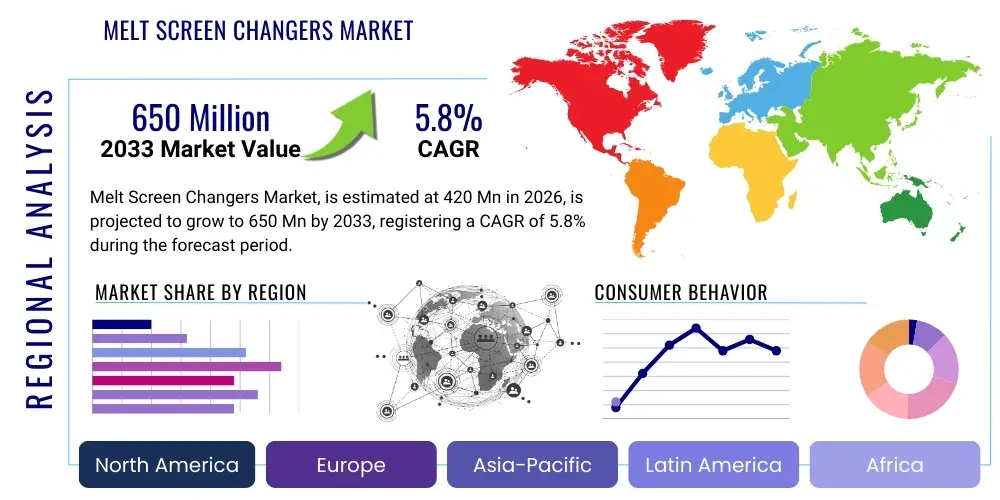

Melt Screen Changers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439311 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Melt Screen Changers Market Size

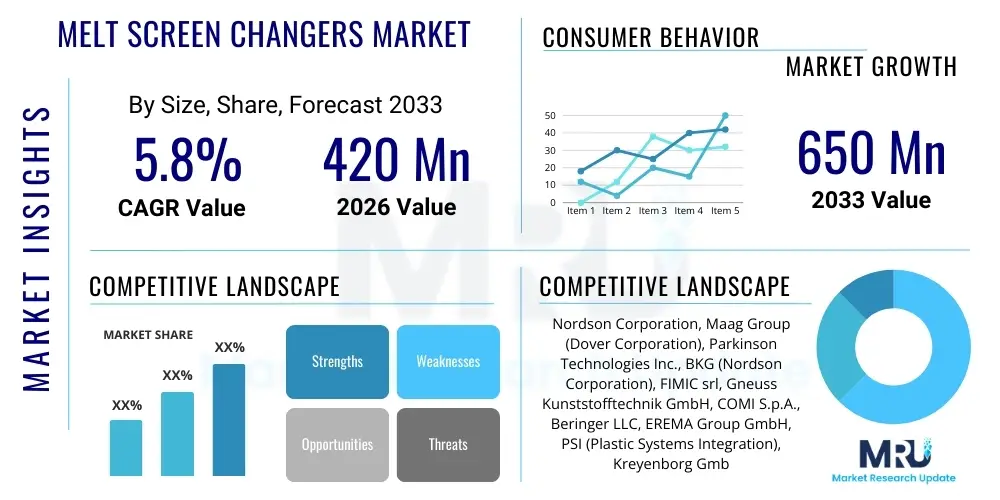

The Melt Screen Changers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 420 Million in 2026 and is projected to reach USD 650 Million by the end of the forecast period in 2033.

Melt Screen Changers Market introduction

The Melt Screen Changers Market is a critical segment within the plastics processing and recycling industry, providing essential equipment designed to filter contaminants from molten polymer streams. These devices are integral to maintaining product quality, protecting downstream machinery from damage, and ensuring uninterrupted production processes. As the demand for high-quality plastic products across various sectors continues to grow, and with an increasing emphasis on circular economy principles through extensive plastic recycling, the role of efficient melt filtration becomes paramount.

Melt screen changers, in their essence, are mechanical filtration systems that remove impurities such as unmolten particles, foreign matter, and degraded polymer fragments from the polymer melt before it enters the die. This purification step is crucial for applications demanding stringent quality standards, including film extrusion, sheet extrusion, pipe and profile extrusion, and compounding. The benefits derived from deploying advanced melt screen changers are multifaceted, encompassing enhanced product aesthetics, improved mechanical properties of the final product, reduction in production downtime due to less frequent die cleaning, and significant protection for sensitive components like gear pumps and dies, thereby extending their operational lifespan and reducing maintenance costs.

Major applications for melt screen changers span a broad spectrum of industries, from packaging and automotive to construction and consumer goods, as well as the rapidly expanding plastics recycling sector. The driving factors behind the market's robust expansion include the global increase in plastic production, stringent quality requirements for end-products, the growing adoption of recycled plastics, and the continuous technological advancements leading to more efficient, automated, and versatile screen changer designs. These innovations address the challenges of processing diverse polymer types and varying levels of contamination, positioning melt screen changers as indispensable assets in modern plastics manufacturing.

Melt Screen Changers Market Executive Summary

The Melt Screen Changers Market is poised for significant expansion, driven by pivotal business trends centered on sustainability, automation, and the escalating demand for high-performance plastic products. Businesses are increasingly investing in advanced filtration technologies to accommodate the rising incorporation of recycled materials into their production lines, necessitated by evolving environmental regulations and consumer preferences for eco-friendly products. This shift towards a circular economy model directly fuels the demand for efficient melt screen changers capable of handling highly contaminated melts without compromising throughput or product quality. Furthermore, the imperative for operational efficiency and reduced labor costs is accelerating the adoption of fully automatic and continuous screen changer systems, enabling longer production runs and minimal human intervention.

Regional trends indicate a robust growth trajectory in emerging economies, particularly across Asia Pacific, driven by rapid industrialization, expanding manufacturing capabilities, and a burgeoning middle class demanding various plastic goods. North America and Europe, while mature markets, are experiencing growth through technological upgrades, stricter environmental policies promoting recycling, and a focus on specialized, high-value applications requiring superior melt purity. Latin America and the Middle East and Africa regions are also demonstrating increasing market potential, supported by infrastructural development and a growing plastics processing industry. The competitive landscape is characterized by innovation, with key players focusing on developing user-friendly interfaces, energy-efficient designs, and systems optimized for specific polymer types and contamination levels.

Segmentation trends reveal a clear preference for continuous automatic screen changers due to their ability to provide uninterrupted production and superior filtration efficiency, particularly in high-volume applications and those involving highly contaminated recycled materials. Discontinuous automatic screen changers maintain their relevance in applications where occasional interruptions for screen changes are acceptable or for smaller production volumes. By application, the packaging and automotive sectors remain dominant, demanding pristine melt quality for functional and aesthetic requirements, while the recycling segment is experiencing the fastest growth. Material trends indicate an increasing need for changers suitable for a broader range of engineering plastics and bioplastics, alongside traditional commodity polymers, reflecting the diversification of the plastics industry.

AI Impact Analysis on Melt Screen Changers Market

The integration of Artificial Intelligence (AI) is set to revolutionize the Melt Screen Changers Market by transforming operational efficiency, predictive maintenance, and quality control. Common user questions often revolve around how AI can minimize downtime, optimize screen change intervals, and predict equipment failures, all while ensuring consistent melt quality. Users are keen to understand AI's capability in analyzing complex operational data to identify patterns, improve decision-making for process parameters, and reduce overall operational costs. The expectation is that AI will move screen changer operations from reactive maintenance to proactive, data-driven management, addressing concerns about throughput variability and the longevity of filtration components.

Another significant area of interest for users concerns AI's role in processing diverse and increasingly challenging materials, especially in recycling applications where contamination levels can fluctuate significantly. Queries frequently arise regarding AI's ability to adapt screen changer settings dynamically based on real-time melt conditions, material viscosity, and contamination loads, thereby optimizing filtration performance without manual intervention. This adaptive capability is seen as critical for maintaining stable process parameters, preventing product defects, and maximizing the efficiency of recycled content integration. The potential for AI to learn from historical data and autonomously adjust operational variables is a key expectation for driving the next generation of melt screen changer technologies, promising a leap forward in system intelligence and reliability.

- Enhanced Predictive Maintenance: AI algorithms analyze operational data (pressure, temperature, flow rates, motor loads) to predict impending component failures or screen blinding, enabling proactive maintenance scheduling and reducing unplanned downtime.

- Optimized Screen Change Intervals: AI can determine the optimal timing for screen changes based on real-time melt contamination levels, pressure differential across the screen, and historical data, minimizing material waste and maximizing screen lifespan.

- Improved Process Control: AI systems can dynamically adjust screen changer parameters (e.g., piston speed, heating elements) to maintain consistent melt pressure and temperature, even with varying material inputs or contamination levels, ensuring stable extrusion processes.

- Real-time Quality Assurance: AI-powered vision systems or sensors integrated with screen changers can monitor melt purity in real-time, detecting anomalies or contamination breakthroughs instantly, leading to immediate corrective actions and reduced product defects.

- Energy Efficiency Optimization: AI can identify patterns in energy consumption and recommend or automatically implement adjustments to heating and cooling cycles, as well as motor speeds, to reduce energy usage without compromising performance.

- Data-driven Material Adaptation: For processing diverse and challenging recycled materials, AI can learn to optimize screen changer settings for specific material recipes and contamination profiles, enhancing throughput and product quality for a wider range of polymers.

- Automated Troubleshooting and Diagnostics: AI can assist operators by providing real-time diagnostics for operational issues and suggesting troubleshooting steps, thereby improving response times and reducing reliance on expert technicians.

DRO & Impact Forces Of Melt Screen Changers Market

The Melt Screen Changers Market is significantly shaped by a dynamic interplay of drivers, restraints, and opportunities, collectively forming the impact forces that dictate its growth trajectory. Key drivers include the ever-increasing global demand for plastic products across diverse industries such as packaging, automotive, and construction, which necessitates robust and reliable processing equipment. Furthermore, the stringent quality requirements for finished plastic goods, especially in sensitive applications like medical devices and high-performance films, mandate superior melt filtration to prevent defects and ensure product integrity. A major impetus also comes from the escalating global focus on plastic recycling and the circular economy, leading to a greater reliance on recycled materials that often contain higher levels of contaminants, thereby creating an indispensable need for efficient screen changers to purify these melts. Technological advancements, leading to more automated, continuous, and efficient screen changer designs, further stimulate market expansion by offering enhanced operational benefits.

However, the market also faces considerable restraints that temper its growth. The high initial capital investment required for purchasing advanced melt screen changers can be a significant barrier for smaller and medium-sized enterprises, particularly in developing regions. Additionally, the operational costs associated with consumables like filter screens and maintenance, though justified by the benefits, can be a deterrent for some manufacturers. Technical challenges related to processing highly abrasive or corrosive polymers, or extremely high contamination levels, can limit the performance and lifespan of some screen changer designs, necessitating specialized and often more expensive solutions. Economic uncertainties and fluctuations in raw material prices can also impact investment decisions in new equipment, potentially slowing market adoption.

Despite these restraints, ample opportunities exist for market expansion and innovation. The rapid industrialization and growth of the plastics processing industry in emerging economies, particularly in Asia Pacific, present significant untapped markets. The continuous innovation in polymer science, leading to new advanced materials and bioplastics, creates demand for screen changers capable of handling these novel formulations effectively. Furthermore, the increasing integration of Industry 4.0 technologies, such as AI and IoT, offers opportunities for developing smart, self-optimizing screen changers that provide predictive maintenance and enhanced operational efficiency. The growing trend towards customization and specialized applications also allows manufacturers to develop niche solutions, catering to unique industrial requirements and securing competitive advantages. These opportunities underscore a promising future for the Melt Screen Changers Market, provided that technological advancements continue to address existing challenges and meet evolving industry demands.

Segmentation Analysis

The Melt Screen Changers Market is meticulously segmented across various parameters to provide a comprehensive understanding of its intricate dynamics and diverse applications. This segmentation allows for a detailed analysis of market trends, consumer preferences, and technological shifts within specific categories. The primary segmentation categories typically include Type, Application, and End-Use Industry, each revealing distinct growth patterns and competitive landscapes. Understanding these segments is crucial for stakeholders to identify lucrative opportunities, tailor product offerings, and formulate effective market penetration strategies.

By dissecting the market into these granular segments, researchers can pinpoint areas of high growth, assess the impact of regulatory changes on specific applications, and evaluate the competitive intensity within different product categories. This granular view also helps in understanding the varying technological requirements and adoption rates across different industrial users, ranging from large-scale plastics manufacturers to specialized recycling plants. The comprehensive segmentation analysis thus serves as a foundational tool for strategic planning and informed decision-making within the melt screen changers industry, highlighting the diverse needs and opportunities present across its expansive scope.

- By Type

- Manual Screen Changers: Systems requiring manual intervention for screen changes, typically used for lower production volumes or less critical applications.

- Automatic Screen Changers: Systems that automatically change screens without stopping production.

- Continuous Screen Changers: Offer uninterrupted melt flow, ideal for high-volume, critical applications.

- Discontinuous Screen Changers: Allow for screen changes with a brief interruption in melt flow, suitable for applications where short stoppages are acceptable.

- By Application

- Film Extrusion: Production of plastic films for packaging, agricultural, and industrial uses.

- Sheet Extrusion: Manufacturing of plastic sheets for thermoforming, signage, and construction.

- Pipe and Profile Extrusion: Production of plastic pipes, conduits, and custom profiles.

- Compounding: Blending polymers with additives or other polymers to create new materials.

- Recycling: Processing of post-consumer or post-industrial plastic waste into reusable pellets.

- Other Extrusion Processes: Including wire and cable coating, blow molding, and fiber extrusion.

- By End-Use Industry

- Packaging Industry: For food and beverage, consumer goods, and industrial packaging.

- Automotive Industry: For interior and exterior components, under-the-hood applications.

- Construction Industry: For pipes, profiles, insulation, and roofing materials.

- Consumer Goods: For appliances, electronics, toys, and household items.

- Recycling Plants: Dedicated facilities for processing various types of plastic waste.

- Medical & Healthcare: For medical tubing, diagnostic components, and sterile packaging.

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Melt Screen Changers Market

The value chain for the Melt Screen Changers Market encompasses a series of interconnected activities that collectively contribute to the creation and delivery of the final product to the end-user. This chain typically begins with upstream activities involving the sourcing of raw materials, such as various grades of steel, alloys, heating elements, and electronic components, which are crucial for the manufacturing of screen changers. Suppliers of these primary materials play a vital role in ensuring quality, cost-effectiveness, and timely delivery, directly impacting the manufacturing process and the final product's performance. Research and development also represent a significant upstream activity, focused on material science, engineering design, and automation technologies to innovate and improve screen changer capabilities.

Midstream activities primarily involve the manufacturing and assembly of melt screen changers. This stage includes precision machining of components like filter bodies, pistons, and screen plates, integration of heating and cooling systems, and the assembly of hydraulic or pneumatic drives. Quality control throughout the manufacturing process is paramount to ensure the durability, reliability, and efficiency of the screen changers. Manufacturers often specialize in different types of screen changers, ranging from manual to fully automatic continuous systems, and may also offer customization options to meet specific client requirements related to polymer type, throughput, and contamination levels. After-sales services, including installation, commissioning, maintenance, and technical support, are also critical components of the midstream value proposition, enhancing customer satisfaction and product longevity.

Downstream analysis focuses on the distribution and end-use of melt screen changers. Distribution channels are typically a mix of direct sales by manufacturers to large industrial clients and indirect sales through a network of distributors, agents, and system integrators. These intermediaries play a crucial role in reaching a wider customer base, providing local support, and often bundling screen changers with other extrusion or recycling equipment. End-users span a wide array of industries including plastics processing (film, sheet, pipe, profile extrusion), compounding, and critically, the plastics recycling sector. The increasing demand from these downstream industries, driven by production growth and quality standards, is a primary driver for the entire value chain, emphasizing the necessity of efficient and reliable melt filtration solutions. The effectiveness of the entire value chain hinges on seamless coordination, technological innovation, and a strong customer-centric approach.

Melt Screen Changers Market Potential Customers

The potential customers for Melt Screen Changers represent a diverse array of industries and processing operations that rely heavily on the extrusion of molten polymers. These end-users are primarily driven by the need to ensure the purity and quality of their plastic products, protect expensive downstream machinery, and optimize their production processes for efficiency and minimal downtime. Manufacturers engaged in the production of various plastic goods, from thin films to robust pipes, form a significant customer base. Their demand is fueled by the requirement to meet stringent product specifications, prevent defects caused by contaminants, and achieve consistent material properties in their end products. As such, any entity involved in the melting and forming of plastics is a potential buyer of melt screen changers, recognizing their indispensable role in maintaining operational integrity and product excellence.

A particularly rapidly expanding segment of potential customers is found within the plastics recycling industry. As global efforts to promote a circular economy intensify, an increasing number of companies are dedicated to processing post-consumer and post-industrial plastic waste into reusable resins. These recycled materials often contain varying levels of impurities, ranging from paper labels and metal particles to different types of plastics, making effective melt filtration absolutely crucial. Recycling plants, compounders incorporating recycled content, and masterbatch producers who utilize recycled polymers are therefore key customers for advanced melt screen changers capable of handling high contamination loads efficiently. Their investment in these systems is directly linked to their ability to produce high-quality recycled pellets that can be re-integrated into manufacturing streams, thereby enabling sustainable practices.

Beyond the core plastics processing and recycling sectors, other niche industries also represent significant potential customers. These include manufacturers of medical devices where sterile and contaminant-free polymers are paramount, wire and cable producers who require precise extrusion for insulation and jacketing, and specialized compounding operations that develop high-performance engineering plastics. These diverse applications underscore the universal need for reliable melt filtration wherever polymers are extruded. The varying requirements across these customer groups, concerning throughput, material type, and contamination levels, drive the demand for a wide range of melt screen changer types and configurations, from manual systems for small-batch operations to highly automated, continuous changers for large-scale, critical production lines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 420 Million |

| Market Forecast in 2033 | USD 650 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nordson Corporation, Maag Group (Dover Corporation), Parkinson Technologies Inc., BKG (Nordson Corporation), FIMIC srl, Gneuss Kunststofftechnik GmbH, COMI S.p.A., Beringer LLC, EREMA Group GmbH, PSI (Plastic Systems Integration), Kreyenborg GmbH, ECON GmbH, CROWN Extrusion Inc., JC Times Technology Co. Ltd., Nanjing Haisi Extrusion Equipment Co. Ltd., Luoyang Gufeng Plastic Machinery Co. Ltd., Suzhou Xinfa Extrusion Machinery Co. Ltd., Polymer Systems Inc., Zhengzhou Great Machinery Equipment Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Melt Screen Changers Market Key Technology Landscape

The Melt Screen Changers Market is characterized by a dynamic and evolving technology landscape, continuously driven by the imperative for increased efficiency, greater automation, and enhanced capability to handle diverse and challenging polymer melts. At the core of this landscape are advancements in filtration media, with innovations in screen materials and designs that offer improved filtration efficiency, extended lifespan, and reduced pressure drop. Multi-layer screens, sintered metal filters, and specialized mesh configurations are examples of how filter technology is being optimized to remove finer contaminants and withstand higher operating pressures, thereby catering to the stringent quality requirements of modern plastics processing.

Beyond the filtration media itself, significant technological progress is evident in the mechanical and control systems of melt screen changers. The development of continuous automatic screen changers, particularly piston-type and backflush systems, has revolutionized production by enabling uninterrupted operation and minimizing downtime associated with screen changes. These systems often incorporate sophisticated hydraulic or pneumatic actuation mechanisms, coupled with advanced sensor technology to monitor melt pressure and temperature differentials. Furthermore, the integration of programmable logic controllers (PLCs) and human-machine interfaces (HMIs) provides operators with precise control over the screen changing process, allowing for real-time adjustments and diagnostics, which are crucial for optimizing performance and preventing costly interruptions.

The most recent and impactful technological trends involve the incorporation of Industry 4.0 concepts, including the Internet of Things (IoT) and Artificial Intelligence (AI). IoT sensors embedded within screen changers gather vast amounts of operational data, such as pressure fluctuations, temperature profiles, motor loads, and screen change frequency. This data is then analyzed by AI algorithms to enable predictive maintenance, anticipating component failures or the optimal timing for screen changes before they impact production. AI also facilitates adaptive process control, allowing the screen changer to dynamically adjust its operation based on real-time melt conditions and material characteristics, particularly beneficial for processing recycled content with variable contamination levels. These smart technologies are transforming screen changers from simple filtration units into intelligent, self-optimizing components of a larger, interconnected extrusion line, promising unprecedented levels of efficiency, reliability, and product quality in the Melt Screen Changers Market.

Regional Highlights

- North America: A mature market characterized by stringent quality standards in industries such as automotive and medical, driving demand for advanced, high-performance melt screen changers. Emphasis on automation and efficient processing of engineering plastics and recycled content. Robust R&D activities and a strong presence of key market players contribute to sustained growth.

- Europe: High adoption rates of advanced melt screen changers, propelled by stringent environmental regulations promoting plastics recycling and a strong focus on circular economy initiatives. Western European countries lead in technological innovation and investment in highly automated, energy-efficient systems. Eastern Europe shows promising growth due to expanding manufacturing bases and modernization efforts.

- Asia Pacific (APAC): The largest and fastest-growing market due to rapid industrialization, expanding manufacturing sectors (especially in China, India, and Southeast Asia), and increasing plastic production and consumption. Growing middle class, urbanization, and the rise of local manufacturers contribute significantly. Increasing investment in recycling infrastructure further fuels demand.

- Latin America: Exhibits steady growth, driven by increasing foreign investments in manufacturing and a growing domestic demand for plastic products. Brazil and Mexico are key markets, with an emphasis on cost-effective yet reliable screen changer solutions. Developing recycling infrastructure also contributes to market expansion.

- Middle East & Africa (MEA): An emerging market with significant growth potential, particularly in the GCC countries, owing to investments in industrial development and diversification away from oil economies. Rising demand for packaging and construction materials drives the need for extrusion equipment, including melt screen changers. Growing awareness and initiatives for plastics recycling are also fostering market development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Melt Screen Changers Market.- Nordson Corporation

- Maag Group (Dover Corporation)

- Parkinson Technologies Inc.

- BKG (Nordson Corporation)

- FIMIC srl

- Gneuss Kunststofftechnik GmbH

- COMI S.p.A.

- Beringer LLC

- EREMA Group GmbH

- PSI (Plastic Systems Integration)

- Kreyenborg GmbH

- ECON GmbH

- CROWN Extrusion Inc.

- JC Times Technology Co. Ltd.

- Nanjing Haisi Extrusion Equipment Co. Ltd.

- Luoyang Gufeng Plastic Machinery Co. Ltd.

- Suzhou Xinfa Extrusion Machinery Co. Ltd.

- Polymer Systems Inc.

- Zhengzhou Great Machinery Equipment Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Melt Screen Changers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Melt Screen Changer and why is it essential in plastics processing?

A Melt Screen Changer is a critical filtration device used in plastic extrusion and recycling to remove contaminants from molten polymer streams. It ensures product quality, protects expensive downstream machinery like dies and pumps from damage, and prevents production downtime by maintaining a clean melt, which is essential for high-quality plastic products and efficient operations.

What are the primary types of Melt Screen Changers available?

Melt Screen Changers are broadly categorized into Manual and Automatic types. Automatic changers are further divided into Continuous (e.g., piston, rotary disk) which allow uninterrupted production, and Discontinuous (e.g., slide plate) where screen changes involve a brief pause in melt flow. The choice depends on production volume, contamination levels, and application requirements.

How do Melt Screen Changers benefit the plastics recycling industry?

In plastics recycling, Melt Screen Changers are indispensable for purifying recycled plastic melts, which often contain higher levels of impurities such as paper, metals, or foreign plastics. They ensure that recycled pellets meet quality standards for re-integration into manufacturing, enabling the production of high-quality recycled products and supporting circular economy initiatives.

What factors should be considered when choosing a Melt Screen Changer?

Key factors include the type of polymer being processed, the expected level and type of contamination, required throughput, desired filtration fineness, budget constraints, available space, and the level of automation desired. Consulting with a specialist is often recommended to match the best system to specific operational needs.

How does AI impact the future of Melt Screen Changers?

AI is set to transform Melt Screen Changers by enabling predictive maintenance, optimizing screen change intervals based on real-time data, and dynamically adjusting process parameters for enhanced efficiency and quality. This leads to reduced downtime, lower operational costs, and improved adaptability to diverse and contaminated material inputs, making operations smarter and more reliable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager