Medical Grade N95 Respirator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436550 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Medical Grade N95 Respirator Market Size

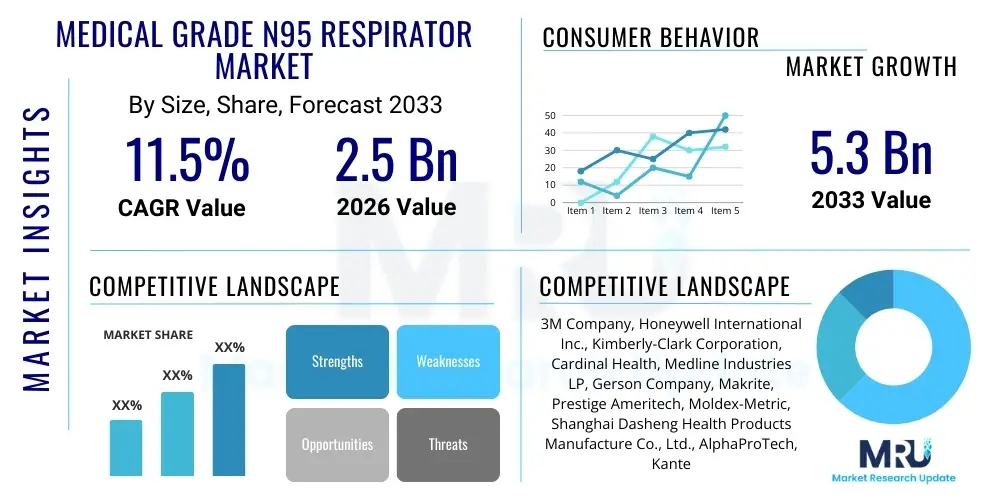

The Medical Grade N95 Respirator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 5.3 Billion by the end of the forecast period in 2033.

Medical Grade N95 Respirator Market introduction

The Medical Grade N95 Respirator Market encompasses the manufacturing, distribution, and sales of high-filtration particulate respirators specifically certified for use in healthcare settings. These respirators, meeting strict standards established by bodies like the U.S. National Institute for Occupational Safety and Health (NIOSH) for N95 classification, are crucial for protecting healthcare workers from airborne pathogens, including viruses and bacteria, and fine particulate matter. The designation "medical grade" emphasizes their fluid resistance and approval for use during surgical procedures or exposure to bodily fluids, distinguishing them from standard industrial N95 masks.

Product descriptions typically highlight multi-layered filtration media, often electrostatically charged non-woven polypropylene fibers, designed to capture at least 95% of airborne particles 0.3 microns or larger. Key applications span critical patient care, surgical environments, emergency response operations, and general hospital use where aerosol-generating procedures (AGPs) are performed. The relentless threat of infectious diseases, coupled with heightened global awareness regarding respiratory protection, has cemented the N95 respirator as an indispensable component of personal protective equipment (PPE) inventory in modern healthcare infrastructure worldwide. The demand is heavily influenced by regulatory mandates and institutional stocking policies.

The core benefits derived from widespread adoption include significantly reducing occupational exposure risks for medical professionals, enhancing patient safety by minimizing cross-contamination, and ensuring continuity of healthcare services during infectious disease outbreaks. Driving factors for market expansion are multi-faceted, notably including increasing government investments in strategic PPE stockpiling, the rising prevalence of respiratory illnesses such as influenza and tuberculosis, and continuous technological advancements aimed at improving fit, comfort, and extended use capabilities. Furthermore, sustained public health education campaigns emphasizing airborne transmission mitigation contribute substantially to consistent demand across diverse healthcare modalities.

Medical Grade N95 Respirator Market Executive Summary

The Medical Grade N95 Respirator Market is poised for significant expansion, driven primarily by intensified global health security concerns, proactive government purchasing, and strict occupational safety regulations imposed across developed economies. The business landscape is characterized by robust competition, with established manufacturers focusing on automation to scale production, improve quality control, and mitigate supply chain vulnerabilities exposed during recent pandemic events. Strategic partnerships between raw material suppliers (specifically melt-blown fabric producers) and respirator assemblers are becoming critical to ensuring supply stability and controlling costs, thereby stabilizing volatile pricing seen in previous years. Furthermore, businesses are heavily investing in product innovation, particularly developing reusable N95 solutions and integrating smart technologies for fit verification and usage tracking, positioning these advanced products as premium offerings.

Regional trends indicate North America currently holds the largest market share, fueled by stringent NIOSH certification requirements and high healthcare expenditure, coupled with significant governmental spending on national strategic stockpiles. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, propelled by rapid development of healthcare infrastructure, massive population density leading to high infection risks, and increasing domestic manufacturing capacity, particularly in countries like China and India. European nations are focusing on creating harmonized regional standards (like FFP2/FFP3 equivalence) and prioritizing local production capabilities to reduce reliance on external suppliers, ensuring resilience against future disruptions. Latin America and MEA are seeing growth linked to modernization of public health systems and international aid programs providing essential medical supplies.

Segmentation trends highlight that the conical (molded) respirator type remains highly utilized due to its ease of donning and relatively comfortable fit, but the flat fold type is rapidly gaining traction, driven by advantages in storage efficiency and lower logistical costs. In terms of end-users, Hospitals and Clinics dominate the consumption landscape, being the primary setting for high-risk procedures. However, the government and strategic stockpiling segment is emerging as a critical revenue generator, as nations move away from just-in-time inventory models toward maintaining multi-year reserves. The key consumer preference shift observed across all segments is a demand for enhanced comfort features, superior breathability, and validated anti-fog characteristics crucial for long shifts in clinical environments.

AI Impact Analysis on Medical Grade N95 Respirator Market

User queries regarding the impact of Artificial Intelligence (AI) on the Medical Grade N95 Respirator market predominantly focus on how AI can enhance manufacturing efficiency, improve fit testing accuracy, and optimize supply chain management to prevent future shortages. Key concerns revolve around the potential for AI-driven automation to disrupt labor markets within established manufacturing facilities, and the regulatory challenges associated with integrating machine learning (ML) diagnostics into quality assurance processes. Users also express strong interest in AI applications for predictive demand forecasting, specifically asking how ML algorithms can use epidemiological data to accurately anticipate regional needs for N95 masks weeks or months in advance, thereby guiding production schedules and reducing waste.

AI is rapidly transforming the manufacturing process by introducing sophisticated predictive maintenance systems that monitor production line performance, identifying potential failures in machinery used for melt-blown fabric creation or mask assembly before they lead to downtime. Furthermore, AI-powered quality control systems utilize computer vision to instantly inspect masks for minute defects, such as imperfections in welding seams or strap attachment, ensuring that every unit meets the stringent medical standards, vastly surpassing the speed and consistency of manual inspections. This infusion of smart technology drives down operational costs, improves yield rates, and ensures consistently high product quality, directly addressing previous industry challenges related to scaling production without compromising certification standards.

Beyond manufacturing, AI significantly enhances market logistics and distribution. Machine learning models analyze complex data sets—including localized infection rates, seasonal trends, geopolitical events, and current inventory levels—to generate highly accurate demand forecasts. This predictive capability allows manufacturers and distributors to dynamically adjust their inventory and logistics networks, ensuring timely delivery of critical supplies to areas facing outbreaks, minimizing panic buying, and stabilizing market pricing. Additionally, AI-driven digital fit-testing tools, using facial recognition and 3D modeling, promise to revolutionize how healthcare workers achieve proper seal checks, improving overall protection efficiency compared to traditional qualitative and quantitative methods.

- AI optimizes manufacturing quality control through computer vision systems, reducing defects.

- Machine learning algorithms enhance predictive demand forecasting using epidemiological data.

- AI-driven supply chain platforms improve inventory management and logistical resilience.

- Robotics and AI facilitate high-volume, automated production lines, boosting scalability.

- Digital AI tools are emerging for personalized N95 fit assessment and training.

- Predictive maintenance driven by AI minimizes costly manufacturing downtime.

DRO & Impact Forces Of Medical Grade N95 Respirator Market

The Medical Grade N95 Respirator Market is subject to significant dynamic forces encompassing robust drivers, structural restraints, crucial opportunities, and high-impact forces that collectively shape its trajectory. The primary driver is the institutionalization of lessons learned from global health crises, leading to permanent increases in PPE consumption rates and continuous strategic stockpiling efforts by national governments and large hospital systems. This proactive approach, coupled with mandatory occupational safety regulations requiring the use of approved respiratory protection in aerosol-rich medical environments, creates a foundation of non-negotiable demand. However, the market faces structural restraints, primarily concerning persistent supply chain fragility, high dependence on specialized melt-blown material, and challenges related to achieving consistent fit and comfort across diverse user populations, leading to compliance issues.

Significant opportunities lie in the development and rapid commercialization of next-generation respirators, specifically those offering enhanced comfort, improved breathability through advanced membrane technology, and certified reusability via effective decontamination protocols. The growing adoption of sustainable manufacturing practices and biodegradable materials also presents a lucrative niche for companies seeking differentiation. Furthermore, expanding market penetration in emerging economies, where healthcare infrastructure investment is accelerating, represents substantial untapped demand. Overcoming the initial investment barriers required for establishing local, high-tech manufacturing hubs in these regions would unlock considerable growth potential and enhance global supply security.

The impact forces dominating this market are primarily regulatory and geopolitical. High-impact regulatory forces include stricter enforcement of quality standards (e.g., enhanced filtration efficiency testing, dermal compatibility), rapid standardization efforts across different international bodies (NIOSH, EN, ISO), and mandates for domestic or regionally secured supply chains. Geopolitical tensions, particularly concerning trade policies affecting raw material movement (especially petrochemical derivatives used in melt-blown production), exert powerful external pressures that can swiftly escalate manufacturing costs and lead to supply volatility. These impact forces necessitate adaptive sourcing strategies, rigorous regulatory compliance protocols, and continuous innovation in material science to maintain market viability and address public health imperatives effectively.

Segmentation Analysis

The Medical Grade N95 Respirator Market is analyzed across various critical segments to provide a detailed understanding of market dynamics, growth pockets, and competitive strategies. Key segmentation parameters include product type, which distinguishes between the traditional conical design and the increasingly popular flat fold variants; material type, focusing on polypropylene and polyurethane components; and end-user categorization, which separates high-volume institutional buyers like hospitals from smaller clinical settings, ambulatory surgical centers, and government purchasing bodies. Furthermore, segmentation by sales channel (direct procurement versus distribution networks) is crucial for understanding pricing elasticity and logistical requirements across different regions.

- By Product Type:

- Conical (Molded) Respirators

- Flat Fold (Duckbill) Respirators

- By Technology:

- Disposable Respirators

- Reusable (Elastomeric/Decontaminable) Respirators

- By Material Type:

- Non-Woven Polypropylene Fabric

- Polyurethane

- Others (e.g., Silicone, Elastomers)

- By End-User:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Government Agencies and Strategic Stockpiles

- Research and Diagnostic Laboratories

- By Sales Channel:

- Direct Sales

- Distributors and Wholesalers

Value Chain Analysis For Medical Grade N95 Respirator Market

The value chain for the Medical Grade N95 Respirator Market is highly complex, beginning with upstream activities focused heavily on specialized material sourcing, followed by energy-intensive manufacturing, and culminating in stringent quality verification and regulated distribution channels. Upstream analysis reveals critical dependency on petrochemical manufacturers supplying polypropylene pellets, which are then converted into high-efficiency melt-blown non-woven fabric. This melt-blown material, responsible for the 95% filtration capability, represents the highest value-add step in the early stages, making the material suppliers key strategic partners or potential bottlenecks. Other upstream components include elastic straps, nose foam, and metal nose clips, sourced globally, but the scarcity or cost fluctuation of melt-blown fabric remains the primary vulnerability.

Midstream activities involve the actual respirator manufacturing and assembly, where processes include ultrasonic welding, cutting, sealing, and packaging. The quality control process at this stage is exhaustive, often requiring independent third-party certification (like NIOSH) to validate fluid resistance and filtration efficacy, thereby adding significant cost and intellectual property value. Downstream analysis focuses on the complex distribution network. Medical grade respirators are often subject to highly regulated procurement processes. Direct channels typically involve large institutional purchases by governmental health bodies or major hospital networks securing bulk contracts, often guaranteeing stable, predictable demand volumes at specific price points. This channel prioritizes reliability and large-scale logistics.

The indirect distribution channel, involving wholesalers, medical supply distributors (e.g., McKesson, Owens & Minor), and specialized regional agents, serves smaller clinics, pharmacies, and niche medical facilities. This channel provides broader market reach but introduces additional layers of margin and complexity. The final delivery to the end-user (healthcare professional) must comply with strict storage and handling guidelines to maintain product integrity. The integration of digital tracking solutions throughout the distribution process, leveraging technologies like RFID and blockchain, is increasingly essential for combating counterfeiting and ensuring the authenticity of medical grade products, thereby maintaining trust in the highly sensitive healthcare procurement environment.

Medical Grade N95 Respirator Market Potential Customers

The primary customer base for Medical Grade N95 Respirators consists overwhelmingly of professional healthcare providers and institutional entities responsible for public health and safety. The largest consumer segment includes general Hospitals and specialized Tertiary Care Centers, where the highest frequency of aerosol-generating medical procedures (AGPs) such as intubation, bronchoscopy, and certain surgical interventions occur. These large institutions have formalized, high-volume procurement contracts, necessitating stable supply chains and competitive pricing models, and often drive demand for specific product features like anti-fogging capabilities and latex-free materials to accommodate staff needs. The shift towards reusable and high-comfort masks is heavily influenced by feedback from this critical end-user group.

A rapidly growing customer segment comprises Government Agencies and National Strategic Stockpiles. Following major global pandemics, nearly all developed and many developing nations have implemented mandates to maintain substantial, multi-year reserves of critical PPE, including N95 respirators, insulating them against future supply shocks. These government customers prioritize long shelf life, verifiable authenticity, and the capacity of suppliers to rapidly scale production during emergencies, often entering into long-term retainer contracts with certified manufacturers. This segment acts as a significant stabilizing force in the market, ensuring baseline demand even during periods of low infectious disease activity.

Secondary but important customer segments include Ambulatory Surgical Centers (ASCs), dental clinics, outpatient specialty clinics (e.g., oncology, pulmonology), and private medical laboratories. While their individual consumption volumes are lower than hospitals, their collective purchasing power is substantial, driven by local occupational health regulations mandating adequate respiratory protection for staff performing procedures involving moderate-to-high aerosol risk. Educational institutions with medical training programs and home healthcare providers also represent niche, but expanding, customer groups that require certified medical grade protection, often procured via specialized distribution networks focused on smaller, recurring orders rather than massive bulk shipments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 5.3 Billion |

| Growth Rate | CAGR 11.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Honeywell International Inc., Kimberly-Clark Corporation, Cardinal Health, Medline Industries LP, Gerson Company, Makrite, Prestige Ameritech, Moldex-Metric, Shanghai Dasheng Health Products Manufacture Co., Ltd., AlphaProTech, Kantex Healthcare, Respro, DemeTECH Corporation, Nexera Medical, RPB Safety, MSA Safety, Drägerwerk AG & Co. KGaA, Ansell Ltd., Zhende Medical |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Medical Grade N95 Respirator Market Key Technology Landscape

The technological landscape of the Medical Grade N95 Respirator Market is centered on enhancing filtration efficiency while simultaneously improving user experience, specifically focusing on breathability, fit, and material sustainability. The fundamental technology remains the electrostatically charged melt-blown non-woven polypropylene filter media, which achieves particle capture through both mechanical interception and electrostatic attraction. Recent innovations are focused on optimizing the charging process and refining fiber diameter distribution to maintain high filtration efficiency (95% or greater) while significantly reducing the pressure drop across the filter, which directly translates to easier breathing and extended wear compliance for healthcare professionals during long shifts.

A pivotal emerging technological area is the development of next-generation reusable and self-decontaminating respirators. This includes incorporating advanced polymer membranes or silicone materials into elastomeric N95-equivalent respirators that can withstand multiple cycles of standard hospital sterilization processes (e.g., vaporized hydrogen peroxide or ethylene oxide). Furthermore, manufacturers are exploring antimicrobial coatings and specialized fabric treatments embedded directly into the outer layers of disposable masks. These treatments aim to inactivate pathogens on contact, reducing the risk of cross-contamination when handling or disposing of the mask, thereby introducing an active protective element beyond passive filtration.

In terms of user interface and validation, the application of smart technology is rapidly gaining traction. Manufacturers are developing digital tools that use augmented reality (AR) or integrated micro-sensors to guide users through proper mask positioning and seal checks, essentially digitizing the often-inconsistent fit-check process. Advanced 3D scanning and printing technologies are also being utilized to create customized N95 respirators or personalized fit testing kits, moving towards a future of highly tailored respiratory protection that maximizes seal integrity for individual users. These technological advancements are crucial for driving market adoption and providing validated solutions that meet the evolving demands for enhanced safety and sustainability in critical care settings.

Regional Highlights

- North America: This region maintains market dominance due to highly established regulatory frameworks (NIOSH standards), immense healthcare expenditure, and robust institutional purchasing power. The U.S. government's commitment to maintaining a robust Strategic National Stockpile (SNS) provides consistent, high-volume demand. Innovation centers and key manufacturing bases contribute to product diversification, particularly in high-comfort and advanced fit technologies.

- Europe: Characterized by stringent, harmonized regional standards (FFP2/FFP3 equivalence) overseen by bodies like CEN (European Committee for Standardization). Market growth is steady, driven by occupational safety mandates and a strong push toward localized, sustainable manufacturing within the EU to enhance self-sufficiency following pandemic-era supply issues. Germany, France, and the UK are key consumers.

- Asia Pacific (APAC): Expected to be the fastest-growing region, fueled by rapidly expanding public and private healthcare infrastructure in countries like China, India, and Southeast Asian nations. High population density and persistent infectious disease risks necessitate aggressive respiratory protection measures. The region is a significant global manufacturing hub, increasingly focused on producing certified medical-grade products for both domestic use and export.

- Latin America: Growth is moderately paced, driven by modernization initiatives within public health systems and increasing awareness of occupational risks. Demand is often correlated with government health budgets and influenced by international aid and donations. Brazil and Mexico represent the largest consumer markets within this area.

- Middle East and Africa (MEA): Market development is uneven, with GCC countries demonstrating high per capita healthcare spending and procurement of premium, certified products. In Africa, market penetration is accelerating, often supported by international organizations and foreign direct investment aimed at enhancing local healthcare resilience and preparedness capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Medical Grade N95 Respirator Market.- 3M Company

- Honeywell International Inc.

- Kimberly-Clark Corporation

- Cardinal Health

- Medline Industries LP

- Gerson Company

- Makrite

- Prestige Ameritech

- Moldex-Metric

- Shanghai Dasheng Health Products Manufacture Co., Ltd.

- AlphaProTech

- Kantex Healthcare

- Respro

- DemeTECH Corporation

- Nexera Medical

- RPB Safety

- MSA Safety

- Drägerwerk AG & Co. KGaA

- Ansell Ltd.

- Zhende Medical

Frequently Asked Questions

Analyze common user questions about the Medical Grade N95 Respirator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between standard N95 and Medical Grade N95 respirators?

The primary distinction is fluid resistance. While both filter 95% of airborne particles, Medical Grade N95 respirators (often referred to as surgical N95s) must meet additional FDA clearance or equivalent regulatory standards for fluid resistance, protecting the wearer from high-velocity splashes of blood and bodily fluids common in surgical settings, which is essential for use in healthcare environments.

How will global government stockpiling initiatives impact long-term market stability?

Government stockpiling creates a baseline level of consistent, guaranteed demand, stabilizing the market and mitigating the extreme cyclical volatility historically linked solely to epidemic outbreaks. This strategy encourages manufacturers to maintain high operational capacity and invest in resilient, localized supply chains, ensuring long-term supply stability and preventing dramatic price spikes.

Which material technology is critical for filtration efficacy in N95 masks?

The critical material technology is melt-blown non-woven polypropylene fabric. This specialized polymer structure is electrostatically charged, allowing it to efficiently capture submicron particles (including viral aerosols) through a combination of mechanical filtration and electrostatic attraction, defining the N95's superior performance characteristics.

Is the trend towards reusable N95 respirators a significant market threat to disposable products?

The trend towards reusable N95-equivalent respirators (elastomeric half-masks or decontaminable devices) presents a growing opportunity rather than a direct threat. While reusable products reduce disposable volume, they drive demand for specialized materials, cleaning validation services, and high-performance filters, catering primarily to long-term clinical and high-risk settings where cost-effectiveness over multiple uses outweighs single-use convenience.

What role does Artificial Intelligence play in future N95 market growth?

AI is crucial for optimizing the manufacturing supply chain, enabling predictive demand forecasting based on real-time public health data, and enhancing quality control through automated visual inspection systems. This integration drives efficiency, reduces defects, and ensures that supply accurately meets unexpected spikes in medical demand, securing future market reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager