Meat Glue Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438421 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Meat Glue Market Size

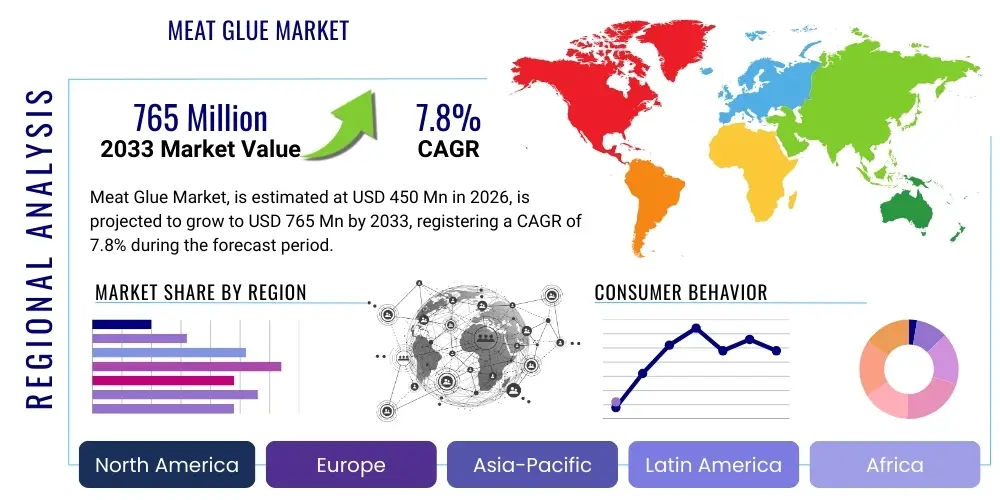

The Meat Glue Market, primarily driven by the increasing adoption of transglutaminase (TG) in the processed food industry, is projected to grow at a robust Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. This growth trajectory reflects expanding applications in meat restructuring, seafood processing, and the development of novel protein products aimed at improving yield and texture. Furthermore, the rising demand for convenient, ready-to-eat, and aesthetically appealing food products contributes significantly to market expansion, particularly in industrialized nations where food efficiency is paramount.

The market is estimated at USD 450 million in 2026, encompassing sales across various forms (powder, liquid) and sources (microbial, animal-derived). The foundational requirement for transglutaminase stems from its unique enzymatic capability to catalyze the formation of covalent bonds between protein-bound lysine and glutamine residues, essential for binding disparate pieces of meat or protein matrices together. This functional benefit is crucial for minimizing waste and enhancing the structural integrity of final food items, which justifies sustained investment in production and application research.

By the end of the forecast period in 2033, the market is projected to reach USD 765 million. This substantial increase is underpinned by global demographic shifts, including urbanization and rising disposable incomes, leading to higher consumption of processed and high-value meat products. Regulatory acceptance, while challenging in certain regions (like the EU where use restrictions are tighter for whole meat cuts), is gradually improving, especially concerning microbial transglutaminase (MTG), which is viewed favorably over traditional chemical binding agents. Continuous technological advancements in enzyme production, focusing on purity, stability, and cost-effectiveness, are further expected to bolster market valuation throughout the forecast timeline.

Meat Glue Market introduction

The Meat Glue Market centers around the production and distribution of transglutaminase (TG), an enzyme used extensively in the food industry to improve the texture, stability, and appearance of protein-rich food products, predominantly meat, poultry, and seafood. Often referred to colloquially as 'meat glue,' this enzyme acts as a biological binder by catalyzing cross-linking reactions between proteins. Although naturally occurring in many physiological processes, the commercially utilized TG is usually produced through microbial fermentation, ensuring high purity and suitability for food grade applications. Its primary utility lies in restructuring smaller, lower-value cuts of meat into standardized, marketable portions, significantly reducing trim waste and enhancing cost efficiency for food processors globally.

Major applications of transglutaminase extend beyond mere meat binding. In the dairy sector, it is employed to improve yogurt texture and cheese yield. In bakery, it enhances dough elasticity and volume. However, its most visible applications remain within protein matrices, enabling the creation of uniform products like reformed steaks, chicken nuggets, and surimi (imitation crab meat). The principal benefits derived from using meat glue include optimized resource utilization, enhanced product consistency, and improved textural attributes, such as firmness and chewiness. For consumers, this translates into standardized product quality and visual appeal, which is particularly vital in the competitive packaged food sector. The safety profile of microbial transglutaminase, when used according to regulatory guidelines, has largely been established, supporting its widespread industrial adoption.

The market is primarily driven by macro-level factors such as the surging global demand for processed foods, particularly those offering convenience and high protein content. Furthermore, the inherent economic benefit of reducing food waste and utilizing lower-cost trimmings fuels rapid adoption among large-scale meat and poultry processors. Regulatory environments, especially those pertaining to food safety and labeling transparency, act as critical external forces shaping market practices. The push towards sustainable food systems also indirectly promotes the use of TG, as it aids in maximizing the utility of raw protein materials. Ongoing research focuses on developing TG variants that function effectively at lower temperatures or specific pH levels, further broadening its application spectrum within complex food manufacturing processes.

Meat Glue Market Executive Summary

The Meat Glue Market is experiencing substantial growth, propelled by robust business trends centered on waste reduction, yield optimization, and the expansion of the global ready-to-eat (RTE) meals sector. Key business imperatives driving this market include the need for processors to maintain price competitiveness while ensuring consistent product quality, especially for highly demanded value-added meat and seafood products. Strategic partnerships between enzyme producers and major food processing conglomerates are accelerating innovation in delivery systems and application techniques. However, the market faces headwinds primarily related to consumer perception and strict labeling requirements in developed economies, necessitating transparent communication regarding ingredient usage and origin.

Regionally, North America and Europe currently dominate the market due to established infrastructure, high penetration of processed foods, and advanced regulatory frameworks favoring industrial enzyme use, particularly microbial transglutaminase (MTG). Asia Pacific (APAC) represents the fastest-growing region, driven by rapid urbanization, increasing per capita consumption of Westernized diets (including processed meats), and the massive expansion of the food manufacturing sector in countries like China and India. The regional landscape is characterized by varying levels of regulatory acceptance; while the U.S. and Canada utilize TG widely, the European Union maintains specific rules that influence how and where the enzyme can be applied, particularly regarding labeling and consumer information, thereby creating distinct operational constraints for manufacturers targeting European markets.

Segmentation trends indicate a strong preference for Microbial Transglutaminase (MTG) over animal-derived alternatives, primarily due to safety concerns (e.g., BSE risks associated with bovine thrombin) and cost-effectiveness. The meat and poultry segment maintains the largest market share owing to its long-standing use in restructuring beef, pork, and chicken products. However, the seafood segment, particularly for surimi and reformed fish fillets, is witnessing the highest growth rate. Furthermore, the shift towards liquid or stabilized forms of TG for easier integration into automated production lines is a significant technological trend. Overall market stability is dependent on sustained investment in enzymatic technology aimed at enhancing functional efficiency, broadening applications across alternative protein sources (e.g., plant-based meats), and navigating complex global labeling standards through verifiable safety data.

AI Impact Analysis on Meat Glue Market

Analysis of common user questions related to the impact of AI on the Meat Glue Market reveals key themes focusing on efficiency gains, quality assurance, and ethical sourcing. Users frequently inquire about AI's role in optimizing enzyme dosage to ensure perfect binding strength without compromising texture, how predictive analytics can forecast ingredient stability under various processing conditions, and whether AI can assist in tracing the origin and purity of microbial transglutaminase strains. The primary concern is moving beyond empirical, trial-and-error manufacturing towards data-driven, precision enzyme application. Users expect AI tools to reduce input costs by minimizing enzyme overuse, enhance product safety through automated quality checks, and support rapid scale-up of novel enzymatic formulations, ensuring the consistency of reformed protein products across vast production facilities.

- AI optimizes enzyme dosing kinetics, leading to precise usage and reduced production costs.

- Machine learning algorithms predict protein matrix stability, improving the binding success rate in restructured products.

- AI-driven supply chain platforms enhance traceability of microbial strains and raw ingredients used in transglutaminase production.

- Predictive maintenance for fermentation reactors ensures high enzyme yield and consistent purity levels.

- Image recognition AI systems conduct automated quality checks on reformed meat products, verifying structural integrity and visual uniformity faster than human inspection.

- Generative AI assists in formulating novel enzyme variants optimized for specific pH or temperature conditions required for alternative protein binding.

DRO & Impact Forces Of Meat Glue Market

The Meat Glue Market is shaped by powerful forces of demand, constraint, and technological progress. Key drivers include the overwhelming industry requirement for reduced food waste and maximized yield from raw protein materials, coupled with the global surge in demand for processed and convenience foods that necessitate standardized textures and shapes. Restraints primarily involve stringent and often varying regulatory requirements across regions, particularly concerning the labeling of products utilizing TG, leading to negative consumer perception (the "Frankenfood" stigma) and subsequent adoption barriers in certain retail segments. Opportunities are emerging from the burgeoning plant-based protein sector, where transglutaminase proves highly effective in texturizing and binding vegetable proteins, offering a new, high-growth application pathway. The impact forces indicate a competitive environment where regulatory clarity and continuous innovation in non-animal derived enzyme sources will dictate market leadership, shifting influence towards biotechnology firms capable of efficient, large-scale microbial production.

Value Chain Analysis For Meat Glue Market

The value chain for the Meat Glue Market is characterized by specialized technological input at the upstream stage, leading to high-volume distribution downstream to the massive food processing industry. Upstream analysis focuses on the production of transglutaminase, which involves highly specialized biotechnological processes, primarily microbial fermentation utilizing specific bacterial or fungal strains (e.g., Streptomyces mobaraensis). Key activities include strain selection, fermentation optimization, and meticulous enzyme extraction and purification processes to achieve food-grade purity. Suppliers in this phase are typically large biotechnology or specialty chemical companies that invest heavily in research and development to improve enzyme stability, activity, and cost-efficiency. The quality of raw materials, such as fermentation media and stabilizing agents, dictates the final efficacy and shelf-life of the TG product, establishing a critical dependence on high-quality input suppliers.

The midstream segment involves formulation, blending, and packaging. Transglutaminase is rarely sold as a pure enzyme; instead, it is often formulated with additives such as caseinates, sodium chloride, or maltodextrin to control activity, ensure stability, and facilitate ease of application (e.g., creating powdered mixes or liquid solutions). Processors convert the bulk enzyme into standardized commercial formats suitable for industrial food applications. Distribution channels are typically specialized and globalized, relying on established networks capable of handling food ingredients, often requiring controlled temperature storage to maintain enzymatic activity. Direct distribution (manufacturer to large food processor) is common for major accounts, while indirect channels utilize specialized food ingredient distributors who provide technical support and smaller volume delivery to medium-sized enterprises.

Downstream analysis centers on the end-users: meat, poultry, and seafood processing companies, along with emerging users in the dairy and plant-based protein sectors. The immediate buyers are R&D and procurement departments within these manufacturing facilities, prioritizing products based on binding strength, cost per application, and ease of regulatory compliance. The ultimate measure of value is the yield improvement and quality consistency provided to the consumer product. The transparency and efficiency of the supply chain are critical, especially given the scrutiny placed on food ingredients. The market structure is highly sensitive to price fluctuations in raw protein materials; when protein costs rise, the economic incentive to use TG to maximize yield increases substantially, driving downstream demand.

Meat Glue Market Potential Customers

Potential customers for transglutaminase are concentrated within the commercial food manufacturing and preparation sectors that handle significant volumes of protein. The primary segment comprises large-scale industrial meat and poultry processing facilities, where the enzyme is crucial for restructuring beef, pork, and chicken trimmings into uniform, high-value cuts like standardized steaks, roasts, or formed chicken portions, significantly boosting economic returns per carcass. These processors seek solutions that offer rapid binding times and reliable structural integrity under high-speed manufacturing conditions. Furthermore, they are highly sensitive to regulatory approval, preferring microbial transglutaminase (MTG) due to its broader acceptance compared to animal-derived alternatives.

The second major group includes seafood processors, particularly those involved in producing reformed fish products, fish cakes, and surimi (imitation crab meat). In this application, TG enhances the elasticity and texture of the final product, replacing or supplementing traditional stabilizers. As global demand for affordable seafood alternatives continues to grow, this customer segment represents a vital, high-growth area. Beyond these traditional areas, manufacturers of ready-to-eat meals, frozen appetizers, and pre-portioned protein kits utilize meat glue to ensure components adhere properly during freezing, thawing, and subsequent cooking processes, ensuring the consumer experiences the intended texture and structure.

Finally, the fastest-growing potential customer base resides within the burgeoning alternative protein industry. Manufacturers creating plant-based meat substitutes (e.g., vegan burgers, sausages) rely heavily on transglutaminase to cross-link various vegetable proteins (soy, pea, wheat) to mimic the fibrous texture and mouthfeel of animal muscle. This application provides texture enhancement that other hydrocolloids often fail to deliver, making TG an indispensable tool for achieving realistic meat analogues. These customers prioritize high-purity, neutral-tasting enzyme formulations that do not interfere with the designed flavor profile of the plant-based product, driving innovation in specialized enzyme strains.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 765 Million |

| Growth Rate | CAGR 7.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ajinomoto Co., Inc., Yiming Biological Products Co., Ltd., C&P Additives, Microorganisms and Enzymes Ltd., Roodin, Saria International GmbH, Jiangsu Jincheng Lisheng Technology Co., Ltd., Novozymes A/S, DMS Food Specialties, Fuso Chemical Co., Ltd., BDF Ingredients, AB Enzymes, Innova Foods, Plover Eggs Co., Ltd., Lonza Group, Shanghai Yaxin Biological Technology Co., Ltd., Shandong Jinyuan Biochemical Co., Ltd., E.I. du Pont de Nemours and Company (Danisco), Creative Enzymes, Xi'an Jintan Biotechnology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Meat Glue Market Key Technology Landscape

The technology landscape of the Meat Glue Market is predominantly defined by advancements in industrial biotechnology and enzyme engineering, aimed at optimizing the production, stability, and functional efficiency of transglutaminase (TG). The core technology involves highly controlled submerged fermentation processes using genetically modified or selected microbial strains, primarily from the Streptomyces genus, to produce Microbial Transglutaminase (MTG). Key technological progress focuses on maximizing enzyme yield and minimizing purification costs, often through the use of high-throughput screening and bioreactor optimization techniques. Furthermore, researchers are employing recombinant DNA technology to engineer TG variants with improved thermostability and activity across a broader pH range, allowing for more flexible use in diverse food matrices and processing environments where traditional enzymes might denature or become inactive. This focus on bio-engineering ensures a consistent, high-purity product essential for regulatory acceptance.

Another crucial technological area involves enzyme stabilization and delivery systems. Since TG is a protein, it is susceptible to degradation during storage and mixing. Encapsulation technology, using food-grade polymers or lipids, is being developed to protect the enzyme until it is activated by moisture or specific temperature conditions in the food matrix, thereby enhancing shelf life and controlled release during the mixing stage. Furthermore, advancements in formulation involve the synergistic use of TG with other hydrocolloids or binding agents (e.g., starches, proteins) to achieve superior textural properties while potentially reducing the required enzyme concentration. These formulation innovations address the industry need for simpler integration into existing production lines and greater consistency in the binding process, particularly in automated meat restructuring operations.

In the non-microbial segment, although less preferred due to regulatory and sourcing concerns, technologies related to extracting and purifying thrombin and fibrinogen (animal-derived binders) are continuously being refined to enhance safety and reduce the risk of contaminants. The overall technological direction, however, favors microbial production due to its scalability, safety profile, and suitability for vegetarian/vegan labeling (when applied to plant-based proteins). Technological convergence, integrating real-time spectroscopic analysis and AI control within fermentation and application systems, is increasingly common, leading to significant reductions in batch variation and material waste during the high-volume production of reformed protein products.

Regional Highlights

Regional dynamics play a significant role in shaping the Meat Glue Market, influenced heavily by consumer eating habits, regulatory environments, and the maturity of the food processing industry.

- North America: This region holds a leading market share due to the large, highly centralized meat and poultry processing industry and the high consumer demand for convenient, pre-portioned, and processed food products. The United States is a massive consumer and producer of restructured meats, utilizing transglutaminase extensively for yield optimization. Favorable regulatory clarity from bodies like the FDA regarding MTG's status as generally recognized as safe (GRAS) supports its widespread commercial application. The market here is highly competitive, focusing on optimizing delivery systems and lowering the cost-per-pound of binding agent.

- Europe: Europe is characterized by a mature food processing sector but faces strict regulatory scrutiny, particularly within the European Union (EU). While microbial transglutaminase (MTG) is authorized as a food additive (E420), its application in specific fresh meat cuts intended for consumers must be explicitly labeled, and its use is highly restricted in certain contexts to prevent misleading consumers about the quality or origin of the meat. This stringent environment limits growth in traditional meat restructuring but drives opportunities in dairy, bakery, and increasingly, the sophisticated plant-based food market within major economies like Germany and the Netherlands.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, primarily fueled by massive population growth, increasing disposable incomes, and the rapid shift towards processed and packaged foods, especially in emerging economies such as China, India, and Southeast Asian countries. The large seafood processing industry, particularly for surimi production, is a major consumer of TG. Furthermore, local manufacturers are rapidly adopting modern enzymatic technology to improve efficiency, driven by strong export markets and domestic demand for consistent product quality. Regulatory frameworks are evolving, often mirroring international standards but sometimes lacking the strict labeling requirements found in the EU, facilitating faster adoption.

- Latin America (LATAM): Growth in this region is moderate but consistent, driven by the expansion of industrial meat processing (especially in Brazil and Argentina, major global beef exporters) and the need to maximize returns on exported protein. Economic volatility and varying food safety standards across countries present operational challenges, but the fundamental economic driver—minimizing waste—ensures sustained market interest and adoption among large, export-focused producers.

- Middle East and Africa (MEA): This region is characterized by niche market growth, predominantly linked to imported processed food technology and investments in local, modern food production facilities. Demand is strong in urbanized centers and GCC countries, where reliance on imported ingredients is high. Applications are focused on institutional catering and packaged goods, where product stability and consistency are crucial. Challenges include complex logistics and the need for Halal certification, which often favors microbial sources of TG.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Meat Glue Market.- Ajinomoto Co., Inc.

- Yiming Biological Products Co., Ltd.

- C&P Additives

- Microorganisms and Enzymes Ltd.

- Roodin

- Saria International GmbH

- Jiangsu Jincheng Lisheng Technology Co., Ltd.

- Novozymes A/S

- DMS Food Specialties

- Fuso Chemical Co., Ltd.

- BDF Ingredients

- AB Enzymes

- Innova Foods

- Plover Eggs Co., Ltd.

- Lonza Group

- Shanghai Yaxin Biological Technology Co., Ltd.

- Shandong Jinyuan Biochemical Co., Ltd.

- E.I. du Pont de Nemours and Company (Danisco)

- Creative Enzymes

- Xi'an Jintan Biotechnology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Meat Glue market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Meat Glue and what is its primary function in food processing?

Meat Glue is the common name for the enzyme Transglutaminase (TG), which functions as a biological catalyst to cross-link proteins, creating strong, permanent chemical bonds. Its primary function in food processing is to bind smaller pieces of meat, poultry, or fish trimmings into larger, uniform cuts, significantly reducing waste and improving product texture and consistency. It is also used extensively in dairy and plant-based protein sectors.

Is Microbial Transglutaminase (MTG) safe and widely accepted by food regulatory bodies?

Yes, Microbial Transglutaminase (MTG), produced via fermentation, is generally recognized as safe (GRAS) by the FDA in the United States and is authorized as a food additive (E420) in the European Union and many other global regulatory jurisdictions. Its safety is based on extensive scientific evaluation; however, regulations require specific labeling when used in certain whole meat products to maintain transparency for consumers regarding the restructuring process.

How does Transglutaminase benefit the plant-based protein market?

TG is critical for the plant-based protein market as it significantly enhances the texture and structure of meat analogues. By cross-linking isolated vegetable proteins (like soy or pea protein), TG helps mimic the fibrous, chewy mouthfeel of animal muscle, improving the overall sensory experience and quality of vegan and vegetarian processed foods, driving innovation in this high-growth sector.

What is the key difference between microbial and animal-derived meat glue?

Microbial transglutaminase (MTG) is produced through fermentation, offering high purity and low risk of pathogens, making it suitable for vegetarian and Halal applications. Animal-derived binders, such as Thrombin/Fibrinogen, are sourced from animal blood plasma. MTG is generally preferred by the industrial market due to its broader regulatory acceptance, lower cost, and consistent supply chain reliability compared to animal-based alternatives.

What regulatory constraints primarily impact the growth of the Meat Glue Market?

The primary constraint is negative consumer perception and mandatory labeling requirements, particularly in regions like the EU, which mandate specific declarations when TG is used to form a single serving of meat from smaller parts. These requirements necessitate high transparency from manufacturers and often increase operational complexity, sometimes leading retailers to avoid using TG-treated products to circumvent potential labeling controversy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager