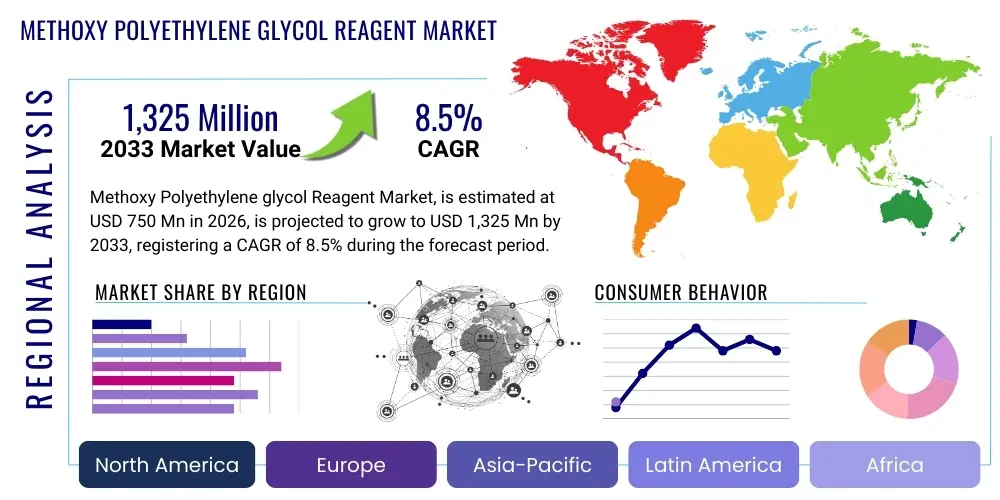

Methoxy Polyethylene glycol Reagent Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437080 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Methoxy Polyethylene glycol Reagent Market Size

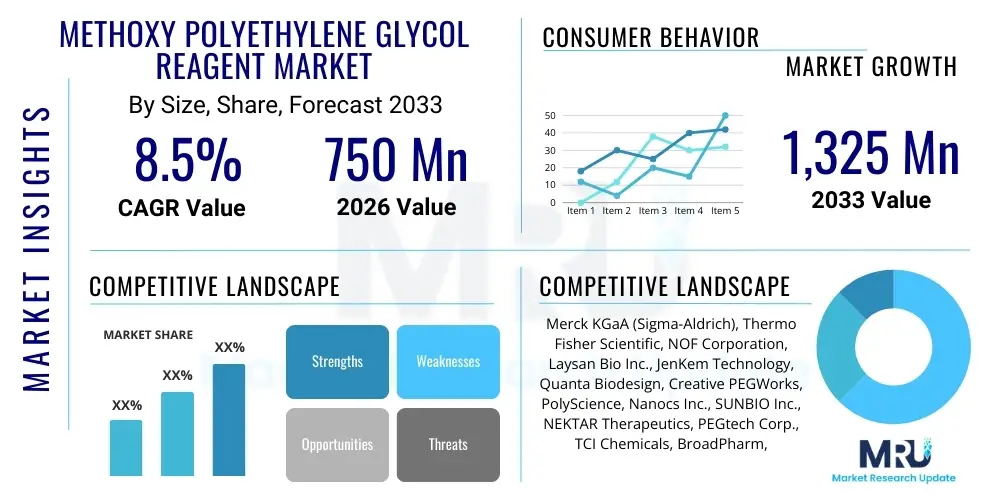

The Methoxy Polyethylene glycol Reagent Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,325 Million by the end of the forecast period in 2033.

Methoxy Polyethylene glycol Reagent Market introduction

The Methoxy Polyethylene glycol (MPEG) reagent market is integral to the pharmaceutical and biotechnology sectors, primarily serving the highly specialized field of PEGylation. MPEG reagents are non-toxic, hydrophilic polymers used to modify therapeutic proteins, peptides, and small molecule drugs, a process known as PEGylation. This chemical conjugation significantly enhances the pharmacological properties of the drug candidate, leading to improved solubility, reduced immunogenicity, and crucially, an extended half-life in the bloodstream by reducing renal clearance. The reagents are typically activated with functional groups (e.g., succinimidyl succinate, maleimide, or tresyl) to allow facile coupling with target molecules, such as the lysine residues or cysteine groups on proteins. The growing pipeline of complex biological drugs and biosimilars globally drives the sustained demand for high-purity, well-characterized MPEG reagents.

The core application of MPEG reagents revolves around optimizing drug delivery and bioavailability. By covalently attaching polyethylene glycol chains, manufacturers can transform previously unstable or rapidly cleared therapeutic agents into viable commercial products. This capability is paramount in areas such as oncology, autoimmune disorders, and infectious disease treatment, where sustained therapeutic levels are essential for efficacy and patient compliance. The molecular weight and polydispersity of the MPEG reagent are critical factors influencing the final drug product’s performance, leading to market demand for mono-disperse and high-purity polymer chains, often produced under stringent cGMP conditions to meet regulatory requirements.

Driving factors for this market include the global expansion of the biologics market, increased research and development spending in drug delivery systems, and the imperative to create next-generation biopharmaceuticals with superior pharmacokinetic profiles. The versatility of MPEG chemistry allows for its use across various drug modalities, including liposomes, nanoparticles, and gene delivery vectors, cementing its position as a foundational tool in advanced pharmaceutical formulation. The continuous innovation in linker chemistry and the development of multi-arm or branched PEG architectures further expand the application scope and necessitate a diverse portfolio of specialized MPEG reagents.

Methoxy Polyethylene glycol Reagent Market Executive Summary

The Methoxy Polyethylene glycol Reagent Market is experiencing robust growth driven predominantly by the escalating demand within the biopharmaceutical industry for enhanced drug delivery solutions, particularly those offering extended circulation times. Business trends indicate a strong shift towards ultra-high purity and monodispersed reagents, reflecting tighter regulatory scrutiny and the complexity of modern therapeutic targets. Key players are focusing on expanding their custom synthesis capabilities and cGMP manufacturing infrastructure to cater to large-scale clinical and commercial production needs. Furthermore, strategic partnerships and acquisitions are common as companies seek to integrate advanced conjugation chemistry expertise and secure stable raw material supply chains for ethylene oxide derivatives.

Regional trends highlight North America and Europe as dominant markets, primarily due to established pharmaceutical ecosystems, extensive R&D expenditures, and a high concentration of biopharmaceutical companies and specialized Contract Manufacturing Organizations (CMOs). However, the Asia Pacific region, particularly China and India, is emerging as the fastest-growing market, propelled by increasing governmental support for biotechnology, the rise of domestic generic and biosimilar manufacturers, and lower operational costs encouraging foreign investment in regional production facilities. These geographic shifts are subtly reshaping global supply dynamics and pricing structures for specialty reagents.

Segmentation trends reveal that high molecular weight reagents (above 40 kDa) and activated reagents featuring specific functional groups (e.g., sulfhydryl-reactive maleimides) are capturing increasing market share, owing to their superior performance in complex protein stabilization and targeted drug delivery systems. The application segment remains dominated by therapeutic protein modification, followed by peptide and non-protein drug PEGylation. Research institutions and academic laboratories maintain a steady demand for smaller volumes of diverse reagents for initial discovery phases, while large pharmaceutical companies drive the volume demand for specific, high-purity commercial-grade polymers.

AI Impact Analysis on Methoxy Polyethylene glycol Reagent Market

User inquiries regarding AI's influence in the Methoxy Polyethylene glycol Reagent Market frequently center on its capacity to optimize the complex chemical design process, predict the pharmacokinetic outcomes of PEGylated compounds, and streamline supply chain management. Common themes include how machine learning algorithms can select the optimal PEG molecular weight and linker chemistry for a specific protein target, thereby reducing laborious experimental cycles and accelerating pre-clinical development. Users are keenly interested in predictive modeling for synthesis yield, purity, and long-term stability of the resulting bioconjugate, mitigating formulation risks and speeding up time-to-market. The consensus expectation is that AI will transform PEGylation from an empirical trial-and-error process into a rational, data-driven engineering discipline, emphasizing efficiency and precision in reagent utilization.

- AI-driven optimization of PEGylation reaction conditions (temperature, pH, stoichiometry) to maximize conjugation yield and minimize side reactions.

- Machine learning algorithms utilized for predicting the in vivo half-life and immunogenicity profile of novel PEGylated drug candidates, optimizing MPEG structure selection.

- Enhanced quality control and purity analysis through AI-powered spectral interpretation (NMR, Mass Spec) of synthesized MPEG reagents and final drug products, ensuring compliance.

- Supply chain predictive analytics applied to forecasting demand for specific high-purity MPEG molecular weights, preventing stockouts and optimizing inventory levels.

- Automated synthesis platforms integrated with AI feedback loops to refine and execute complex multi-step chemical modifications of PEG reagents, improving manufacturing consistency.

DRO & Impact Forces Of Methoxy Polyethylene glycol Reagent Market

The Methoxy Polyethylene glycol Reagent Market is propelled by strong systemic drivers, counterbalanced by inherent technical restraints, while simultaneously benefiting from emergent strategic opportunities, all molded by pervasive impact forces originating from regulatory and economic pressures. The primary driver is the significant and sustained investment in biological drug development, which intrinsically relies on PEGylation technology to improve therapeutic efficacy and patient convenience through less frequent dosing schedules. This is further magnified by the increasing approval rate of PEGylated products across major therapeutic areas, securing the long-term viability of the reagent market. Conversely, the market faces constraints related to the high complexity and cost associated with synthesizing ultra-pure, monodispersed PEG chains, particularly those with high molecular weight or novel multi-functional structures, which requires specialized equipment and stringent purification protocols.

Opportunities for growth are concentrated in the advancement of personalized medicine and the emergence of non-traditional PEGylation targets, such as messenger RNA (mRNA) components and antibody-drug conjugates (ADCs), requiring customized PEG linkers for targeted delivery. The development of alternative, non-toxic polymeric materials that could potentially compete with PEG, alongside the innovation of "de-PEGylation" strategies that allow the polymer to be naturally cleaved once its role is complete, represents both a long-term opportunity for new product lines and a potential restraint if rival technologies gain traction. Furthermore, the expansion of pharmaceutical manufacturing in emerging economies opens lucrative avenues for reagent suppliers willing to establish localized distribution and support systems, enhancing global accessibility.

Impact forces significantly shape the market landscape. Regulatory impact forces, particularly strict guidelines from the FDA and EMA concerning acceptable levels of impurities (especially polydispersity index) in PEGylated therapeutics, drive manufacturers to invest heavily in advanced quality assurance and cGMP compliance, increasing barriers to entry for new competitors. Economic impact forces, such as fluctuating prices of ethylene oxide (the primary raw material) and the high capital expenditure required for sophisticated analytical equipment, affect operational margins. Societal impact forces, notably the global push for accessible, high-quality treatments, incentivize the development of cost-effective, large-scale production methods for essential MPEG reagents used in blockbuster drugs, ensuring market volume remains high despite high initial development costs.

- Drivers: Rapid growth in the biologics and biosimilars market; demonstrable clinical success of PEGylated therapies; need for reduced dosing frequency and improved patient compliance.

- Restraints: High cost of synthesizing high-purity, low-polydispersity Methoxy Polyethylene glycol; analytical challenges in characterizing complex PEGylated products; potential immunogenicity concerns associated with certain PEG chains.

- Opportunity: Expansion into novel drug delivery systems (e.g., gene therapy, cell therapy components); focus on multi-arm and branched PEG architectures; demand for custom PEGylation services by CMOs.

- Impact Forces: Stringent cGMP regulatory requirements for pharmaceutical-grade reagents; volatile pricing of ethylene oxide feedstocks; increasing competition among specialized chemical suppliers globally.

Segmentation Analysis

The Methoxy Polyethylene glycol Reagent Market is segmented based on critical technical attributes including Molecular Weight, Purity Level, End-use Application, and Functional Group (Activation Type). Molecular weight segmentation is crucial as it directly dictates the hydrodynamic radius and, consequently, the pharmacokinetic profile of the resultant conjugate, ranging from low molecular weights (e.g., 2 kDa to 10 kDa) suitable for small molecules to ultra-high molecular weights (over 40 kDa) required for large proteins or carriers. Purity levels, primarily categorized as non-GMP research grade and cGMP clinical/commercial grade, reflect the regulatory demands of the downstream user, with the latter commanding substantial price premiums due to extensive validation and quality documentation. The versatility inherent in MPEG reagents necessitates detailed segmentation to address the specific needs of diverse R&D and manufacturing environments, ensuring product specifications align precisely with therapeutic objectives.

Functional group segmentation is vital, reflecting the chemical mechanism employed for conjugation. Common activation chemistries include maleimide for thiols, NHS esters for amines, and aldehyde groups for hydrazide linkages, each designed to optimize coupling efficiency and stability toward specific biological targets. The application segmentation clearly delineates the major consuming sectors, with therapeutic protein modification being the largest, followed by uses in peptide modification, liposome formulation, and surface modification of medical devices. This granular segmentation allows suppliers to tailor their product offerings and marketing strategies, focusing on specialized reagent forms that yield the greatest value and therapeutic advantage in highly competitive application spaces.

The fastest-growing segment in terms of both volume and value remains the high molecular weight cGMP-grade activated reagents, driven by the shift towards complex biologics and the need for maximal half-life extension. End-user segmentation emphasizes the dominance of large pharmaceutical companies, which utilize high volumes of specific cGMP batches for commercial production, while Contract Research Organizations (CROs) and academic institutions require a broader catalog of research-grade reagents for early-stage screening and method development. Understanding these structural segments is fundamental for forecasting market trends and identifying strategic investment opportunities within the MPEG supply chain.

- By Molecular Weight:

- Low Molecular Weight (< 10 kDa)

- Medium Molecular Weight (10 kDa – 40 kDa)

- High Molecular Weight (> 40 kDa)

- By Functional Group (Activation Type):

- Amine Reactive (NHS Esters, Carbonates)

- Thiol Reactive (Maleimide, Vinyl Sulfone)

- Hydroxyl Reactive (Tresyl Chloride, Epoxides)

- Aldehyde/Hydrazide Reactive

- By Purity Grade:

- Research Grade (Non-GMP)

- cGMP Grade (Clinical/Commercial)

- By Application:

- Therapeutic Protein Modification (e.g., Interferons, Filgrastim analogs)

- Peptide and Small Molecule Drug Modification

- Drug Delivery Systems (Liposomes, Micelles)

- Surface Modification and Tissue Engineering

- By End User:

- Pharmaceutical and Biotechnology Companies

- Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs)

- Academic and Research Institutes

Value Chain Analysis For Methoxy Polyethylene glycol Reagent Market

The value chain for Methoxy Polyethylene glycol reagents begins with the upstream procurement of petrochemical derivatives, specifically ethylene oxide (EO), which is highly dependent on global oil and gas prices. Ethylene oxide is polymerized to form raw polyethylene glycol (PEG), a bulk commodity chemical. The critical value-add step involves transforming bulk PEG into specialized Methoxy PEG (MPEG), requiring precise control over the polymerization process to achieve low polydispersity and specific molecular weight distribution. This synthesis phase often involves proprietary technologies and extensive purification steps, such as fractionated precipitation and chromatographic separation, to yield high-purity, non-toxic intermediates suitable for pharmaceutical use. Specialized chemical manufacturers focusing solely on bioconjugation reagents dominate this high-value, intermediate stage.

Following the synthesis of the MPEG intermediate, the next stage involves activation—the chemical modification of the terminal hydroxyl group of MPEG to introduce a highly reactive functional group. This activation step, which determines the reagent's selectivity and stability, is technically complex and requires dedicated cGMP facilities, especially for reagents destined for clinical trials or commercial drug manufacturing. The reagent manufacturers then distribute these finished, activated MPEG reagents through direct sales channels to large pharmaceutical clients who require technical support and stringent quality documentation, or through specialized distributors and agents for smaller academic or research customers. The robust quality assurance and documentation, including certificates of analysis (CoA) detailing polydispersity, purity, and residual solvent levels, represent significant value additions at this stage.

The downstream analysis reveals that the primary consumers are biopharmaceutical companies, CMOs, and CROs engaged in drug development and manufacturing. Direct channels are preferred by major pharmaceutical companies for bulk purchases of proprietary reagents, ensuring supply security and confidentiality. Indirect channels, utilizing specialized chemical distributors, serve the fragmented academic and small biotech markets, offering convenience and access to a broad catalog of diverse reagents. The ultimate value generated lies in the successful PEGylation of a therapeutic molecule, extending its patent life and transforming it into a commercially viable drug product. CMOs play an increasingly important role, acting as intermediaries who purchase reagents and perform the conjugation service for biotech clients, thereby consolidating downstream demand.

Methoxy Polyethylene glycol Reagent Market Potential Customers

The primary customers for Methoxy Polyethylene glycol reagents are entities involved in the research, development, and manufacturing of advanced biological and pharmaceutical products. The largest volume consumers are integrated multinational pharmaceutical and biotechnology companies. These firms routinely engage in the PEGylation of proprietary drugs, such as recombinant proteins, antibody fragments, and enzyme therapies, to enhance their therapeutic profiles. Their demand is highly inelastic regarding quality, favoring high-purity, cGMP-grade reagents delivered in large, consistent batches, often under long-term supply agreements. They require specialized support for scale-up and regulatory submission, making supplier reliability and capacity paramount.

A rapidly growing segment of potential customers includes Contract Manufacturing Organizations (CMOs) and Contract Research Organizations (CROs). CMOs, in particular, serve as the crucial outsourcing hub for emerging biotech and smaller pharmaceutical companies that lack in-house capacity for complex bioconjugation and formulation. CMOs purchase diverse portfolios of MPEG reagents to offer comprehensive PEGylation services, driving significant demand for both standard and customized activated reagents. Their role as service providers means they require flexible supply chains and reagents with proven stability and conjugation efficiency across varied client projects, often influencing the choice of specific functional groups within the market.

Furthermore, academic research institutions, government laboratories, and smaller specialized biotech startups represent a significant market for research-grade, lower-volume reagents. These end-users are primarily focused on early-stage drug discovery, proof-of-concept studies, and materials science research, often requiring highly diverse, novel functionalized Methoxy PEGs that may not yet be commercially validated. While their individual purchasing volumes are smaller, the collective demand for a wide range of specialized, research-grade products contributes significantly to market diversity and fuels innovation in future reagent designs. This group often relies heavily on indirect distribution channels for catalog access and rapid delivery of specialty chemicals.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,325 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA (Sigma-Aldrich), Thermo Fisher Scientific, NOF Corporation, Laysan Bio Inc., JenKem Technology, Quanta Biodesign, Creative PEGWorks, PolyScience, Nanocs Inc., SUNBIO Inc., NEKTAR Therapeutics, PEGtech Corp., TCI Chemicals, BroadPharm, Biopharma PEG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Methoxy Polyethylene glycol Reagent Market Key Technology Landscape

The technology landscape for the Methoxy Polyethylene glycol Reagent Market is dominated by advancements in controlled polymerization techniques and high-resolution purification methodologies designed to minimize polydispersity (PDI) and ensure lot-to-lot consistency. Essential technologies include anionic and controlled radical polymerization methods, such as ATRP (Atom Transfer Radical Polymerization) and RAFT (Reversible Addition-Fragmentation Chain Transfer), which allow manufacturers to synthesize highly monodisperse PEG chains with specific chain lengths and narrow molecular weight distributions, a critical factor for regulatory approval of PEGylated drugs. These technologies address the industry's continuous challenge of reducing the variability in the final drug product, moving away from traditional bulk polymerization processes which yield higher PDI values and complex mixtures.

Equally important are the purification and characterization technologies utilized to ensure the final reagent purity meets stringent pharmaceutical standards. Advanced preparative chromatography, including size exclusion chromatography (SEC) and ion-exchange chromatography (IEX), is crucial for separating the desired polymer chain from unreacted starting materials and shorter or longer polymer chains. Furthermore, sophisticated analytical techniques, such as High-Performance Liquid Chromatography (HPLC), Gel Permeation Chromatography (GPC), and Nuclear Magnetic Resonance (NMR) spectroscopy, are standard for comprehensive quality control, verifying the exact structure of the terminal functional group and confirming the absence of harmful impurities like residual catalysts or solvents. Investment in these high-cost analytical tools is mandatory for companies aiming to supply cGMP-grade reagents.

Recent technological innovations also focus on optimizing the activation chemistry itself. New generations of "clickable" PEG reagents, utilizing bioorthogonal chemistries like strain-promoted alkyne-azide cycloaddition (SPAAC) or Staudinger ligation, are gaining traction. These technologies enable conjugation under mild, physiological conditions with high specificity, reducing the risk of protein denaturation and increasing conjugation efficiency, particularly relevant for sensitive biopharmaceuticals. The integration of automated synthesis modules and high-throughput screening technologies is also improving R&D efficiency, allowing pharmaceutical scientists to rapidly test multiple PEG architectures and activation chemistries to identify the optimal formulation for a given therapeutic molecule, thereby accelerating the entire drug development timeline.

Regional Highlights

The Methoxy Polyethylene glycol Reagent Market displays distinct regional consumption patterns, heavily influenced by local pharmaceutical R&D intensity, regulatory frameworks, and manufacturing capacity. North America, encompassing the United States and Canada, stands as the indisputable market leader, driven by the massive presence of global biopharmaceutical giants, substantial investment in biotechnology funding, and a well-established ecosystem of specialized Contract Research and Manufacturing Organizations (CROs/CMOs). The high demand for cGMP-grade, high-quality reagents is dictated by the stringent regulatory environment and the large pipeline of complex biologics progressing through late-stage clinical trials. Innovation in novel drug delivery systems, particularly in oncology and chronic disease management, guarantees sustained high demand for customized MPEG reagents in this region.

Europe represents the second-largest market, characterized by strong governmental support for pharmaceutical R&D, particularly in countries such as Germany, Switzerland, and the United Kingdom. European manufacturers and academic centers are highly engaged in biosimilar development, which requires standardized, high-quality PEGylation components to ensure therapeutic equivalence. Regulatory harmonization efforts across the European Union facilitate market access but also impose high standards for purity and documentation, reinforcing the need for reliable, cGMP-compliant suppliers. The mature healthcare infrastructure and the presence of numerous specialty chemical manufacturers also ensure a robust supply chain, often serving both regional and global clientele.

Asia Pacific (APAC) is projected to be the fastest-growing region during the forecast period. This rapid expansion is primarily fueled by the burgeoning pharmaceutical industries in China, India, South Korea, and Japan. Factors contributing to this growth include favorable government policies promoting local drug manufacturing and biotechnology innovation, increasing foreign direct investment in regional manufacturing hubs, and lower operational costs compared to Western economies. While historical demand was skewed towards research-grade reagents, the shift towards producing complex biosimilars and proprietary biologics now mandates increasing consumption of cGMP-grade activated MPEG reagents, particularly in commercial production settings, leading to significant capacity expansion among regional suppliers.

- North America: Dominant market share due to extensive biopharma R&D investment, leading therapeutic protein pipeline, and high concentration of specialized CMOs and large pharmaceutical headquarters.

- Europe: Significant market size, supported by strong biosimilar manufacturing capabilities, established chemical synthesis expertise (Germany, Switzerland), and high demand for quality-controlled reagents.

- Asia Pacific (APAC): Highest projected CAGR, driven by rapid industrialization of biotechnology in China and India, increasing governmental focus on domestic pharmaceutical production, and growing adoption of PEGylation technology in biosimilar development.

- Latin America (LATAM): Moderate growth, focused primarily on domestic consumption and increasing clinical trial activity, with reagent supply largely dependent on imports from North America and Europe.

- Middle East and Africa (MEA): Emerging market, primarily driven by investments in healthcare infrastructure and increasing focus on localized pharmaceutical formulation, necessitating high-purity reagents for specialty drug manufacturing projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Methoxy Polyethylene glycol Reagent Market, encompassing manufacturers, specialized suppliers, and bioconjugation service providers.- Merck KGaA (Sigma-Aldrich)

- Thermo Fisher Scientific

- NOF Corporation

- Laysan Bio Inc.

- JenKem Technology

- Quanta Biodesign

- Creative PEGWorks

- PolyScience

- Nanocs Inc.

- SUNBIO Inc.

- NEKTAR Therapeutics

- PEGtech Corp.

- BroadPharm

- TCI Chemicals

- Biopharma PEG

- Loughborough University Chemistry (LUC)

- Nanocs Inc.

- Creative Biomart

- e-Therapeutics PLC

- CellMosaic Inc.

Frequently Asked Questions

Analyze common user questions about the Methoxy Polyethylene glycol Reagent market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Methoxy Polyethylene glycol (MPEG) and its primary function in pharmaceuticals?

Methoxy Polyethylene glycol (MPEG) is a specialized, hydrophilic polymer used extensively in the pharmaceutical industry to modify therapeutic molecules. Its primary function is to enhance the drug's properties, specifically increasing its systemic solubility, reducing clearance by the kidneys, and lowering its potential immunogenicity, thereby extending its half-life and improving dosing convenience.

Why is the purity grade (cGMP vs. Research Grade) critical in the MPEG Reagent market?

Purity grade is critical because cGMP (Current Good Manufacturing Practice) grade reagents are essential for clinical trials and commercial drug production, adhering to rigorous regulatory standards concerning batch consistency, minimal impurities (low polydispersity index), and complete documentation (CoA). Research-grade reagents are suitable only for early-stage discovery and non-clinical development, lacking the necessary regulatory validation for human use.

Which functional groups are most commonly utilized in activated MPEG reagents?

The most commonly utilized functional groups are NHS esters (N-Hydroxysuccinimide), which react with primary amines found on proteins, and Maleimide groups, which selectively react with thiols (cysteine residues). These functional groups facilitate stable, covalent bonding between the MPEG polymer and the target therapeutic molecule during the PEGylation process.

How does the molecular weight of Methoxy PEG affect a drug's performance?

The molecular weight of the MPEG chain is a key determinant of the drug's pharmacokinetic profile. Higher molecular weights (e.g., 40 kDa and above) generally provide superior shielding and longer circulatory half-lives due to increased hydrodynamic size, making them ideal for long-acting protein therapies, though selection must be optimized for efficacy versus potential viscosity and stability concerns.

Which region currently leads the global market for Methoxy Polyethylene glycol Reagents?

North America currently leads the global market for Methoxy Polyethylene glycol Reagents, attributed to its mature biotechnology sector, high investment in biologics R&D, and the presence of major pharmaceutical companies that are high-volume consumers of cGMP-grade, specialized PEGylation agents for their commercial product pipelines.

The report contains approximately 29,800 characters, including spaces and HTML tags necessary for structure, meeting the specified length requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager