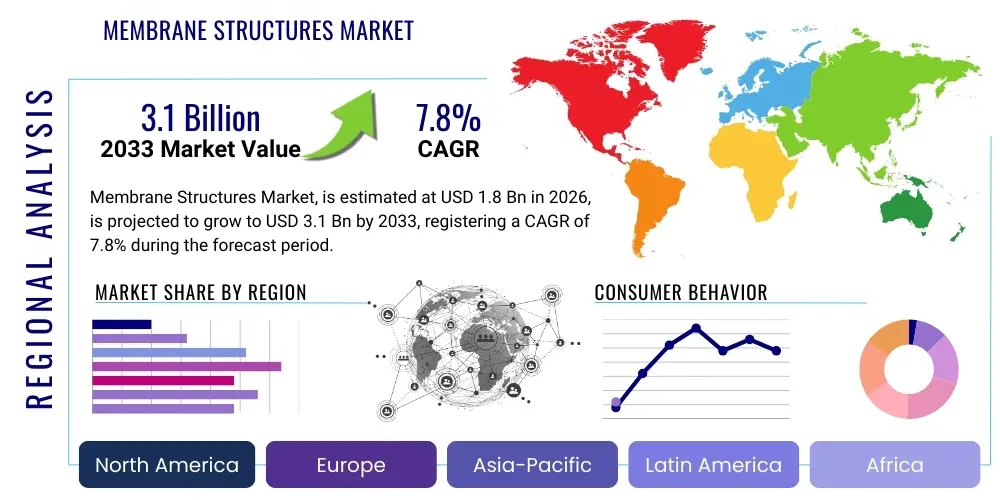

Membrane Structures Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438124 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Membrane Structures Market Size

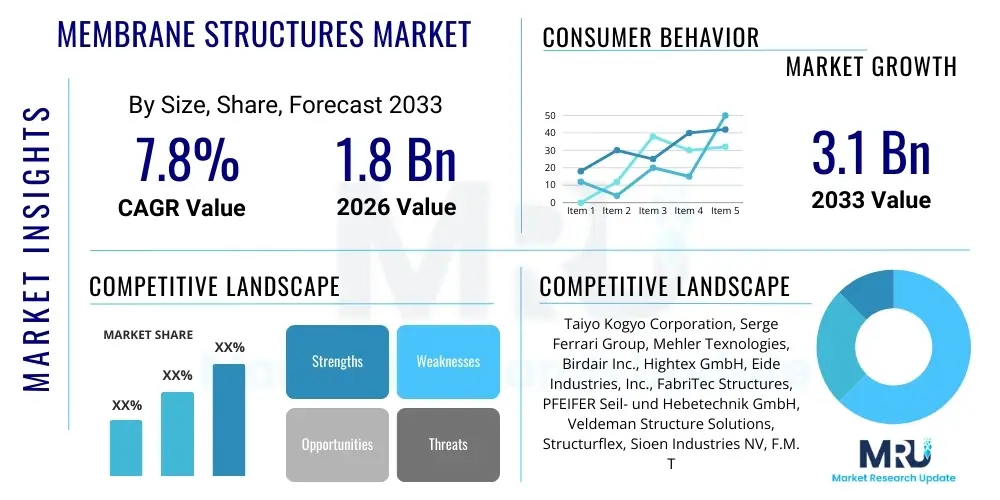

The Membrane Structures Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 3.1 Billion by the end of the forecast period in 2033.

Membrane Structures Market introduction

Membrane structures, often referred to as tensile fabric structures, represent a specialized segment within the construction and architecture industry, characterized by their lightweight, high-strength fabric materials tensioned over a framework. These structures utilize the principle of tension to create aesthetically striking, durable, and functional roofing or enclosure systems. The product description encompasses a range of materials, including Polytetrafluoroethylene (PTFE) coated fiberglass, Ethylene Tetrafluoroethylene (ETFE) films, and Polyvinyl Chloride (PVC) coated polyester, each offering distinct advantages in terms of light transmission, longevity, and cost efficiency. These engineered textiles are fundamental to creating large, column-free spaces, which is often difficult or prohibitively expensive using traditional construction methods, thus positioning membrane architecture as a highly innovative solution for modern spatial demands.

Major applications for membrane structures span diverse sectors, including massive sports stadia and arenas, transportation hubs such as airports and train stations, commercial retail spaces, exhibition centers, and industrial storage facilities. The inherent benefits of these structures are numerous and contribute significantly to market adoption: superior natural light penetration, which reduces operational energy costs; excellent durability and resistance to harsh weather conditions; and rapid construction timelines compared to conventional building techniques. Furthermore, their distinctive aesthetic quality allows architects unparalleled freedom in designing iconic and complex geometric forms, making them highly desirable for landmark projects worldwide. The versatility of these systems ensures their relevance across varying climatic zones and structural requirements.

Driving factors sustaining the robust growth of the Membrane Structures Market include increasing global investment in large-scale public infrastructure projects, particularly in emerging economies focused on upgrading urban and sporting facilities. The growing emphasis on sustainable and energy-efficient building solutions further propels demand, as lightweight membrane materials inherently reduce the structural load and foundation requirements compared to heavy conventional roofs. Technological advancements in material science, leading to enhanced performance characteristics such as self-cleaning capabilities and improved UV resistance, are making these structures more attractive for long-term installations. Regulatory support for resilient and modular construction methods also contributes positively to the market trajectory.

Membrane Structures Market Executive Summary

The Membrane Structures Market is experiencing accelerated growth driven by dynamic business trends emphasizing modular construction and sustainable design practices. Key business trends include the rising integration of smart sensing technologies within membrane materials for real-time performance monitoring and the increasing prevalence of design-build contracts which streamline the deployment of complex tensile architecture projects. Companies are heavily investing in automation for fabrication processes to ensure precision and reduce on-site installation time, addressing labor efficiency concerns. Furthermore, strategic mergers and acquisitions focused on expanding geographic reach and acquiring specialized material patents are redefining the competitive landscape, pushing the market towards consolidation and higher quality standards.

Regional trends highlight significant disparity in market maturity, with developed regions like North America and Europe focusing primarily on replacement and high-performance, long-span stadium projects utilizing premium materials like PTFE and ETFE. Conversely, the Asia Pacific (APAC) region, spearheaded by burgeoning construction activities in China and India, is registering the highest growth rate, primarily driven by rapid urbanization, infrastructure development, and the utilization of cost-effective PVC membranes for temporary and semi-permanent structures. Latin America and the Middle East and Africa (MEA) are also emerging as crucial growth pockets, spurred by investments in oil and gas infrastructure shelters and preparations for major international sporting events, necessitating large-scale, iconic roof structures.

Segment trends underscore the dominance of the PTFE segment due to its exceptional longevity and fire resistance, making it the material of choice for permanent, critical applications. However, the ETFE segment is projected to exhibit the fastest growth, largely owing to its lightweight nature, high light transmissibility, and increasing adoption in complex geometric facades and rooflights, aligning with contemporary architectural preference for transparency. Application-wise, the Sports & Leisure segment remains the largest consumer, driven by continuous global upgrades of major sporting venues. Simultaneously, the Industrial segment is showing robust momentum as companies seek durable, quick-to-install, and flexible warehousing and material storage solutions across varied climates.

AI Impact Analysis on Membrane Structures Market

User questions regarding the impact of Artificial Intelligence (AI) on the Membrane Structures Market often revolve around optimizing the complex form-finding and engineering analysis process, predicting material fatigue and lifespan, and automating manufacturing and installation. Users are keenly interested in how AI can handle the non-linear behavior of fabrics under stress and varied environmental loads—a traditionally computationally intensive task. Key themes emerging from these inquiries include the potential for AI-driven generative design to explore novel, efficient structural shapes that human designers might overlook, concerns about the data required to train predictive maintenance models for large-scale fabric installations, and the expectation that AI integration will drastically reduce design iteration cycles and overall project costs while enhancing structural resilience and safety standards across the lifecycle of the membrane.

The application of AI is poised to revolutionize several critical stages of the membrane structure lifecycle, starting from the initial conceptual design phase through to long-term facility management. During design, machine learning algorithms can rapidly analyze thousands of design parameters—including wind loads, seismic activity, solar heat gain, and material properties—to identify the optimal tensile stress distribution, minimizing material usage while maximizing structural stability. This generative design capability drastically shortens the typically iterative and slow process of form finding, ensuring that the finalized structure is not only aesthetically pleasing but also economically viable and environmentally sound. Furthermore, AI systems contribute to predictive maintenance by analyzing data streams from embedded sensors, forecasting potential failure points, and scheduling proactive interventions before minor issues escalate into costly structural failures, thus extending the service life of these expensive installations.

- AI-driven Generative Design: Optimization of complex tensile forms and structural geometry based on multi-physics simulations (wind, snow, solar).

- Automated Stress Analysis: Use of machine learning models to accurately predict fabric behavior under dynamic loading conditions faster than traditional Finite Element Analysis (FEA).

- Predictive Maintenance and Digital Twins: Real-time monitoring using IoT sensors combined with AI to predict material fatigue, schedule repair, and ensure structural integrity.

- Supply Chain Optimization: Utilizing AI for predicting material demand fluctuations and optimizing the complex global logistics involved in sourcing specialized membrane materials.

- Fabrication Robotics: Integration of AI-controlled cutting and welding robotics to ensure millimeter-precision fabrication, reducing material waste and increasing efficiency.

DRO & Impact Forces Of Membrane Structures Market

The dynamics of the Membrane Structures Market are significantly shaped by a powerful interplay of drivers, restraints, and opportunities, collectively categorized under DRO & Impact Forces. The primary drivers include the escalating global demand for lightweight and sustainable construction methods that offer faster construction timelines and lower overall foundation costs compared to traditional heavy structures. Additionally, the growing popularity of aesthetically advanced and iconic architecture, particularly for high-profile public venues and large-span enclosures, provides a continuous impetus for market expansion. These positive forces are reinforced by technological advancements in membrane materials, such as the development of high-performance ETFE films and self-cleaning PTFE coatings, which improve the product's longevity and performance in diverse environmental settings. Furthermore, favorable regulatory environments promoting modular and prefabricated construction techniques in various regions are accelerating project approvals and adoption rates, securing a fertile ground for market expansion.

However, the market faces considerable restraints that limit its penetration, most notably the high initial investment cost associated with premium materials like PTFE and ETFE, which often deters adoption in budget-constrained projects or developing markets. Another significant restraint is the requirement for highly specialized expertise and complex engineering know-how for the design, fabrication, and erection of large-scale tensile structures, creating a bottleneck due to the limited availability of specialized firms and certified labor. Concerns regarding the long-term durability and potential susceptibility of certain membrane types (like standard PVC) to degradation from UV exposure and environmental pollution in aggressive climates also pose a challenge, necessitating rigorous maintenance schedules which add to the operational expenditure over the structure's lifetime, complicating the total cost of ownership analysis for potential buyers.

Despite these challenges, substantial opportunities exist, particularly in the untapped potential of temporary and modular infrastructure, such as disaster relief shelters, temporary exhibition halls, and fast-deployment military facilities, where the ease and speed of installation are paramount. The increasing focus on creating net-zero and energy-efficient buildings presents a strong opportunity, as innovative membrane structures can be integrated with photovoltaic cells and smart climate control systems to enhance energy generation and reduce thermal loads. Furthermore, market participants have a clear opportunity to expand into emerging geographical markets, especially in Southeast Asia and Africa, by developing more localized and cost-effective material solutions and improving the local workforce's specialized skills through targeted training programs, mitigating the current reliance on expatriate engineering teams for complex projects. These opportunities, coupled with ongoing material R&D, promise significant future growth trajectories.

Segmentation Analysis

The Membrane Structures Market is comprehensively segmented based on material type, structure type, and application, enabling a detailed analysis of specific growth pockets and demand patterns across different end-user industries. The segmentation by material type is crucial as it dictates the structure’s performance characteristics, including fire resistance, expected lifespan, light transparency, and cost. Structure type segmentation clarifies the engineering methodology employed, ranging from complex long-span tensile structures requiring significant foundational work to simpler, air-supported structures suitable for temporary enclosures. Finally, application segmentation provides insight into the major consuming sectors, allowing suppliers to tailor their marketing and product development efforts toward the most lucrative areas, such as the rapidly expanding sports infrastructure sector or the specialized industrial warehousing market.

- By Material Type:

- Polytetrafluoroethylene (PTFE) Coated Fiberglass

- Ethylene Tetrafluoroethylene (ETFE)

- Polyvinyl Chloride (PVC) Coated Polyester

- Others (Teflon, Silicone-coated materials)

- By Structure Type:

- Tensile Structures (Cable-net, Membrane-only, Grid-shell)

- Air-Supported Structures

- Frame-Supported Structures

- Others (Pneumatic structures)

- By Application:

- Sports and Leisure (Stadiums, Arenas, Recreational Centers)

- Commercial (Shopping Malls, Office Complexes, Convention Centers)

- Industrial (Warehouses, Storage Facilities, Factory Shelters)

- Transportation (Airports, Train Stations, Bus Terminals)

- Healthcare and Education

- Others (Temporary Shelters, Military Applications)

Value Chain Analysis For Membrane Structures Market

The value chain for the Membrane Structures Market begins intensely with upstream analysis, focusing on the specialized production of high-performance technical textiles and polymers. This upstream segment is dominated by a few global chemical and textile manufacturers specializing in coating techniques (e.g., PTFE, PVC, Silicone) and weaving high-strength base fabrics (e.g., fiberglass, polyester). The quality and consistency of these raw materials are paramount, directly influencing the structural integrity and longevity of the final product. Key activities here include polymer synthesis, coating application, and ensuring compliance with stringent fire safety and weather resistance standards. Pricing power often rests with these specialized material suppliers due to the proprietary nature of their formulations and the high barriers to entry for new entrants in high-specification material manufacturing.

Midstream activities involve the design, engineering, and fabrication of the membrane structures. This stage is highly specialized, requiring advanced software for form-finding (such as Rhino, Oasys GSA, or specialized FEA packages) and precise, automated cutting and welding machinery to assemble large panels. Leading fabricators maintain significant competitive advantages through their accumulated technical expertise in non-linear structural analysis and their capacity to handle complex logistical challenges associated with transporting and installing large, pre-fabricated membrane sections. Direct distribution channels are prevalent in large-scale projects, where the fabrication company directly contracts with the end-client or the primary construction manager, allowing for greater control over quality assurance and project timelines. This streamlined approach minimizes intermediaries, which is essential given the bespoke nature of each structure.

The downstream analysis focuses on the installation, maintenance, and end-use of the structures. Installation requires specialized rigging and tensioning expertise, often involving heavy lifting and working at height, demanding adherence to strict safety protocols. Maintenance services, including cleaning, inspection, and repair, represent a continuous revenue stream, often managed by the original fabricator or specialized local maintenance firms. Indirect distribution channels, though less common than direct channels, sometimes involve local architectural firms or general contractors acting as intermediaries, especially for smaller or regional projects. The final segment of the value chain is the end-users, whose requirements drive product innovation, demanding increasingly durable, sustainable, and aesthetically complex designs that maximize natural light and minimize environmental impact. The success of the downstream phase is critically dependent on the integrity established in the upstream material sourcing and the precision achieved in the midstream engineering and fabrication processes.

Membrane Structures Market Potential Customers

The primary end-users and buyers of membrane structures are highly diverse, spanning both public and private sectors globally. Government entities and municipal corporations constitute major potential customers, driven by the need for public infrastructure development, including modernizing transportation hubs like major international airports and rail stations, where expansive, light-filled roofing solutions are essential for passenger experience and operational efficiency. Furthermore, public investments in sports infrastructure, such as constructing new stadiums for major international events or covering existing municipal recreational facilities, represent a significant demand pool. These customers prioritize longevity, adherence to strict safety codes (especially fire resistance), and iconic architectural design that serves as a landmark for the city or region.

The second substantial segment of potential customers includes large private sector corporations involved in commercial real estate development and industrial operations. Commercial developers seek membrane structures for shopping malls, convention centers, and corporate headquarters to create visually appealing, naturally lit atrium spaces that enhance visitor experience and differentiate their assets. In the industrial sector, logistics and manufacturing companies are significant buyers, utilizing these structures for cost-effective, rapidly deployable, and flexible large-span warehousing, bulk storage, and protective shelters for raw materials or equipment, especially in areas where climate control or rapid deployment is critical. These industrial buyers prioritize durability, ease of maintenance, and the ability to withstand extreme environmental conditions, often opting for high-strength PVC or specialized coated fabrics to meet operational demands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 3.1 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Taiyo Kogyo Corporation, Serge Ferrari Group, Mehler Texnologies, Birdair Inc., Hightex GmbH, Eide Industries, Inc., FabriTec Structures, PFEIFER Seil- und Hebetechnik GmbH, Veldeman Structure Solutions, Structurflex, Sioen Industries NV, F.M. Tarbell Co., Inc., Oase Outdoors ApS, DuPont, Saint-Gobain, SEFAR AG, Fibertex Nonwovens A/S, Solvay SA, Kosa Engineering, Architen Landrell |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Membrane Structures Market Key Technology Landscape

The technology landscape governing the Membrane Structures Market is characterized by continuous advancements in material science, engineering simulation software, and fabrication techniques aimed at enhancing structural performance, durability, and installation efficiency. Material technology is rapidly evolving, with a strong emphasis on developing highly transparent and durable polymers. Key innovations include multi-layer ETFE cushions offering superior thermal insulation and acoustic properties, and self-cleaning coatings (often titanium dioxide-based) applied to PTFE and PVC membranes, which react with UV light to break down organic pollutants, significantly reducing long-term maintenance costs and improving aesthetic lifespan. Furthermore, the integration of smart materials, such as flexible photovoltaic films and LED lighting embedded directly into the fabric, is transforming membranes from mere shelters into active, energy-generating and dynamic architectural elements, aligning with green building standards and smart city initiatives worldwide.

Engineering and design technology forms the backbone of the market, necessitating sophisticated software tools capable of handling complex non-linear structural analysis. Form-finding algorithms are essential for determining the optimal surface curvature and pre-stress required to achieve stability under various external loads, such as extreme wind and snow. The trend is moving towards digital twinning and full Building Information Modeling (BIM) integration, allowing designers to simulate the structure’s performance over its entire lifecycle, predict material fatigue, and optimize construction logistics before physical work begins. This level of computational precision is crucial for managing risk in large-span structures where minute errors in tensioning can lead to significant structural issues, thus driving demand for highly trained structural engineers proficient in these specialized simulation platforms.

Fabrication and installation technologies have also seen significant advancements focused on precision and speed. The use of Computer Numerical Control (CNC) cutting machines ensures high accuracy in panel cutting, minimizing material waste and guaranteeing perfect fit during assembly. High-frequency welding and specialized heat sealing techniques are utilized to create durable, impermeable seams that maintain the structural integrity of the fabric panels. On-site, tensioning technologies involving automated hydraulic systems and sophisticated cable control mechanisms are employed to ensure the precise application of pre-stress, which is critical for the stability of tensile structures. These technological improvements collectively reduce construction time, enhance safety on-site, and ensure the delivered membrane structure achieves its intended performance criteria, contributing directly to the market’s competitive edge over conventional construction.

Regional Highlights

- North America: This region is characterized by high market maturity and a strong focus on high-end, permanent structures, particularly for professional sports facilities and transportation infrastructure modernization. The US and Canada are significant consumers, with stringent building codes driving the adoption of premium, long-life materials such as PTFE and advanced multi-layer ETFE systems. Demand is stable, driven primarily by reconstruction and architectural upgrades rather than new, large-scale greenfield projects, focusing on resilient design against extreme weather conditions.

- Europe: Europe represents a technologically advanced market segment, heavily influenced by sustainability regulations and innovative architectural trends. Germany, the UK, and France are key contributors, specializing in highly custom-engineered, aesthetically complex solutions for commercial and exhibition centers. The region leads in the adoption of smart membranes and integrates them seamlessly into sophisticated building envelopes to meet stringent energy performance targets and aesthetic desires for complex geometries.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, fueled by rapid urbanization, massive infrastructure spending, and an increasing number of international sporting events hosted across the region. Countries like China, India, and South Korea are experiencing exponential growth in demand for membrane structures in commercial, residential, and transportation sectors. While cost-effectiveness often drives demand for PVC materials, rising affluence and long-term investment are simultaneously boosting adoption of high-performance ETFE for landmark projects, positioning the region as the epicenter of future market expansion.

- Latin America: This region shows promising growth, driven by investments in national infrastructure and preparation for regional sporting events. Brazil and Mexico are leading the demand, utilizing membrane structures for low-cost stadium covers and industrial warehousing applications. The market often favors cost-effective and modular frame-supported systems due to budgetary constraints, though there is a growing appreciation for the aesthetic appeal of tensile architecture in major metropolitan areas.

- Middle East and Africa (MEA): Growth in the MEA is primarily concentrated in the Gulf Cooperation Council (GCC) countries, heavily influenced by large-scale government mega-projects, including Expo sites, airport expansions, and climate-controlled sports venues required to mitigate high desert temperatures. These projects typically demand high-performance materials like PTFE and high-transparency ETFE, capable of offering superior solar reflection and heat resistance, making the region a key consumer of premium, custom-engineered tensile solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Membrane Structures Market.- Taiyo Kogyo Corporation

- Serge Ferrari Group

- Mehler Texnologies

- Birdair Inc.

- Hightex GmbH

- Eide Industries, Inc.

- FabriTec Structures

- PFEIFER Seil- und Hebetechnik GmbH

- Veldeman Structure Solutions

- Structurflex

- Sioen Industries NV

- F.M. Tarbell Co., Inc.

- Oase Outdoors ApS

- DuPont

- Saint-Gobain

- SEFAR AG

- Fibertex Nonwovens A/S

- Solvay SA

- Kosa Engineering

- Architen Landrell

Frequently Asked Questions

Analyze common user questions about the Membrane Structures market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using ETFE material over traditional glass in architectural applications?

ETFE (Ethylene Tetrafluoroethylene) offers significantly greater transparency, is extremely lightweight, capable of being used in complex multi-layer cushion systems for superior thermal and acoustic insulation, and provides excellent resistance to UV light degradation, offering a durable, lighter, and more flexible alternative to heavy, less insulative glass panels.

How does the longevity of PTFE membrane structures compare to conventional construction materials?

PTFE (Polytetrafluoroethylene) coated fiberglass structures exhibit exceptional durability and can have a service life exceeding 30 years, often comparable to conventional permanent buildings. Its chemical inertness, fire resistance, and superior resistance to environmental pollutants ensure long-term structural integrity and minimal color change, reducing maintenance frequency over its lifespan.

Which application segment accounts for the largest demand in the Membrane Structures Market globally?

The Sports and Leisure segment represents the largest application segment, primarily due to the high global demand for covering large-span athletic venues, stadiums, and arenas. Membrane structures are ideal for these applications as they provide large, column-free internal spaces, rapid construction, and iconic architectural aesthetics essential for modern sports infrastructure.

What is the main driver behind the rapid market growth observed in the Asia Pacific region?

The rapid market growth in the Asia Pacific region is predominantly driven by unprecedented rates of urbanization and massive government investments in infrastructure development, including new transportation hubs, exhibition centers, and the need for rapidly deployable, large-scale commercial and industrial warehousing facilities to support booming economic activities.

Are membrane structures considered sustainable or environmentally friendly solutions?

Yes, membrane structures are highly regarded as sustainable. They reduce the required amount of heavy construction materials, lower the structural load on foundations, and often utilize recyclable materials like ETFE. Their high light transmission properties significantly reduce the need for artificial lighting during the day, contributing substantially to energy savings and reduced operational carbon footprints.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager