Melamine Polyphosphate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439872 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Melamine Polyphosphate Market Size

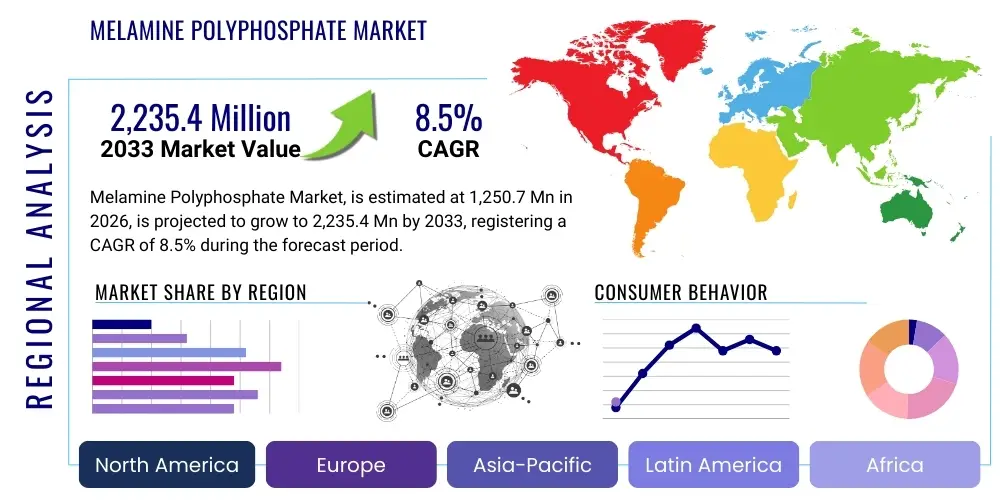

The Melamine Polyphosphate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1,250.7 Million in 2026 and is projected to reach USD 2,235.4 Million by the end of the forecast period in 2033.

Melamine Polyphosphate Market introduction

Melamine Polyphosphate (MPP) stands as a critically important, non-halogenated flame retardant, gaining widespread adoption across a multitude of industries due to its superior performance and favorable environmental profile. This advanced material is specifically designed to enhance the fire safety of various products without contributing to the environmental and health hazards associated with traditional halogenated flame retardants. MPP distinguishes itself through its excellent thermal stability, enabling it to withstand high processing temperatures, and its remarkable char-forming capabilities, which create an insulating barrier that effectively impedes flame spread and smoke generation during a fire event. Its inherent low toxicity and reduced smoke density upon combustion further solidify its position as a preferred choice for manufacturers striving to meet increasingly stringent global fire safety regulations and consumer demands for safer, eco-conscious materials across all sectors.

The principal applications for Melamine Polyphosphate are expansive, encompassing critical sectors such as plastics, protective coatings, specialized textiles, and the intricate wiring and cabling infrastructure. Within the plastics industry, MPP proves particularly effective in polymers like polyolefins, engineered plastics, and thermoset resins, where it imparts essential flame retardancy for a diverse range of products including casings for electronic devices, vital automotive components, and structural elements in the construction industry. For both coatings and textiles, MPP delivers durable and robust fire protection, a feature indispensable for enhancing safety in public transportation, commercial and residential buildings, and various interior design applications. The multifaceted benefits of utilizing MPP extend to its impressive processing stability, minimal impact on material aesthetics, and exceptional long-term performance, collectively making it an indispensable component for manufacturers dedicated to upholding the highest safety standards and environmental stewardship.

Several potent driving factors are propelling the growth of the Melamine Polyphosphate market forward. Foremost among these is the escalating global demand for intrinsically fire-safe materials within the booming building and construction industry, a trend exacerbated by rapid urbanization, significant infrastructure development projects, and a renewed focus on resilient architecture worldwide. Concurrently, the continuously expanding electrical and electronics sector, characterized by its rigorous flame retardancy requirements for consumer electronics, industrial machinery, and intricate data infrastructure, represents another substantial driver for MPP market expansion. Furthermore, the accelerating transition towards electric vehicles (EVs) is creating an unprecedented demand for high-performance flame retardants to safeguard battery modules, critical power electronics, and vehicle interiors against potential fire hazards. As such, MPP is increasingly recognized as a vital, high-performance solution essential for ensuring both safety and structural integrity in the evolving landscape of future mobility and smart city initiatives, guaranteeing its sustained market relevance and growth.

Melamine Polyphosphate Market Executive Summary

The Melamine Polyphosphate (MPP) market is currently navigating a period of dynamic expansion, underpinned by significant global shifts towards more sustainable and safer material solutions. Prevailing business trends indicate a robust emphasis on extensive research and development initiatives, aimed at continually refining MPP's performance attributes such as its dispersion stability, cost-effectiveness in diverse polymer systems, and its overall compatibility with an even broader spectrum of raw materials. Strategic collaborations and partnerships are becoming increasingly integral across the value chain, linking upstream raw material suppliers with downstream end-product manufacturers. These alliances are designed to optimize supply chain efficiencies, accelerate the pace of product innovation, and ensure a resilient and responsive market infrastructure. Moreover, leading market participants are making substantial investments in augmenting their production capacities, driven by the escalating demand from core application sectors. This expansion is frequently accompanied by a strong commitment to integrating sustainable manufacturing practices, aligning with overarching global environmental objectives and enhancing corporate social responsibility profiles.

From a regional perspective, the Asia Pacific market stands out as a dominant force and the primary engine of growth for Melamine Polyphosphate. This surge is directly attributable to the region's relentless pace of industrialization, monumental construction booms, and the flourishing electronics manufacturing hubs in economic powerhouses like China, India, and across Southeast Asian nations. Meanwhile, established markets in Europe and North America continue to exhibit robust demand, primarily fueled by their rigorously enforced fire safety regulations, sophisticated automotive industries, and an unwavering commitment to developing and adopting eco-friendly product formulations. These technologically advanced regions are also at the forefront of integrating MPP into highly specialized, high-performance applications, including advanced aerospace components and bespoke industrial coatings, pushing the boundaries of material science. Furthermore, regions such as the Middle East and Africa, alongside Latin America, are emerging as promising new frontiers. Their increasing investments in infrastructure development and burgeoning industrial sectors are progressively contributing to a rising demand for advanced fire retardant materials, albeit from a relatively lower current market base, signaling future growth opportunities.

An in-depth analysis of market segment trends reveals that the plastics application segment consistently remains the preeminent contributor to the Melamine Polyphosphate market's overall revenue. This dominance is particularly pronounced within the polyolefins and engineering plastics sub-segments, owing to their extensive and critical utilization in manufacturing consumer goods, automotive parts, and various electrical enclosures, where fire safety is paramount. The coatings and textile segments are concurrently projected to experience substantial growth, largely driven by escalating regulatory mandates for fire safety in public infrastructure, commercial establishments, and transport systems. Notably, innovations in ultra-fine grade MPP formulations are significantly broadening its applicability, offering enhanced surface finishes and improved mechanical properties, especially in complex composite materials and high-precision applications. Furthermore, the demand for high-purity grades of MPP is gaining considerable traction in sensitive applications where even minimal impurities could compromise performance or safety, underscoring a broader market shift towards highly specialized and quality-assured product offerings tailored for specific high-stakes industrial requirements.

AI Impact Analysis on Melamine Polyphosphate Market

Common user questions regarding the influence of artificial intelligence on the Melamine Polyphosphate market frequently center on AI's potential to revolutionize efficiency, quality, and innovation across the entire value chain. Users are keen to understand how AI can optimize the complex chemical synthesis processes of MPP for greater yield and consistency, enable predictive maintenance protocols to minimize downtime in manufacturing facilities, and significantly accelerate the discovery and formulation of novel MPP variants with enhanced properties. There is also considerable interest in AI's capacity to assist in navigating and ensuring compliance with rapidly evolving global regulatory landscapes, streamline intricate supply chain operations for improved resilience, and contribute meaningfully to waste reduction initiatives throughout the product lifecycle. Expectations are high that AI will facilitate the personalization of material solutions for niche applications, provide more accurate and dynamic market demand forecasting, and foster the intelligent design of materials optimized for specific industrial performance criteria, ultimately leading to the development of more sustainable, high-performance, and economically viable flame retardant solutions. This predictive capability and optimization potential represent a significant paradigm shift for the industry.

- AI can profoundly optimize the chemical synthesis processes for Melamine Polyphosphate, utilizing advanced algorithms for real-time monitoring and control of reaction parameters, leading to higher yields, improved product consistency, reduced energy consumption, and lower operational costs.

- Predictive analytics, powered by AI and machine learning models, can significantly enhance quality control measures by analyzing vast datasets from production. This enables early detection of potential defects or deviations in MPP batches, minimizing waste, ensuring strict adherence to product specifications, and maintaining batch-to-batch uniformity.

- AI-driven material discovery platforms are poised to revolutionize the research and development landscape, allowing researchers to rapidly explore vast chemical spaces and simulate molecular interactions. This capability dramatically accelerates the identification and development of new, more efficient MPP formulations, including synergistic blends with other additives, tailored for specific polymer systems and performance requirements.

- The implementation of AI in supply chain management can optimize complex logistics, provide highly accurate inventory forecasting, and predict market demand for both raw materials and finished MPP products. This leads to enhanced operational responsiveness, reduced lead times, minimized stockouts, and significant cost efficiencies across the entire global distribution network.

- AI can facilitate the development and integration of smart fire safety systems that dynamically incorporate MPP-treated materials. These systems leverage sensor data and AI algorithms for real-time environmental monitoring, advanced hazard assessment, and intelligent response mechanisms in critical applications such as smart buildings and infrastructure, significantly enhancing overall safety.

- Regulatory compliance processes can be substantially streamlined through AI algorithms capable of analyzing, interpreting, and cross-referencing vast volumes of complex fire safety standards, environmental regulations, and material specifications from various jurisdictions. This ensures that MPP products consistently meet global requirements, reducing compliance risks and accelerating market entry.

- The application of AI in research and development enables sophisticated virtual testing and simulation of MPP performance characteristics within diverse polymer matrices and under various fire scenarios. This capability drastically reduces the reliance on costly and time-consuming physical experiments, accelerating product validation and bringing innovative solutions to market faster.

- AI and machine learning can be employed for advanced market analysis, providing deeper insights into consumer preferences, emerging application trends, and competitive dynamics. This enables manufacturers to develop more targeted product strategies, optimize pricing, and identify new market opportunities for Melamine Polyphosphate formulations.

DRO & Impact Forces Of Melamine Polyphosphate Market

The Melamine Polyphosphate (MPP) market's trajectory is profoundly shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces, each contributing to its unique growth dynamics and competitive intensity. A predominant driver is the escalating global enforcement of stringent fire safety regulations across a multitude of industries, most notably in the building and construction, automotive, and electrical & electronics sectors. These regulations increasingly mandate the incorporation of highly effective flame retardants to protect lives and assets. Concurrently, there is a powerful global shift towards non-halogenated flame retardant solutions, driven by heightened environmental awareness and growing concerns over the health risks associated with traditional halogenated compounds. This fundamental preference significantly bolsters the demand for environmentally benign options like MPP. Furthermore, the relentless pace of urbanization and large-scale infrastructure development projects in rapidly industrializing economies are directly fueling construction activities worldwide, consequently escalating the imperative for fire-safe building materials and components, making MPP an essential additive.

Despite these powerful growth drivers, the MPP market encounters several formidable restraints that temper its expansion. A significant challenge lies in the relatively higher initial cost of Melamine Polyphosphate when compared to some conventional flame retardant alternatives. This cost differential can act as a substantial barrier to widespread adoption, particularly in price-sensitive developing markets where economic considerations often outweigh premium performance. The market is also characterized by the availability of a diverse array of alternative non-halogenated flame retardants, including various phosphate-based compounds, metal hydroxides, and silicone-based systems. These alternatives present a robust competitive challenge, necessitating continuous innovation, superior performance demonstration, and aggressive market positioning from MPP manufacturers to differentiate their offerings. Moreover, while generally considered a safer alternative, potential regulatory ambiguities or evolving scrutiny on specific melamine derivatives, though not directly targeting MPP, could introduce market uncertainties or impose additional compliance burdens in certain regions, potentially impacting market stability and requiring adaptive business strategies.

Abundant opportunities exist for sustained market growth, primarily through relentless investment in ongoing research and development initiatives. These efforts are focused on engineering enhanced MPP formulations that exhibit superior dispersibility in complex polymer matrices, improved processing ease, and synergistic effects when combined with other specialized additives. Such innovations aim to broaden MPP's applicability and improve its performance-to-cost ratio. Strategic expansion into niche, high-performance applications and burgeoning emerging markets, particularly in regions experiencing robust industrial growth and the implementation of evolving safety standards, presents significant potential for market penetration and revenue growth. Furthermore, the escalating global focus on developing and deploying sustainable and eco-friendly material solutions presents a compelling opportunity for MPP, given its inherent environmental advantages over halogenated counterparts. Beyond these, broader impact forces, such as the inherent volatility in global raw material prices, macro-economic fluctuations impacting industrial and construction output, and the intensely competitive landscape populated by both established players and agile new entrants, continuously shape the market dynamics. Successfully navigating these forces demands agile business models, strategic foresight, and a consistent commitment to innovation from all market participants.

Segmentation Analysis

The Melamine Polyphosphate (MPP) market is meticulously segmented across several critical parameters, encompassing distinct product types, diverse application areas, and a wide array of end-use industries. This comprehensive segmentation is instrumental for market stakeholders, including manufacturers, distributors, and investors, as it provides a granular and actionable understanding of market dynamics, specific consumer preferences, and lucrative growth avenues. By dissecting the market in this manner, businesses can effectively identify underserved niches, accurately gauge demand patterns for specialized formulations, and strategically tailor their product portfolios to precisely meet the varied and evolving requirements of different market segments. Each segment, regardless of its size, contributes significantly to the overall market ecosystem, collectively driving the broad applicability, sustained demand, and continuous innovation of Melamine Polyphosphate as a leading, high-performance flame retardant solution across the global industrial landscape.

- By Type:

- Standard Grade: This segment represents the foundational offering of Melamine Polyphosphate, characterized by its balanced properties and cost-effectiveness. It is widely employed for general-purpose flame retardancy applications across various polymer systems where robust fire protection is required without necessitating ultra-specific processing or purity levels. Its versatility makes it a staple in numerous industrial formulations.

- High Purity Grade: Designed for specialized and sensitive applications, this grade of MPP boasts superior purity levels and often exhibits enhanced performance characteristics. It is particularly critical in contexts where minimal impurities are paramount, such as in high-performance electronics, medical devices, or optical components, ensuring optimal product integrity and long-term reliability.

- Ultra-fine Grade: Distinguished by its exceptionally small particle size, the ultra-fine grade MPP is tailored for advanced material applications where achieving uniform dispersion, minimal impact on mechanical properties, and excellent surface finish are crucial. This grade finds extensive use in thin coatings, film applications, and advanced composites, where macroscopic particles could compromise performance or aesthetic quality.

- By Application:

- Plastics: Representing the largest and most dynamic application segment, MPP is extensively integrated into a broad spectrum of polymer types to impart essential fire retardancy.

- Polyolefins (Polypropylene, Polyethylene): Utilized in consumer goods, packaging films, automotive interiors, and various general-purpose plastic articles requiring enhanced fire safety.

- Engineering Plastics (Polyamides, Polybutylene Terephthalate): Crucial for high-performance applications such as electrical connectors, under-the-hood automotive components, industrial machinery parts, and specialized housings where mechanical strength and flame retardancy are both critical.

- Thermosets (Epoxy Resins, Unsaturated Polyester Resins): Essential for composites used in wind turbine blades, circuit boards (FR-4 laminates), and structural components in construction and marine applications, providing superior fire resistance.

- Coatings: MPP is a key ingredient in fire-resistant paints, clear varnishes, and intumescent coatings, which are designed to swell and form an insulating char layer when exposed to heat. These are extensively used for passive fire protection in buildings, industrial structures, and transportation infrastructure.

- Textiles: Applied to various fabrics for upholstery, carpets, protective workwear, drapes, and other interior furnishings, especially in public spaces, commercial establishments, and transportation vehicles, where stringent fire safety standards for textiles are mandated.

- Adhesives: Incorporated into fire-resistant glues, sealants, and caulks used in construction, automotive assembly, and manufacturing processes, providing crucial fire barriers and enhanced structural integrity under thermal stress.

- Wires & Cables: Absolutely vital for electrical insulation, cable sheathing, and jacketing materials in electrical infrastructure, data centers, consumer electronics, and industrial power systems. MPP prevents flame propagation, reduces smoke generation, and protects critical circuits in the event of a fire.

- Others: This diverse category encompasses niche applications in rubber products, specialized paper and board coatings, foams, and various custom-engineered compounds for specific industrial and technical uses where fire safety is a critical design parameter.

- Plastics: Representing the largest and most dynamic application segment, MPP is extensively integrated into a broad spectrum of polymer types to impart essential fire retardancy.

- By End-Use Industry:

- Building & Construction: A major consumer, MPP is extensively used in fire-rated insulation, wall panels, flooring, roofing membranes, pipes, cables, and various interior finishes to meet evolving fire codes and enhance occupant safety in residential, commercial, and industrial buildings.

- Electrical & Electronics: Crucial for circuit boards (PCBs), connectors, device housings, battery enclosures, and internal wiring in consumer electronics, IT infrastructure, telecommunication equipment, and industrial electrical systems, where fire protection is paramount to prevent short circuits and component failures.

- Automotive: Employed in vehicle interior components, under-the-hood plastics, battery enclosures (especially for electric vehicles), charging infrastructure, and cable insulation to significantly enhance fire safety and protect critical systems, contributing to overall vehicle passenger safety.

- Furniture: Utilized in upholstery fabrics, foams, and structural components of both residential and commercial furniture to comply with fire safety regulations for public spaces, hotels, offices, and homes, reducing the flammability of common furnishings.

- Aerospace: Applied in aircraft cabin interiors, structural composites, and insulation materials where extremely stringent fire, smoke, and toxicity (FST) standards must be met, ensuring the highest level of safety for passengers and crew.

- Others: Includes applications in marine vessels, mining equipment, defense industries, rail transport, and other specialized industrial machinery where high-performance flame retardant materials are essential for operational safety and regulatory compliance.

Value Chain Analysis For Melamine Polyphosphate Market

The value chain for the Melamine Polyphosphate (MPP) market is a sophisticated network of interconnected stages, initiating with the meticulous sourcing of foundational raw materials and extending comprehensively through specialized manufacturing processes, intricate distribution networks, and culminating in diverse end-user applications. The upstream segment of this value chain is primarily concerned with the procurement of critical chemical precursors such as melamine, phosphoric acid, and other essential additives. These raw materials are sourced from a global network of chemical suppliers, and their consistent quality, purity, and stable supply are paramount to ensure the integrity and performance of the final MPP product. Manufacturers in this initial phase focus heavily on establishing robust supplier relationships, implementing stringent quality control measures, and optimizing procurement strategies to mitigate supply chain risks and cost fluctuations, which directly impact the downstream production economics.

Following the successful procurement of raw materials, the next crucial stage involves the advanced manufacturing of Melamine Polyphosphate. This process typically entails complex chemical synthesis, often involving polymerization and highly controlled reaction conditions, to yield different grades of MPP, each meticulously tailored for specific end-use applications. This manufacturing phase leverages specialized technologies such as continuous or semi-batch reactors, followed by sophisticated purification, drying, and particle size reduction techniques like micronization. The objective is to produce MPP with consistent chemical composition, desired particle morphology, and optimal dispersibility. Moreover, some manufacturers employ surface modification technologies to enhance MPP's compatibility with various polymer matrices, thereby improving its processing characteristics and overall flame retardancy effectiveness in diverse material systems. Investment in R&D at this stage is continuous, aiming to develop more efficient synthesis routes and novel MPP variants.

The downstream segment of the value chain focuses on the efficient distribution and ultimate application of the manufactured Melamine Polyphosphate to a diverse and global customer base. Distribution channels are typically bifurcated into direct and indirect routes. Direct sales involve manufacturers supplying MPP directly to large-scale industrial customers, such as major plastics compounders, significant textile producers, or specialized coating manufacturers. This direct engagement fosters deeper technical collaboration, allows for bespoke product formulations, and ensures tailored technical support, forming strong, long-term partnerships. Conversely, indirect distribution relies on an extensive network of regional distributors, agents, and specialty chemical suppliers. These intermediaries play a vital role in market penetration by providing localized inventory, efficient logistics, and accessible technical expertise to a broader base of small and medium-sized enterprises across various geographical markets. Both strategies are indispensable for achieving comprehensive market coverage, enabling MPP to reach its wide array of applications in industries ranging from critical building materials and sophisticated electrical and electronics components to specialized automotive parts, ensuring pervasive market presence and product accessibility.

Melamine Polyphosphate Market Potential Customers

The Melamine Polyphosphate (MPP) market serves an expansive and diverse base of potential customers across numerous industrial sectors, all united by an imperative need for enhanced fire safety and adherence to evolving regulatory standards within their products and operational environments. A primary and substantial segment of end-users consists of manufacturers within the plastics and polymer industries, including prominent compounders, masterbatch producers, and resin suppliers. These entities integrate MPP directly into their polymer formulations to achieve the requisite fire retardancy levels for a vast array of products, ranging from intricate electronic housings and robust appliance casings to essential automotive components and durable construction materials. These customers are continuously seeking high-performance, cost-effective, and environmentally compliant flame retardant solutions that seamlessly integrate into their existing processes without negatively impacting the mechanical properties, processing characteristics, or aesthetic quality of their final products. The persistent and growing demand for fire-retardant thermoplastics and thermosets in both general-purpose and high-performance applications positions these manufacturers as central to the MPP market's continued growth.

Another critically important customer segment encompasses manufacturers operating within the global building and construction industry. This broad category includes producers of thermal insulation materials, fire-protective coatings and paints, resilient flooring, specialized roofing membranes, advanced piping systems, and crucial electrical wiring and cabling components. As building codes and fire safety regulations become increasingly stringent and universally adopted, particularly in rapidly urbanizing regions, the demand for inherently fire-resistant construction materials is experiencing an unprecedented surge. MPP is highly valued for its efficacy in intumescent coatings, where it forms an insulating char layer under heat, and its performance in fire-rated panels and cable sheathing, providing indispensable protection for both public infrastructure and private properties. Similarly, the extensive network of textile manufacturers, especially those supplying specialized fabrics for upholstery, commercial carpets, protective workwear, and drapes, represents a significant customer base. Their demand is driven by rigorous fire safety requirements in public transportation systems, the hospitality sector, and residential applications, where material flammability is a paramount concern.

Furthermore, the dynamic electrical and electronics industry, encompassing manufacturers of sophisticated consumer electronics, critical IT equipment, telecommunication infrastructure, and complex industrial electrical systems, constitutes a vital and growing customer segment for MPP. These manufacturers deploy MPP in critical components such as circuit board laminates, electrical connectors, device enclosures, and insulating cable jackets to mitigate fire hazards, prevent short circuits, and ensure full compliance with stringent international safety standards. The rapidly accelerating global growth of the electric vehicle (EV) market is concurrently establishing itself as a burgeoning and major potential customer base. Within the EV ecosystem, battery manufacturers and automotive component suppliers require advanced, high-performance, and non-halogenated flame retardants like MPP for critical applications within battery packs, vital charging infrastructure, and vehicle interiors. These applications are essential for effectively mitigating fire risks associated with high-voltage battery systems and ensuring overall vehicle safety. These diverse, safety-conscious customer groups collectively prioritize reliable, high-performance, and environmentally responsible flame retardant solutions, making Melamine Polyphosphate an indispensable and strategically vital material in their continuous product development, innovation, and manufacturing processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,250.7 Million |

| Market Forecast in 2033 | USD 2,235.4 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Clariant AG, Lanxess AG, Albemarle Corporation, ICL Group Ltd., ADEKA Corporation, JBC GROUP, Shandong Jiahua Chemical Co. Ltd., Jiangsu Kangxiang Flame Retardant Chemical Co. Ltd., Guangzhou Weixian Chemical Co. Ltd., Futian Chemical Group, Hebei Minbang Chemical Co. Ltd., Liansheng Chemical Co. Ltd., Sanmu Group, Zhejiang Wansheng Co. Ltd., Nanjing Huadong Chemical Co. Ltd., Changchun Group, Huntsman Corporation, Huber Engineered Materials, Tolsa S.A., FRX Polymers Inc., Kyowa Chemical Industry Co. Ltd., Dongyi Chemical Co. Ltd., Budenheim Ibérica S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Melamine Polyphosphate Market Key Technology Landscape

The Melamine Polyphosphate (MPP) market is fundamentally driven by a dynamic and evolving technological landscape, constantly pushing the boundaries of material science to optimize its synthesis, enhance its performance characteristics, and refine its seamless integration into a diverse array of advanced material systems. At the core of MPP manufacturing are sophisticated polymerization techniques, including precisely controlled continuous or semi-batch processes. These methods are crucial for achieving high purity, ensuring a consistent and narrowly distributed particle size, and attaining the desired molecular weight and structure of the polyphosphate chains. Complementing these synthesis techniques, advanced micronization technologies, such as jet milling and advanced ball milling, are indispensable. They enable the production of ultra-fine grade MPP powders, which are critical for applications demanding exceptional dispersion uniformity within complex polymer matrices, minimal impact on mechanical properties, and impeccable surface finish in end products like thin films, specialized coatings, and intricate electronic components. Furthermore, pioneering surface modification techniques, including encapsulation, grafting with silanes, or functionalization with other coupling agents, are becoming increasingly vital. These processes significantly improve the compatibility of inherently hydrophilic MPP with hydrophobic polymer systems, thereby enhancing its dispersibility, reducing moisture absorption, and ultimately boosting its flame retardancy effectiveness and processability across a broader range of materials.

In the realm of application technologies, substantial advancements are continually being made in compounding and extrusion methodologies. These techniques require exceptionally precise control over process parameters such as temperature profiles, shear forces, and residence time to ensure that MPP is uniformly incorporated into various plastic resins without thermal degradation, which could compromise its efficacy. The development of innovative synergistic flame retardant systems represents a significant technological frontier. In these systems, MPP is strategically combined with other specialized additives, such as intumescent agents, specific char promoters, or highly efficient smoke suppressants. These synergistic blends capitalize on the unique strengths of each component, collectively achieving superior overall fire performance, often with lower total additive loadings. This approach maintains the desirable physical, mechanical, and aesthetic properties of the host material while significantly enhancing its fire resistance. Moreover, the field benefits immensely from the continuous refinement of sophisticated analytical techniques, including advanced thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), oxygen index (LOI) testing, and cone calorimetry. These precise tools are instrumental for rigorously evaluating and optimizing the fire retardancy performance of MPP-containing materials under simulated real-world fire conditions.

Looking forward, emerging technologies are poised to further transform the MPP market. The burgeoning field of nanotechnology is paving the way for the development of hybrid flame retardants that cleverly incorporate MPP, potentially leading to novel materials exhibiting not only enhanced thermal stability and significantly reduced smoke emissions but also improved mechanical strength and other desirable properties. Advanced computational modeling and highly sophisticated simulation tools are increasingly being deployed in the accelerated design and optimization of novel MPP formulations. These tools allow for the accurate prediction of material behavior under various fire scenarios, dramatically shortening the traditionally lengthy and costly research and development cycles. Furthermore, the integration of Industry 4.0 principles, including pervasive sensor-based monitoring, real-time data analytics, and artificial intelligence-driven process optimization, is revolutionizing MPP production. This integration leads to greater manufacturing efficiency, enhanced quality control, improved resource utilization, and a reduced environmental footprint throughout the production lifecycle. These collective technological advancements are not only driving the evolution of Melamine Polyphosphate towards more efficient, sustainable, and high-performance fire safety solutions but also cementing its role as an indispensable material in addressing global safety challenges across a diverse and expanding range of industries.

Regional Highlights

- North America: This region represents a mature yet dynamically growing market for Melamine Polyphosphate, primarily propelled by the rigorous enforcement of fire safety codes and building regulations, particularly within the construction, automotive, and electrical & electronics sectors. There is a high adoption rate of non-halogenated flame retardants, driven by stringent environmental policies and increasing consumer awareness regarding health and safety. The United States and Canada stand as leading markets, characterized by substantial investments in research and development aimed at innovating sustainable and high-performance material solutions. The robust presence of advanced manufacturing and a strong focus on high-value applications further underpins market growth here.

- Europe: The European market is a significant consumer of MPP, distinguished by its exceptionally robust environmental regulations and an unwavering emphasis on health and safety standards, which collectively drive a strong demand for eco-friendly flame retardants. Major economies such as Germany, France, the United Kingdom, and Italy are key contributors, with demand predominantly originating from their highly developed automotive, electrical & electronics, and building & construction industries. The region also benefits from a vibrant landscape of research initiatives, technological advancements in polymer science, and a strong commitment to sustainable material development, ensuring continued growth and innovation in MPP applications.

- Asia Pacific (APAC): Positioned as the largest and most rapidly expanding market for Melamine Polyphosphate globally, the APAC region's growth is dramatically fueled by unprecedented rates of industrialization, expansive urbanization, and the flourishing manufacturing bases in economic powerhouses like China, India, Japan, and South Korea. Monumental infrastructure development projects, a booming electronics manufacturing sector, and rapidly increasing automotive production, especially in the electric vehicle segment, contribute significantly to the escalating demand for MPP. Emerging economies across Southeast Asia are also experiencing substantial growth in the adoption of advanced fire-safe materials, cementing APAC's role as the primary growth engine for the MPP market.

- Latin America: This region is an emerging market for MPP, demonstrating steady and promising growth, primarily influenced by ongoing construction booms, increasing foreign direct investment in manufacturing, and overall industrial development, particularly notable in Brazil, Mexico, and Argentina. Rising awareness about fire safety, coupled with the progressive implementation of evolving regulatory frameworks for construction and industrial safety, is anticipated to significantly boost the adoption of Melamine Polyphosphate in the coming years. Economic stability and regional trade agreements are further expected to facilitate market expansion.

- Middle East and Africa (MEA): The MEA region is experiencing considerable growth in the Melamine Polyphosphate market, largely attributable to large-scale urban development projects, ambitious infrastructure initiatives, and concerted efforts towards economic diversification, especially within the Gulf Cooperation Council (GCC) countries like the UAE and Saudi Arabia, as well as South Africa. The increasing demand for fire-retardant materials in new residential, commercial, and industrial constructions, coupled with growing investments in manufacturing capabilities and adherence to international safety standards, is driving the market forward in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Melamine Polyphosphate Market.- BASF SE

- Clariant AG

- Lanxess AG

- Albemarle Corporation

- ICL Group Ltd.

- ADEKA Corporation

- JBC GROUP

- Shandong Jiahua Chemical Co. Ltd.

- Jiangsu Kangxiang Flame Retardant Chemical Co. Ltd.

- Guangzhou Weixian Chemical Co. Ltd.

- Futian Chemical Group

- Hebei Minbang Chemical Co. Ltd.

- Liansheng Chemical Co. Ltd.

- Sanmu Group

- Zhejiang Wansheng Co. Ltd.

- Nanjing Huadong Chemical Co. Ltd.

- Changchun Group

- Huntsman Corporation

- Huber Engineered Materials

- Tolsa S.A.

- FRX Polymers Inc.

- Kyowa Chemical Industry Co. Ltd.

- Dongyi Chemical Co. Ltd.

- Budenheim Ibérica S.A.

Frequently Asked Questions

What is Melamine Polyphosphate (MPP) and what are its core advantages as a flame retardant?

Melamine Polyphosphate (MPP) is a high-performance, non-halogenated chemical compound extensively used as an environmentally conscious flame retardant. Its primary mechanism of action involves forming a stable, insulating char layer when exposed to heat, which effectively prevents the spread of flames and significantly reduces smoke generation. The core advantages of MPP include its superior thermal stability, low smoke density, minimal toxicity upon combustion, and its non-corrosive nature. These attributes make it a preferred and safer alternative to traditional halogenated flame retardants, aligning with increasingly stringent global health and environmental regulations while ensuring robust fire protection in a wide array of applications.

Which key industries are the primary consumers and beneficiaries of Melamine Polyphosphate?

The primary consumers and beneficiaries of Melamine Polyphosphate span numerous critical industrial sectors. These include the building and construction industry, where it is vital for fire-rated insulation, panels, and coatings; the electrical and electronics manufacturing sector, which uses it in circuit boards, device housings, and cables for enhanced safety; the automotive industry, particularly for components in electric vehicles requiring advanced fire protection for batteries and interiors; and textile producers, who apply it to fabrics for upholstery, carpets, and protective clothing. These industries rely on MPP to meet rigorous fire safety standards, improve product resilience, and comply with environmental mandates.

How do regulatory frameworks globally influence the demand and adoption of Melamine Polyphosphate?

Regulatory frameworks globally exert a profound influence on the demand and adoption of Melamine Polyphosphate. Stringent fire safety codes, such as those in Europe (e.g., REACH, RoHS) and North America (e.g., UL 94, ASTM standards), mandate the use of effective flame retardants, often favoring non-halogenated alternatives due to environmental and health considerations. This directly drives the adoption of MPP. Furthermore, evolving global standards for sustainability and product safety in various end-use industries continuously compel manufacturers to integrate safer and more eco-friendly materials like MPP into their products, thereby significantly accelerating market growth and penetration across diverse regions.

What are the significant technological advancements shaping the Melamine Polyphosphate market?

Significant technological advancements shaping the MPP market include the development of advanced micronization techniques for producing ultra-fine grades, which improve dispersion and performance in various materials. Innovations in surface modification technologies enhance MPP's compatibility with diverse polymer matrices. Furthermore, the creation of sophisticated synergistic flame retardant systems, combining MPP with other additives for superior fire performance, and the increasing application of computational modeling and AI for accelerated material design and process optimization are key advancements driving the market's evolution towards more efficient and effective solutions.

What are the major growth opportunities for Melamine Polyphosphate in emerging markets?

Major growth opportunities for Melamine Polyphosphate in emerging markets, particularly in Asia Pacific, Latin America, and the Middle East & Africa, stem from rapid industrialization, massive infrastructure development, and growing urbanization. These regions are witnessing increased construction activities, expanding manufacturing bases, and a rising awareness of fire safety, often accompanied by the gradual implementation of more stringent local regulations. The burgeoning electronics and automotive industries in these areas, coupled with a growing preference for sustainable and non-halogenated flame retardants, present substantial untapped market potential for MPP, driving its adoption in new applications and sectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager