Medical Grade CPP Film Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439762 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Medical Grade CPP Film Market Size

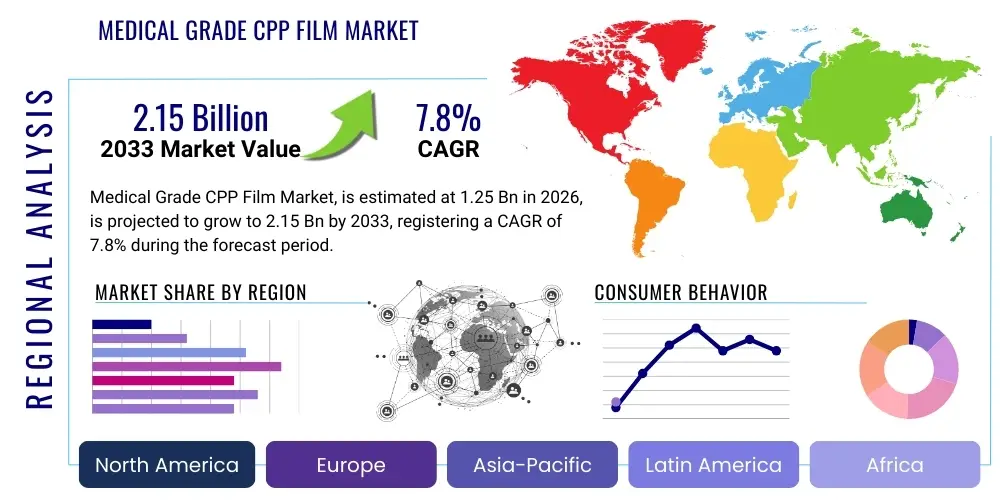

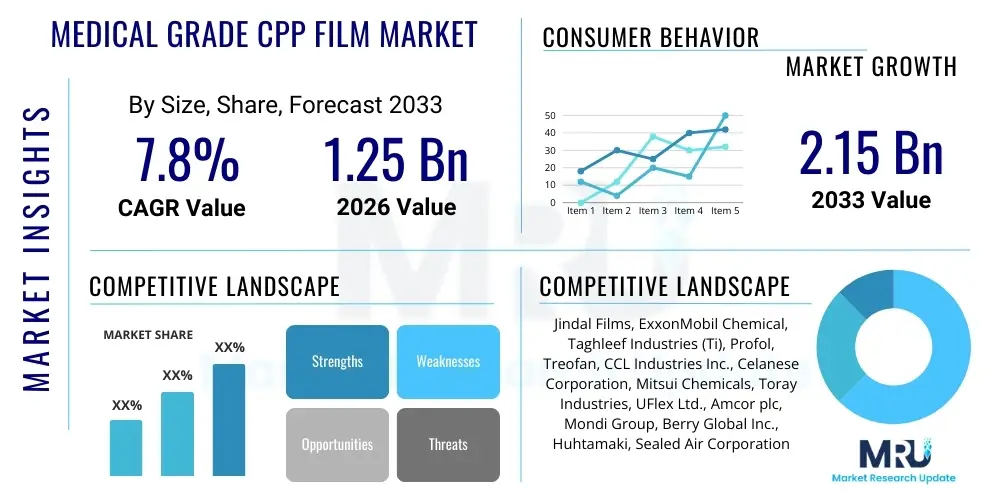

The Medical Grade CPP Film Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 2.15 billion by the end of the forecast period in 2033.

Medical Grade CPP Film Market introduction

The Medical Grade Cast Polypropylene (CPP) Film market encompasses specialized polypropylene films designed and manufactured to meet stringent medical and pharmaceutical industry standards. These films offer superior clarity, excellent sealability, barrier properties, and sterilizability, making them indispensable for various healthcare applications. They are primarily used in packaging for medical devices, pharmaceuticals, diagnostic kits, and wound care products, where maintaining sterility and product integrity is paramount. Key benefits include moisture resistance, chemical inertness, and the ability to withstand diverse sterilization methods such as autoclave, gamma irradiation, and ethylene oxide (EtO). The market is significantly driven by the escalating demand for sterile medical packaging, advancements in healthcare infrastructure globally, and the growing focus on patient safety and regulatory compliance.

Medical Grade CPP Film is a thermoplastic polymer film produced by casting molten polypropylene onto a chilled roller, resulting in a non-stretched film with balanced properties. Its excellent optical clarity allows for visual inspection of packaged contents, while its robust mechanical strength and tear resistance ensure product protection during handling and transportation. The film's low specific gravity also contributes to reduced packaging weight and associated logistics costs. This versatile material is crucial for applications requiring high-performance films that can be easily processed through various packaging machinery, including form-fill-seal operations.

Major applications include the creation of sterilization pouches and bags for instruments, flexible packaging for intravenous (IV) solutions, blister packs for tablets, and primary packaging for disposable medical supplies like syringes, catheters, and surgical gloves. The inherent properties of CPP film, such as its thermal stability and chemical resistance, make it an ideal choice for protecting sensitive medical products from external contaminants and environmental factors. Furthermore, its adaptability to various printing and lamination techniques expands its utility, allowing for sophisticated multi-layer structures that enhance barrier performance and functionality, thereby meeting the evolving demands of the medical sector.

Medical Grade CPP Film Market Executive Summary

The Medical Grade CPP Film market is currently experiencing robust growth, primarily propelled by global increases in healthcare expenditure, an aging population, and heightened awareness regarding infection control. Business trends indicate a strong focus on sustainable packaging solutions and the development of advanced films with enhanced barrier properties to meet stringent regulatory requirements. Manufacturers are investing in R&D to innovate new film compositions that offer improved resistance to sterilization processes and extend product shelf life, while also exploring eco-friendly alternatives. The market is characterized by strategic collaborations and mergers aimed at consolidating market share and expanding product portfolios to address diverse medical applications effectively.

Regional trends highlight the Asia Pacific as a rapidly expanding market due to its burgeoning pharmaceutical and medical device manufacturing industries, coupled with significant investments in healthcare infrastructure in countries like China and India. North America and Europe maintain substantial market shares, driven by established healthcare systems, rigorous regulatory frameworks, and high adoption rates of advanced medical technologies. Emerging economies in Latin America and the Middle East & Africa are also showing promising growth, fueled by improving access to healthcare and increasing demand for sterile medical products. These regions present significant opportunities for market penetration and expansion as their healthcare sectors mature.

Segment trends reveal a particular surge in demand for high-barrier CPP films, essential for packaging sensitive pharmaceuticals and advanced medical devices that require superior protection from moisture, oxygen, and light. The sterilization packaging segment continues to dominate, underscoring the critical need for films that can withstand harsh sterilization cycles without compromising integrity. Furthermore, there is a noticeable shift towards customized film solutions that cater to specific medical applications, offering tailored properties such as anti-fog capabilities for diagnostic kits or enhanced peelability for surgical kits. This customization trend is driven by the desire for optimized performance and user convenience within clinical settings.

AI Impact Analysis on Medical Grade CPP Film Market

User inquiries concerning AI's influence on the Medical Grade CPP Film market frequently revolve around its potential to revolutionize manufacturing efficiency, enhance product quality control, optimize supply chain logistics, and accelerate new material development. Users are keen to understand how AI can reduce production costs, minimize waste, ensure consistent film properties, predict market demand fluctuations, and assist in designing novel film formulations with improved medical attributes. Concerns often include the initial investment required for AI integration, data privacy in sensitive medical contexts, and the need for a skilled workforce capable of managing AI-driven systems. There is a clear expectation that AI will drive innovation and operational excellence, ultimately contributing to safer and more efficient medical packaging solutions.

- AI can optimize manufacturing processes for medical grade CPP films by predicting equipment failures, adjusting parameters in real-time, and minimizing material waste, leading to increased production efficiency and reduced operational costs.

- Enhanced quality control systems powered by AI can detect microscopic defects or inconsistencies in film properties more accurately and rapidly than traditional methods, ensuring superior product quality and compliance with stringent medical standards.

- AI-driven predictive analytics can optimize inventory management and supply chain logistics for raw materials and finished medical films, improving delivery times and reducing storage costs while mitigating supply disruptions.

- Artificial intelligence can accelerate the research and development of new medical grade CPP film formulations by simulating material properties and predicting performance under various sterilization conditions, significantly shortening innovation cycles.

- AI-powered market analysis tools can identify emerging trends in medical packaging demand, allowing manufacturers to proactively adapt their product offerings and production capacities to better serve evolving healthcare needs.

- Machine learning algorithms can personalize film specifications based on specific medical device requirements, enabling tailor-made solutions for unique applications and improving overall packaging functionality.

- Robotics and automation, often integrated with AI, can enhance precision and consistency in film processing, particularly in aseptic environments, further ensuring the integrity of medical grade films.

DRO & Impact Forces Of Medical Grade CPP Film Market

The Medical Grade CPP Film market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, which collectively shape its growth trajectory. Key drivers include the escalating global demand for sterile and safe medical packaging, fueled by rising healthcare expenditures, the expansion of the pharmaceutical and medical device industries, and an increasing focus on infection prevention in hospitals and clinics. Advancements in medical technologies, particularly in disposable devices and single-use diagnostics, also significantly boost the adoption of high-performance CPP films. Furthermore, the robust barrier properties, excellent sealability, and ability to withstand various sterilization methods inherent to CPP films make them an indispensable choice for critical medical applications. These factors collectively create a strong foundational demand for medical grade CPP films globally.

However, the market also faces notable restraints. The volatility of raw material prices, primarily polypropylene resin, poses a significant challenge, impacting production costs and profit margins for manufacturers. Stringent regulatory approval processes for medical packaging materials, while ensuring safety, can prolong product development cycles and increase compliance costs. Environmental concerns surrounding plastic waste and the growing pressure for sustainable packaging solutions present another restraint, pushing manufacturers to invest in eco-friendly alternatives or develop recyclable/biodegradable CPP options, which often come with higher production costs. Moreover, intense competition from alternative packaging materials like medical grade papers, foils, and other polymer films also acts as a market constraint, necessitating continuous innovation from CPP film producers.

Despite these challenges, substantial opportunities exist for market expansion and innovation. The increasing penetration of healthcare services in emerging economies, coupled with their expanding middle-class populations, presents untapped markets for medical grade CPP films. Technological advancements in film manufacturing, such as the development of multi-layer co-extrusion technologies, enable the creation of films with enhanced barrier properties and specialized functionalities, opening new application avenues. The rising demand for personalized medicine and home healthcare solutions further drives the need for flexible, high-performance packaging. Opportunities also lie in the development of smart packaging solutions incorporating sensors or indicators for temperature, integrity, or authenticity, adding value and improving patient safety. Furthermore, strategic collaborations between film manufacturers and medical device/pharmaceutical companies can foster innovation and market penetration.

Segmentation Analysis

The Medical Grade CPP Film market is extensively segmented to reflect the diverse applications, material properties, and end-user requirements across the healthcare industry. These segmentations provide a granular view of market dynamics, enabling stakeholders to identify specific growth areas and tailor their strategies effectively. The primary segmentation typically involves categorizing films by type, application, and end-use industry, each revealing distinct market trends and competitive landscapes. Understanding these divisions is crucial for comprehensive market analysis and strategic planning, as different segments exhibit varying growth rates, demand drivers, and technological requirements, reflecting the multifaceted nature of medical packaging needs.

- By Type

- Standard CPP Film

- High-Barrier CPP Film

- Metallized CPP Film

- Anti-fog CPP Film

- Sterilizable CPP Film

- By Application

- Sterilization Packaging (pouches, bags, lids)

- Pharmaceutical Packaging (blister packs, strip packs, sachets)

- Medical Device Packaging (syringes, catheters, surgical instruments)

- Wound Care Packaging

- Diagnostic Kits Packaging

- IV Solutions Packaging

- By End-Use Industry

- Pharmaceutical Companies

- Medical Device Manufacturers

- Hospitals & Clinics

- Diagnostic Centers & Laboratories

- Contract Packaging Organizations (CPOs)

Value Chain Analysis For Medical Grade CPP Film Market

The value chain for the Medical Grade CPP Film market begins with upstream activities involving the sourcing and production of raw materials, primarily polypropylene resin. Key suppliers in this stage are petrochemical companies that refine crude oil and natural gas into polymer granules. The quality and purity of these resins are critical, as they directly impact the final film's performance and compliance with medical standards. Efficiency in resin production and stable supply chains are paramount for film manufacturers to maintain consistent output and cost-effectiveness. Innovations in resin technology, such as metallocene catalysts, contribute to enhanced film properties, driving demand for specialized raw materials. This upstream segment forms the foundational layer, dictating initial material costs and overall film characteristics.

Moving downstream, the value chain encompasses the manufacturing and conversion of CPP films. This stage involves specialized film extrusion companies that process polypropylene resin into medical grade CPP films, often incorporating advanced co-extrusion technologies to create multi-layer films with tailored barrier properties, sealability, and sterilizability. Following film production, converters further process these films into various packaging formats such as sterilization pouches, lidding films, or flexible laminates, ready for use by medical device and pharmaceutical manufacturers. These converters employ sophisticated printing, slitting, and sealing technologies to meet specific design and functional requirements. The efficiency and quality control measures at this stage are critical for ensuring the films meet stringent regulatory and performance specifications for medical applications.

The distribution channels for medical grade CPP films are typically direct or indirect. Direct channels involve film manufacturers and converters selling directly to large pharmaceutical companies, medical device manufacturers, or contract packaging organizations (CPOs) that require bulk quantities and specialized specifications. Indirect channels leverage distributors and wholesalers who maintain inventories and supply smaller healthcare providers, clinics, or regional manufacturers. These distributors often offer value-added services such as inventory management and just-in-time delivery. The choice of distribution channel depends on factors like customer size, geographic reach, and the complexity of product customization. Effective distribution ensures timely delivery of critical packaging materials to end-users, supporting the continuity of medical product supply.

Medical Grade CPP Film Market Potential Customers

The primary potential customers for Medical Grade CPP Film are entities within the vast and rapidly expanding healthcare industry, particularly those involved in the manufacturing, sterilization, and distribution of medical products. These end-users require packaging solutions that guarantee product sterility, integrity, and safety throughout their shelf life and supply chain. Pharmaceutical companies, for instance, utilize CPP films for blister packaging of tablets, sachets for powders, and pouches for drug delivery systems, where barrier properties and chemical inertness are critical. Similarly, medical device manufacturers are significant consumers, relying on CPP films for packaging everything from sterile gloves and syringes to complex surgical instruments and implants, demanding high peel strength and sterilizability.

Hospitals and clinics represent another crucial segment, often through their purchasing of pre-packaged sterile supplies or by using CPP films in their own sterile processing departments for instrument sterilization pouches. Diagnostic centers and laboratories also procure medical grade CPP films for packaging various diagnostic kits, reagents, and sample collection devices, where moisture barriers and product visibility are important. Additionally, contract packaging organizations (CPOs) that specialize in packaging services for the medical and pharmaceutical sectors are significant buyers, as they cater to a wide range of clients and require diverse film specifications. These customers are driven by the need for regulatory compliance, patient safety, cost-effectiveness, and operational efficiency in their packaging processes.

Emerging markets and regions with developing healthcare infrastructures also represent a growing customer base. As access to modern medicine expands globally, the demand for sterile and well-protected medical products increases proportionally. Companies supplying home healthcare products, ranging from wound care dressings to disposable medical equipment for chronic disease management, are also increasingly adopting medical grade CPP films for their packaging needs due to its versatility and protective qualities. The ongoing trend towards personalized medicine and advanced therapies further expands the scope of potential customers, as these specialized products often require unique and highly protective packaging solutions tailored to their specific characteristics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.15 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Jindal Films, ExxonMobil Chemical, Taghleef Industries (Ti), Profol, Treofan, CCL Industries Inc., Celanese Corporation, Mitsui Chemicals, Toray Industries, UFlex Ltd., Amcor plc, Mondi Group, Berry Global Inc., Huhtamaki, Sealed Air Corporation, Constantia Flexibles, Innovia Films, Mitsubishi Chemical Corporation, Borealis AG, Sabic |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Medical Grade CPP Film Market Key Technology Landscape

The Medical Grade CPP Film market is underpinned by a sophisticated technology landscape focused on enhancing film performance, manufacturing efficiency, and sustainability. A critical technology is multi-layer co-extrusion, which enables the production of films with multiple distinct layers, each contributing specific properties such as improved barrier against moisture and oxygen, enhanced sealability, or specialized peel characteristics. This allows manufacturers to tailor films precisely to the demanding requirements of various medical applications, from sterile pouches to drug delivery systems. The precise control over layer thickness and material composition achieved through co-extrusion is vital for ensuring consistent quality and performance across batches.

Another significant technological advancement lies in surface treatment and coating technologies. These include plasma treatments, silicone coatings, and specialized barrier coatings that further enhance the film's properties, such as anti-fog characteristics for diagnostic kits or improved adhesion for printing and lamination. Metallization, where a thin layer of aluminum is deposited onto the film, is also a key technology for creating high-barrier CPP films that protect light-sensitive pharmaceuticals. Furthermore, advancements in film formulation, incorporating specialty additives like anti-static agents, slip agents, and antimicrobial compounds, contribute to the film's functionality and safety, addressing specific challenges in medical packaging.

Process control and automation technologies are equally vital, ensuring the precise and consistent production of medical grade CPP films that meet stringent quality and regulatory standards. High-precision winding and slitting technologies are essential for handling thin films without damage and preparing them for subsequent conversion processes. Emerging technologies include the integration of biodegradable or bio-based polymers into CPP formulations to address environmental concerns, as well as the exploration of smart packaging features, such as embedded sensors for temperature or integrity monitoring, using advanced printing and material science techniques. These innovations collectively drive the evolution of medical grade CPP films, making them more versatile, efficient, and environmentally responsible.

Regional Highlights

- North America: A mature market characterized by stringent regulatory standards, high healthcare expenditure, and a strong presence of pharmaceutical and medical device manufacturers. The U.S. and Canada are leaders in adopting advanced medical packaging solutions, driving demand for high-performance CPP films.

- Europe: Driven by well-established healthcare systems, an aging population, and a focus on sustainable packaging innovations. Germany, France, and the UK are key contributors, with ongoing R&D into recyclable and biodegradable medical grade films.

- Asia Pacific (APAC): The fastest-growing region, fueled by expanding healthcare infrastructure, increasing population, rising disposable incomes, and a booming pharmaceutical and medical device manufacturing sector in countries like China, India, and Japan. This region offers significant opportunities for market players.

- Latin America: Showing steady growth due to improving access to healthcare, government initiatives to modernize medical facilities, and increasing foreign investments in the healthcare sector. Brazil and Mexico are prominent markets.

- Middle East and Africa (MEA): An emerging market with growing healthcare investments, particularly in the Gulf Cooperation Council (GCC) countries, and increasing demand for sterile medical supplies. Economic diversification efforts are also supporting healthcare sector expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Medical Grade CPP Film Market.- Jindal Films

- ExxonMobil Chemical

- Taghleef Industries (Ti)

- Profol

- Treofan (part of Jindal Films)

- CCL Industries Inc.

- Celanese Corporation

- Mitsui Chemicals

- Toray Industries

- UFlex Ltd.

- Amcor plc

- Mondi Group

- Berry Global Inc.

- Huhtamaki

- Sealed Air Corporation

- Constantia Flexibles

- Innovia Films

- Mitsubishi Chemical Corporation

- Borealis AG

- Sabic

Frequently Asked Questions

Analyze common user questions about the Medical Grade CPP Film market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is medical grade CPP film?

Medical grade CPP film is a specialized cast polypropylene film engineered to meet strict medical and pharmaceutical standards, offering superior clarity, barrier properties, and sterilizability for packaging sensitive healthcare products.

What are the primary applications of medical grade CPP film?

Primary applications include sterilization pouches, pharmaceutical packaging (e.g., blister packs), medical device packaging, wound care packaging, and diagnostic kit packaging, ensuring product sterility and integrity.

How does medical grade CPP film handle sterilization processes?

Medical grade CPP film is designed to withstand common sterilization methods such as autoclave (steam), gamma irradiation, and ethylene oxide (EtO) without compromising its structural integrity or barrier properties.

What are the key drivers for the Medical Grade CPP Film market?

Key drivers include the rising demand for sterile medical packaging, growth in the pharmaceutical and medical device industries, increasing global healthcare expenditure, and advancements in medical technology requiring high-performance films.

What are the environmental considerations for medical grade CPP film?

Environmental concerns drive efforts towards developing sustainable options, including recyclable and biodegradable CPP film alternatives, as well as optimizing manufacturing processes to reduce waste and energy consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager