Metal Wire Crimping Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436441 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Metal Wire Crimping Machine Market Size

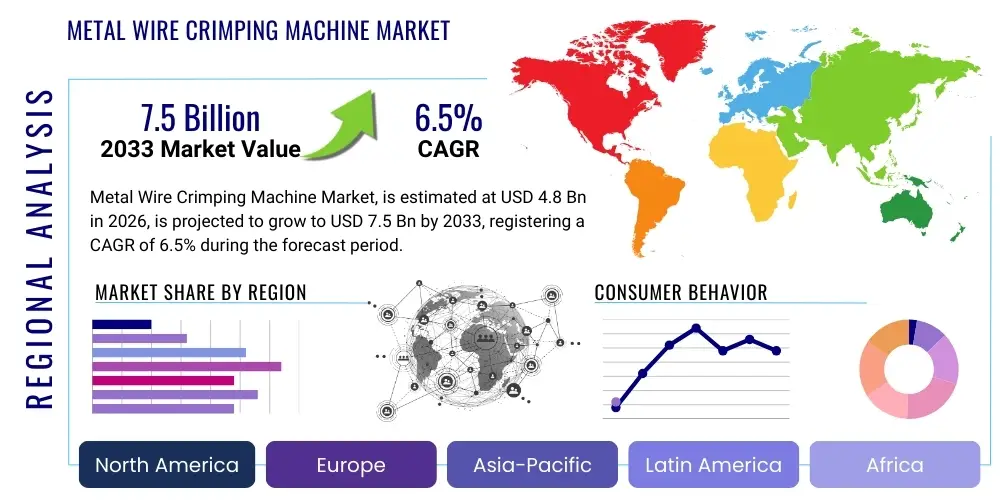

The Metal Wire Crimping Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033.

Metal Wire Crimping Machine Market introduction

The Metal Wire Crimping Machine Market encompasses specialized industrial equipment designed to join electrical wires and cables to terminals or connectors by deformation, ensuring a secure, gas-tight electrical and mechanical connection. These machines are pivotal in wire harness assembly, a fundamental process across numerous high-tech manufacturing sectors. The core function involves precisely applying pressure to cold-form the terminal barrel around the stripped wire conductors, creating a connection superior in reliability and performance compared to soldering or simple twisting. Technological advancements in these machines focus on improving crimp quality monitoring, speed, repeatability, and the ability to handle a diverse range of wire gauges and terminal types, from simple insulated connectors to complex sealed automotive terminals.

Major applications for metal wire crimping machines span the entire spectrum of modern electrical systems, including complex wiring systems in vehicles, consumer electronics, industrial automation equipment, and data infrastructure. The demand is intrinsically linked to the growth of sectors prioritizing reliable electrical connections, such as the rapidly expanding Electric Vehicle (EV) industry, which requires high-voltage crimping solutions, and the ongoing rollout of 5G infrastructure, necessitating robust telecommunications harnesses. These machines offer significant benefits, including superior manufacturing efficiency, reduced labor costs due to automation, enhanced quality control through integrated sensors and measurement systems, and compliance with stringent industry standards (like UL, CSA, and various automotive specifications).

Key driving factors accelerating market expansion include the global trend toward vehicle electrification, which necessitates extremely precise and high-volume wire processing equipment; the proliferation of smart manufacturing (Industry 4.0), which integrates crimping machines into fully automated production lines; and increasing complexity in electronic devices demanding multi-core and specialized wire processing capabilities. Furthermore, rising labor costs in traditional manufacturing hubs prompt greater investment in automated solutions, thereby sustaining the growth trajectory of the high-speed and robotic crimping machine segments. Reliability and quality assurance remain non-negotiable prerequisites, fueling demand for sophisticated machinery capable of real-time quality verification and minimal downtime.

Metal Wire Crimping Machine Market Executive Summary

The Metal Wire Crimping Machine Market is witnessing robust growth, driven primarily by pervasive digitalization and the monumental shift toward electric mobility, mandating high levels of automation and quality control in electrical connection assembly. Business trends indicate a strong move toward highly flexible, modular crimping systems that can be rapidly reconfigured to accommodate short-run productions and frequent changes in wire harness specifications, a vital necessity for suppliers serving diverse OEMs. This is coupled with increased investment in digital monitoring capabilities, allowing manufacturers to integrate crimp force analysis and geometric inspection tools directly into the production line to achieve zero-defect manufacturing goals, thereby transforming traditional crimping operations into data-driven processes that improve overall equipment effectiveness (OEE).

Regionally, the Asia Pacific (APAC) market, particularly China and India, dominates both consumption and manufacturing, fueled by the massive automotive and consumer electronics production base located there, alongside government initiatives promoting industrial automation. North America and Europe maintain strong market share, characterized by high adoption rates of advanced, fully automatic crimping centers that prioritize sophisticated software integration and precision for applications in aerospace and high-end industrial machinery. The mature markets are also leading the charge in adopting sustainable manufacturing practices, favoring energy-efficient electric crimping systems over older hydraulic or pneumatic variants, setting a global standard for operational efficiency and environmental compliance within the market segment.

Segmentation trends highlight the dominance of the fully automatic crimping machine segment, which provides the scalability and speed required by mass-market industries, exhibiting the highest projected CAGR over the forecast period. However, the semi-automatic and manual segments retain significance in specialized, low-volume, high-precision applications, or in emerging economies where initial capital investment constraints are a factor. From an end-use perspective, the Automotive sector remains the largest consumer, driven intensely by the complex wiring requirements of Advanced Driver-Assistance Systems (ADAS) and battery management systems (BMS) in hybrid and electric vehicles, thereby demanding crimping solutions capable of handling specialized high-voltage cable and terminal combinations with utmost accuracy and reliability.

AI Impact Analysis on Metal Wire Crimping Machine Market

Common user questions regarding the influence of Artificial Intelligence (AI) on the Metal Wire Crimping Machine Market center on themes of predictive maintenance, automated quality assurance, and enhanced machine optimization. Users frequently inquire: "How can AI reduce downtime in crimping centers?", "Will AI-driven inspection eliminate manual quality checks?", and "What role does machine learning play in optimizing crimp parameters for new materials?". These questions collectively highlight user expectations for AI to transition crimping operations from reactive maintenance and quality control to proactive, data-informed processes, significantly reducing waste and improving throughput. The key thematic summary is that stakeholders anticipate AI integration to deliver a substantial leap in precision engineering, operational efficiency, and overall manufacturing resilience by making the machines 'smarter' and more autonomous in decision-making regarding calibration and defect detection.

AI is beginning to revolutionize the market by facilitating real-time crimp quality monitoring through sophisticated force curve analysis. Traditional crimping involves setting static parameters, but AI algorithms can analyze the dynamic force-displacement curve during the crimping process and instantly compare it against thousands of successful historical data points. If subtle anomalies suggestive of a weak or imperfect crimp (such as minor variations caused by insulation inconsistencies or slight tooling wear) are detected, the system can automatically flag the product, adjust machine settings, or stop operation before a large batch of defective parts is produced. This level of proactive quality control is unattainable using conventional statistical process control methods, dramatically reducing scrap rates and enhancing end-product reliability, which is critical in safety-sensitive applications like aerospace and automotive braking systems.

Furthermore, AI-driven predictive maintenance systems are transforming the service lifecycle of crimping equipment. By continuously monitoring vibration, temperature, and current consumption of key components (like feeding mechanisms, motors, and tooling), AI can accurately predict the remaining useful life of specific parts and schedule maintenance before catastrophic failure occurs. This capability shifts maintenance from time-based or reactive to condition-based, maximizing machine uptime and extending the life of high-precision tooling. The integration of generative AI is also anticipated in the future, where machine learning models could suggest optimal crimping die designs for newly introduced terminal geometries, accelerating the introduction of new product lines and specialized wire harnesses.

- AI enables real-time, dynamic crimp force curve analysis for superior quality assurance.

- Predictive maintenance driven by machine learning algorithms reduces unexpected downtime and extends tool life.

- Automated defect detection minimizes reliance on subjective human inspection and reduces scrap rates significantly.

- Optimization of machine parameters based on wire gauge, material type, and terminal specifications occurs autonomously.

- AI facilitates faster calibration and setup times, improving flexibility for handling diverse production batches (short-run capability).

DRO & Impact Forces Of Metal Wire Crimping Machine Market

The Metal Wire Crimping Machine Market dynamics are fundamentally shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces dictating market trajectory. The primary Driver is the inexorable growth of the electric vehicle (EV) sector globally, demanding specialized, high-precision crimping solutions for high-voltage cables and battery assemblies. Concurrently, the global push toward industrial automation (Industry 4.0) necessitates sophisticated, network-enabled machines capable of high-speed, continuous operation with minimal human intervention. These drivers are bolstered by increasing regulatory pressure, particularly in the automotive and medical device industries, which mandates traceable, validated crimp quality, achievable only through advanced, monitored machinery.

Despite strong underlying demand, the market faces significant Restraints, notably the high initial capital investment required for purchasing fully automatic crimping centers. These machines represent a major expenditure, especially for Small and Medium Enterprises (SMEs), creating a barrier to rapid adoption in emerging markets. Another restraint involves the complexity and specialization required for high-precision tooling. Tooling wear and calibration are constant operational challenges, and the shortage of skilled technicians capable of operating, programming, and maintaining these complex electromechanical systems poses a persistent labor constraint. Furthermore, economic volatility and supply chain disruptions can impact the procurement and deployment of high-cost machinery components, slowing capital expenditure decisions globally.

Opportunities in the market center on technological innovation and geographical expansion. The growing adoption of smart factory concepts provides a fertile ground for developing and deploying modular, AI-integrated crimping solutions that offer superior flexibility and data transparency. Significant opportunities also exist in the rapidly expanding Telecommunications sector, driven by 5G deployment, and the burgeoning renewable energy sector (solar and wind), both requiring specialized high-reliability connections. The strategic development of user-friendly interfaces and remote diagnostic capabilities (IoT integration) represents a key opportunity for manufacturers to reduce service costs and enhance customer support, further incentivizing the replacement of older, less efficient equipment. The market's overall Impact Forces skew positively, driven by inescapable technological shifts in end-use industries, necessitating continuous investment in advanced crimping technology for competitive advantage and regulatory compliance.

Segmentation Analysis

The Metal Wire Crimping Machine Market is rigorously segmented based on crucial factors, including the degree of automation (Type), the power mechanism utilized (Operation Mode), and the industry application (End-Use Industry). Analyzing these segments provides a nuanced understanding of market maturity, technological adoption rates, and specific demands from diverse manufacturing environments. The segmentation reflects a dual market dynamic: high-volume industries like automotive favor the speed and consistency offered by automatic machines, while niche sectors may still rely on manual or semi-automatic systems for specialized, low-volume tasks requiring high operator dexterity or non-standard configurations. This structured analysis is essential for machine manufacturers to tailor their product development and market strategies effectively.

Segmentation by Type—Automatic, Semi-Automatic, and Manual—is the most indicative of technological trends, showing a clear shift towards fully automatic, modular crimping centers that minimize material handling and maximize throughput. However, segmentation by Operation Mode—Pneumatic, Hydraulic, and Electric—highlights a growing preference for electric machines due to their superior precision, lower noise levels, better energy efficiency, and easier integration into digital feedback loops compared to traditional pneumatic or hydraulic systems, especially in applications where repeatable force control is paramount for safety standards. The largest segment by far, End-Use Industry, confirms the market's dependency on durable goods manufacturing, particularly transportation and consumer electronics, which demand massive volumes of wire harnesses.

- Type

- Automatic Crimping Machines

- Semi-Automatic Crimping Machines

- Manual/Handheld Crimping Tools

- Operation Mode

- Electric

- Hydraulic

- Pneumatic

- End-Use Industry

- Automotive & Transportation (Largest Segment)

- Electronics & Consumer Goods

- Aerospace & Defense

- Telecommunications

- Industrial Machinery

- Medical Devices

Value Chain Analysis For Metal Wire Crimping Machine Market

The value chain for the Metal Wire Crimping Machine Market begins with the Upstream Analysis, which focuses primarily on the procurement of specialized raw materials and high-precision components. This includes advanced steel alloys required for durable crimping dies and tooling, complex sensor technologies for quality monitoring systems, and high-performance electronic components for machine control and automation software. Key upstream suppliers are specialized tooling manufacturers, sensor providers, and industrial automation software developers. The bargaining power of these suppliers is moderate to high, especially for proprietary technologies like highly durable carbide tooling, making supply chain resilience and strategic sourcing critical for machine manufacturers to maintain cost competitiveness and production schedules.

The midstream segment is dominated by the original equipment manufacturers (OEMs) of the crimping machines themselves, such as Komax, Schleuniger, and other key players listed. These firms focus on R&D, designing machines that meet increasingly rigorous demands for speed, precision, and integration into factory automation systems. Following manufacturing, the distribution channel plays a crucial role. Direct distribution is favored for large, complex, fully automatic crimping centers, where OEMs engage directly with large end-users (Tier 1 automotive suppliers) to provide installation, specialized training, and ongoing maintenance contracts. This direct approach ensures that complex integration requirements are met and that technical support is readily available, often involving tailored customization of the machinery.

Conversely, indirect distribution, involving authorized dealers, distributors, and value-added resellers (VARs), is commonly utilized for manual and semi-automatic crimping tools, standard bench-top machines, and consumable tooling/spare parts. These intermediaries provide localized sales, inventory management, and basic service support, particularly important for reaching SMEs and smaller workshops globally. The Downstream Analysis focuses on the End-User/Buyers, which are predominantly high-volume manufacturers (e.g., automotive harness suppliers, appliance manufacturers). Their purchasing decisions are heavily influenced by Total Cost of Ownership (TCO), machine reliability, throughput capacity, and the machine's ability to ensure regulatory compliance and validated crimp quality, highlighting the importance of after-sales service and software updates provided by the midstream OEMs.

Metal Wire Crimping Machine Market Potential Customers

Potential customers for Metal Wire Crimping Machines are overwhelmingly dominated by entities involved in the assembly of electrical and electronic systems requiring robust, permanent wire-to-terminal connections. The largest segment comprises Tier 1 and Tier 2 suppliers in the Automotive and Transportation industry, who specialize in manufacturing complex wire harnesses used throughout internal combustion engine (ICE) and, crucially, electric vehicles (EVs). These customers require high-speed, highly automated crimping centers capable of handling specialized high-voltage and shielded cables used in battery packs and power electronics, prioritizing repeatability and integrated quality monitoring systems to meet stringent vehicle safety standards.

Beyond the transportation sector, manufacturers of Electronics and Consumer Goods form a significant customer base. This includes producers of large home appliances, small electronic devices, and computer peripherals that necessitate standardized, high-volume wire preparation and crimping. Their demand focuses on compact, fast, and versatile bench-top machines or automated lines that can quickly adapt to varied product cycles. Furthermore, companies operating in specialized, high-reliability domains—such as Aerospace & Defense (for aircraft and military vehicle wiring) and Medical Devices (for internal patient monitoring or surgical equipment)—are key buyers, often opting for semi-automatic or precision manual tools where ultra-low volume and extremely high quality validation are prerequisites, prioritizing traceability over sheer speed.

The emerging potential customer segments include firms engaged in renewable energy infrastructure, particularly solar panel manufacturing and utility-scale energy storage solutions, which require durable, weather-resistant crimp connections for heavy-gauge cables. Similarly, the rapid build-out of data centers and telecommunications networks (5G infrastructure) creates demand for crimping machines specialized in handling delicate fiber optic connections and high-density terminal blocks. Across all sectors, the common need driving purchasing decisions is the assurance of a defect-free, measurable, and reliable electrical connection, forcing customers to continually upgrade from outdated mechanical systems to advanced digital, electric crimping solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Komax Holding AG, Schleuniger Group, TE Connectivity (AMP), Tyco Electronics, Rittal GmbH & Co. KG, JST Mfg. Co., Inc., Ideal Industries, Inc., Weidmüller Interface GmbH & Co. KG, Kitzman Tooling, Inc., ShinMaywa Industries, Ltd., Mecal Srl, Zoller + Fröhlich GmbH, Haimer GmbH, Greenlee Textron, Delphi Technologies (Aptiv), Lear Corporation, Furukawa Electric Co., Ltd., Sumitomo Electric Industries, Ltd., JAM S.p.A., Eraser Co. Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Metal Wire Crimping Machine Market Key Technology Landscape

The technological landscape of the Metal Wire Crimping Machine Market is rapidly evolving, moving far beyond basic mechanical presses to integrated electromechanical systems governed by sophisticated software. A pivotal technology driving this evolution is the utilization of Electric Servo-Driven Crimp Presses. Unlike older hydraulic or pneumatic systems, servo-driven machines offer precise control over every aspect of the crimping cycle—force, speed, and position. This level of control is essential for achieving consistently high-quality crimps across various materials and terminal types, particularly important for sensitive electronic applications where force variations can compromise connection integrity. The electric nature of these machines also facilitates easier integration with industrial control networks and significantly reduces energy consumption and noise levels in the factory environment.

Another defining technological trend is the pervasive adoption of Integrated Crimp Force Monitoring (CFM) Systems. CFM systems employ highly sensitive load cells to measure the force applied during the crimp process and generate a dynamic force-displacement curve. Sophisticated machine software then analyzes this curve in real time, comparing it against a known "good" reference curve. Any deviation indicating potential flaws—such as missing wire strands, inadequate insulation crimp, or incorrect wire insertion—is immediately flagged, and the machine halts or marks the defective part. This technology represents the standard for quality assurance in high-reliability applications, significantly reducing the reliance on destructive pull-force testing and ensuring 100% process verification necessary for industries like automotive safety systems.

Furthermore, the move toward Modular and Highly Flexible Automation Platforms is reshaping machine design. Modern crimping centers are not monolithic units but are composed of interchangeable modules for wire feeding, stripping, sealing, tinning, and crimping. This modularity allows manufacturers to rapidly reconfigure production lines to handle different wire harness specifications, dramatically improving operational flexibility and reducing changeover times. Coupled with this is the integration of Industrial Internet of Things (IIoT) connectivity, enabling remote diagnostics, software updates, and the transmission of OEE data to centralized manufacturing execution systems (MES), supporting the broader goals of Industry 4.0 by providing unprecedented transparency into the production process and facilitating advanced predictive maintenance strategies.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing region in the Metal Wire Crimping Machine Market, primarily driven by massive production volumes in the electronics and automotive manufacturing sectors, particularly in China, South Korea, and Japan. The region benefits from lower manufacturing costs and increasing adoption of automation to counteract rising local labor expenses. The proliferation of electric vehicle manufacturing hubs across China and India is the core catalyst for high-speed, fully automatic crimping machine deployment.

- North America: North America holds a significant market share, characterized by high demand for advanced, high-precision machinery, especially within the Aerospace & Defense and high-end industrial machinery sectors. The focus here is on quality, traceability, and the integration of machines into complex IT infrastructure. The US market is also heavily investing in automation to bring manufacturing capacity back onshore, favoring highly sophisticated, software-driven crimping centers capable of handling complex military and aviation harnesses.

- Europe: Europe represents a mature market known for pioneering high-quality standards and technological innovation. Countries like Germany, Switzerland, and Italy host key industry leaders (OEMs) and major automotive manufacturers. The European market prioritizes sustainability and precision, leading to high adoption rates of energy-efficient, electric servo-driven machines. Regulatory compliance, especially concerning RoHS and REACH directives, heavily influences machine design and material use in this region.

- Latin America (LATAM): The LATAM region, particularly Mexico and Brazil, serves as a crucial manufacturing and assembly hub for the North American and South American automotive supply chains. The market demand is stable, focusing predominantly on semi-automatic and robust automatic machines that balance cost-effectiveness with reliable performance for high-volume automotive component production. Investment in automation is steadily increasing, though often lagging behind APAC and mature Western markets.

- Middle East and Africa (MEA): The MEA market is currently smaller but exhibits potential growth, linked to investments in infrastructure development, telecommunications expansion, and burgeoning domestic automotive assembly operations (e.g., Turkey and South Africa). Demand here is concentrated on foundational industrial machinery and essential services, often driven by government-backed infrastructure projects requiring reliable electrical connection technology.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Metal Wire Crimping Machine Market.- Komax Holding AG

- Schleuniger Group

- TE Connectivity (AMP)

- Tyco Electronics

- Rittal GmbH & Co. KG

- JST Mfg. Co., Inc.

- Ideal Industries, Inc.

- Weidmüller Interface GmbH & Co. KG

- Kitzman Tooling, Inc.

- ShinMaywa Industries, Ltd.

- Mecal Srl

- Zoller + Fröhlich GmbH

- Haimer GmbH

- Greenlee Textron

- Delphi Technologies (Aptiv)

- Lear Corporation

- Furukawa Electric Co., Ltd.

- Sumitomo Electric Industries, Ltd.

- JAM S.p.A.

- Eraser Co. Inc.

Frequently Asked Questions

Analyze common user questions about the Metal Wire Crimping Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for fully automatic crimping machines?

The surging demand for fully automatic crimping machines is primarily driven by the massive expansion of the Electric Vehicle (EV) industry and the global push towards Industry 4.0 automation, requiring high-speed, high-volume production with guaranteed, traceable quality control, which only automated centers can reliably provide.

How does Crimp Force Monitoring (CFM) technology improve crimp quality?

CFM technology uses sophisticated sensors to measure the force-displacement curve in real-time during the crimping cycle. This data is instantly analyzed by software to detect subtle deviations indicative of flaws (such as missing strands or incorrect terminal position), ensuring 100% process verification and compliance with strict safety standards without destructive testing.

What is the expected CAGR for the Metal Wire Crimping Machine Market between 2026 and 2033?

The Metal Wire Crimping Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% during the forecast period (2026–2033), fueled by electrification trends and ongoing digitalization in manufacturing processes globally.

Which regional market holds the largest share for Metal Wire Crimping Machine adoption?

The Asia Pacific (APAC) region currently holds the largest market share, predominantly due to the massive scale of automotive manufacturing and consumer electronics production in countries like China, necessitating extensive investment in high-throughput wire harness assembly equipment.

What is the key technological advantage of electric servo-driven crimping machines over hydraulic versions?

Electric servo-driven machines offer superior precision and repeatability in force and position control, which is essential for consistent crimp geometry and adherence to demanding specifications. They are also quieter, more energy-efficient, and easily integrated into digital factory networks for enhanced monitoring and data logging.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager