Mechanical Supercharger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436551 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Mechanical Supercharger Market Size

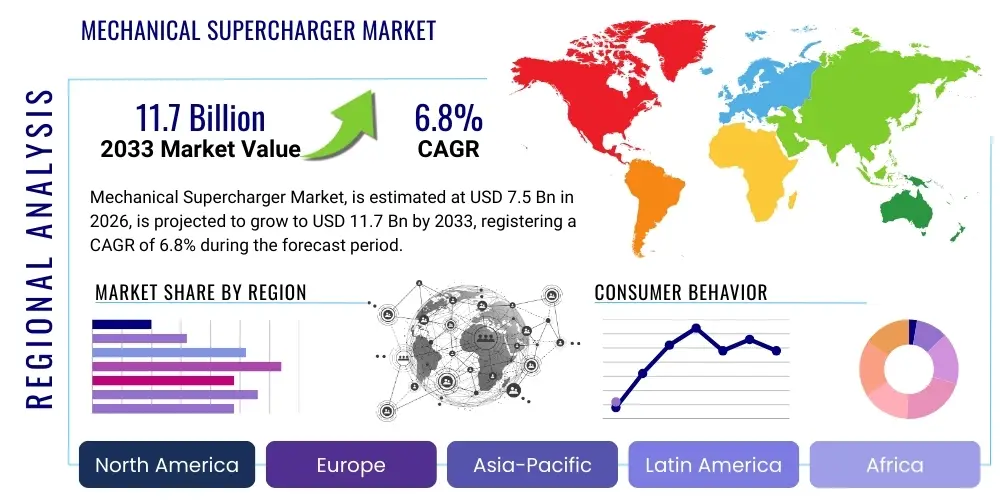

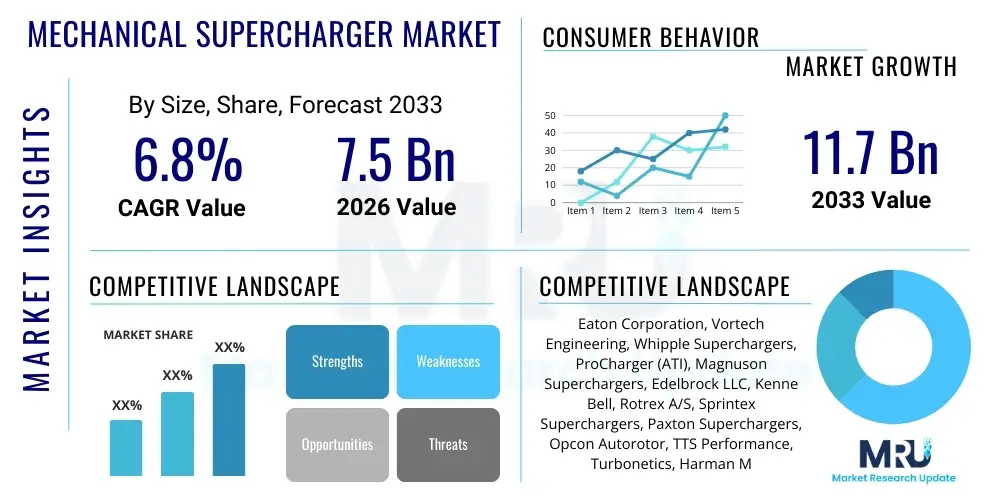

The Mechanical Supercharger Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 7.5 Billion in 2026 and is projected to reach USD 11.7 Billion by the end of the forecast period in 2033.

Mechanical Supercharger Market introduction

The Mechanical Supercharger Market encompasses components and systems designed to enhance internal combustion engine performance by increasing the density of air supplied to the engine cylinders. This forced induction mechanism, driven directly by the engine’s crankshaft via a belt or gear system, ensures a constant boost delivery across the entire RPM range, offering superior throttle response compared to turbochargers at lower speeds. Key applications span high-performance passenger vehicles, marine engines, heavy-duty commercial vehicles, and specialized industrial equipment where immediate power delivery and consistent torque are critical operational requirements.

The core product in this market includes three primary types: Roots-type (positive displacement, effective at low RPMs), Twin-Screw (highly efficient positive displacement, superior thermal management), and Centrifugal (dynamic compression, high efficiency at high RPMs). The primary benefit of employing mechanical superchargers is the significant increase in power and torque output without dramatically altering the engine's original displacement, supporting the industry trend toward engine downsizing coupled with performance maintenance (right-sizing). Furthermore, modern supercharger designs integrate advanced cooling and bypass technologies to mitigate parasitic drag and improve overall fuel efficiency, addressing evolving stringent emission standards.

Market growth is predominantly driven by the persistent global demand for high-performance sports and luxury vehicles, particularly in North America and Asia Pacific. Additionally, the aftermarket tuning segment contributes substantially, offering specialized kits for performance upgrades. While facing competitive pressure from advanced turbocharging solutions, the mechanical supercharger maintains its niche appeal due to its reliability, straightforward installation, and immediate power delivery characteristics, which are favored in certain racing and heavy-duty applications. Innovations in materials, particularly lightweight alloys, are further optimizing supercharger efficiency and reducing inertia, solidifying its position within the high-performance powertrain landscape.

Mechanical Supercharger Market Executive Summary

The Mechanical Supercharger Market exhibits robust growth, primarily propelled by sustained demand for high-power density engines in the automotive sector and increasing performance customization in the aftermarket. Key business trends include the strategic development of electrically assisted mechanical superchargers to address the historic issue of parasitic loss, offering improved low-end torque while maximizing fuel economy. Furthermore, consolidation among key manufacturers is observed, focusing on intellectual property related to adiabatic efficiency and noise reduction, particularly for Twin-Screw and Centrifugal designs. The shift towards milder hybridization in vehicles also presents an opportunity, as mechanical superchargers can be effectively integrated into hybrid drivetrains to bridge power gaps during electric-to-combustion transitions.

Regionally, North America remains the dominant revenue generator, characterized by a strong culture of high-displacement engines, muscle cars, and a massive aftermarket modification industry. However, the Asia Pacific (APAC) region, driven by countries like China and India, is emerging as the fastest-growing market due to rising disposable incomes, expanding luxury vehicle sales, and increased adoption of forced induction technology in locally manufactured vehicles designed to navigate congested, efficiency-critical environments. European markets show stable growth, heavily influenced by strict Euro 7 emission standards, pushing manufacturers to utilize efficient forced induction systems in smaller engine platforms.

In terms of segment trends, the Centrifugal supercharger type is expected to witness the highest CAGR, primarily due to its superior efficiency at high boost pressures, making it ideal for OEM applications requiring peak performance under sustained load. The Passenger Vehicle segment continues its reign as the largest application area, although the Commercial Vehicle sector (specifically light and medium-duty trucks) is increasingly adopting mechanical superchargers to meet towing demands while complying with emissions regulations. Fuel type segmentation confirms that gasoline engines account for the majority of the market share, given the historical preference for supercharging in high-octane performance applications, although diesel applications are growing in niche heavy-duty environments.

AI Impact Analysis on Mechanical Supercharger Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Mechanical Supercharger Market center primarily around predictive maintenance, optimization of boost control, and seamless integration within complex hybrid and autonomous vehicle architectures. Users are concerned about how AI can mitigate the inherent parasitic losses of mechanical systems and optimize the engine control unit (ECU) programming to handle the immediate power delivery characteristics of superchargers while ensuring regulatory compliance regarding emissions. Key themes include the use of AI algorithms for real-time diagnostics, predicting component wear (especially belts, bearings, and gears), and dynamically adjusting bypass valve actuation to maximize efficiency under varying load conditions, thereby bridging the gap between performance and fuel economy expectations.

The integration of AI technologies allows for a revolutionary shift from static boost management to dynamic, predictive control systems. AI models process vast amounts of data from engine sensors, environmental conditions, and driver inputs (e.g., throttle position, speed, altitude) to instantaneously determine the optimal bypass valve setting and intercooler fluid flow. This real-time optimization minimizes drag on the crankshaft during periods when maximum boost is not required, thereby increasing overall fuel efficiency and longevity of the supercharger unit. Furthermore, AI-driven calibration tools significantly reduce the development time for new supercharger applications, enabling faster time-to-market for OEMs.

In the maintenance domain, AI algorithms analyze acoustic signatures, vibration patterns, and temperature fluctuations within the supercharger unit. By establishing a baseline of normal operation, AI can accurately detect anomalies indicative of potential failures long before catastrophic breakdown occurs. This capability is crucial for fleet operators of commercial vehicles relying on supercharged diesel engines, minimizing costly downtime and improving operational reliability. Consequently, AI is transforming the mechanical supercharger from a purely mechanical component into a smart, interconnected system optimized for performance, efficiency, and predictive lifespan management, thus ensuring its continued relevance in modern powertrain architectures.

- AI enables predictive maintenance by analyzing vibration and acoustic data, forecasting component failure (e.g., bearing wear).

- Dynamic Boost Control (DBC) utilizes AI algorithms to adjust bypass valve positioning in milliseconds, optimizing efficiency and reducing parasitic drag.

- AI improves integration into hybrid systems by managing torque fill requirements and coordinating power delivery between the electric motor and the supercharged ICE.

- Generative design using AI assists in optimizing impeller and housing geometry for improved adiabatic efficiency and reduced noise emissions.

- Machine learning models enhance ECU calibration, ensuring optimal air-fuel ratio and timing under varying boost conditions for emissions compliance.

DRO & Impact Forces Of Mechanical Supercharger Market

The Mechanical Supercharger Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities. The principal driver is the enduring consumer demand for superior vehicle performance and immediate torque delivery, particularly in premium and sports car segments where the supercharger’s lag-free response is highly valued. Simultaneously, the global trend toward engine downsizing and right-sizing—using smaller displacement engines augmented by forced induction to maintain or exceed the performance of larger naturally aspirated counterparts—is a key market catalyst. Restraints primarily involve the substantial parasitic power loss inherent to mechanical linkage systems, which can negatively impact fuel economy compared to exhaust-gas driven turbochargers. Regulatory pressures, such as increasingly strict CO2 emission targets, also pose challenges, requiring extensive technological adaptation.

Opportunities for growth are largely centered around technology infusion, specifically the integration of mechanical superchargers into hybrid vehicle drivetrains. Electrically-assisted mechanical superchargers, which use small electric motors to spin the compressor during low RPMs, effectively eliminate lag and parasitic drag during transient operation, positioning the technology competitively against advanced twin-turbo systems. Furthermore, the robust and lucrative aftermarket modification segment provides a consistent revenue stream, as enthusiasts seek reliable and relatively simple methods for significant power gains. The impact forces indicate a medium-high market attractiveness, driven by technological necessity in performance segments, yet tempered by the high investment required to meet emissions standards and maintain competitiveness with highly efficient turbocharging technologies.

The market also faces an impact force from fluctuating raw material prices, particularly for high-grade aluminum and specialized coatings used in rotors and impellers, affecting manufacturing costs and final product pricing. However, advancements in manufacturing precision, such as high-speed CNC machining and specialized internal coatings, are improving the thermal efficiency and mechanical durability of the units, sustaining their value proposition. The balance between performance enhancement (Driver) and fuel consumption/emissions compliance (Restraint) dictates the pace of innovation, emphasizing opportunities in variable drive ratios and sophisticated electronic bypass controls to optimize performance only when necessary, mitigating the primary restraint.

Segmentation Analysis

The Mechanical Supercharger Market is systematically segmented based on Type, Vehicle Type, Fuel Type, and Geographic Region, providing a granular view of demand patterns and technological adoption across various applications. Type segmentation, encompassing Roots, Twin-Screw, and Centrifugal, reveals distinct preference patterns tied to performance characteristics; Roots and Twin-Screw are favored for low-end torque and instantaneous boost, often utilized in muscle cars and heavy-duty towing, while Centrifugal chargers are dominant in high-RPM, high-efficiency racing and performance applications. The Vehicle Type segmentation highlights the Passenger Vehicle segment as the primary revenue contributor, driven by OEM installations in high-end vehicles, though the Commercial Vehicle segment is increasingly important due to performance requirements in diesel applications.

- By Type:

- Roots Supercharger

- Twin-Screw Supercharger

- Centrifugal Supercharger

- By Vehicle Type:

- Passenger Cars

- Commercial Vehicles (Light, Medium, Heavy-Duty)

- Sports Cars and High-Performance Vehicles

- By Fuel Type:

- Gasoline

- Diesel

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Mechanical Supercharger Market

The value chain for the Mechanical Supercharger Market is characterized by highly specialized stages, beginning with the upstream supply of advanced materials. Upstream analysis involves sourcing precision metals such as high-strength aluminum alloys, specialized steel for gears and shafts, and proprietary coatings essential for rotor longevity and thermal management. Key players in this stage are metallurgical and specialized component manufacturers. Manufacturing then focuses on precision engineering, including high-tolerance machining of impellers, rotors, and housing units, requiring significant capital investment in advanced CNC machinery and quality control systems to ensure the mechanical integrity and thermal efficiency of the final product.

Midstream activities involve the assembly and integration of the supercharger unit, often followed by extensive testing and calibration specific to the intended engine platform. Distribution channels are bifurcated: direct channels involve sales to Original Equipment Manufacturers (OEMs) for factory installation, demanding just-in-time logistics and rigorous quality compliance. Indirect channels, predominantly serving the aftermarket and performance tuning segments, rely on a network of specialized distributors, tuning shops, and online retailers. The efficiency of the indirect channel is crucial for maximizing reach into the performance enthusiast community, which requires quick access to comprehensive installation kits and technical support.

The downstream analysis focuses on the end-user segments, comprising vehicle manufacturers, performance tuners, and individual vehicle owners seeking performance upgrades. Aftermarket service and support form a critical part of the downstream value delivery, including maintenance, repairs, and performance tuning consultation. The complexity of installing and tuning these systems necessitates highly skilled labor at the dealership or specialized garage level. The overall health of the value chain is highly dependent on the stability of the automotive manufacturing sector and the continued innovation in materials science to reduce weight and improve the efficiency of forced induction components.

Mechanical Supercharger Market Potential Customers

The primary potential customers and end-users of mechanical superchargers are diverse, spanning multiple segments within the automotive and power generation industries. Original Equipment Manufacturers (OEMs) constitute the largest buyer base, particularly manufacturers specializing in high-performance luxury vehicles (e.g., Jaguar Land Rover, Mercedes-AMG, Ford Performance) where superchargers are utilized to deliver distinctive power characteristics and maintain brand performance heritage. These OEM buyers demand extremely high standards of reliability, integration, and noise suppression, driving bulk procurement volumes and demanding strict adherence to supply chain agreements.

The second major category involves the extensive aftermarket performance tuning and customization segment. This includes independent tuning houses, specialized garages, and individual car enthusiasts who purchase complete supercharger kits for vehicle modification. These customers prioritize ease of installation, compatibility with various engine platforms, and maximum achievable power gains, often opting for Centrifugal or Twin-Screw systems. Additionally, customers in the commercial sector, such as fleet operators or manufacturers of heavy-duty marine and industrial engines, constitute a growing buyer group, utilizing superchargers to ensure reliable torque output under demanding operational conditions, particularly in regions requiring efficient power generation at high altitudes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.5 Billion |

| Market Forecast in 2033 | USD 11.7 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation, Vortech Engineering, Whipple Superchargers, ProCharger (ATI), Magnuson Superchargers, Edelbrock LLC, Kenne Bell, Rotrex A/S, Sprintex Superchargers, Paxton Superchargers, Opcon Autorotor, TTS Performance, Turbonetics, Harman Motive, ESS Tuning |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mechanical Supercharger Market Key Technology Landscape

The Mechanical Supercharger Market is characterized by continuous technological refinement aimed at overcoming the challenges of parasitic drag and thermal management while maximizing air compression efficiency. A crucial technological focus involves Rotor Geometry Optimization, particularly for Twin-Screw and Roots types, where advanced computational fluid dynamics (CFD) are utilized to design profiles that minimize internal air leakage and reduce the heat generated during compression (improving adiabatic efficiency). This optimization includes the use of specialized coatings, such as PTFE (Polytetrafluoroethylene), applied to rotor tips to maintain minimal clearances without physical contact, significantly enhancing volumetric efficiency and durability.

Another pivotal area is the integration of Sophisticated Bypass and Electronic Control Systems. Modern superchargers are no longer purely mechanical; they incorporate electronically actuated bypass valves that quickly divert air flow when boost is not needed, minimizing the load on the engine during cruising and idling, thereby reducing parasitic losses and improving fuel economy substantially. These systems are closely linked to the Engine Control Unit (ECU), which uses complex algorithms to modulate boost pressure based on real-time engine load, throttle input, and environmental factors. Furthermore, advanced thermal management systems, incorporating highly efficient water-to-air intercoolers, are essential for cooling the compressed air before it enters the engine, dramatically increasing air density and preventing engine knock.

The emergence of Electrically Assisted Supercharging (EAS) represents a significant technological leap. While maintaining the core mechanical structure, an electric motor is integrated to assist the supercharger, particularly at low engine speeds, effectively eliminating throttle lag and mitigating the parasitic loss associated with driving the supercharger when the engine is under minimal load. This hybrid approach allows for much smaller engine pulley ratios, delivering instant boost while offering the reliability of the mechanical drive at peak power. Finally, ongoing material science efforts focus on lightweight magnesium and aluminum alloys for housing construction, aiming to reduce the overall weight and inertia of the supercharger assembly, contributing to better engine response and reduced vibration and noise levels.

Regional Highlights

Geographic analysis reveals diverse market dynamics and maturity levels across key global regions, heavily influenced by regional vehicle culture, regulatory landscapes, and economic factors.

- North America (Dominant Market): North America holds the largest market share, driven by a strong heritage of high-horsepower V8 engines, particularly within the US muscle car segment. The massive demand for aftermarket performance kits and high-capacity pickup trucks utilizing supercharged engines for towing capabilities cement its leadership. OEMs like Ford and GM frequently use superchargers in their performance divisions.

- Europe (Efficiency and Niche Growth): The European market demonstrates steady growth, primarily focused on incorporating high-efficiency Centrifugal and Twin-Screw units into premium European sports cars (e.g., certain models from Mercedes-AMG and Audi). Strict Euro emissions standards mandate highly efficient forced induction systems, favoring technologies that minimize CO2 output, leading to greater adoption of electronically controlled bypass systems and E-superchargers.

- Asia Pacific (APAC) (Fastest Growing): APAC is projected to exhibit the highest CAGR, spurred by rising affluence in countries like China, India, and South Korea, leading to increased purchases of luxury and performance vehicles. Furthermore, the region’s focus on engine efficiency in crowded urban environments encourages the use of small, supercharged engines for optimal urban driving performance without sacrificing fuel economy.

- Latin America & MEA (Emerging Potential): These regions show potential, driven mainly by resource extraction industries (requiring durable supercharged commercial vehicles) and small but growing enthusiast communities for performance vehicles. Market penetration is currently lower but is expected to accelerate with infrastructure development and increased automotive investment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mechanical Supercharger Market.- Eaton Corporation

- Vortech Engineering

- Whipple Superchargers

- ProCharger (ATI)

- Magnuson Superchargers

- Edelbrock LLC

- Kenne Bell

- Rotrex A/S

- Sprintex Superchargers

- Paxton Superchargers

- Opcon Autorotor

- TTS Performance

- Turbonetics

- Harman Motive

- ESS Tuning

- HKS Co. Ltd.

- AC Schnitzer

- KMP Motorsport

- BorgWarner Inc. (Indirectly via forced induction technology)

- Cobb Tuning

Frequently Asked Questions

Analyze common user questions about the Mechanical Supercharger market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a mechanical supercharger and a turbocharger?

A mechanical supercharger is driven directly by the engine's crankshaft via a belt or gears, providing immediate, linear boost with no throttle lag. A turbocharger is driven by exhaust gases, offering higher potential peak efficiency and power but often suffering from initial lag at low RPMs.

Which type of mechanical supercharger offers the best low-end torque?

Positive displacement superchargers, specifically the Roots and Twin-Screw types, are superior for generating immediate, strong boost and optimal low-end torque, as they move a fixed volume of air per rotation regardless of engine speed.

How does parasitic loss affect the efficiency of mechanical superchargers?

Parasitic loss refers to the power consumed by the engine to drive the supercharger. While constant, modern designs mitigate this through electronic bypass valves and optimized rotor geometry, ensuring the supercharger only draws maximum power when boost is actively required by the engine.

Is the Mechanical Supercharger Market shifting towards electric hybridization?

Yes, the market is increasingly integrating electrically assisted superchargers (EAS) to leverage the mechanical system’s instantaneous response while using an electric motor to eliminate low-speed parasitic drag and enhance transitional performance, supporting mild-hybrid architectures.

What are the main drivers of the aftermarket segment for mechanical superchargers?

The aftermarket segment is primarily driven by performance enthusiasts seeking reliable, significant power increases, often favoring bolt-on kits due to their relative ease of installation compared to complex turbo setups, particularly in North American muscle car platforms.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager