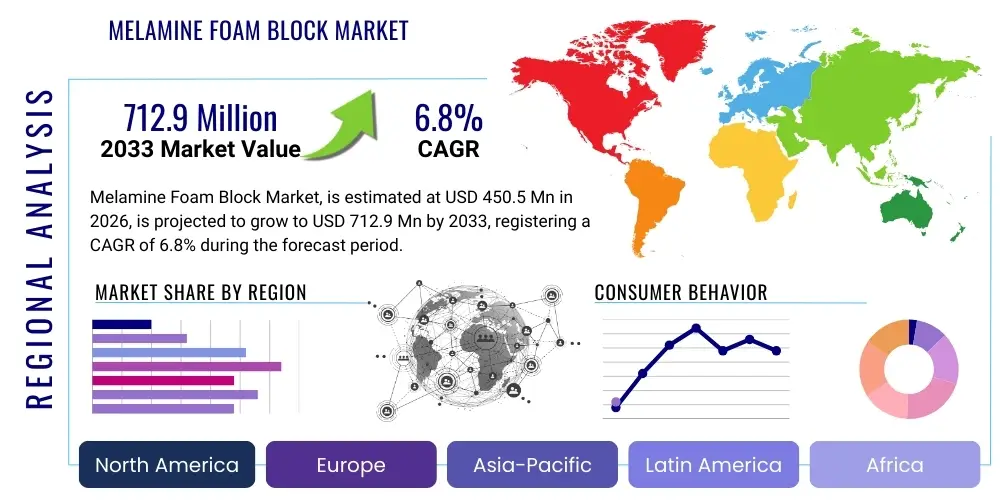

Melamine Foam Block Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435930 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Melamine Foam Block Market Size

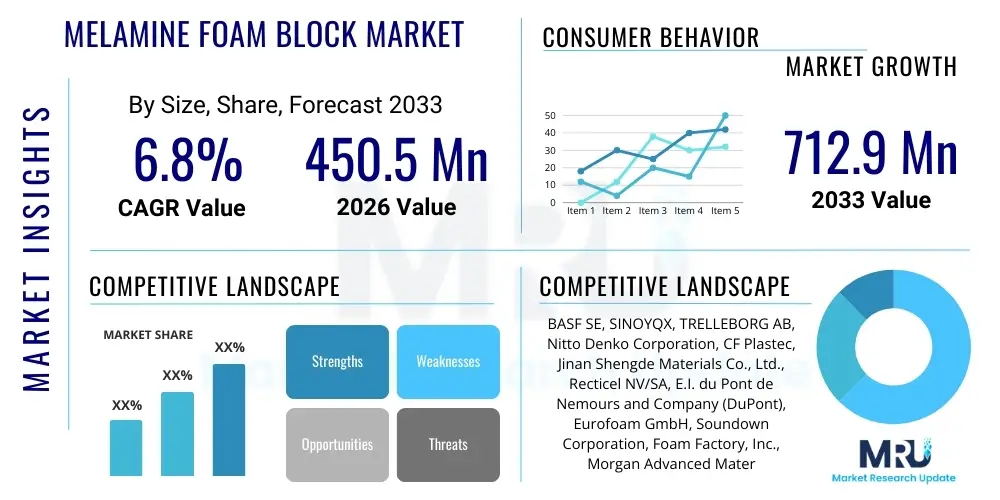

The Melamine Foam Block Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 712.9 Million by the end of the forecast period in 2033.

Melamine Foam Block Market introduction

The Melamine Foam Block Market encompasses the production, distribution, and application of rigid, open-cell foam derived from melamine-formaldehyde condensation. This specialized thermoset polymer is highly valued globally for its unique combination of light weight, excellent acoustic absorption properties, superior thermal insulation characteristics, and inherent flame resistance. Initially utilized primarily in soundproofing and cryogenic insulation, the market has expanded significantly due to its use in consumer cleaning products, where its fine abrasive structure acts as a highly effective micro-scrubber, commonly known as a magic eraser. The low thermal conductivity and high-temperature stability of melamine foam make it indispensable in industries requiring passive fire protection and energy efficiency.

Melamine foam blocks are commercially available in various densities and sizes, tailored to meet specific industrial and consumer demands. Product customization often involves specialized treatments to enhance durability, water resistance, or specific aesthetic qualities, particularly for architectural acoustics applications. Major applications span construction, automotive, aerospace, and general consumer goods. In construction, it is extensively used for insulating ductwork and external wall systems, complying with stringent fire safety regulations. The automotive sector utilizes melamine foam for lightweight sound dampening in engine compartments and passenger cabins, contributing to noise reduction and fuel efficiency improvements.

Key driving factors propelling market growth include the escalating global focus on energy-efficient building standards, increased regulatory pressure concerning noise pollution, and the continuous demand for lightweight materials in transportation. Furthermore, the robust growth in the Asia-Pacific construction sector, particularly in China and India, represents a substantial opportunity for insulation material manufacturers. The versatility and cost-effectiveness compared to competing acoustic and thermal insulators solidify melamine foam's position as a preferred material across diverse manufacturing landscapes. These material benefits, coupled with enhanced processing techniques that reduce production waste, are expected to sustain market momentum throughout the forecast period.

Melamine Foam Block Market Executive Summary

The Melamine Foam Block Market is experiencing robust expansion driven predominantly by structural changes in the global construction and automotive industries, emphasizing lightweighting and enhanced noise control. Business trends indicate a strong move toward product diversification, where core manufacturers are developing higher density variants and composite materials combining melamine foam with other polymers to improve mechanical strength without sacrificing thermal or acoustic performance. Strategic partnerships between foam producers and specialized applicators are becoming common, particularly in niche high-end acoustic installations and customized thermal management solutions for electric vehicle (EV) battery packs. Sustainability is emerging as a critical competitive factor, pushing manufacturers to explore bio-based precursors and closed-loop recycling processes for spent foam materials.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, primarily fueled by massive infrastructure development and the rapid expansion of manufacturing capabilities, positioning it as both a major producer and consumer. North America and Europe, characterized by mature regulatory environments and high consumer awareness regarding building energy performance and indoor air quality, maintain significant market shares, focusing on premium, high-performance acoustic and thermal insulation products. The adoption rate of melamine foam in Latin America and the Middle East & Africa (MEA) is accelerating, driven by urbanization and subsequent increases in residential and commercial construction projects, though price sensitivity remains a constraint in these emerging economies.

Segmentation trends reveal that the acoustic segment holds a dominant market share due to stringent noise regulations in urban centers and the demand for superior sound quality environments in theaters, offices, and recording studios. However, the cleaning segment is projected to exhibit the highest growth rate, fueled by the persistent popularity and cost-effectiveness of melamine-based consumer cleaning sponges across household and commercial cleaning applications. Furthermore, the standard density product type maintains market leadership due to its balance of performance and cost, while high-density foams are gaining traction in specialized industrial applications requiring greater structural integrity and superior compression set resistance, such as aerospace components and vibration dampening pads.

AI Impact Analysis on Melamine Foam Block Market

Common user questions regarding AI's impact on the Melamine Foam Block Market generally revolve around how advanced analytics can optimize manufacturing efficiency, predict material degradation, and personalize product offerings. Users are keenly interested in whether AI can reduce production variability, specifically concerning foam cell structure consistency, which is crucial for predictable thermal and acoustic performance. Key themes summarize to the expectation that AI and Machine Learning (ML) will primarily revolutionize the production stage through predictive maintenance and quality control, ensuring high throughput and minimizing material waste. Furthermore, end-users anticipate AI tools aiding in complex acoustic modeling and thermal simulations, allowing architects and engineers to specify optimal foam types and geometries more accurately for specific project requirements, thus enhancing the overall value proposition of melamine foam.

The influence of artificial intelligence on the market is expected to manifest primarily through the enhancement of polymerization and foaming processes. AI algorithms can analyze real-time sensor data—such as temperature, pressure, and chemical concentrations—during the melamine polymerization stage to ensure uniform block formation and consistent cell sizes. This predictive quality control minimizes the batch-to-batch inconsistencies that can affect insulation R-values and Noise Reduction Coefficients (NRCs). By integrating ML models, manufacturers can dynamically adjust process parameters, leading to higher yield rates and reduced raw material consumption, ultimately lowering operational costs and improving competitiveness against conventional insulation materials.

Beyond manufacturing, AI significantly impacts the supply chain and application development. Demand forecasting, optimized by ML, allows manufacturers to better manage inventory and respond swiftly to fluctuating demand from construction and automotive sectors. In the application space, AI-powered design tools can simulate complex acoustic environments (e.g., concert halls or data centers) to determine the precise thickness, density, and placement of melamine foam required to achieve target acoustic performance, moving beyond traditional, simplified calculations. This precision engineering driven by AI expands the feasible application range for melamine foam blocks and accelerates adoption in sophisticated engineered systems.

- AI optimizes polymerization process for uniform cell structure consistency, boosting performance reliability.

- Machine Learning enables predictive maintenance on production lines, reducing downtime and operational expenditure.

- Advanced analytics facilitates precise demand forecasting, optimizing inventory management and supply chain resilience.

- AI-powered simulation tools enhance acoustic and thermal engineering, allowing for tailored product placement in complex structures.

- Integration of robotics and vision systems utilizing AI improves post-processing quality checks (cutting, shaping, inspection).

- Data-driven insights aid in the development of novel foam composites with improved mechanical characteristics.

DRO & Impact Forces Of Melamine Foam Block Market

The dynamics of the Melamine Foam Block Market are shaped by a powerful combination of supportive drivers, significant structural restraints, and emerging opportunities that collectively dictate the trajectory of growth. The primary drivers stem from mandatory governmental regulations promoting energy efficiency in buildings and stringent standards for fire safety, particularly in commercial and high-occupancy residential structures where melamine foam's inherent non-flammability is highly valued. Simultaneously, the persistent global focus on reducing noise pollution, alongside the expanding applications in the electric vehicle industry for lightweight battery housing insulation and noise reduction, exert substantial positive influence. These drivers solidify the foam's position as a premium material essential for modern engineering demands across core industrial sectors.

However, the market faces several notable restraints. The relatively high cost of melamine foam compared to commodity insulation materials like fiberglass or mineral wool presents a significant hurdle, particularly in price-sensitive emerging markets. Furthermore, the material’s inherent fragility and low mechanical strength limit its use in load-bearing or high-impact applications, requiring additional reinforcement or lamination processes that increase overall system complexity and cost. Environmental concerns related to the formaldehyde component in the production process, although residual levels are typically low in the final product, trigger scrutiny from environmental regulatory bodies and consumer groups, necessitating ongoing research into safer, green chemical precursors.

Opportunities for market players are abundant, focusing primarily on technological innovation and market penetration into specialized areas. Significant opportunity lies in developing bio-based or formaldehyde-free melamine foam variants that address sustainability concerns and open doors to markets with strict green procurement policies. Expansion into aerospace for cabin insulation and noise mitigation, leveraging the material's ultra-lightweight nature, represents a high-value niche. Additionally, improving post-processing techniques to create durable, aesthetically pleasing melamine foam acoustic panels for architectural design offers a chance to capture the high-margin commercial interior design market. The market's future growth hinges on overcoming material fragility and optimizing cost structures through process efficiencies and large-scale manufacturing.

Segmentation Analysis

The Melamine Foam Block Market is comprehensively segmented based on its structural composition (Product Type), its intended functional use (Application), and the ultimate purchasing industries (End-User). Analyzing these segments provides critical insights into consumption patterns and key revenue streams. The dominance of the standard density segment is attributed to its optimal cost-performance ratio for general cleaning and basic insulation applications, making it accessible across diverse consumer and industrial bases. In contrast, the application segmentation highlights the strategic importance of acoustic insulation, reflecting global priorities in sound management across transportation and civil infrastructure, which drives substantial demand for premium foam grades designed for maximum sound absorption.

The segmentation by Product Type, typically categorized into Standard Density and High Density, differentiates the foam based on structural integrity and specific performance metrics. High-density foams, offering enhanced compression resistance and improved durability, are seeing increased uptake in rigorous industrial environments, especially in thermal barriers within high-temperature mechanical systems. Conversely, the market is geographically fragmented, with manufacturing concentrated in regions possessing advanced chemical synthesis capabilities, while consumption is tied directly to regional economic activity, particularly in construction and automotive manufacturing outputs.

End-User segmentation clearly illustrates the dual nature of the market: a high-volume consumer cleaning sector versus a high-value, specialized industrial segment (Acoustics & Thermal Insulation). The Construction & Building segment remains the bedrock of industrial demand due to global mandatory requirements for non-flammable, energy-efficient insulation. The ongoing shift toward electric and hybrid vehicles provides a persistent growth engine for the Automotive sector, utilizing melamine foam blocks for lightweight thermal management and noise, vibration, and harshness (NVH) mitigation, emphasizing the critical role of material properties in modern vehicle design.

- Product Type

- Standard Density Melamine Foam

- High Density Melamine Foam

- Application

- Acoustic Insulation (Soundproofing)

- Thermal Insulation (Cryogenics, HVAC)

- Cleaning Products (Abrasive Sponges)

- Aerospace and Defense Components

- Industrial Equipment and Pipe Insulation

- End-User Industry

- Construction and Building

- Automotive and Transportation

- Consumer Goods and Retail

- Electronics and Appliances

- Aerospace and Marine

- Form

- Blocks and Slabs

- Sheets and Rolls

- Pre-formed Shapes (Custom Die-cut)

Value Chain Analysis For Melamine Foam Block Market

The value chain for the Melamine Foam Block Market begins with the upstream procurement of critical raw materials, primarily melamine and formaldehyde, which are derived from petrochemical feedstocks, alongside specialized foaming agents and catalysts. This stage is dominated by large, integrated chemical companies that control the synthesis and purification of these essential precursors. Fluctuations in crude oil and natural gas prices directly impact the cost of melamine and formaldehyde, introducing volatility at the initial stage of the value chain. Efficiency in the upstream segment relies heavily on maintaining steady supply lines and implementing continuous process improvements in chemical synthesis to ensure high purity and low cost of raw materials delivered to the foam producers.

The midstream segment involves the core manufacturing process: the polycondensation of melamine and formaldehyde to form the melamine resin, followed by specialized foaming processes, typically incorporating microwaves or steam, to expand the resin into open-cell foam blocks. This manufacturing stage requires high capital investment in sophisticated reactors and foaming machinery. Differentiation in this stage is achieved through proprietary techniques that control foam density, cell size distribution, and fire resistance properties. Major foam producers often operate globally to mitigate logistical costs and serve regional customer bases efficiently, converting raw resin into bulk blocks, slabs, and rolls ready for further processing.

Downstream activities include conversion, distribution, and end-user application. Conversion involves slicing, shaping, lamination, and the addition of protective coatings to the raw blocks to meet specific end-user requirements, such as acoustic panels or complex automotive parts. Distribution channels are highly fragmented, spanning direct sales to large industrial customers (e.g., HVAC manufacturers) and indirect channels utilizing wholesalers, specialized distributors, and mass-market retailers for consumer cleaning products. The final stage involves the application, where performance, such as adherence to building codes for insulation or acoustic efficiency in commercial spaces, dictates material selection, emphasizing the role of specialized contractors and installers.

Melamine Foam Block Market Potential Customers

The primary end-users and potential buyers of melamine foam blocks are categorized into high-volume industrial consumers seeking specialized material properties and vast consumer bases utilizing the product for domestic cleaning applications. In the industrial segment, large HVAC system manufacturers, particularly those focusing on commercial climate control and cleanroom environments, constitute major buyers, relying on the foam’s non-flammability and superior thermal performance for ductwork insulation. Furthermore, original equipment manufacturers (OEMs) in the automotive industry, across both internal combustion engine (ICE) and electric vehicle (EV) platforms, are critical consumers, purchasing customized pre-formed shapes for NVH reduction and thermal management within the vehicle structure.

The construction and architectural sector represents another significant purchasing demographic. Acoustic consultants, architectural firms, and specialized building contractors procure melamine foam blocks and panels for soundproofing public spaces, recording studios, educational facilities, and high-rise commercial buildings. These buyers prioritize NRC ratings, fire ratings (A-rated non-combustible), and aesthetic finishes. The trend toward open-plan offices and noise mitigation mandates in densely populated areas ensures continuous, high-value demand from this sector for custom-colored and laminated acoustic products designed for visible installation.

Lastly, the consumer goods sector, encompassing major global retail chains and private label manufacturers of cleaning supplies, constitutes the highest volume purchasing group. These buyers acquire melamine foam in bulk quantities, which are then packaged and marketed as "magic erasers" or specialized abrasive cleaning sponges. The demand here is driven by cost-effectiveness, consumer recognition, and the foam's unique ability to remove stubborn stains without chemical solvents. This dual market structure necessitates distinct sales and distribution strategies for producers, catering separately to high-specification industrial orders and high-throughput retail requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 712.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, SINOYQX, TRELLEBORG AB, Nitto Denko Corporation, CF Plastec, Jinan Shengde Materials Co., Ltd., Recticel NV/SA, E.I. du Pont de Nemours and Company (DuPont), Eurofoam GmbH, Soundown Corporation, Foam Factory, Inc., Morgan Advanced Materials, Tenneco Inc., Saint-Gobain S.A., 3M Company, Rogers Corporation, L&L Products, Guangzhou Kinganda Co., Ltd., Changzhou Jiusheng Foam Products Co., Ltd., Jiangsu Tenghui New Material Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Melamine Foam Block Market Key Technology Landscape

The manufacturing process of melamine foam blocks relies on the advanced chemical engineering technique of polycondensation followed by controlled thermal expansion. Key technological advancements center around optimizing the foaming process to achieve precise control over the open-cell structure. Traditional methods often utilize microwave technology to rapidly heat the melamine resin, triggering the foaming and curing process. Recent innovations focus on continuous manufacturing lines that enhance uniformity and reduce cycle times. Furthermore, manufacturers are investing in specialized chemical additives, such as flame retardants and cross-linking agents, to enhance structural integrity and meet increasingly strict international fire resistance standards, pushing the material into high-end fire-resistant barrier applications.

A critical area of technological innovation is focused on improving the mechanical robustness of the foam without compromising its light weight and acoustic performance. Since pure melamine foam is inherently brittle, manufacturers are developing composite technologies, such as lamination with polymer films (polyethylene or polyurethane) or reinforcement with fibrous materials. These composites enable the foam to withstand higher mechanical stress, making it suitable for applications like automotive sound barriers and complex structural insulation where standard foam would fail. The use of advanced cutting and shaping technologies, including high-precision CNC routers and waterjet cutters, allows for the creation of intricate, custom-fit insulation and acoustic components, minimizing material waste and maximizing installation efficiency.

Another significant development involves 'Green Chemistry' initiatives aimed at mitigating the use of formaldehyde and reducing volatile organic compound (VOC) emissions during production. Research is actively exploring alternative curing agents and bio-based precursors to develop more environmentally friendly melamine foam variants. Additionally, surface modification technologies, such as plasma treatment or specialized coating application, are being employed to enhance hydrophobic properties, making the foam resistant to moisture uptake, which is crucial for exterior building insulation and marine applications. These technological developments are vital for maintaining the competitive edge of melamine foam against emerging sustainable insulating materials.

Regional Highlights

- North America: Characterized by mature markets and strict regulatory regimes governing building energy codes and noise pollution. The region sees strong demand from the aerospace and automotive sectors (particularly EV manufacturing) for lightweight, fire-resistant insulation. High disposable income drives robust consumer demand for premium cleaning products. The US and Canada are leaders in utilizing melamine foam for complex acoustic solutions in commercial architecture.

- Europe: Driven by the European Union’s ambitious energy performance targets for buildings and stringent acoustic comfort requirements (e.g., DIN 4109 and ISO 717 standards). Germany and the UK are key markets, focusing heavily on thermal bridging reduction and high-performance façade insulation. The high concentration of premium automotive manufacturers dictates continuous demand for high-specification NVH materials.

- Asia Pacific (APAC): Represents the fastest-growing market due to rapid urbanization, massive infrastructure spending, and the expansion of the manufacturing base, particularly in China, Japan, and South Korea. China is both the largest producer and consumer, utilizing the foam extensively in its burgeoning construction sector and electronics manufacturing supply chains. Lower labor costs in manufacturing contribute to its regional dominance.

- Latin America: An emerging market characterized by increasing urbanization and corresponding growth in residential and commercial construction. Market adoption is accelerating, though hampered slightly by price sensitivity compared to conventional insulators. Brazil and Mexico are the primary centers for melamine foam consumption, driven by local automotive production and infrastructure modernization projects.

- Middle East and Africa (MEA): Growth is fueled by mega-construction projects (e.g., hospitality and commercial towers) in the Gulf Cooperation Council (GCC) nations, where demand for high-temperature and non-flammable insulation is critical due to harsh climate conditions and strict fire codes. Demand in the African continent is nascent but growing, particularly in South Africa, focusing on specialized industrial insulation applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Melamine Foam Block Market.- BASF SE

- SINOYQX

- TRELLEBORG AB

- Nitto Denko Corporation

- CF Plastec

- Jinan Shengde Materials Co., Ltd.

- Recticel NV/SA

- E.I. du Pont de Nemours and Company (DuPont)

- Eurofoam GmbH

- Soundown Corporation

- Foam Factory, Inc.

- Morgan Advanced Materials

- Tenneco Inc.

- Saint-Gobain S.A.

- 3M Company

- Rogers Corporation

- L&L Products

- Guangzhou Kinganda Co., Ltd.

- Changzhou Jiusheng Foam Products Co., Ltd.

- Jiangsu Tenghui New Material Technology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Melamine Foam Block market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary performance advantages of melamine foam blocks over other insulation materials?

Melamine foam offers superior acoustic absorption (high Noise Reduction Coefficient, NRC) and exceptionally low thermal conductivity, making it an excellent insulator. Crucially, it possesses inherent fire resistance, meeting stringent fire safety standards (often Class A non-flammable) without added chemical retardants, and is remarkably lightweight.

How is the market influenced by environmental regulations and sustainability demands?

The market is increasingly pressured to address environmental concerns related to the use of formaldehyde in production. This is driving technological investment into developing formaldehyde-free or bio-based melamine foam precursors and implementing closed-loop recycling processes to meet growing demand for sustainable and low-VOC construction materials.

What is the main driver of demand for high-density melamine foam variants?

High-density melamine foam is predominantly utilized in demanding industrial applications, such as aerospace components, specialized HVAC systems, and automotive parts, where superior structural integrity, enhanced durability, and better compression set resistance are required compared to standard density foam.

Which geographical region exhibits the fastest growth potential for melamine foam?

The Asia Pacific (APAC) region, led by China and India, is projected to be the fastest-growing market. This growth is directly attributable to the rapid expansion of construction and infrastructure projects, coupled with the increasing adoption of melamine foam in the region’s massive automotive manufacturing sector.

How is melamine foam utilized in the electric vehicle (EV) industry?

In the EV sector, melamine foam is critical for lightweight thermal management and safety. It is used to insulate battery packs against temperature extremes and provide passive fire protection. Its acoustic properties are also employed to mitigate noise, vibration, and harshness (NVH) within the silent electric powertrain architecture.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager