Medical Grade Soda Lime Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440587 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Medical Grade Soda Lime Market Size

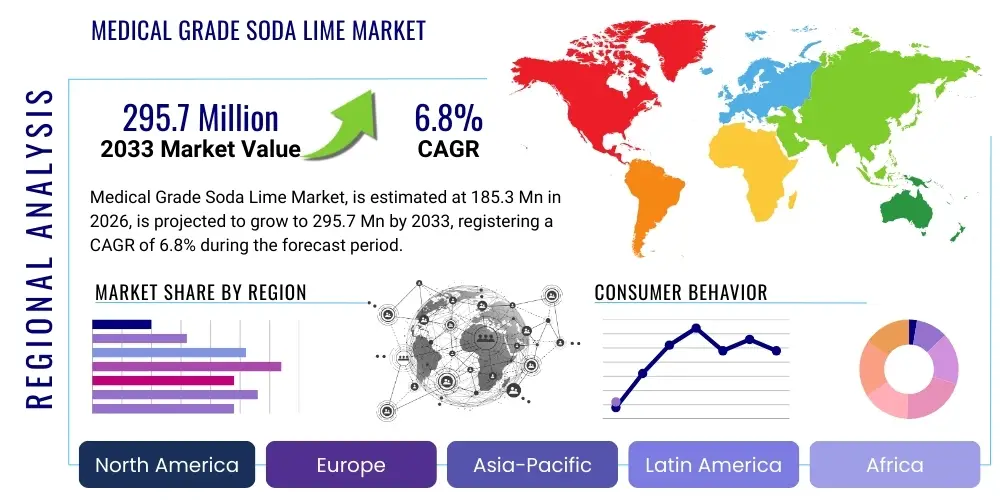

The Medical Grade Soda Lime Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 185.3 Million in 2026 and is projected to reach USD 295.7 Million by the end of the forecast period in 2033.

Medical Grade Soda Lime Market introduction

The Medical Grade Soda Lime Market encompasses the global production and distribution of soda lime specifically formulated for medical applications, primarily in anesthesia and respiratory care. This essential compound acts as a carbon dioxide absorbent in closed or semi-closed breathing circuits, preventing hypercapnia in patients undergoing surgery or requiring ventilatory support. Its composition, typically a mixture of calcium hydroxide, sodium hydroxide, and a small amount of potassium hydroxide, is carefully balanced to ensure efficient CO2 removal while minimizing the risk of harmful byproducts. The product is vital for maintaining a safe and stable breathing environment, particularly during prolonged surgical procedures where gas recirculation is employed.

Major applications for medical grade soda lime include its integration into anesthesia machines, rebreather systems for diving and hyperbaric medicine, and various medical gas purification systems. The efficacy of soda lime in these contexts relies on its ability to chemically react with exhaled carbon dioxide, forming carbonates and water, thereby allowing the rebreathing of anesthetic gases and oxygen. This process significantly reduces the consumption of fresh anesthetic gases, leading to substantial cost savings and environmental benefits by decreasing the release of volatile agents. Beyond its primary function, medical grade soda lime must adhere to stringent quality and safety standards, including low dust generation, consistent particle size, and absence of harmful contaminants, to ensure patient safety and optimal equipment performance.

The market's growth is predominantly driven by the increasing number of surgical procedures worldwide, a rising prevalence of chronic respiratory diseases necessitating ventilator support, and the continuous demand for safe and efficient anesthetic practices. Advancements in anesthesia delivery systems, coupled with a heightened focus on patient safety protocols in healthcare facilities, further propel the adoption of high-quality medical grade soda lime. The benefits of using medical grade soda lime extend to improved patient outcomes, reduced operational costs for hospitals, and enhanced environmental sustainability in healthcare settings. Furthermore, ongoing research into optimized formulations that offer extended absorption capacity and reduced risk of compound A formation continues to influence market dynamics and product innovation.

Medical Grade Soda Lime Market Executive Summary

The Medical Grade Soda Lime Market is experiencing robust expansion, primarily fueled by the global surge in surgical volumes and the imperative for advanced respiratory support systems. Key business trends indicate a strong emphasis on product innovation, with manufacturers investing in formulations that offer enhanced safety features, such as color indicators for exhaustion and improved efficiency in CO2 absorption. Strategic partnerships between soda lime producers and medical equipment manufacturers are becoming more prevalent, aiming to integrate absorption solutions seamlessly into next-generation anesthesia and ventilator technologies. Furthermore, increasing regulatory scrutiny worldwide is driving demand for certified, high-purity medical grade soda lime, prompting market players to adhere to international quality standards like ISO and pharmacopoeia specifications, thus ensuring product reliability and patient safety across diverse clinical environments.

Regionally, North America and Europe currently represent the largest market shares, attributed to their sophisticated healthcare infrastructures, high per capita healthcare spending, and advanced surgical capabilities. However, the Asia Pacific region is projected to exhibit the fastest growth over the forecast period, driven by rapidly developing healthcare sectors in countries like China and India, expanding medical tourism, and a growing patient population requiring surgical and critical care interventions. Latin America and the Middle East & Africa also present significant growth opportunities, as healthcare access improves and awareness of modern medical practices increases. These emerging markets are seeing increased investment in hospital infrastructure and medical equipment, consequently boosting the demand for essential consumables like medical grade soda lime.

From a segmentation perspective, the market is broadly categorized by form (granular, pellets, cartridges), application (anesthesia machines, diving rebreathers, hyperbaric chambers), and end-user (hospitals, ambulatory surgical centers, clinics). The granular form remains dominant due to its widespread compatibility and cost-effectiveness, although pre-filled cartridges are gaining traction for their convenience, reduced dust exposure, and improved safety. Hospitals continue to be the primary end-users, reflecting the high volume of surgical procedures performed in these facilities. However, ambulatory surgical centers and specialized clinics are also contributing significantly to market demand, driven by the shift towards outpatient procedures and the expansion of specialized medical services that require sophisticated respiratory support and anesthesia delivery systems.

AI Impact Analysis on Medical Grade Soda Lime Market

The integration of Artificial Intelligence (AI) into the healthcare ecosystem is poised to introduce transformative changes across various facets, including the supply chain and operational efficiency surrounding critical medical consumables like soda lime. Users frequently inquire about how AI might optimize inventory management for such essential supplies, predicting demand fluctuations with greater accuracy to prevent shortages or overstocking in hospitals and clinics. There is considerable interest in AI's potential to streamline logistics, from manufacturing to point-of-care delivery, reducing lead times and ensuring the timely availability of medical grade soda lime. Furthermore, questions often arise regarding AI's role in quality control, particularly in monitoring production processes to detect impurities or inconsistencies in soda lime formulations, thereby enhancing patient safety and product reliability.

Another area of user concern and expectation revolves around AI's capacity to enhance the performance and safety of anesthesia delivery systems that utilize soda lime. Users are keen to understand if AI-driven algorithms could optimize gas flow settings in anesthesia machines, potentially extending the lifespan of soda lime absorbers or providing real-time alerts about absorber exhaustion before traditional color indicators become fully visible. There is also a curiosity about AI's potential to analyze patient physiological data in conjunction with anesthesia delivery, enabling more personalized and precise anesthetic management, which might indirectly influence the consumption patterns and specifications of medical grade soda lime. The overarching theme is the pursuit of greater efficiency, predictability, and enhanced patient safety through intelligent automation and data analysis in the medical field.

Beyond operational improvements, the long-term impact of AI on market research and product development within the medical grade soda lime sector is also a topic of discussion. AI and machine learning could significantly accelerate the development of novel soda lime formulations, predicting optimal chemical compositions for improved CO2 absorption kinetics, reduced byproduct formation, and enhanced stability. This could lead to a new generation of absorbers that are safer, more effective, and environmentally friendly. Additionally, AI-powered market analysis tools could provide deeper insights into market trends, competitive landscapes, and unmet clinical needs, allowing manufacturers to more effectively tailor their product offerings and strategic investments, thereby shaping the future trajectory of the medical grade soda lime market through data-driven innovation and foresight.

- Optimized inventory management and demand forecasting for hospitals and suppliers.

- Enhanced supply chain logistics, reducing delivery times and improving product availability.

- Improved quality control during manufacturing through AI-powered process monitoring and defect detection.

- Potential for AI algorithms to optimize gas flow and ventilator settings, influencing soda lime lifespan.

- Development of smart anesthesia machines with predictive analytics for absorber exhaustion.

- Acceleration of R&D for novel soda lime formulations with improved safety and efficiency.

- Data-driven insights for market trend analysis and strategic product development.

- Reduced human error in handling and replacement through intelligent system integration.

- Personalized anesthesia delivery based on AI-analyzed patient data, affecting usage patterns.

DRO & Impact Forces Of Medical Grade Soda Lime Market

The Medical Grade Soda Lime Market is significantly shaped by a confluence of Drivers, Restraints, and Opportunities, collectively influenced by various impact forces. The primary drivers include the escalating global volume of surgical procedures, spurred by an aging population, rising incidence of chronic diseases, and advancements in medical technology enabling more interventions. The indispensable role of soda lime in modern anesthesia machines for carbon dioxide absorption ensures its constant demand in operating rooms and critical care units. Furthermore, a heightened focus on patient safety and the prevention of intraoperative hypercapnia compels healthcare providers to consistently procure high-quality, reliable soda lime products. The economic advantages of rebreathing anesthetic gases, leading to reduced consumption and lower costs, also strongly propel market growth, making soda lime an attractive component for healthcare systems worldwide.

Despite these strong drivers, the market faces several notable restraints. One significant challenge is the potential for harmful byproduct formation, such as Compound A, when certain volatile anesthetics react with dehydrated soda lime, necessitating strict hydration control and careful monitoring. Concerns regarding the safe disposal of spent soda lime, which can contain absorbed CO2 and other chemical residues, pose environmental and logistical hurdles. The availability of alternative CO2 absorption technologies, although less common in mainstream practice, could also present a future restraint if they prove to be more cost-effective or safer. Additionally, the inherent hygroscopic nature of soda lime requires careful packaging and storage to prevent premature degradation, adding complexity and cost to the supply chain. These factors collectively require manufacturers and end-users to maintain rigorous protocols and quality controls to mitigate risks.

Opportunities within the Medical Grade Soda Lime Market primarily stem from continuous innovation in product formulations, aiming to develop absorbers with enhanced absorption capacity, reduced dust generation, and lower potential for byproduct formation. The expansion of healthcare infrastructure in emerging economies presents a vast untapped market, with increasing access to surgical care driving demand. Strategic collaborations between soda lime manufacturers and medical device companies can lead to integrated solutions, improving user convenience and safety. Furthermore, the growing awareness and adoption of sustainable healthcare practices are fostering interest in soda lime products that are more environmentally friendly, potentially through improved recyclability or reduced hazardous waste generation. These opportunities provide pathways for market players to expand their reach, improve product offerings, and address evolving clinical and environmental needs, ultimately contributing to sustained market growth and development in the long term.

Segmentation Analysis

The Medical Grade Soda Lime Market is comprehensively segmented to provide granular insights into its various dimensions, allowing for a detailed understanding of market dynamics and consumer preferences. These segmentations typically revolve around the product's physical form, its diverse applications within medical settings, and the specific end-user categories that utilize these essential CO2 absorbents. Such a breakdown helps identify key growth areas, competitive landscapes, and the specific requirements of different market niches, facilitating targeted marketing strategies and product development efforts. Each segment plays a crucial role in defining the overall market structure and future trajectory, reflecting the varied needs of a global healthcare system increasingly focused on efficiency, safety, and specialized care delivery.

- By Form:

- Granular: Traditional, widely used form compatible with most anesthesia machines.

- Pellets: Uniform shape, often used for specific absorber designs.

- Cartridges: Pre-filled, disposable units offering convenience and reduced dust exposure.

- By Application:

- Anesthesia Machines: Primary application for CO2 absorption during surgery.

- Diving Rebreathers: Essential for closed-circuit breathing apparatus in underwater exploration.

- Hyperbaric Chambers: Used in multi-place chambers to maintain safe CO2 levels.

- Medical Gas Purification: Specific uses in gas analysis or industrial medical gas production.

- Others: Niche applications in specialized respiratory support systems.

- By End-User:

- Hospitals: Largest end-user segment due to high volume of surgical procedures.

- Ambulatory Surgical Centers (ASCs): Growing segment driven by outpatient procedures.

- Clinics: Smaller medical facilities performing minor surgeries or procedures requiring sedation.

- Research & Academic Institutions: For experimental setups and educational purposes.

- Emergency Medical Services (EMS): Limited use in portable ventilation devices.

Value Chain Analysis For Medical Grade Soda Lime Market

The value chain for the Medical Grade Soda Lime Market begins with the upstream analysis, focusing on the sourcing and processing of raw materials. Key components include calcium hydroxide, sodium hydroxide, and potassium hydroxide, along with binders and indicators. Suppliers of these chemical precursors play a critical role, and their quality, consistency, and cost directly impact the final product. Manufacturers often engage in long-term contracts with reputable chemical suppliers to ensure a steady and reliable supply chain. The efficiency of raw material extraction and preliminary processing methods, such as lime production and caustic soda manufacturing, significantly influences the overall production cost and environmental footprint of medical grade soda lime. Quality control at this initial stage is paramount to ensure that only pharmaceutical-grade components are utilized, minimizing impurities in the end product and adhering to stringent medical standards.

Moving downstream, the manufacturing process involves precision blending, granulation, and packaging of the soda lime product. This stage is highly specialized, requiring controlled environments to prevent contamination and maintain product integrity, particularly regarding moisture content and particle size uniformity. Manufacturers invest heavily in sophisticated production lines that ensure consistent quality, low dust generation, and accurate color indicators. Post-production, packaging is a critical step, as medical grade soda lime must be hermetically sealed to prevent CO2 absorption from the atmosphere and preserve its reactivity. Specialized packaging materials and techniques are employed to extend shelf life and ensure the product remains sterile and effective until its point of use. This phase also includes rigorous in-house quality assurance and testing to verify that each batch meets regulatory and pharmacopoeial standards, which is a non-negotiable aspect in medical device consumables.

The distribution channel for medical grade soda lime is multifaceted, encompassing both direct and indirect sales strategies. Direct distribution often involves large manufacturers selling directly to major hospital networks, government healthcare procurement agencies, or specialized distributors with broad logistical capabilities. This approach allows for closer relationships with key clients and better control over the supply chain. Indirect distribution, however, utilizes a network of medical equipment distributors, pharmaceutical wholesalers, and regional suppliers who then deliver to individual hospitals, clinics, and ambulatory surgical centers. These intermediaries often provide value-added services such as inventory management, local technical support, and smaller, more frequent deliveries. The choice between direct and indirect channels often depends on geographical reach, customer base size, and the need for specialized logistical support, with hybrid models becoming increasingly common to optimize market penetration and responsiveness across diverse healthcare settings.

Medical Grade Soda Lime Market Potential Customers

The primary potential customers for medical grade soda lime are diverse healthcare entities that utilize anesthesia and respiratory support systems requiring carbon dioxide absorption. Hospitals, particularly their operating theaters, intensive care units (ICUs), and emergency departments, represent the largest segment of end-users. These facilities conduct a high volume of surgical procedures daily, ranging from routine operations to complex, long-duration interventions, all of which necessitate efficient CO2 removal from closed-circuit anesthesia machines. The consistent demand from hospitals is driven by the continuous patient turnover, the need to replenish consumed soda lime regularly, and the imperative to maintain the highest standards of patient safety during anesthesia and mechanical ventilation. Furthermore, university hospitals and medical research centers also procure soda lime for training purposes, simulation labs, and research studies on respiratory physiology and anesthetic gas dynamics.

Ambulatory Surgical Centers (ASCs) constitute a rapidly growing segment of potential customers. As healthcare systems increasingly shift towards outpatient procedures due to cost-effectiveness and patient convenience, ASCs are performing a wider array of surgeries that require general anesthesia or deep sedation. These centers, while typically smaller than hospitals, still rely heavily on modern anesthesia equipment and, consequently, a steady supply of medical grade soda lime. The focus on efficiency and quick patient turnover in ASCs also drives demand for convenient, easy-to-use soda lime formats, such as pre-filled cartridges. Additionally, specialized clinics, including dental surgery clinics, plastic surgery centers, and endoscopy units that utilize anesthesia, also represent significant, albeit smaller, customer bases, demanding high-quality soda lime to support their specific procedural needs.

Beyond traditional surgical settings, other niche but important end-users include hyperbaric oxygen therapy centers and professional diving operations that utilize rebreather technology. Hyperbaric chambers, especially multi-place units, require constant CO2 scrubbing to maintain a safe atmosphere for patients undergoing high-pressure oxygen therapy. Similarly, closed-circuit diving rebreathers, used by military divers, scientific researchers, and technical recreational divers, depend on medical grade soda lime to absorb exhaled carbon dioxide, enabling extended dive times and preventing CO2 buildup. While these applications represent a smaller volume compared to hospitals, they demand highly specialized and reliable soda lime products, often with specific performance characteristics tailored to extreme environmental conditions. Research institutions and academic bodies also represent potential customers, procuring soda lime for experimental setups, advanced respiratory research, and the development of new medical technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.3 Million |

| Market Forecast in 2033 | USD 295.7 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Molecular Products Group, Drägerwerk AG & Co. KGaA, Medisize (part of Phillips-Medisize), Intersurgical Ltd., Allied Healthcare Products, Inc., Smiths Medical (now part of ICU Medical), GE Healthcare, Becton, Dickinson and Company (BD), Cardinal Health, Teleflex Incorporated, Ambu A/S, Vyaire Medical, Inc., Armstrong Medical, Jiangsu Konsung Medical Equipment Co., Ltd., Shanghai Medical Instrument Co., Ltd., Henan Huasheng Medical Technology Co., Ltd., Bio-Medical Devices International, Pryor Medical, Inc., Respiratorius AB, Surgicorp, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Medical Grade Soda Lime Market Key Technology Landscape

The technology landscape for the Medical Grade Soda Lime Market is characterized by continuous refinement of chemical formulations and manufacturing processes to enhance safety, efficiency, and user experience. A primary technological focus is on optimizing the chemical composition of soda lime to maximize its carbon dioxide absorption capacity while minimizing the generation of harmful byproducts, such as Compound A, when reacting with halogenated anesthetics like sevoflurane. This involves precise ratios of calcium hydroxide and sodium hydroxide, along with the careful inclusion of a small percentage of potassium hydroxide or lithium hydroxide, which act as catalysts. Additionally, the incorporation of specific hydration levels and moisture-retaining agents is a critical technological aspect, as the reactivity of soda lime is directly dependent on its water content, and dehydrated products pose a higher risk of adverse reactions. Manufacturers are continually investing in R&D to develop "low-flow" or "dry" soda lime formulations that perform safely under low fresh gas flow anesthesia techniques.

Another significant technological advancement in the market pertains to the physical characteristics and indicators integrated into the soda lime product. Innovations in granulation technology ensure a uniform particle size and shape, which is crucial for optimizing gas flow through the absorber canister and preventing channeling, thereby maximizing the surface area available for CO2 absorption. Dust generation is a major concern, as fine dust particles can lead to respiratory irritation or equipment malfunction; thus, manufacturing technologies focus on producing robust granules with minimal friability. Furthermore, the development of reliable color indicators, which change hue as the soda lime becomes exhausted, is a vital safety feature. The technological challenge lies in creating indicators that provide clear, unambiguous color changes without being affected by ambient light or other environmental factors, offering clinicians a precise visual cue for replacement. Research is also exploring non-visual, electronic exhaustion indicators for integration into advanced anesthesia machines.

The packaging and delivery systems for medical grade soda lime also represent a critical technological area. Pre-filled cartridges and disposable absorber units are gaining popularity due to their convenience, reduced handling, and minimized risk of dust exposure for healthcare personnel. The design of these cartridges involves sophisticated engineering to ensure efficient gas flow dynamics, secure sealing, and easy, leak-free replacement in anesthesia machines. The materials used for packaging are also technologically advanced, designed to prevent moisture ingress, maintain sterility, and provide a long shelf life. Moreover, the integration of radio-frequency identification (RFID) or barcode technology into these cartridges facilitates automated inventory management, tracking of expiry dates, and enhances patient safety by ensuring the correct product is used. These technological advancements collectively aim to improve the overall performance, safety, and operational efficiency of medical grade soda lime in clinical practice, adapting to the evolving demands of modern healthcare.

Regional Highlights

- North America: Dominant market share due to advanced healthcare infrastructure, high surgical volumes, and strong regulatory frameworks. The U.S. leads in adoption of sophisticated anesthesia equipment.

- Europe: Significant market presence, driven by high healthcare spending, an aging population requiring more surgeries, and stringent quality standards (e.g., CE marking). Germany, UK, and France are key contributors.

- Asia Pacific (APAC): Fastest-growing region, fueled by expanding healthcare sectors in China and India, increasing medical tourism, and rising disposable incomes. Growing demand for modern medical consumables.

- Latin America: Emerging market with increasing investments in healthcare infrastructure and rising awareness of advanced medical practices. Brazil and Mexico are key markets in this region.

- Middle East & Africa (MEA): Growth driven by developing healthcare facilities, government initiatives to improve medical services, and increasing prevalence of lifestyle diseases requiring surgical interventions, particularly in Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Medical Grade Soda Lime Market.- Molecular Products Group

- Drägerwerk AG & Co. KGaA

- Medisize (part of Phillips-Medisize)

- Intersurgical Ltd.

- Allied Healthcare Products, Inc.

- Smiths Medical (now part of ICU Medical)

- GE Healthcare

- Becton, Dickinson and Company (BD)

- Cardinal Health

- Teleflex Incorporated

- Ambu A/S

- Vyaire Medical, Inc.

- Armstrong Medical

- Jiangsu Konsung Medical Equipment Co., Ltd.

- Shanghai Medical Instrument Co., Ltd.

- Henan Huasheng Medical Technology Co., Ltd.

- Bio-Medical Devices International

- Pryor Medical, Inc.

- Respiratorius AB

- Surgicorp, Inc.

Frequently Asked Questions

What is medical grade soda lime and why is it used in healthcare?

Medical grade soda lime is a chemical absorbent specifically formulated to remove carbon dioxide (CO2) from breathing circuits in medical applications. It is primarily used in anesthesia machines and rebreather systems during surgery or respiratory support to prevent CO2 buildup (hypercapnia) in patients. The compound reacts chemically with exhaled CO2, converting it into harmless carbonates and water, thereby allowing the safe rebreathing of anesthetic gases and oxygen. This process is crucial for patient safety, maintaining physiological stability, and significantly reducing the consumption of fresh anesthetic agents, offering both clinical and economic benefits in healthcare settings.

What are the primary applications of medical grade soda lime?

The primary applications of medical grade soda lime are in anesthesia delivery systems, specifically anesthesia machines used in operating theaters and critical care units. It is also extensively used in closed-circuit breathing apparatus such as diving rebreathers, where it is vital for maintaining safe breathing gas compositions over extended periods underwater. Furthermore, medical grade soda lime finds application in hyperbaric oxygen therapy chambers, where it helps in scrubbing CO2 from the controlled atmosphere to ensure patient safety during high-pressure treatments. Other niche applications include certain medical gas purification processes and specialized respiratory support equipment designed for CO2 removal, highlighting its versatile and critical role in diverse medical and specialized environments.

How does AI impact the medical grade soda lime market?

AI impacts the medical grade soda lime market by enhancing efficiency and safety across its value chain. In logistics, AI can optimize inventory management and demand forecasting for hospitals, preventing shortages and reducing waste. During manufacturing, AI-powered systems can monitor production for quality control, ensuring consistent purity and performance. Future impacts may include AI integration into anesthesia machines to optimize gas flow settings, potentially extending soda lime life or providing predictive alerts for exhaustion. AI could also accelerate research and development of new, safer formulations of soda lime by analyzing complex chemical interactions, leading to more effective and environmentally friendly products and influencing market competition.

What are the key factors driving the growth of the medical grade soda lime market?

The medical grade soda lime market's growth is primarily driven by several critical factors. A significant driver is the increasing global volume of surgical procedures, fueled by an aging population, rising prevalence of chronic diseases, and advancements in surgical techniques. The indispensable role of soda lime in modern anesthesia for safe and efficient CO2 absorption ensures continuous demand. Additionally, a heightened focus on patient safety protocols in healthcare, coupled with the economic benefits of rebreathing anesthetic gases to reduce costs, further propels market expansion. The growing demand from emerging economies, investing in advanced healthcare infrastructure and medical facilities, also contributes substantially to market growth, as these regions adopt more sophisticated medical practices and equipment.

What are the main types of medical grade soda lime available?

Medical grade soda lime is primarily available in several forms, each catering to specific needs and equipment designs. The most common type is granular soda lime, which is widely used in standard anesthesia absorber canisters due to its effective CO2 absorption and cost-efficiency. Another form is pellets, which offer a more uniform shape compared to granules, sometimes preferred for specific absorber designs to ensure optimal gas flow. A growing trend is the use of pre-filled cartridges or disposable absorber units, which offer enhanced convenience, reduce dust exposure for medical personnel, and provide a safer, more hygienic option for quick replacement in modern anesthesia machines. These types reflect advancements in manufacturing and user-centric design to improve clinical utility and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager