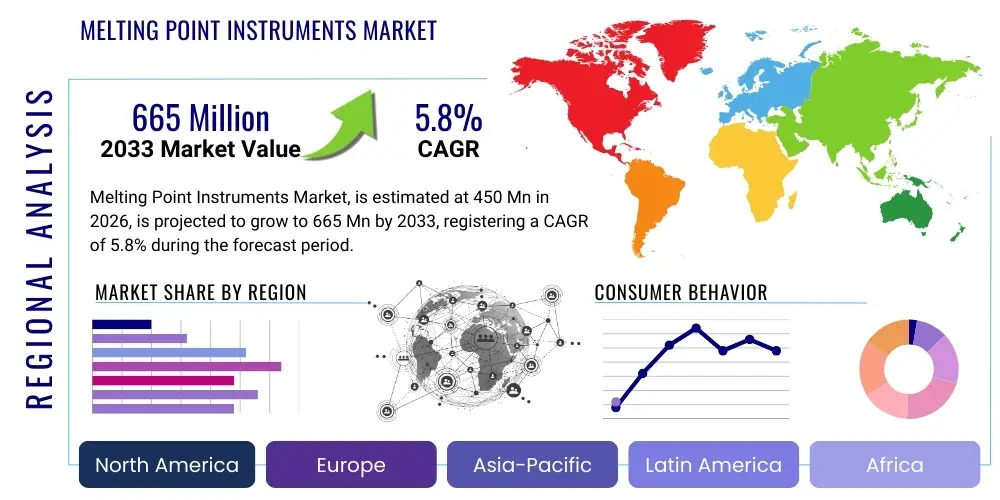

Melting Point Instruments Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439818 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Melting Point Instruments Market Size

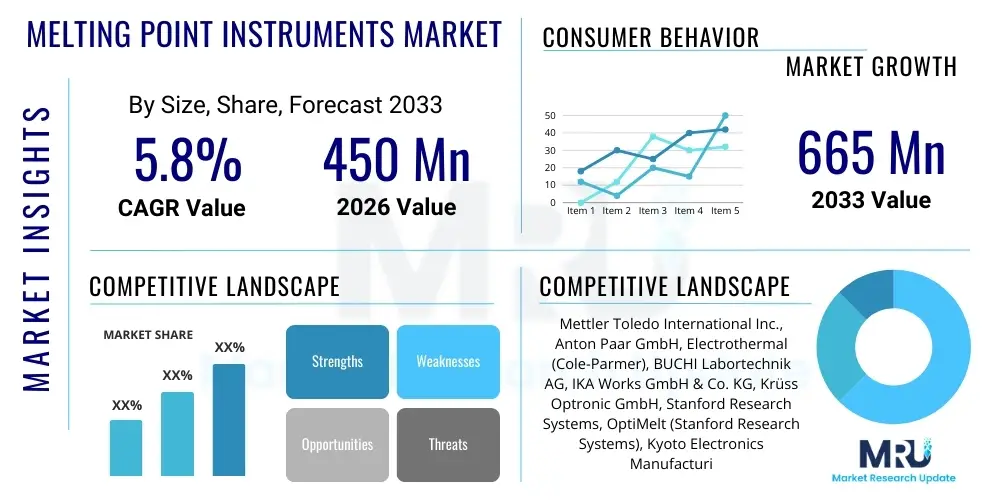

The Melting Point Instruments Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033.

Melting Point Instruments Market introduction

The Melting Point Instruments Market encompasses devices designed to accurately determine the melting point of a substance, a crucial parameter for identification, purity assessment, and quality control across diverse industries. These instruments measure the temperature at which a solid transitions into a liquid phase, offering fundamental insights into the physicochemical properties of materials. Their utility spans a broad spectrum, from identifying unknown compounds and verifying material authenticity to ensuring the quality and consistency of raw materials and finished products in critical sectors.

Major applications of melting point instruments are predominantly found in the pharmaceutical, chemical, and food & beverage industries, as well as in academic research and materials science. In pharmaceuticals, they are indispensable for drug discovery, development, and quality assurance, ensuring active pharmaceutical ingredients (APIs) and excipients meet stringent purity standards. The chemical industry leverages these instruments for characterizing new compounds, monitoring reaction progress, and ensuring product specifications. Benefits include enhanced precision, reproducibility, and automation, which significantly reduce human error and improve throughput compared to traditional manual methods. Key driving factors for market growth include increasing global R&D activities, stricter regulatory requirements for product quality, and continuous technological advancements leading to more sophisticated and user-friendly instruments.

Melting Point Instruments Market Executive Summary

The Melting Point Instruments Market is experiencing robust growth driven by escalating demand for precise material characterization and quality control across a multitude of industries. Business trends indicate a strong move towards automation and digital integration, with manufacturers focusing on developing instruments that offer higher throughput, enhanced accuracy, and seamless data management capabilities. This shift addresses the increasing volume of samples requiring analysis and the need for reliable, audit-trail-compliant results, particularly in highly regulated environments like pharmaceuticals and specialty chemicals. Companies are also investing in user-friendly interfaces and remote diagnostic features to improve operational efficiency and reduce the total cost of ownership for end-users.

Regional trends highlight significant growth in Asia Pacific, propelled by expanding pharmaceutical manufacturing bases, burgeoning chemical industries, and increased government funding for research and development in countries like China and India. North America and Europe continue to be dominant markets, characterized by established R&D infrastructure, stringent quality control regulations, and a high adoption rate of advanced analytical technologies. Segmentation trends reveal a growing preference for automatic and semi-automatic instruments over traditional manual methods, as these offer superior precision, repeatability, and efficiency. The pharmaceutical and biotechnology segment remains the largest end-user, while academic and research institutions are increasingly adopting these technologies for fundamental scientific exploration and material innovation. The market is also seeing niche growth in segments like food and beverage, where purity and quality checks are paramount for consumer safety and product integrity.

AI Impact Analysis on Melting Point Instruments Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into the Melting Point Instruments Market is poised to revolutionize several aspects of material analysis, addressing common user questions around data interpretation, predictive capabilities, and workflow optimization. Users frequently inquire about AI's potential to automate complex data analysis, reduce human intervention in result interpretation, and provide faster, more accurate insights into material properties. There is also significant interest in how AI can enhance the predictive capabilities of instruments, moving beyond simple measurement to anticipate material behavior under different conditions or identify anomalies indicative of impurities without extensive manual validation.

The primary themes emerging from user concerns and expectations revolve around leveraging AI to improve data integrity, accelerate decision-making, and streamline laboratory operations. Users are looking for AI to not only process raw melting point data but also to correlate it with other analytical techniques, identify patterns that might indicate polymorphic forms, degradation, or batch variations, and even suggest optimal analytical parameters. The expectation is that AI will transform melting point analysis from a purely empirical measurement into a sophisticated predictive and diagnostic tool, thereby enhancing overall efficiency, reliability, and scientific utility within research, development, and quality control workflows. This advanced analytical capability is crucial for industries facing increasing pressure to accelerate product development cycles and ensure uncompromised product quality.

- AI-driven algorithms can automate data analysis, reducing manual interpretation errors and improving result consistency across different operators and instruments.

- Predictive modeling powered by AI can correlate melting point data with other physicochemical properties, enabling more comprehensive material characterization and early detection of impurities or quality deviations.

- Enhanced automation through AI can optimize instrument parameters, calibrate systems more efficiently, and even self-diagnose minor issues, minimizing downtime and improving operational efficiency.

- AI can facilitate the creation of extensive material databases, allowing for rapid comparison of experimental data with known profiles, thus speeding up identification and quality verification processes.

- Machine learning applications can identify subtle patterns in melting curves that human analysts might miss, providing deeper insights into polymorphism, crystallinity, and purity levels of complex substances.

- Integration with Laboratory Information Management Systems (LIMS) can be significantly improved by AI, enabling seamless data flow, automated reporting, and enhanced traceability, which are crucial for regulatory compliance.

DRO & Impact Forces Of Melting Point Instruments Market

The Melting Point Instruments Market is significantly shaped by a confluence of driving forces, inherent restraints, and burgeoning opportunities that collectively determine its trajectory. Key drivers include the escalating global investment in research and development across pharmaceutical, chemical, and biotechnology sectors, where precise material characterization is fundamental. Strict regulatory frameworks, particularly in pharmaceuticals and food safety, mandate rigorous quality control and purity assessments, thereby boosting the adoption of reliable melting point instruments. Furthermore, continuous technological advancements leading to automated, high-precision, and digitally integrated instruments enhance efficiency and accuracy, attracting a broader user base and expanding application areas.

However, the market also faces several restraints. The high initial capital investment required for advanced automated melting point instruments can be a barrier for small and medium-sized enterprises (SMEs) or academic institutions with limited budgets. Additionally, the operation and maintenance of sophisticated equipment often demand skilled personnel, which can be a challenge in regions with a shortage of trained technicians. Opportunities within the market are substantial, particularly with the growth of biopharmaceutical research, the increasing number of contract research and manufacturing organizations (CROs/CMOs), and the potential for developing miniaturized and portable instruments for on-site analysis. The integration of artificial intelligence and machine learning also presents a unique opportunity to enhance data analysis, prediction, and automation, further solidifying the market's growth prospects.

Segmentation Analysis

The Melting Point Instruments Market is extensively segmented by various critical parameters including type, application, and end-user, each providing a distinct perspective on market dynamics and growth potential. This segmentation helps in understanding the diverse needs of different industries and how manufacturers are tailoring solutions to meet specific requirements. The market is predominantly divided into automatic, semi-automatic, and manual instrument types, reflecting different levels of automation, precision, and cost. Applications range from critical pharmaceutical quality control and chemical characterization to food safety and academic research, each demanding specific functionalities and levels of regulatory compliance. End-user categories highlight the primary consumers of these instruments, from large pharmaceutical corporations to research institutions, influencing market demand patterns and technological priorities.

- Type

- Automatic Melting Point Instruments

- Semi-Automatic Melting Point Instruments

- Manual Melting Point Instruments

- Application

- Pharmaceuticals

- Chemicals & Petrochemicals

- Food & Beverages

- Academia & Research

- Material Science

- Others

- End-User

- Pharmaceutical & Biotechnology Companies

- Chemical & Petrochemical Industries

- Food & Beverage Manufacturers

- Contract Research Organizations (CROs)

- Academic & Research Institutions

- Quality Control Laboratories

Value Chain Analysis For Melting Point Instruments Market

The value chain for the Melting Point Instruments Market begins with upstream activities involving raw material suppliers and component manufacturers. This segment includes providers of precision optics, temperature sensors, heating elements, cooling systems (e.g., Peltier elements), and electronic control units. Key players in this stage focus on delivering high-quality, durable, and reliable components that are crucial for the accuracy and longevity of the final instruments. Relationships at this stage are often characterized by long-term contracts and strategic partnerships, ensuring a consistent supply of specialized parts that meet stringent performance specifications for analytical instrumentation.

Midstream activities encompass the design, manufacturing, assembly, and quality assurance processes undertaken by melting point instrument manufacturers. This stage involves significant R&D investment to innovate instrument design, incorporate advanced automation features, and develop intuitive software interfaces. Manufacturers engage in meticulous assembly, calibration, and rigorous testing to ensure their products comply with international standards such as ISO and GMP. Downstream activities involve the distribution channel, which can be direct or indirect. Direct channels involve manufacturers selling directly to end-users through their sales teams, offering personalized support, installation, and training. Indirect channels involve a network of distributors, regional dealers, and value-added resellers (VARs) who provide local market access, technical support, and sometimes integration services, particularly in regions where manufacturers do not have a strong direct presence. Both direct and indirect channels are critical for reaching a diverse customer base, including pharmaceutical companies, chemical manufacturers, research institutions, and food processors globally.

Melting Point Instruments Market Potential Customers

Potential customers for melting point instruments span a wide array of industries and research sectors, driven by the critical need for material characterization, quality assurance, and purity testing. The largest segment of end-users are pharmaceutical and biotechnology companies, where these instruments are indispensable for drug discovery, formulation development, and stringent quality control of active pharmaceutical ingredients (APIs), excipients, and final drug products. These organizations rely on precise melting point determination for identifying substances, verifying purity, and assessing the physical stability of compounds, all of which are crucial for regulatory compliance and patient safety.

Beyond pharmaceuticals, the chemical and petrochemical industries represent a substantial customer base, utilizing melting point instruments for the characterization of new compounds, monitoring reaction progress, and ensuring the quality of polymers, waxes, and other chemical products. Food and beverage manufacturers also employ these instruments for quality control of fats, oils, and other ingredients, ensuring product consistency and compliance with food safety standards. Academic and research institutions, alongside contract research organizations (CROs), form another significant segment, using melting point analysis for fundamental scientific research, material science studies, and various analytical service offerings. Quality control laboratories across all these sectors are constant purchasers, highlighting the pervasive need for these analytical tools in maintaining product integrity and meeting industry standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mettler Toledo International Inc., Anton Paar GmbH, Electrothermal (Cole-Parmer), BUCHI Labortechnik AG, IKA Works GmbH & Co. KG, Krüss Optronic GmbH, Stanford Research Systems, OptiMelt (Stanford Research Systems), Kyoto Electronics Manufacturing Co., Ltd., Analytik Jena AG (Endress+Hauser), Shimadzu Corporation, Sartorius AG, PerkinElmer Inc., Thermo Fisher Scientific Inc., VWR International (Avantor), Corning Inc., Lauda-Brinkmann, Systronics (India) Ltd., Gornell Industries, Reichert Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Melting Point Instruments Market Key Technology Landscape

The technology landscape of the Melting Point Instruments Market is characterized by continuous innovation aimed at enhancing precision, automation, and data management. Modern instruments leverage advanced heating and cooling technologies, such as Peltier elements, to achieve highly accurate and stable temperature control, crucial for precise melting point determination. Digital displays and intuitive user interfaces have become standard, replacing older analog systems and improving ease of use. Automation is a significant trend, with instruments capable of automatically detecting melting points via advanced optical systems, often employing high-resolution cameras and image analysis software to precisely identify the onset and clear point of melting, reducing subjective operator bias.

Furthermore, the integration of sophisticated software platforms is transforming how melting point data is collected, processed, and managed. These software solutions often include features for comprehensive data logging, compliance with regulatory standards (e.g., 21 CFR Part 11), statistical analysis, and seamless connectivity with Laboratory Information Management Systems (LIMS). This allows for improved data integrity, traceability, and streamlined workflow in regulated environments. Miniaturization and portability are also emerging trends, particularly for applications requiring on-site analysis, driven by advancements in sensor technology and power efficiency. The incorporation of cloud connectivity and remote diagnostics further enhances the capabilities of these instruments, allowing for real-time monitoring and support, thereby contributing to the overall efficiency and reliability of melting point analysis.

Regional Highlights

- North America: This region holds a significant share of the Melting Point Instruments Market, driven by robust pharmaceutical and biotechnology industries, extensive R&D investments, and stringent regulatory requirements for quality control. The presence of major market players and a high adoption rate of advanced analytical technologies further solidify its market position. The United States, in particular, leads in innovation and market demand.

- Europe: Europe is another dominant market, characterized by a well-established chemical sector, a strong pharmaceutical industry, and a high focus on research and academic activities. Countries like Germany, Switzerland, and the UK are key contributors, benefiting from technological advancements, government support for scientific research, and a strong emphasis on product quality and safety standards.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate during the forecast period. This growth is fueled by rapid industrialization, expanding pharmaceutical and biotechnology manufacturing bases, and increasing investments in research and development in emerging economies such as China, India, and Japan. Rising awareness of product quality and safety, coupled with government initiatives to boost local R&D, are key drivers.

- Latin America: This region is an emerging market for melting point instruments, with growing pharmaceutical and chemical industries, particularly in Brazil and Mexico. Increased foreign investment and the gradual adoption of international quality standards are contributing to market expansion, albeit at a slower pace compared to APAC.

- Middle East and Africa (MEA): The MEA market is witnessing steady growth, primarily driven by investments in healthcare infrastructure, growth in chemical industries, and increasing emphasis on quality control in food and beverage sectors in countries like Saudi Arabia and South Africa. However, market adoption is comparatively slower due to economic and infrastructural challenges.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Melting Point Instruments Market.- Mettler Toledo International Inc.

- Anton Paar GmbH

- Electrothermal (Cole-Parmer)

- BUCHI Labortechnik AG

- IKA Works GmbH & Co. KG

- Krüss Optronic GmbH

- Stanford Research Systems

- OptiMelt (Stanford Research Systems)

- Kyoto Electronics Manufacturing Co., Ltd.

- Analytik Jena AG (Endress+Hauser)

- Shimadzu Corporation

- Sartorius AG

- PerkinElmer Inc.

- Thermo Fisher Scientific Inc.

- VWR International (Avantor)

- Corning Inc.

- Lauda-Brinkmann

- Systronics (India) Ltd.

- Gornell Industries

- Reichert Inc.

Frequently Asked Questions

What is a melting point instrument and why is it important?

A melting point instrument is a device used to precisely determine the temperature range at which a solid substance transitions into a liquid. This measurement is crucial for identifying unknown compounds, verifying the purity of materials, assessing their quality, and ensuring consistency in various industries such as pharmaceuticals, chemicals, and food and beverages, as purity directly impacts efficacy and safety.

What are the primary applications of melting point instruments?

Melting point instruments are primarily applied in quality control and research & development across diverse sectors. Key applications include quality assurance of active pharmaceutical ingredients (APIs) and excipients, characterization of new chemical compounds, purity checks for raw materials and finished products in the chemical industry, quality control of fats and oils in the food sector, and fundamental material science research in academic institutions and contract research organizations (CROs).

How has technology advanced melting point analysis?

Technological advancements have transformed melting point analysis from manual, subjective methods to highly automated and precise techniques. Modern instruments feature advanced optical detection systems (e.g., high-resolution cameras), sophisticated temperature control via Peltier elements, integrated software for automated data analysis and regulatory compliance (like 21 CFR Part 11), and connectivity to Laboratory Information Management Systems (LIMS), significantly enhancing accuracy, throughput, and data integrity while reducing human error.

What are the regulatory requirements for melting point analysis in pharmaceuticals?

In the pharmaceutical industry, melting point analysis must adhere to stringent regulatory guidelines set by bodies like the FDA, EMA, and pharmacopoeias (e.g., USP, EP, JP). These requirements mandate validated methods, calibration of instruments, and comprehensive documentation to ensure accuracy, reproducibility, and data integrity. Compliance often involves systems that meet 21 CFR Part 11 for electronic records and signatures, ensuring an audit trail and secure data management for all measurements.

What is the future outlook for the Melting Point Instruments Market?

The future outlook for the Melting Point Instruments Market is positive, driven by continuous growth in global R&D, increasing demand for quality control, and ongoing technological innovations. The market is expected to see further integration of automation, artificial intelligence for enhanced data interpretation and predictive analytics, and the development of more compact and portable instruments. Emerging markets in Asia Pacific will significantly contribute to growth, while established markets will focus on adopting high-throughput, digitally integrated solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager