Metal Disc Coupling Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434931 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Metal Disc Coupling Market Size

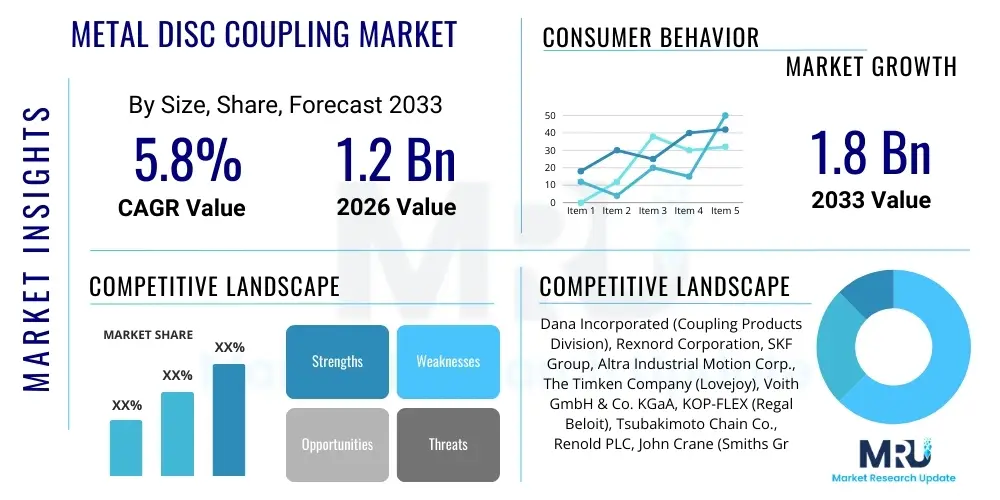

The Metal Disc Coupling Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.8 Billion by the end of the forecast period in 2033.

Metal Disc Coupling Market introduction

Metal disc couplings, often referred to simply as disc couplings, are mechanical components designed to transmit torque from a driving shaft to a driven shaft while accommodating misalignment. They achieve this transmission using thin, flexible metal discs or membranes bolted alternately between the drive hubs and the spacer elements. These couplings are highly valued in industrial applications due to their high torsional stiffness, absence of lubrication requirements, and suitability for high-speed operation, offering a significant advantage over traditional gear or elastomeric couplings in precision environments. Their primary function is ensuring reliable power transmission without introducing excessive reactionary loads on associated machinery bearings, which significantly enhances the operational lifespan of industrial assets.

The core product design revolves around stainless steel or specialized alloy discs that flex to handle angular, parallel, and axial misalignments. The performance characteristics, such as high balance quality and infinite life (when operated within specified misalignment limits), make them indispensable in demanding sectors. Major applications span high-performance rotating equipment like turbomachinery, compressors, large industrial pumps, and power generation systems. Their zero-backlash capability is crucial in high-precision control systems, indexing machinery, and test stands where accuracy and repeatability are paramount. The reliability offered by metal disc couplings directly translates into reduced maintenance costs and minimized downtime for large-scale industrial operations.

Key benefits driving the market include their non-lubricated design, which lowers operational expenditure and simplifies maintenance routines. Furthermore, the robust construction provides resistance to harsh operating conditions, including high temperatures and corrosive environments common in the oil & gas and chemical processing industries. The market expansion is primarily driven by the increasing global demand for energy, necessitating more efficient and reliable power transmission systems in power plants and midstream oil infrastructure. Additionally, the ongoing industrial automation trend, requiring precision movement and highly accurate shaft alignment, further fuels the adoption of high-quality metal disc couplings globally.

Metal Disc Coupling Market Executive Summary

The Metal Disc Coupling Market is experiencing steady growth, fueled predominantly by robust investment in global infrastructure, particularly in the power generation and oil & gas sectors. Business trends indicate a strong movement toward customizable coupling solutions that offer higher power density and better thermal resistance, accommodating the stringent requirements of modern, high-speed rotating equipment. Key manufacturers are focusing on material science innovation, utilizing advanced stainless steels and composite materials to enhance coupling lifespan and performance under extreme operational stress. The shift towards predictive maintenance and Industry 4.0 principles necessitates highly reliable components, positioning metal disc couplings favorably over less robust alternatives.

Geographically, Asia Pacific (APAC) dominates the market, driven by rapid industrialization, large-scale energy projects in China and India, and expanding manufacturing bases requiring precision machinery. North America and Europe maintain a mature but strong market, characterized by demand for replacement parts and upgrades to existing infrastructure, focusing on efficiency and environmental compliance. Segment trends reveal that double-disc couplings are gaining traction due to their enhanced ability to handle greater misalignment capabilities compared to single-disc designs, making them preferred in critical applications. Furthermore, the application segment of pumps and compressors remains the largest consumer, reflecting ongoing growth in chemical processing and pipeline transportation infrastructure globally.

Overall, the market trajectory is positive, supported by structural economic drivers such as global energy transition initiatives and the continuous need for upgrading aging industrial assets worldwide. Challenges related to high initial cost compared to commodity couplings are being mitigated by demonstrating the superior Total Cost of Ownership (TCO) achievable through reduced maintenance and extended component life. Strategic partnerships between coupling manufacturers and Original Equipment Manufacturers (OEMs) are crucial, ensuring that coupling designs integrate seamlessly with next-generation high-speed machinery. This strategic alignment is a critical factor influencing market growth and product development throughout the forecast period.

AI Impact Analysis on Metal Disc Coupling Market

User queries regarding the impact of Artificial Intelligence (AI) on the Metal Disc Coupling market primarily center on how AI-driven predictive maintenance systems influence coupling longevity, monitoring capabilities, and design optimization. Users frequently ask if AI can predict coupling failure before conventional methods, how sensor data integration (IoT/IIoT) is feeding into AI models, and whether AI tools are being used to simulate and optimize coupling material stress and misalignment compensation during the design phase. A key concern is the integration complexity—specifically, whether legacy systems can be economically upgraded to leverage AI-enhanced monitoring. The consensus summary highlights that AI’s role is shifting from reactive failure analysis to proactive performance optimization, extending the Mean Time Between Failures (MTBF) and enabling manufacturers to offer 'Coupling-as-a-Service' models based on guaranteed uptime derived from sophisticated diagnostic algorithms.

- AI algorithms analyze vibration and temperature data from sensors embedded in or near couplings, predicting fatigue and failure points weeks or months in advance.

- Generative Design capabilities powered by AI are optimizing disc geometries for maximum torsional stiffness and misalignment capacity while minimizing material use.

- Machine learning models optimize manufacturing processes, reducing defects in disc forging and assembly, thereby enhancing product quality and consistency.

- AI-driven supply chain management improves inventory forecasting for specific coupling types and spare parts, especially crucial for high-demand industrial sectors like refineries.

- Digital Twin technology, supported by AI, simulates real-world operating conditions, allowing end-users to test new operational parameters safely before physical implementation, impacting coupling selection.

DRO & Impact Forces Of Metal Disc Coupling Market

The Metal Disc Coupling market is shaped by a confluence of accelerating drivers (D), persistent restraints (R), emerging opportunities (O), and potent impact forces. Key drivers include stringent efficiency standards in power generation and petrochemical industries, necessitating high-performance, maintenance-free components like disc couplings. The global increase in energy demand, coupled with modernization projects in aging industrial infrastructure across developed economies, further stimulates demand for reliable torque transmission solutions. However, market growth is restrained by the high initial manufacturing cost associated with precision components and specialized materials, making cheaper elastomeric or fluid couplings attractive for less demanding, lower-speed applications. Furthermore, susceptibility to foreign particle contamination in highly polluted industrial settings can potentially compromise disc longevity if not properly shielded.

Opportunities for market expansion are significant, particularly through the development of hybrid coupling solutions integrating disc technology with advanced composite materials to improve weight-to-power ratios, crucial in aerospace and high-performance industrial machinery. The growing penetration of IIoT (Industrial Internet of Things) allows manufacturers to develop 'smart couplings' with integrated sensors for real-time monitoring and predictive diagnostics, creating new revenue streams through service contracts. Geographically, untapped potential lies in expanding industrial sectors in Southeast Asia and parts of Africa undergoing rapid industrialization and needing dependable rotating machinery components.

The primary impact forces influencing this market include technological innovation focusing on superior material science (e.g., lightweight, high-strength alloys) and standardization efforts to simplify component interchangeability across different machinery brands. Economic factors, such as volatile raw material costs (especially specialized steels), heavily influence profitability and pricing strategies. Regulatory shifts toward greater energy efficiency and reduced emissions in manufacturing also push end-users towards adopting high-efficiency, precision-engineered couplings that minimize mechanical losses. Furthermore, the competitive intensity among key global players drives continuous research and development, primarily centered on increasing the power density and reducing the dimensional footprint of coupling systems.

Segmentation Analysis

The Metal Disc Coupling market is meticulously segmented across multiple dimensions, including coupling type, the number of discs, material composition, application, and the end-use industry. This segmentation is crucial for understanding specific market dynamics and tailoring product offerings to meet diverse industrial needs. The coupling type segment differentiates between single-flexing and double-flexing disc couplings, with double-flexing units typically preferred for larger, high-speed applications requiring greater misalignment capacity. Material science plays a significant role, as performance requirements dictate the use of high-strength stainless steel (e.g., 17-4 PH) or specialized nickel alloys for enhanced corrosion and thermal resistance, particularly in chemical and nuclear environments. These segments define product complexity and, consequently, pricing structure.

Application-based segmentation highlights the primary consuming machinery, such as pumps, compressors, turbines, and generators. Compressors and pumps, especially in the oil & gas and chemical processing industries, constitute the largest volume consumers due to the constant need for reliable fluid handling and gas compression. The end-use industry analysis reveals market concentration, with Oil & Gas and Power Generation leading due to the severe operating conditions and high costs associated with equipment failure in these sectors. Furthermore, the Manufacturing and HVAC (Heating, Ventilation, and Air Conditioning) sectors represent significant growing segments, driven by general industrial expansion and the demand for energy-efficient building systems requiring precise motor-to-fan/pump coupling.

- By Type: Single Disc Couplings, Double Disc Couplings, Spacer Type Disc Couplings, Non-Spacer Type Disc Couplings.

- By Number of Discs/Flexures: Two Disc Pack Couplings, Four Disc Pack Couplings, Six Disc Pack Couplings.

- By Material: Stainless Steel, Nickel Alloys, High-Strength Composites (Used in specific parts).

- By Application: Pumps, Compressors, Turbines, Generators, Fans & Blowers, Gearboxes, Test Stands, Indexing Machines.

- By End-Use Industry: Oil & Gas (Upstream, Midstream, Downstream), Power Generation (Thermal, Nuclear, Renewables), Manufacturing & General Industry, Chemical & Petrochemical, HVAC, Marine.

Value Chain Analysis For Metal Disc Coupling Market

The value chain for the Metal Disc Coupling Market starts with upstream activities dominated by raw material suppliers and precision component manufacturers. Critical inputs include high-grade stainless steel alloys (such as 300 series and proprietary high-strength materials) and specialized coatings necessary for corrosion resistance and durability. The quality of these raw materials is paramount as coupling performance is directly dependent on the fatigue strength and metallurgical stability of the discs. Suppliers must adhere to stringent quality control standards, often dictated by sector-specific regulatory bodies (e.g., API standards for Oil & Gas). The increasing cost volatility of strategic metals poses a continuous challenge in this segment, forcing manufacturers to engage in long-term supply agreements and optimize material usage through advanced design techniques.

The manufacturing stage involves highly specialized processes, including precision machining, laser cutting for disc profile creation, balancing, and rigorous quality testing (such as dynamic balancing to ISO standards). Direct distribution channels involve manufacturers selling high-volume, standard products directly to large OEMs (Original Equipment Manufacturers) for inclusion in new machinery builds, ensuring rapid integration and consistent supply tailored to specific product lines. Indirect distribution utilizes a network of specialized industrial distributors, integrators, and engineering firms that provide localized inventory, technical support, and replacement parts to smaller end-users and for Maintenance, Repair, and Overhaul (MRO) applications. This indirect channel is essential for penetrating regional markets and providing after-sales service.

Downstream activities are dominated by end-users across heavy industries. Maintenance services and technical support constitute a vital part of the downstream value proposition. As couplings require minimal maintenance, the focus shifts to predictive diagnostics, alignment services, and rapid replacement component delivery to minimize equipment downtime. The shift towards IIoT integration is further transforming the downstream segment, enabling manufacturers to offer condition monitoring services, monetizing data gathered from installed couplings, and moving beyond simple product sales into long-term service partnerships. This holistic approach enhances customer retention and provides valuable feedback for product improvement and next-generation design.

Metal Disc Coupling Market Potential Customers

The potential customers for metal disc couplings are entities operating high-speed, high-torque, or precision rotating machinery where reliability and minimal maintenance are non-negotiable requirements. The primary customer base resides in heavy industrial sectors where equipment failure results in substantial financial loss and safety risks. Key buyers include large Oil & Gas companies (both operators and engineering, procurement, and construction (EPC) firms involved in midstream pipeline projects and refineries) that utilize vast arrays of high-pressure compressors and pumps. These customers demand couplings certified to demanding international standards (like API 671) ensuring predictable performance over multi-year operational cycles.

Another major segment encompasses Power Generation utilities, including traditional fossil fuel plants, nuclear facilities, and increasingly, large utility-scale renewable energy installations where disc couplings are essential for linking turbines or generators to gearboxes or prime movers. These buyers prioritize long operational life and the ability of couplings to handle continuous, high-load operation without requiring shutdown for lubrication. Furthermore, large-scale industrial manufacturing and processing plants—particularly in chemical production, cement, and pulp & paper—are perpetual buyers, needing couplings for mixers, cooling towers, and essential utility pumps and fans, often purchasing through specialized MRO distributors.

The Original Equipment Manufacturers (OEMs) of rotating equipment form a foundational customer group, sourcing couplings in bulk for integration into their new product lines (e.g., manufacturers of centrifugal compressors, industrial gas turbines, and specialized high-speed gearboxes). These OEM customers are highly sensitive to coupling integration specifications, supply chain reliability, and pricing consistency. The technical buying process in all these customer groups is highly rigorous, involving engineering departments and reliability teams that assess couplings based on performance curves, material certifications, balancing reports, and the manufacturer's proven track record in similar critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dana Incorporated (Coupling Products Division), Rexnord Corporation, SKF Group, Altra Industrial Motion Corp., The Timken Company (Lovejoy), Voith GmbH & Co. KGaA, KOP-FLEX (Regal Beloit), Tsubakimoto Chain Co., Renold PLC, John Crane (Smiths Group), R+W Coupling Technology, ABB Ltd., Falk Couplings (RethinkX), Huco-Dynatork (Elesa Group), Bibby Turboflex, KTR Systems GmbH, Zero-Max Inc., Mayr Power Transmission, Helical Products Company, Shaft-Saver. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Metal Disc Coupling Market Key Technology Landscape

The technological landscape of the Metal Disc Coupling market is continuously evolving, focusing on enhancing torque density, increasing speed limits, and improving component resilience. A crucial technological focus involves proprietary disc pack designs, specifically the geometry of the flexible elements. Innovations include Finite Element Analysis (FEA) driven optimization of disc profiles to distribute stress more uniformly, thereby increasing the fatigue life and tolerance for misalignment. Manufacturers are utilizing advanced non-linear FEA tools during the design phase to accurately predict behavior under dynamic load conditions, critical for API-compliant applications in the petrochemical industry. Furthermore, advancements in specialized coatings and surface treatments, such as nitriding and proprietary anti-corrosion applications, are extending the operational suitability of standard couplings into increasingly harsh chemical environments.

Another significant technological advancement centers on precision manufacturing techniques. The zero-backlash characteristic essential to disc couplings requires extremely tight tolerances during machining and assembly, achieved through high-precision CNC equipment and advanced balancing methodologies (G 2.5 or better). Key players are integrating automated assembly lines and utilizing laser measurement systems to ensure perfect stack-up tolerances and alignment of disc packs before final assembly. Furthermore, material science is pivotal, with ongoing research into using high-strength, lightweight materials like specialized aerospace-grade stainless steels and carbon fiber reinforced polymers (CFRP) for the spacer elements, especially in large-span couplings, to reduce mass and associated overhung moment, thereby enhancing critical speed limits.

The integration of sensing technology represents a transformative area. Modern disc couplings are increasingly being designed to accommodate non-contact sensors (e.g., proximity probes, accelerometers) for continuous Condition Monitoring (CM). This embedded intelligence facilitates real-time data collection on vibration, speed, and thermal parameters. Technologies like Wireless Sensor Networks (WSN) allow data transmission to centralized predictive maintenance platforms, supporting Industry 4.0 initiatives. This technological shift requires coupling manufacturers to collaborate closely with sensor technology providers and software developers, ensuring seamless data integration and enhancing the overall reliability and diagnostics capabilities offered by the coupling system.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing and largest regional market, driven by massive infrastructure investments, rapid industrialization, and expansion of the manufacturing and energy sectors, particularly in China, India, and Southeast Asian nations. The region's increasing demand for thermal and nuclear power generation and the expansion of chemical complexes necessitate high volumes of durable, large-bore disc couplings for essential rotating equipment.

- North America: Characterized by a highly mature market, North America exhibits high demand for specialized, high-specification couplings, largely driven by strict regulatory requirements in the oil & gas (shale and conventional) and aerospace sectors. Market growth is sustained by the replacement and upgrade cycle of existing machinery, focusing heavily on IIoT integration and advanced diagnostics solutions to maximize operational efficiency and compliance.

- Europe: Europe holds a strong position, particularly in Western economies like Germany and Italy, fueled by robust manufacturing of specialized industrial machinery and adherence to high environmental and efficiency standards. The focus here is on precision couplings for renewable energy installations (wind turbines) and advanced automation systems. Demand is steady, emphasizing quality, zero-backlash performance, and compliance with stringent ATEX standards for hazardous environments.

- Middle East & Africa (MEA): This region is experiencing significant market expansion directly tied to vast hydrocarbon exploration and production projects, especially in Saudi Arabia, UAE, and Qatar. The demand is heavily concentrated in large, high-torque, API 671 compliant disc couplings for massive refinery and gas compression facilities. Investment in new pipeline infrastructure acts as a primary market stimulant.

- Latin America: Growth in Latin America is tied primarily to the recovery of the oil and mining industries in Brazil and Mexico. While smaller than APAC, the market presents opportunities for basic and standardized disc couplings in general industry and agricultural processing, alongside specialized needs for ongoing deep-water exploration and processing platforms.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Metal Disc Coupling Market.- Dana Incorporated (Coupling Products Division)

- Rexnord Corporation

- SKF Group

- Altra Industrial Motion Corp.

- The Timken Company (Lovejoy)

- Voith GmbH & Co. KGaA

- KOP-FLEX (Regal Beloit)

- Tsubakimoto Chain Co.

- Renold PLC

- John Crane (Smiths Group)

- R+W Coupling Technology

- ABB Ltd.

- Falk Couplings (RethinkX)

- Huco-Dynatork (Elesa Group)

- Bibby Turboflex

- KTR Systems GmbH

- Zero-Max Inc.

- Mayr Power Transmission

- Helical Products Company

- Shaft-Saver

Frequently Asked Questions

Analyze common user questions about the Metal Disc Coupling market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of disc couplings over gear or elastomeric couplings?

Disc couplings offer key advantages including high torsional stiffness, requiring no lubrication or maintenance, and possessing a zero-backlash characteristic essential for precision applications. Unlike gear couplings, they eliminate sliding friction, and unlike elastomeric couplings, they operate reliably at high speeds and temperatures without degradation.

Which industry accounts for the highest demand for Metal Disc Couplings?

The Oil & Gas and Power Generation sectors are the largest consumers due to their reliance on high-speed, mission-critical rotating equipment such as industrial gas turbines, large compressors, and high-pressure pumps. These industries require couplings that meet stringent API standards for extreme reliability and extended operational life.

What is the typical lifespan of a Metal Disc Coupling, and how is it maximized?

Metal disc couplings are often marketed as having an "infinite life" provided they are operated within their specified misalignment limits and rated torque capacity. Lifespan is maximized by ensuring precise shaft alignment during installation, avoiding shock loads, and utilizing predictive maintenance systems to detect and correct operational anomalies early.

How does the integration of IIoT technology affect the Metal Disc Coupling Market?

IIoT integration is crucial as it enables continuous condition monitoring of coupling performance via embedded sensors (vibration, temperature). This transition supports predictive maintenance strategies, reducing unplanned downtime, improving overall system reliability, and creating new service revenue opportunities for coupling manufacturers.

What is the difference between single-disc and double-disc coupling configurations?

Single-disc (or single-flexing) couplings can accommodate angular misalignment but are limited in parallel misalignment capacity. Double-disc (or double-flexing) couplings use two flexible disc packs separated by a spacer, allowing them to effectively handle both angular and significant parallel misalignment, making them suitable for longer span applications or installations with high thermal growth variations.

The Metal Disc Coupling market report details the complex interaction of technology, industry demand, and global economic forces driving growth. The continued advancement in materials science and the integration of smart monitoring technologies are positioning disc couplings as the preferred choice for critical, high-performance rotating machinery worldwide. Strategic regional expansion, particularly in APAC and MEA, will be key to capitalizing on new energy and industrial infrastructure projects. Manufacturers must continue to innovate in design and production efficiency to mitigate the impact of fluctuating raw material costs and maintain a competitive edge against alternative coupling technologies. The trend towards customized, high-precision solutions that minimize total cost of ownership remains the central factor dictating procurement decisions across all major end-use sectors, ensuring that quality and reliability remain the highest priorities in this highly specialized industrial segment. The formal analysis provided underscores the robust health and projected stability of the metal disc coupling ecosystem over the forecast period.

Further analysis into emerging market segments, such as robotics and electric vehicle manufacturing components, suggests untapped potential for smaller, highly precise metal disc couplings. While traditionally dominated by heavy industry, the need for zero-backlash, high-speed power transmission in sophisticated automation environments is opening new avenues for product diversification. Companies that successfully adapt their existing high-torque designs into compact, modular units suitable for specialized automation machinery will be well-positioned for future market penetration. Moreover, sustainability concerns are increasingly influencing procurement, favoring manufacturers who can demonstrate reduced material waste in production and offer products with verifiable extended lifespans, aligning with global green manufacturing initiatives.

The regulatory environment also plays a pivotal role, especially standards set by organizations like the American Petroleum Institute (API) which mandate strict compliance for couplings used in oil and gas production. Adherence to these standards requires substantial investment in testing and certification, acting as a high barrier to entry for smaller manufacturers but reinforcing the dominance of established global players. The formal technical requirements ensure that the quality floor for critical applications remains extremely high, thereby justifying the premium pricing often associated with high-performance metal disc coupling products. This stringent technical environment fosters continuous, incremental innovation aimed at improving safety margins and reliability under extreme operating conditions, cementing the product's value proposition in essential industrial infrastructure globally. The market's resilience is intrinsically linked to the continuous global demand for reliable power, resources, and manufacturing efficiency.

In conclusion, the dynamics of the Metal Disc Coupling Market are characterized by high technical barriers, stringent performance requirements, and a strong correlation with global capital expenditure in energy and manufacturing. Successful market navigation requires a deep understanding of sectoral compliance, robust supply chain management for specialized materials, and an aggressive strategy in adopting digital technologies for predictive diagnostics. The projected CAGR reflects a stable growth trajectory, supported by non-discretionary spending on critical infrastructure maintenance and expansion worldwide. Future profitability will largely depend on a manufacturer's ability to offer bespoke engineering services and long-term service agreements based on data-driven performance guarantees, moving the market structure further toward specialized technical partnerships rather than mere transactional sales.

The global competitive landscape remains concentrated among a few key multinational entities that possess the requisite manufacturing scale and intellectual property in disc pack design. However, regional specialization is noticeable, with certain smaller companies dominating niche applications like high-speed test stands or specialized turbomachinery couplings. Consolidation via mergers and acquisitions remains an ongoing feature as larger players seek to acquire proprietary technology or expand their regional distribution networks. The ongoing economic cycles, particularly in commodity prices, will inevitably introduce short-term volatility, but the underlying structural demand for reliable, maintenance-free torque transmission in critical processes ensures the long-term viability and growth of the Metal Disc Coupling Market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager