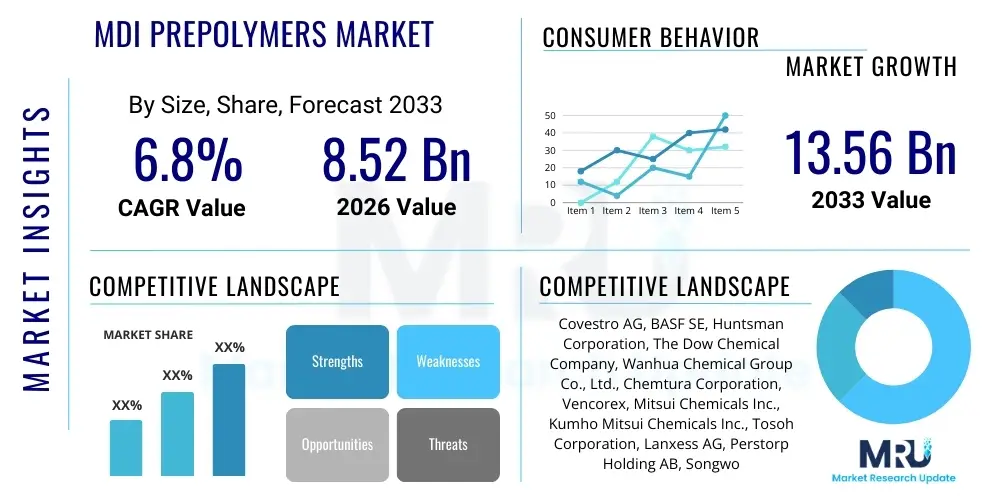

MDI Prepolymers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435729 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

MDI Prepolymers Market Size

The MDI Prepolymers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.75% between 2026 and 2033. The market is estimated at USD 8.52 Billion in 2026 and is projected to reach USD 13.56 Billion by the end of the forecast period in 2033.

MDI Prepolymers Market introduction

MDI (Methylene Diphenyl Diisocyanate) prepolymers are crucial intermediate materials predominantly utilized in the production of high-performance polyurethane systems. Unlike pure MDI, prepolymers are synthesized through the controlled reaction of MDI with a polyol (such as polyether or polyester polyols) in a specific stoichiometry, resulting in an end product with lower levels of free MDI monomer. This modification significantly reduces the vapor pressure and inherent toxicity associated with handling the raw isocyanate, making the prepolymer safer and easier to process, particularly in specialized manufacturing environments like coating and adhesive formulation.

The primary function of MDI prepolymers lies in their ability to offer enhanced control over the final polymer properties, including improved mechanical strength, flexibility, chemical resistance, and thermal stability. These tailored characteristics make them indispensable across the CASE (Coatings, Adhesives, Sealants, and Elastomers) sector. In coatings, they provide superior abrasion resistance and durability; in adhesives, they ensure strong, flexible bonding; and in elastomers, they contribute to high resilience and load-bearing capabilities. The formulation flexibility afforded by these prepolymers allows manufacturers to meet stringent performance requirements across diverse applications, ranging from automotive components to industrial insulation materials.

Major applications driving the demand for MDI prepolymers include the construction sector, where they are utilized in high-efficiency insulation foams and durable roofing materials, and the automotive industry, where they contribute to lightweighting initiatives through the production of flexible molded parts, steering wheels, and interior components. The increasing global focus on energy efficiency and sustainable building practices further accelerates their adoption, as polyurethane systems based on MDI prepolymers offer excellent thermal resistance. Key benefits include precise control over viscosity, rapid curing times, and improved processing safety, positioning MDI prepolymers as a cornerstone of advanced polymer chemistry.

MDI Prepolymers Market Executive Summary

The MDI Prepolymers market is experiencing robust growth driven primarily by escalating demand from the construction and automotive sectors, particularly in the Asia Pacific region. A significant business trend involves the shift towards low-free MDI prepolymers, addressing growing regulatory pressure and enhancing worker safety standards globally. Key manufacturers are focusing heavily on developing high-performance, specialized formulations that cater to niche applications requiring extreme durability, such as high-load elastomers used in industrial machinery and advanced protective coatings for infrastructure. Furthermore, strategic capacity expansions in emerging economies demonstrate the proactive effort by market leaders to secure supply chains and capitalize on rapid industrialization.

Regionally, Asia Pacific maintains its dominance, spurred by massive infrastructure projects in China, India, and Southeast Asian nations, leading to unprecedented consumption in insulation, adhesives, and sealants. Europe and North America, while mature, exhibit strong demand centered around technological innovation, notably the adoption of bio-based polyols for greener prepolymer synthesis and stringent quality demands in the aerospace and medical device sectors. The European Union's focus on circular economy principles and REACH regulations necessitates continuous innovation in prepolymer design to ensure compliance while maintaining performance characteristics, driving investment in sustainable chemistry R&D.

Segmentation trends indicate that the Elastomers segment, crucial for demanding industrial and footwear applications, shows the highest proportional growth, reflecting increased industrial activity and consumer demand for durable goods. The Polyether-based prepolymer type continues to hold the largest market share due to its superior hydrolytic stability and low-temperature flexibility, making it ideal for coatings and flexible foams. Companies are actively engaging in mergers and acquisitions to consolidate market positions, broaden their product portfolios, and integrate backward into raw material supply, aiming to mitigate price volatility of feedstock MDI and polyols, thereby ensuring a stable competitive edge in this highly specialized chemical market.

AI Impact Analysis on MDI Prepolymers Market

User queries regarding the impact of Artificial Intelligence (AI) on the MDI Prepolymers Market frequently center on efficiency gains in complex chemical synthesis, predictive maintenance for production units, and accelerated material discovery. Users are specifically concerned with how AI can optimize the challenging stoichiometry control during the prepolymer reaction—a process crucial for determining the final product's molecular weight and free isocyanate content. Key themes emerging from these analyses include leveraging machine learning (ML) for real-time quality assurance, optimizing energy consumption in exothermic reactions, and accurately predicting raw material price fluctuations (MDI and Polyol feedstocks) to enhance procurement strategies.

AI’s influence is profound in accelerating the Research and Development lifecycle. Traditionally, formulating a new prepolymer with specific physical properties (e.g., viscosity, NCO content, curing profile) involves extensive, time-consuming laboratory trials. AI algorithms, particularly deep learning models, can analyze vast datasets of chemical properties, reaction parameters, and end-use performance characteristics, enabling virtual screening and predicting the optimal polyol type, molecular weight, and reaction temperature required to achieve desired prepolymer specifications. This capability drastically reduces the time-to-market for specialized, high-performance formulations critical for niche applications like electric vehicle battery encapsulation or specialized medical elastomers.

Furthermore, within manufacturing, AI is revolutionizing process control and supply chain resilience. Predictive maintenance algorithms analyze sensor data from reactors, mixing tanks, and pumps to preemptively identify equipment failures, minimizing costly downtime and ensuring continuous, high-volume production crucial for a commodity chemical intermediary like MDI prepolymers. On the logistical front, AI-driven demand forecasting, integrated with global macroeconomic indicators and regional construction schedules, allows companies to dynamically adjust production rates and manage inventory levels, thereby reducing waste and improving overall operational efficiency across the global supply chain network.

- AI optimizes complex polymerization stoichiometry for precise NCO content control.

- Machine learning models accelerate R&D, predicting optimal prepolymer formulations and physical properties.

- Predictive maintenance minimizes reactor downtime and increases production throughput efficiency.

- AI-driven supply chain management forecasts raw material price volatility and demand fluctuations.

- Integration of computational chemistry tools enables the rapid virtual screening of sustainable, bio-based polyol alternatives.

DRO & Impact Forces Of MDI Prepolymers Market

The MDI Prepolymers market dynamics are heavily influenced by a confluence of accelerating drivers (D), significant restraints (R), evolving opportunities (O), and potent impact forces. A primary driver is the global infrastructure spending surge, particularly in developing nations, fueling demand for high-performance polyurethane insulation, protective coatings for structural steel, and durable waterproofing membranes in commercial and residential construction. Additionally, the automotive industry's continuous push towards vehicle lightweighting to improve fuel efficiency and increase electric vehicle range necessitates the use of high-strength, low-density materials derived from MDI prepolymers, thereby sustaining long-term demand.

However, the market faces considerable restraints, chief among them being the volatility and high cost of raw materials, specifically MDI (Methylene Diphenyl Diisocyanate) and various polyols (Polyether and Polyester). MDI production is highly dependent on upstream petrochemical processes, making its pricing susceptible to crude oil price swings, geopolitical instability, and supply chain disruptions. Furthermore, increasing regulatory scrutiny regarding residual free isocyanate monomer content in prepolymers, although mitigated by prepolymerization, still poses a compliance challenge and demands continuous process optimization and investment in low-free MDI technologies, raising production costs.

Significant opportunities lie in the adoption of bio-based MDI prepolymers, synthesized using renewable polyols derived from vegetable oils or agricultural waste. This shift aligns with global sustainability mandates and appeals to environmentally conscious end-users, potentially unlocking premium market segments. Emerging markets in Latin America and Southeast Asia present untapped potential for market penetration as their manufacturing and construction sectors mature. Impact forces, such as advancements in continuous reaction technology leading to higher quality and consistency, and increasing consumer awareness regarding the benefits of durable, energy-efficient building materials, exert strong upward pressure on market growth and technological innovation.

Segmentation Analysis

The MDI Prepolymers market is meticulously segmented based on the chemistry of the raw materials, the specific physical characteristics desired (NCO content, viscosity), and the end-use application requiring specialized polyurethane systems. The market split allows manufacturers to tailor their production capabilities and offerings to meet precise industry standards, particularly in demanding fields like aerospace and electronics. Key segmentations include differentiation by polyol type (Polyether and Polyester), which determines flexibility and hydrolytic stability, and by application (CASE, Foams), which dictates the required molecular weight and cross-linking density of the resultant polymer.

- By Type:

- Polyether-based MDI Prepolymers

- Polyester-based MDI Prepolymers

- By Application:

- Coatings (Protective, Industrial)

- Adhesives & Sealants (Construction, Automotive)

- Elastomers (Cast, Thermoplastic)

- Foams (Flexible, Rigid, Semi-rigid)

- Binders (Wood, Rubber)

- By End-Use Industry:

- Construction & Infrastructure

- Automotive & Transportation

- Footwear (Soles, Midsoles)

- Industrial & Marine

- Electronics & Appliances

Value Chain Analysis For MDI Prepolymers Market

The MDI Prepolymers value chain begins with the highly capital-intensive upstream segment involving the production of key raw materials: MDI and polyols. MDI synthesis is complex, originating from petrochemicals (Aniline and Formaldehyde). Polyols, primarily polyether and polyester types, are derived from petroleum or increasingly, from bio-based sources. Control over these upstream inputs is crucial, as the fluctuating prices of crude oil and associated commodities directly impact the final cost structure of the prepolymer. Major chemical giants often integrate backward to control the MDI supply, gaining a competitive edge and ensuring raw material security.

The manufacturing and synthesis stage, where the prepolymers are created, forms the core of the value chain. Here, MDI reacts with the polyol under controlled temperature and pressure to achieve the desired percentage of free isocyanate (NCO content) and viscosity. This stage requires significant technical expertise and specialized reaction equipment. Manufacturers focus on achieving stringent quality control, especially concerning monomer purity and low-free MDI content, which is critical for compliance in Western markets. The output is typically high-viscosity liquid prepolymers customized for specific applications.

The downstream segment involves distribution and formulation. MDI prepolymers are sold directly to large end-users (e.g., major automotive component suppliers, large construction companies) or via specialized distributors and formulators. Formulators often take the base prepolymer and blend it with additives, catalysts, and chain extenders to create the final polyurethane system (e.g., specialized coatings or casting elastomers). Direct distribution ensures better technical support and faster delivery for custom orders, whereas indirect distribution through chemical supply houses is vital for reaching smaller, geographically dispersed customers in the CASE industries, ultimately connecting the product to the end-use applications like insulating panels, resilient footwear components, and durable industrial floor coatings.

MDI Prepolymers Market Potential Customers

The primary consumers of MDI prepolymers are sophisticated manufacturers across several high-value industrial sectors, seeking materials that offer superior mechanical performance and processing safety compared to raw isocyanates. Construction material manufacturers represent a significant customer base, demanding prepolymers for rigid foam insulation panels, spray foam applications, and durable sealing products necessary for meeting increasingly rigorous energy efficiency standards in both new building and retrofitting projects globally. These customers prioritize thermal performance, fire resistance, and long-term dimensional stability.

Another crucial customer segment is the automotive and transportation industry, which utilizes MDI prepolymers extensively for manufacturing parts requiring specific viscoelastic properties, noise, vibration, and harshness (NVH) mitigation, and high impact resistance. This includes steering wheel components, flexible dashboards, chassis mounts, and specialized coatings applied to vehicle exteriors for protection against environmental factors. As the trend towards electric vehicles accelerates, the demand for prepolymers in battery potting and encapsulation—providing thermal management and structural integrity—is creating a new, highly specialized customer requirement.

Furthermore, the footwear and sportswear industries, along with general industrial manufacturers producing specialized elastomers and coatings, form the third major customer group. Footwear companies utilize MDI prepolymers for lightweight, highly resilient soles and midsoles. Industrial customers, including those in mining, oil and gas, and marine sectors, rely on cast and thermoplastic polyurethane elastomers derived from MDI prepolymers for conveyor belts, pipeline coatings, heavy machinery gaskets, and protective linings, valuing the material's exceptional abrasion and chemical resistance in harsh operational environments. These customers require consistent quality and highly customized formulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.52 Billion |

| Market Forecast in 2033 | USD 13.56 Billion |

| Growth Rate | 6.75% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Covestro AG, BASF SE, Huntsman Corporation, The Dow Chemical Company, Wanhua Chemical Group Co., Ltd., Chemtura Corporation, Vencorex, Mitsui Chemicals Inc., Kumho Mitsui Chemicals Inc., Tosoh Corporation, Lanxess AG, Perstorp Holding AB, Songwon Industrial Co., Ltd., Coim Group, Sinopec Shanghai Petrochemical Company Limited, DIC Corporation, Marvel Specialty Chemicals, Shekou Huada Polymers, Shanghai Dongda Chemical, Yantai Wanhua Polyurethanes Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

MDI Prepolymers Market Key Technology Landscape

The technological landscape of the MDI Prepolymers market is centered around precision chemical engineering aimed at controlling the exothermic reaction kinetics and minimizing the residual free monomer content. A critical technology is the development of Continuous Reaction Processes, moving away from batch synthesis. Continuous stirred-tank reactors (CSTRs) and tubular reactors offer superior control over temperature profiles and residence time distribution, ensuring highly consistent prepolymer quality, tighter molecular weight distribution, and uniform NCO functionality. This consistency is paramount for high-volume applications like footwear manufacturing and automated automotive parts production, where variation can lead to significant material wastage and performance failure.

A second major technological trend is the advancement in Low-Free MDI Prepolymer Synthesis. Driven by increasingly stringent occupational health regulations, especially in Europe (REACH), manufacturers utilize specialized techniques such as wiped-film evaporation or thin-film distillation after the initial reaction to strip unreacted MDI monomer below the standard regulatory threshold, often achieving levels below 0.1%. While these post-processing steps add complexity and cost, the resulting low-free MDI prepolymers offer a safer handling profile, opening doors to new applications in consumer goods and sensitive environments like healthcare facilities, thus providing a significant market differentiation and technological advantage.

Furthermore, the integration of advanced analytical chemistry and computer-aided formulation tools plays a crucial role. Techniques like Gel Permeation Chromatography (GPC) and Fourier-Transform Infrared Spectroscopy (FTIR) are used for real-time monitoring of the polymerization process, ensuring that the target molecular weight and NCO content are achieved precisely. Computational chemistry and simulation software are increasingly utilized during the R&D phase to model the interaction between MDI, different polyols, and chain extenders, predicting the final polymer structure and performance without relying solely on expensive, iterative physical testing, thereby drastically accelerating the innovation cycle for custom prepolymer solutions.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for MDI prepolymers, primarily due to immense industrial growth in China, India, and Southeast Asia. The surging construction industry, coupled with major automotive manufacturing hubs, drives high consumption in insulation, adhesives, and elastomers. Government investments in infrastructure and urbanization initiatives ensure sustained demand for high-performance polyurethane systems.

- North America: This region is characterized by high demand for specialized, high-value prepolymers, particularly in the aerospace, medical device, and premium automotive sectors. Stringent environmental regulations favor the adoption of low-free MDI formulations and bio-based polyols. Market maturity emphasizes technological innovation and sophisticated end-use application development.

- Europe: Europe is defined by strict regulatory environments (REACH compliance), making low-free MDI prepolymers a requirement rather than an option. The region is a leader in sustainability, driving R&D into renewable and bio-based feedstock utilization. Key consuming sectors include high-efficiency building insulation and specialized industrial elastomers, maintaining steady, quality-focused growth.

- Latin America (LAMEA): Growth in this region is moderate but promising, driven by expanding construction sectors in Brazil and Mexico and increasing foreign direct investment in manufacturing. The market focuses mainly on price-competitive, bulk applications, though technical sophistication is gradually increasing, especially in automotive assembly.

- Middle East and Africa (MEA): Demand is concentrated in large-scale infrastructure and energy projects, particularly in the Gulf Cooperation Council (GCC) nations. MDI prepolymers are vital for pipeline coatings, durable sealants, and high-temperature stable insulation systems required in the region’s harsh climate. Market growth is closely tied to volatile oil and gas investment cycles.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the MDI Prepolymers Market.- Covestro AG

- BASF SE

- Huntsman Corporation

- The Dow Chemical Company

- Wanhua Chemical Group Co., Ltd.

- Chemtura Corporation (now part of Lanxess)

- Vencorex

- Mitsui Chemicals Inc.

- Kumho Mitsui Chemicals Inc.

- Tosoh Corporation

- Lanxess AG

- Perstorp Holding AB

- Songwon Industrial Co., Ltd.

- Coim Group

- Sinopec Shanghai Petrochemical Company Limited

- DIC Corporation

- Marvel Specialty Chemicals

- Shekou Huada Polymers

- Shanghai Dongda Chemical

- Yantai Wanhua Polyurethanes Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the MDI Prepolymers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of MDI prepolymers over raw MDI?

The primary advantage of MDI prepolymers is significantly reduced free MDI monomer content, which lowers the vapor pressure and inherent toxicity. This results in safer handling, easier processing, and compliance with stringent occupational exposure limits, while also allowing for customized viscosity and reactivity profiles for specific end-use systems like specialized elastomers or coatings.

Which end-use application accounts for the largest demand in the MDI Prepolymers Market?

The construction industry, particularly for high-efficiency rigid polyurethane foam insulation and advanced adhesives/sealants, currently accounts for the largest share of MDI prepolymer consumption globally. This is driven by worldwide mandates for energy conservation and sustainable building practices requiring superior thermal performance materials.

How do Polyether-based and Polyester-based MDI prepolymers differ in application?

Polyether-based prepolymers offer excellent hydrolytic stability, good low-temperature flexibility, and high resilience, making them ideal for flexible foams, adhesives, and industrial elastomers. Polyester-based prepolymers, conversely, provide superior resistance to solvents, oils, and abrasion, preferred for high-strength coatings, rigid structural components, and high-performance footwear soles.

What is driving the market shift towards Low-Free MDI Prepolymers?

The market shift is fundamentally driven by tightening global regulatory standards, notably the European Union’s REACH regulations, aimed at minimizing worker exposure to sensitizing diisocyanates. Manufacturers are adopting advanced post-processing techniques (like thin-film distillation) to ensure residual monomer levels fall below hazardous thresholds, enhancing safety and enabling market access.

Which region dominates the MDI Prepolymers market growth and why?

The Asia Pacific (APAC) region dominates market growth due to its rapid urbanization, massive infrastructure development, and status as a global manufacturing hub for automotive components and consumer goods. High investment in commercial and residential construction, particularly in China and India, is the leading catalyst for consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- MDI Prepolymers Market Size Report By Type (Polymeric MDI, Monomeric MDI), By Application (Rigid Foam, Flexible Foam, Coatings, Elastomers, Adhesives & Sealants, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- MDI Prepolymers Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Polymeric MDI, Monomeric MDI), By Application (Rigid Foam, Flexible Foam, Coatings, Elastomers, Adhesives and Sealants, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager