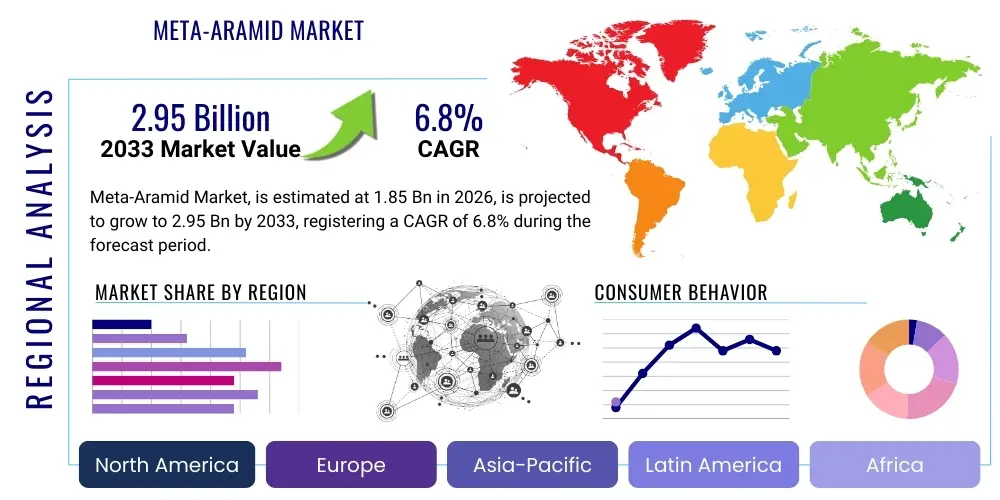

Meta-Aramid Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439699 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Meta-Aramid Market Size

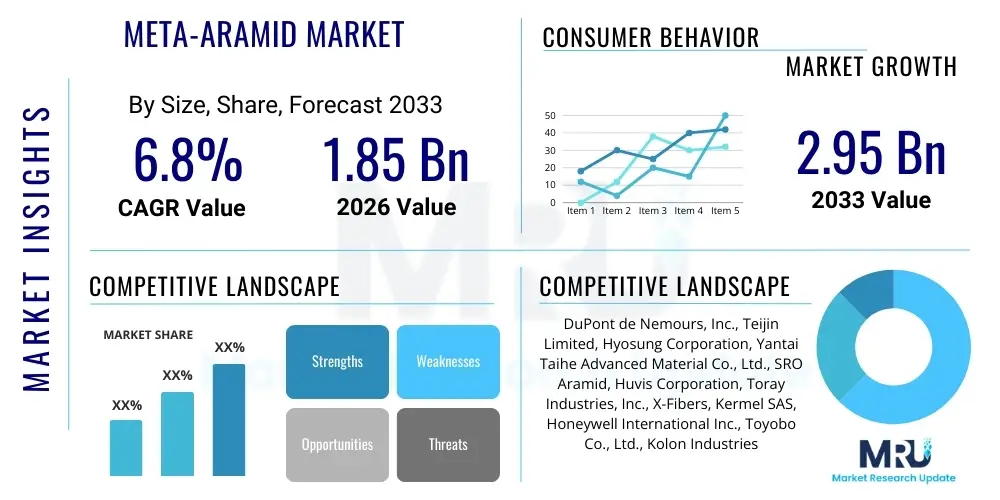

The Meta-Aramid Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.95 Billion by the end of the forecast period in 2033.

Meta-Aramid Market introduction

The Meta-Aramid Market encompasses the global production and consumption of meta-aramid fibers, a class of high-performance synthetic polymers renowned for their exceptional thermal stability, flame resistance, chemical resistance, and mechanical strength. These unique properties make meta-aramids indispensable across a diverse range of critical applications where extreme conditions or demanding environments necessitate superior material performance. Originally developed for advanced aerospace and military applications, their utility has expanded significantly into industrial safety, electrical insulation, and sophisticated composite materials due to their ability to withstand high temperatures, open flames, and various corrosive agents without melting or dripping.

The product, meta-aramid, is typically produced through a polycondensation reaction, resulting in a robust polymer that can be spun into staple fibers, continuous filaments, or pulps. Major applications include protective apparel for firefighters, military personnel, and industrial workers; electrical insulation in motors, transformers, and cables; industrial filtration media for hot gas and chemical filtration; and reinforcement in rubber products and advanced composites for aerospace and automotive industries. The inherent benefits of meta-aramid materials, such as their outstanding heat and flame resistance, high tenacity, good dimensional stability, and excellent resistance to chemicals and radiation, drive their adoption in these sectors. These characteristics ensure enhanced safety, extended product lifespan, and improved operational reliability in mission-critical scenarios.

Key driving factors for the Meta-Aramid Market include the escalating global demand for stringent safety standards in industrial and military sectors, leading to increased adoption of protective clothing and equipment. Furthermore, the continuous growth in the electrical and electronics industry necessitates advanced insulation materials, while the expanding aerospace and automotive sectors seek lightweight, high-performance composites. Regulatory mandates enforcing worker safety and environmental protection further amplify the market's trajectory, compelling industries to invest in meta-aramid-based solutions that offer superior protection and longevity. The ongoing innovation in textile engineering and material science also contributes to the development of new applications and improved performance characteristics for meta-aramids, sustaining their market expansion.

Meta-Aramid Market Executive Summary

The Meta-Aramid Market is experiencing robust growth, primarily propelled by increasing global awareness and enforcement of safety regulations across diverse industries. Business trends indicate a consistent upward trajectory, with manufacturers focusing on expanding production capacities and developing innovative meta-aramid products to cater to specialized demands in high-growth application areas such as lightweight composites for electric vehicles and advanced ballistic protection systems. Strategic collaborations between raw material suppliers, fiber manufacturers, and end-product producers are becoming more prevalent, aimed at optimizing supply chains and accelerating product development cycles. Furthermore, significant investments in research and development are geared towards enhancing the performance characteristics of meta-aramids, reducing production costs, and exploring sustainable manufacturing processes, thereby ensuring competitive advantage and market relevance.

Regional trends highlight Asia Pacific as the leading and fastest-growing market, driven by rapid industrialization, burgeoning manufacturing sectors, and increasing defense expenditures in countries like China, India, and South Korea. North America and Europe also maintain substantial market shares, underpinned by well-established industrial safety norms, a strong presence of aerospace and defense industries, and continuous technological advancements. The Middle East and Africa, along with Latin America, are emerging as promising markets due to increasing infrastructure development projects, rising demand for protective industrial wear, and diversification of economic activities. Each region’s unique regulatory landscape and industrial ecosystem significantly influence the demand patterns and application spectrum for meta-aramid products, shaping regional market dynamics.

In terms of segmentation, the protective apparel segment continues to dominate the market, largely due to the indispensable role of meta-aramids in fire-resistant garments, military uniforms, and industrial protective suits. However, other segments such as electrical insulation and industrial filtration are also demonstrating significant growth, driven by advancements in smart grids, renewable energy infrastructure, and increasingly stringent environmental emission controls. The market for meta-aramid fibers in automotive and aerospace composites is also projected to expand substantially, fueled by the global push for fuel efficiency, lightweighting, and enhanced safety features in transport applications. The versatility of meta-aramid across these varied applications ensures a diversified revenue stream and resilience against market fluctuations in any single end-use sector.

AI Impact Analysis on Meta-Aramid Market

Common user questions regarding AI's impact on the Meta-Aramid Market frequently revolve around potential disruptions and efficiencies across the entire value chain. Users are keenly interested in how AI can optimize manufacturing processes, improve material quality control, accelerate R&D for new applications, and enhance supply chain resilience. Concerns often touch upon the initial investment required for AI integration, the complexity of data management, and the need for a skilled workforce capable of leveraging AI technologies. Expectations typically include reduced operational costs, faster innovation cycles for novel meta-aramid composites, and the development of intelligent, self-monitoring protective gear, ultimately leading to higher efficiency and product performance in a highly specialized market.

- Manufacturing Optimization: AI-driven process control can monitor and adjust parameters in real-time, optimizing reaction conditions during polymerization and fiber spinning, reducing waste, and improving batch consistency and yield.

- Quality Assurance & Inspection: Automated visual inspection systems utilizing AI can detect microscopic defects in meta-aramid fibers and fabrics far more efficiently and accurately than manual methods, ensuring high-quality output and adherence to stringent performance specifications.

- Predictive Maintenance: AI algorithms can analyze sensor data from manufacturing equipment to predict potential failures, enabling proactive maintenance, minimizing downtime, and extending the lifespan of critical machinery in meta-aramid production facilities.

- Material R&D Acceleration: AI and machine learning models can simulate molecular structures and predict material properties, significantly expediting the discovery and development of new meta-aramid variants or composites with enhanced characteristics for specific applications.

- Supply Chain Efficiency: AI tools can analyze vast datasets to forecast demand more accurately, optimize inventory levels, route logistics more efficiently, and identify potential disruptions, thereby enhancing the overall resilience and responsiveness of the meta-aramid supply chain.

- Market Intelligence & Sales Forecasting: AI-powered analytics can process market trends, economic indicators, and customer behavior data to provide superior insights for strategic planning, sales forecasting, and identifying emerging application opportunities for meta-aramids.

- Development of Smart Textiles: Integrating AI with meta-aramid-based smart textiles can lead to protective apparel with embedded sensors for real-time monitoring of vital signs, environmental hazards, or structural integrity, particularly for military, firefighting, and industrial safety applications.

DRO & Impact Forces Of Meta-Aramid Market

The Meta-Aramid Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and competitive landscape. Key drivers primarily stem from the escalating global emphasis on safety and protection across industrial, military, and civil sectors, necessitating high-performance materials capable of withstanding extreme conditions. This includes the growing demand for flame-resistant clothing for firefighters, protective gear for military personnel, and industrial workers exposed to high heat or chemicals, alongside regulatory frameworks that mandate such safety standards. Additionally, the continuous expansion of the electrical and electronics sector, coupled with advancements in aerospace and automotive industries seeking lightweight, durable, and thermally stable components, further propels market growth. The superior properties of meta-aramids, such as exceptional thermal stability, inherent flame resistance, high strength-to-weight ratio, and chemical inertness, make them indispensable in these critical applications, ensuring their sustained demand.

However, the market also faces considerable restraints that temper its growth potential. Foremost among these are the relatively high production costs associated with meta-aramid fibers, which can make end-products more expensive compared to conventional materials, potentially limiting adoption in cost-sensitive applications. The complex and energy-intensive manufacturing processes, often requiring specialized equipment and skilled labor, contribute to these elevated costs. Furthermore, intense competition from alternative high-performance materials, including para-aramids, PBO (polybenzoxazole), and advanced inorganic fibers, which may offer different property profiles or cost advantages for specific niches, poses a challenge. Environmental concerns related to chemical use in production and disposal of non-biodegradable synthetic fibers also present potential hurdles, compelling manufacturers to invest in more sustainable practices and explore greener alternatives, adding to operational complexities.

Despite these challenges, substantial opportunities exist for market expansion and innovation. Emerging economies, particularly in Asia Pacific and Latin America, present vast untapped markets with increasing industrialization and evolving safety regulations, promising new avenues for meta-aramid adoption. Continued research and development efforts aimed at reducing manufacturing costs, enhancing material performance, and developing novel applications across various industries are crucial. The growing trend towards lightweighting in aerospace, automotive, and defense sectors, driven by fuel efficiency and performance requirements, creates significant demand for meta-aramid-reinforced composites. Furthermore, the development of advanced multi-functional meta-aramid fabrics and blends with other high-performance fibers can unlock new application areas and cater to specialized performance needs, such as enhanced moisture management or improved abrasion resistance, thereby expanding the market's reach and ensuring long-term growth prospects.

Segmentation Analysis

The Meta-Aramid Market is comprehensively segmented across various dimensions to provide a granular understanding of its diverse landscape and to identify specific growth drivers and opportunities within distinct categories. These segmentations typically include analyses by type of fiber, application area, and end-use industry, each offering unique insights into market dynamics. Such a detailed breakdown allows stakeholders to accurately assess market size, growth rates, competitive intensity, and consumer preferences within specific niches, facilitating targeted strategic planning and product development efforts. The interplay between these segments often reveals synergistic growth opportunities, particularly as industries converge and demand for multi-functional materials increases, driving innovation in meta-aramid compositions and textile structures. Understanding these segmentations is paramount for market players seeking to optimize their product portfolios and geographical outreach.

- By Type:

- Staple Fiber: Widely used in protective apparel, industrial felts, and filtration due to its excellent processability and blendability.

- Filament Fiber: Employed in applications requiring high strength and continuous length, such as sewing threads, ropes, and reinforced composites.

- Pulp: Utilized as a reinforcement material in friction products, gaskets, and specialty papers, providing excellent heat and wear resistance.

- By Application:

- Protective Apparel: Firefighting suits, military uniforms, industrial protective clothing, heat-resistant gloves, and balaclavas.

- Electrical Insulation: Insulation papers, tapes, laminates for motors, transformers, generators, and cables.

- Industrial Filtration: Hot gas filtration bags, chemical resistant filters, and liquid filtration media.

- Rubber Reinforcement: Hoses, belts, and other rubber products requiring enhanced durability and heat resistance.

- Aerospace & Automotive: Lightweight composite components, interior materials, and engine parts.

- Composites: High-performance structural components for various industries, offering strength and thermal stability.

- Other Applications: Gaskets, packing materials, friction materials, and specialty papers.

- By End-Use Industry:

- Firefighting & Emergency Services: Uniforms, helmets, gloves, and blankets.

- Military & Law Enforcement: Ballistic vests, flight suits, combat uniforms, and vehicle components.

- Electrical & Electronics: Transformers, motors, generators, circuit boards, and cables.

- Chemical & Petrochemical: Protective clothing for chemical handling, filtration systems, and process equipment.

- Automotive: Brake pads, clutch linings, hoses, gaskets, and interior fabrics.

- Aerospace: Aircraft interiors, structural components, insulation, and engine parts.

- Building & Construction: Fire barriers, insulation materials, and architectural textiles.

- Industrial Manufacturing: General protective wear, conveyor belts, and machinery insulation.

Value Chain Analysis For Meta-Aramid Market

The value chain for the Meta-Aramid Market is a complex, multi-stage process beginning with upstream raw material procurement and extending through manufacturing, distribution, and ultimately, to diverse end-use applications. Upstream analysis involves the sourcing and production of key precursors such as meta-phenylenediamine (MPD) and isophthaloyl chloride (IPC), which are critical for the polycondensation reaction. This segment is characterized by a limited number of specialized chemical manufacturers, high capital intensity, and stringent quality control standards. The efficient and cost-effective procurement of these chemical intermediates directly impacts the overall production cost and quality of the final meta-aramid fibers. Strategic relationships with raw material suppliers are crucial for ensuring a stable supply, managing price volatility, and maintaining competitive manufacturing costs, which are vital for the economic viability of meta-aramid fiber producers.

The core of the value chain is the manufacturing process, where these precursors are polymerized and subsequently spun into various forms of meta-aramid fibers, including staple fibers, filament yarns, and pulp. This stage requires sophisticated chemical engineering expertise, advanced spinning technologies, and significant capital investment in specialized production facilities. Manufacturers often focus on optimizing process efficiency, enhancing fiber properties, and developing new product variants to meet evolving market demands. Downstream analysis then covers the conversion of meta-aramid fibers into intermediate products such as fabrics, nonwovens, yarns, and insulation papers, which are then further processed into finished goods by converters and product integrators. These processes involve weaving, knitting, coating, laminating, and assembly into items like protective apparel, electrical components, or filtration media, each requiring specific technical know-how and adherence to industry standards. The performance and functionality of the final product are heavily dependent on the quality and characteristics imparted during these downstream processing stages.

Distribution channels for meta-aramid products are diverse, encompassing both direct and indirect sales models. Direct distribution often involves large-volume sales to major industrial clients, original equipment manufacturers (OEMs) in aerospace and automotive, or government procurement agencies for defense and emergency services. This channel allows for closer customer relationships, customized solutions, and direct technical support. Indirect distribution, on the other hand, relies on a network of specialized distributors, agents, and wholesalers who serve smaller businesses, regional markets, and a broader range of end-users. These intermediaries play a crucial role in market penetration, inventory management, and providing localized support. The choice of distribution channel is influenced by factors such as market maturity, customer size, geographical reach, and the complexity of the end product, with many manufacturers employing a hybrid approach to maximize market coverage and efficiency.

Meta-Aramid Market Potential Customers

Potential customers for meta-aramid products span a wide array of industries and applications, primarily comprising entities with critical needs for high-performance materials offering exceptional thermal, flame, and chemical resistance. These end-users are driven by stringent safety regulations, performance requirements in extreme environments, and the pursuit of enhanced durability and reliability in their products and operations. The diverse range of applications, from personal protective equipment to advanced industrial components, ensures a broad and robust customer base for meta-aramid manufacturers. Each customer segment presents unique demands and specifications, requiring tailored solutions and specialized product offerings, underscoring the versatility and critical importance of meta-aramid materials in modern industrial landscapes. Understanding these customer segments allows market players to develop targeted sales strategies and innovate products that precisely meet specific industry requirements.

Key segments of end-users or buyers include manufacturers of protective apparel, encompassing fire departments, military and defense organizations, law enforcement agencies, and various industrial sectors such as chemical processing, oil and gas, metallurgy, and utilities. These customers demand fabrics and garments that provide superior protection against heat, flames, arc flash, and chemical splashes, ensuring the safety of personnel operating in hazardous conditions. Another significant customer base lies within the electrical and electronics industry, including manufacturers of motors, transformers, generators, power cables, and circuit boards. Here, meta-aramid is valued for its excellent dielectric strength, thermal insulation properties, and long-term stability under high temperatures, crucial for enhancing the reliability and lifespan of electrical equipment. The increasing complexity and power requirements of modern electrical systems continually drive demand for advanced insulation solutions, positioning meta-aramids as a preferred material choice.

Furthermore, the automotive and aerospace industries represent rapidly growing customer segments, where meta-aramids are incorporated into lightweight composites, interior components, and specialized parts requiring high strength, stiffness, and thermal stability. Automotive manufacturers utilize meta-aramid in brake pads, clutch facings, hoses, and gaskets for its excellent friction and heat resistance, while aerospace companies integrate it into aircraft interiors, structural components, and engine parts to reduce weight, improve fuel efficiency, and enhance safety. Industrial filtration system providers, rubber product manufacturers, and construction companies also constitute important customer groups, leveraging meta-aramid fibers for hot gas filtration, reinforcement in high-performance rubber articles like conveyor belts and hoses, and fire barriers in building materials, respectively. The ongoing drive for performance optimization, safety enhancement, and regulatory compliance across these sectors ensures a sustained and expanding customer base for the Meta-Aramid Market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont de Nemours, Inc., Teijin Limited, Hyosung Corporation, Yantai Taihe Advanced Material Co., Ltd., SRO Aramid, Huvis Corporation, Toray Industries, Inc., X-Fibers, Kermel SAS, Honeywell International Inc., Toyobo Co., Ltd., Kolon Industries Inc., Sinopec Yizheng Chemical Fibre Co., Ltd., PBI Performance Products, Inc., Fibrex Inc., Aramid HPM, Formosa Plastics Corporation, DUPONT-TORAY CO., LTD., W. L. Gore & Associates, Inc., Jiangsu Liyang Aramid Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Meta-Aramid Market Key Technology Landscape

The Meta-Aramid Market is underpinned by a sophisticated technological landscape encompassing advanced polymerization techniques, precise fiber spinning methods, and innovative processing technologies that enhance material properties and expand application possibilities. At the core of meta-aramid production is the solution polymerization process, typically involving monomers like meta-phenylenediamine (MPD) and isophthaloyl chloride (IPC) in a polar aprotic solvent. The precise control over reaction conditions, monomer purity, and solvent recovery is critical for achieving the desired molecular weight, polymer structure, and ultimately, the high performance characteristics of the meta-aramid. Innovations in polymerization aim to improve yield, reduce energy consumption, and minimize environmental impact, often leveraging continuous process technologies over batch methods for greater efficiency and consistency.

Following polymerization, the nascent meta-aramid polymer is processed into various fiber forms through advanced spinning technologies. Wet spinning is the predominant method for producing meta-aramid fibers, where the polymer solution is extruded through a spinneret into a coagulation bath, forming continuous filaments. Subsequent drawing, washing, and drying steps are meticulously controlled to orient the polymer chains, enhance mechanical strength, and remove residual solvent. Developments in spinning technology focus on creating finer denier fibers, improving fiber uniformity, and developing specialized cross-sections to optimize performance for specific end-uses, such as increased surface area for filtration or enhanced comfort in textiles. Additionally, for pulp applications, precision milling and fibrillation techniques are crucial for producing short, highly fibrillated fibers that effectively reinforce various matrices.

Beyond fiber production, the technology landscape includes innovations in textile processing and finishing. This involves advanced weaving, knitting, and non-woven manufacturing techniques tailored for meta-aramid fibers to produce high-performance fabrics, felts, and insulation papers. Developments in dyeing technologies, often challenging due to the inherent chemical resistance of meta-aramids, are also significant, allowing for broader aesthetic applications without compromising protective properties. Furthermore, the integration of meta-aramids into multi-material composites, through processes like resin infusion or prepreg manufacturing, represents a key technological frontier, enabling the creation of lightweight and high-strength structures for aerospace, automotive, and defense. Coating technologies and surface treatments are also advancing to provide additional functionalities, such as enhanced water repellency, improved abrasion resistance, or anti-static properties, further broadening the utility and value proposition of meta-aramid products.

Regional Highlights

- Asia Pacific (APAC): Emerging as the dominant and fastest-growing region, driven by rapid industrialization, burgeoning manufacturing sectors in China, India, and Southeast Asian countries. Increasing defense spending, rising disposable incomes, and stricter safety regulations in these developing economies fuel demand for protective apparel, electrical insulation, and automotive components. Significant investments in infrastructure and renewable energy also contribute to market expansion.

- North America: A mature yet robust market, characterized by strong demand from the aerospace and defense industries, stringent industrial safety standards, and a well-established electrical and electronics sector. Continuous technological advancements, a focus on high-performance materials, and significant R&D activities, particularly in the United States, underpin its market stability and growth in specialized applications.

- Europe: A significant market driven by stringent worker safety regulations, advanced automotive manufacturing, and a strong aerospace industry. Countries like Germany, France, and the UK are key contributors, with an emphasis on sustainability, high-quality protective textiles, and innovative composite materials. The region's focus on circular economy principles and green manufacturing also influences product development.

- Latin America: An emerging market experiencing growth due to increasing industrialization, particularly in Brazil and Mexico, and expanding oil and gas exploration activities. Rising awareness of industrial safety and a growing automotive sector are driving the adoption of meta-aramid-based protective equipment and components. Infrastructure development projects also contribute to demand for fire-resistant materials.

- Middle East and Africa (MEA): This region is poised for significant growth, largely due to substantial investments in oil and gas, petrochemicals, and construction sectors, particularly in the GCC countries. The escalating need for industrial safety gear for a large expatriate workforce, coupled with increasing defense expenditures, positions MEA as a promising market for meta-aramid products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Meta-Aramid Market.- DuPont de Nemours, Inc.

- Teijin Limited

- Hyosung Corporation

- Yantai Taihe Advanced Material Co., Ltd.

- SRO Aramid

- Huvis Corporation

- Toray Industries, Inc.

- X-Fibers

- Kermel SAS

- Honeywell International Inc.

- Toyobo Co., Ltd.

- Kolon Industries Inc.

- Sinopec Yizheng Chemical Fibre Co., Ltd.

- PBI Performance Products, Inc.

- Fibrex Inc.

- Aramid HPM

- Formosa Plastics Corporation

- DUPONT-TORAY CO., LTD.

- W. L. Gore & Associates, Inc.

- Jiangsu Liyang Aramid Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Meta-Aramid market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of meta-aramid fibers?

Meta-aramid fibers are primarily used in protective apparel for firefighting, military, and industrial safety due to their exceptional flame and heat resistance. They are also critical in electrical insulation, industrial filtration, rubber reinforcement, and advanced composites for aerospace and automotive industries, offering high strength, durability, and chemical resistance.

How do meta-aramids differ from para-aramids?

While both are high-performance aramid fibers, meta-aramids (e.g., Nomex) excel in thermal stability, flame resistance, and textile processability, making them ideal for protective clothing and electrical insulation. Para-aramids (e.g., Kevlar, Twaron) offer superior tensile strength and modulus, making them preferred for ballistic protection, ropes, and structural composites where extreme strength-to-weight ratio is paramount.

What factors are driving the growth of the meta-aramid market?

Key drivers include increasingly stringent global safety regulations, particularly in industrial and military sectors, leading to higher demand for protective gear. Growth in the electrical and electronics industry, expansion of aerospace and automotive sectors, and the need for high-performance materials in extreme environments also significantly contribute to market expansion.

What are the main challenges faced by the meta-aramid market?

The meta-aramid market faces challenges such as high production costs, which can limit broader adoption; intense competition from alternative high-performance materials; and complex manufacturing processes requiring significant capital investment. Environmental concerns related to production chemicals and material disposal also present hurdles for manufacturers.

Which regions are key contributors to the meta-aramid market?

Asia Pacific is currently the leading and fastest-growing market, driven by rapid industrialization and increasing safety standards. North America and Europe also hold significant market shares due to established aerospace, defense, and industrial sectors, alongside strong regulatory frameworks. Emerging markets in Latin America and MEA are also showing promising growth.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Aramid (Aramid Fiber) Market Size Report By Type (Para-aramid Fibers, Meta-aramid Fibers), By Application (Body Armor & Helmet, Aerospace Materials, Sports Materials, Tire, High Strength Rope, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Aramid Market Statistics 2025 Analysis By Application (Body Armor & Helmet, Aerospace Materials, Sports Materials, Tire, High Strength Rope), By Type (Para-aramid Fibers, Meta-aramid Fibers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Meta-Aramid Fiber Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (PPTA, PMIA), By Application (Industry, Aerospace, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager