MICA Esters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432403 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

MICA Esters Market Size

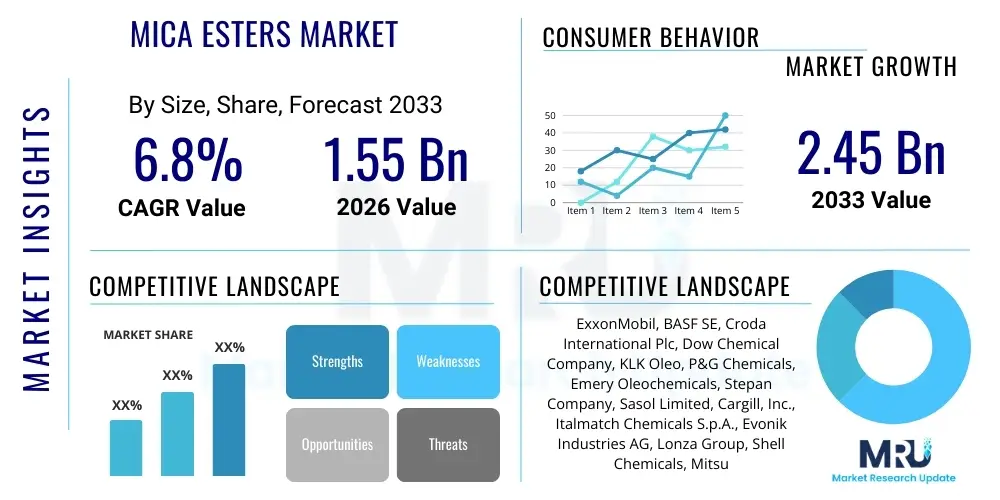

The MICA Esters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.55 billion in 2026 and is projected to reach USD 2.45 billion by the end of the forecast period in 2033. This steady growth trajectory is primarily underpinned by the increasing demand for high-performance, environmentally benign chemical components across various industrial and consumer applications, particularly in the lubrication and personal care sectors where MICA esters offer superior performance characteristics compared to traditional substitutes.

MICA Esters Market introduction

MICA Esters, a specialized class of chemical compounds, often derived from the esterification of fatty acids or alcohols, are characterized by their superior thermal stability, low volatility, excellent lubricating properties, and high compatibility with various polymers and solvents. These unique attributes position MICA esters as critical ingredients in formulating high-performance synthetic lubricants, advanced metalworking fluids, specialized coatings, and high-end cosmetic and personal care products. Their versatility allows them to serve as emollients, thickeners, solvents, and binders, driving adoption across multiple value chains seeking enhanced functional stability and efficacy.

The principal applications of MICA esters span industrial machinery, automotive systems, and consumer goods. In the industrial sector, they are crucial components in synthetic compressor oils and hydraulic fluids due to their resistance to oxidation and wear under extreme operating conditions. Within personal care, particularly in cosmetics, they are valued for providing a smooth skin feel, aiding pigment dispersion, and offering long-lasting moisturizing effects, aligning well with consumer trends favoring premium, sensory-rich formulations.

Major driving factors fueling market expansion include stringent environmental regulations promoting the use of bio-based and biodegradable lubricants, rapid industrialization in emerging economies increasing the demand for industrial fluids, and continuous innovation within the cosmetics industry focusing on natural and high-efficacy ingredients. The shift away from mineral oil-based compounds toward synthetic alternatives that offer greater efficiency and lower environmental impact further solidifies the market growth for specialized esters like MICA esters.

MICA Esters Market Executive Summary

The MICA Esters Market is characterized by robust growth driven by the acceleration of industrial automation and the premiumization trend in the cosmetics industry. Business trends indicate a strong focus on sustainability, pushing manufacturers toward developing bio-derived MICA ester variants to meet both regulatory requirements and consumer preferences for green chemistry. Key market players are prioritizing capacity expansion and strategic collaborations to secure raw material supply chains and penetrate high-growth regional markets, specifically in Asia Pacific, where manufacturing activity and disposable incomes are rapidly increasing.

Regionally, Asia Pacific (APAC) stands out as the dominant growth engine, fueled by burgeoning automotive manufacturing, expansion of infrastructure, and a massive consumer base driving demand for personal care products. North America and Europe, while mature, exhibit high value consumption, characterized by strict performance specifications, particularly in aerospace and high-end automotive lubrication, thereby commanding premium pricing for specialty MICA ester formulations. Regulatory frameworks such as REACH in Europe continue to shape product development towards safer and more compliant chemical inputs, reinforcing the shift towards high-quality synthetic esters.

Segment trends reveal that the Lubricants and Greases application segment maintains the largest market share due to the indispensability of these esters in synthetic fluid formulations requiring enhanced thermal stability and reduced friction. However, the Cosmetics and Personal Care segment is expected to register the highest Compound Annual Growth Rate (CAGR), driven by the proliferation of specialized skincare, color cosmetics, and sun care products utilizing MICA esters for improved texture, spreadability, and UV stability. The market structure remains moderately consolidated, with fierce competition centered on product purity, customization, and cost-effectiveness in high-volume applications.

AI Impact Analysis on MICA Esters Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the MICA Esters Market typically center on how AI can optimize synthesis processes, enhance quality control, predict demand fluctuations, and accelerate material innovation. Users are keen to understand if AI-driven computational chemistry can shorten the R&D cycle for novel ester structures with specific performance profiles, such as improved biodegradability or exceptional thermal resistance. Furthermore, concerns often arise about the integration complexity and data requirements needed to deploy machine learning models effectively across heterogeneous manufacturing environments.

AI is beginning to revolutionize the chemical manufacturing process for MICA esters, primarily by enabling predictive maintenance and optimizing reaction kinetics. Machine learning algorithms analyze vast datasets encompassing temperature, pressure, catalyst concentration, and yield, allowing producers to fine-tune batch processes in real-time, thereby minimizing waste and maximizing energy efficiency during esterification. This heightened operational efficiency directly impacts profitability and reduces the environmental footprint associated with MICA ester production, addressing key sustainability goals.

Beyond manufacturing, AI and advanced data analytics play a crucial role in supply chain management and demand forecasting. Predictive models help MICA ester producers anticipate shifts in raw material availability and pricing, especially for fatty acids, which are often subject to agricultural volatility. This proactive approach minimizes inventory risk and ensures a stable supply to end-user industries like automotive and cosmetics, which rely heavily on just-in-time inventory systems for specialized chemical inputs.

- AI optimizes esterification reactions by analyzing real-time process parameters, leading to improved purity and yield.

- Machine learning facilitates predictive modeling for novel MICA ester formulations, accelerating R&D for bio-based and high-performance variants.

- AI-driven supply chain platforms enhance transparency and resilience, mitigating risks related to volatile raw material sourcing (e.g., natural oils).

- Predictive maintenance schedules for production equipment, powered by AI, minimize downtime and ensure consistent product quality.

- Data analytics supports precise demand forecasting, aiding manufacturers in optimizing production capacity and reducing market surplus or deficits.

DRO & Impact Forces Of MICA Esters Market

The MICA Esters Market growth is primarily driven by the escalating global demand for synthetic, high-performance fluids, while facing constraints related to raw material price volatility and complex synthesis requirements. Opportunities lie significantly in developing specialized, sustainable ester derivatives catering to niche high-margin applications. The interplay of these forces—Drivers, Restraints, and Opportunities (DRO)—shapes market profitability and competitive dynamics, leading to strategic investments focused on backward integration and technological differentiation, especially concerning bio-based feedstock utilization.

The major drivers include the shift in industrial and automotive lubrication towards synthetic bases offering extended drain intervals and enhanced thermal stability, a necessity for modern high-efficiency engines and machinery. Simultaneously, the restraints are predominantly linked to the fluctuating costs of precursor chemicals, complex purification steps required to achieve pharmaceutical or cosmetic grade purity, and the need for significant capital investment in esterification plants. These restraints often limit market access for smaller players and necessitate robust supply contracts for key raw materials.

The primary opportunities for market expansion involve the development of tailored MICA ester compositions for emerging fields such as electric vehicle (EV) thermal management fluids and advanced battery electrolyte components, leveraging the inherent dielectric and thermal properties of these compounds. The overarching impact forces—including technological advancement in catalysis, evolving environmental policies, and global economic stability—determine the speed and direction of market penetration across different end-use sectors, continuously pushing manufacturers to optimize both cost and functional performance.

Drivers

- Growing demand for high-performance synthetic lubricants in automotive, aerospace, and industrial machinery due to superior thermal and oxidative stability.

- Increasing regulatory pressure favoring biodegradable and non-toxic chemical ingredients, boosting the adoption of bio-based MICA esters.

- Expansion of the personal care and cosmetics industry, where MICA esters are crucial for improving product texture, spreadability, and moisturizing properties.

- Technological advancements in esterification processes leading to higher purity and cost-effective production.

Restraints

- Volatile pricing and supply instability of key raw materials, particularly natural fatty acids and specialty alcohols.

- High capital expenditure required for setting up specialized synthesis and purification facilities.

- Competition from established conventional chemical substitutes, particularly in price-sensitive bulk applications.

- Complex and time-consuming regulatory approval processes, especially for cosmetic and pharmaceutical grade esters.

Opportunities

- Development of MICA esters for niche, high-growth applications such as EV battery cooling fluids and specialized electronics insulation.

- Focus on research and development of novel, ultra-high-performance ester types suitable for extreme pressure and temperature environments.

- Expansion into untapped markets in developing regions with rapid industrial growth and increasing consumer spending on premium cosmetics.

- Strategic partnerships with cosmetic formulators and lubricant producers to co-develop customized ester solutions.

Impact Forces

- Environmental Impact: Strict global regulations (e.g., EU Ecolabel, EPA) pushing for sustainable and low-toxicity esters (High Impact).

- Technological Advancements: Breakthroughs in biocatalysis and continuous flow chemistry improving production efficiency (Medium Impact).

- Economic Cyclicality: Sensitivity to global industrial output, particularly in automotive and construction sectors (Medium Impact).

- Consumer Preferences: Growing demand for natural and clean-label cosmetic ingredients accelerating adoption (High Impact).

Segmentation Analysis

The MICA Esters market is systematically segmented primarily based on Application, Type, and End-Use Industry, reflecting the diverse functional requirements these specialty chemicals fulfill across different economic sectors. The segmentation allows for a granular assessment of market dynamics, identifying which specific ester types are gaining traction due to superior performance attributes or regulatory advantages. For instance, the separation based on Type, such as low molecular weight esters versus high molecular weight esters, is crucial as it dictates suitability for light-duty emollients versus heavy-duty industrial lubrication respectively.

Application segmentation reveals that industrial applications, including lubricants, metalworking fluids, and functional fluids, constitute the core revenue generators due to the high volume consumption and rigorous performance specifications required in industrial machinery and automotive engines. Conversely, the Cosmetics and Personal Care segment, while smaller in volume, often commands higher price points due to the necessity for ultra-high purity and specific sensory profiles, making it a high-growth, high-margin segment.

Geographically, market segmentation is vital for strategic planning, with Asia Pacific dominating in terms of volume due to manufacturing concentration, whereas North America and Europe lead in innovation and the rapid adoption of premium, environmentally certified products. This clear delineation enables manufacturers to tailor their product portfolio and distribution strategies to align with regional regulatory landscapes and dominant industrial practices.

- By Type:

- Low Molecular Weight Esters

- High Molecular Weight Esters

- Specialty Esters (e.g., Bio-based Esters)

- By Application:

- Lubricants and Greases (Automotive, Industrial, Marine)

- Cosmetics and Personal Care (Skincare, Color Cosmetics, Sun Care)

- Functional Fluids (Hydraulic Fluids, Heat Transfer Fluids)

- Coatings and Resins

- Others (Pharmaceuticals, Agrochemicals)

- By End-Use Industry:

- Automotive

- Industrial Manufacturing

- Personal Care and Cosmetics

- Aerospace and Defense

- Chemical and Materials

Value Chain Analysis For MICA Esters Market

The MICA Esters value chain begins with upstream activities involving the sourcing and processing of raw materials, primarily fatty acids (derived from natural oils like palm, coconut, or petrochemical sources) and alcohols. Stability and cost effectiveness at this stage are critical, as raw material costs typically constitute a significant portion of the final product price. Key upstream challenges include managing the sustainability profile of feedstock and ensuring consistent quality, particularly for cosmetic and bio-based grades, necessitating robust sourcing mechanisms and quality verification protocols.

Midstream processing involves complex esterification and purification. Manufacturers employ advanced catalytic processes (heterogeneous or homogeneous catalysis) and sophisticated separation techniques (distillation, filtration) to produce high-purity MICA esters tailored to specific application needs. Investment in continuous flow chemistry technologies is becoming increasingly important to enhance efficiency, reduce energy consumption, and manage exothermic reactions safely. Differentiation at this stage relies heavily on proprietary catalyst systems and process know-how to achieve optimal yield and minimize undesirable side products.

Downstream activities include formulation, distribution, and end-use application. MICA esters are typically sold directly to large B2B clients—such as major lubricant blenders, cosmetic formulators, and chemical distributors. The distribution channel is bifurcated into direct sales for high-volume, customized industrial contracts and indirect sales through specialized chemical distributors who provide technical support and smaller, specialized batches to niche customers. Success in the downstream segment is predicated on strong technical service capabilities and deep application knowledge to assist clients in formulation development.

MICA Esters Market Potential Customers

The primary potential customers for MICA Esters are major players within highly technical and performance-driven industries, specifically those requiring lubricants with superior thermal and oxidative stability, or cosmetic ingredients offering excellent skin feel and emulsification properties. The largest volume consumers are lubricant blending companies and integrated petrochemical firms that use MICA esters as base stocks or high-performance additives in their synthetic oil product lines, targeting applications such as extreme-temperature bearing lubrication or automotive gearbox fluids.

The second major group comprises cosmetic and personal care product manufacturers, ranging from multinational giants producing mass-market skincare to specialized boutique brands focused on clean beauty and premium formulations. These customers prioritize specific physicochemical characteristics, including low irritation, high spreadability, and compatibility with sensitive ingredients, driving demand for ultra-pure, often sustainably sourced, MICA ester grades.

Additionally, specialty chemical formulators serving the aerospace, defense, and electronics industries represent high-value potential customers. These sectors demand bespoke MICA ester formulations for mission-critical applications such as hydraulic fluids in aircraft or dielectric fluids in power electronics, where product failure is unacceptable. The purchasing criteria for these segments are dominated by compliance with stringent industry standards (e.g., API, MIL-SPEC) and highly technical performance specifications rather than just cost efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.55 billion |

| Market Forecast in 2033 | USD 2.45 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ExxonMobil, BASF SE, Croda International Plc, Dow Chemical Company, KLK Oleo, P&G Chemicals, Emery Oleochemicals, Stepan Company, Sasol Limited, Cargill, Inc., Italmatch Chemicals S.p.A., Evonik Industries AG, Lonza Group, Shell Chemicals, Mitsui Chemicals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

MICA Esters Market Key Technology Landscape

The technology landscape of the MICA Esters market is defined by continuous process innovation aimed at improving efficiency, purity, and sustainability. Key technological advancements center around optimizing the esterification reaction, which involves combining alcohols and fatty acids. Traditional batch processes are being rapidly supplemented by continuous flow reactors, which offer superior control over reaction parameters, resulting in narrower product distribution, reduced energy consumption, and inherently safer operation, especially when dealing with high-temperature reactions.

Catalysis science is another critical area of focus. Manufacturers are moving away from traditional mineral acid catalysts towards more selective, environmentally friendly alternatives such as heterogeneous solid acid catalysts or enzymatic (biocatalytic) methods. Enzymatic esterification, in particular, allows for highly specific synthesis under milder conditions, minimizing side-product formation and generating esters with enhanced thermal stability and purity, crucial for premium cosmetic and food-grade applications, aligning with green chemistry principles.

Furthermore, advanced purification technologies, including short-path distillation and specialized membrane filtration, are essential for producing the ultra-high purity MICA esters demanded by high-end industries like aerospace and personal care. These technologies ensure the removal of residual catalyst, unreacted raw materials, and color bodies, thereby meeting stringent specifications for color stability, odor, and toxicological profiles. Investment in these purification capabilities is a major strategic differentiator among top-tier MICA ester suppliers, enabling them to command premium pricing for specialized grades.

Regional Highlights

Regional dynamics within the MICA Esters Market are highly heterogeneous, reflecting variances in industrial maturity, regulatory stringency, and consumer expenditure patterns. Asia Pacific (APAC) represents the largest and fastest-growing market due to robust economic growth, massive industrial expansion, particularly in automotive production in China and India, and surging demand for localized personal care and cosmetic manufacturing. The region benefits from lower production costs and increasing disposable income leading to higher consumption of specialty end products.

Europe holds a significant market share, characterized by its mature industrial base and, critically, the highest level of regulatory control (REACH). This regulatory environment necessitates the use of environmentally preferred and highly documented chemical ingredients, favoring premium, bio-based MICA esters over conventional alternatives. European demand is driven by the aerospace industry, advanced industrial lubrication, and a highly sophisticated cosmetics sector prioritizing sustainability and compliance.

North America is a key market for innovation and high-value applications, particularly in synthetic lubricants for energy and defense sectors. Demand here is driven by performance, with strong uptake of specialized esters in hydraulic fluids and compressor oils required for fracking operations and advanced manufacturing. The focus remains on product efficiency and adherence to strict performance standards (e.g., OEM specifications), promoting robust investment in R&D and proprietary formulation technologies.

- Asia Pacific (APAC): Dominant market share and fastest growth; driven by industrialization, automotive production expansion, and rising middle-class consumer spending on cosmetics. Key countries include China, India, and Japan.

- Europe: High value market characterized by stringent environmental regulations (REACH); strong demand from advanced manufacturing, aerospace, and high-end natural/organic cosmetic sectors. Focus on bio-based and highly certified specialty esters.

- North America: Mature market focused on high-performance lubrication for oil & gas, defense, and high-tech manufacturing. Significant investment in R&D for next-generation synthetic fluids and EV applications.

- Latin America: Emerging market with increasing industrial activity, particularly in Brazil and Mexico. Growth is tied to local automotive assembly and expanding industrial maintenance requirements.

- Middle East and Africa (MEA): Growth driven by infrastructure projects, expanding petrochemical refining capacity, and demand for specialty lubricants in the region's vast energy sector.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the MICA Esters Market.- ExxonMobil

- BASF SE

- Croda International Plc

- Dow Chemical Company

- KLK Oleo

- P&G Chemicals

- Emery Oleochemicals

- Stepan Company

- Sasol Limited

- Cargill, Inc.

- Italmatch Chemicals S.p.A.

- Evonik Industries AG

- Lonza Group

- Shell Chemicals

- Mitsui Chemicals

- Vantage Specialty Chemicals

- Daikin Industries, Ltd.

- Lanxess AG

- Ashland Global Holdings Inc.

- Innospec Inc.

Frequently Asked Questions

Analyze common user questions about the MICA Esters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving the MICA Esters Market growth?

The market growth is primarily driven by the increasing global demand for high-performance synthetic lubricants in the automotive and industrial sectors, alongside the rapid expansion of the cosmetics and personal care industry where MICA esters function as premium emollients and texture enhancers.

How do MICA Esters contribute to sustainability in industrial applications?

MICA Esters, especially bio-based variants, contribute to sustainability by offering superior thermal stability, which extends the operational life of lubricants (longer drain intervals), reducing overall oil consumption. Their inherent biodegradability also minimizes environmental impact compared to conventional mineral oil derivatives.

Which geographical region holds the largest market share for MICA Esters?

Asia Pacific (APAC) currently holds the largest market share, fueled by massive industrialization, high volume automotive manufacturing, and burgeoning consumer demand for specialty chemicals in countries like China and India.

What is the main challenge facing MICA Esters manufacturers?

The primary challenge is the significant price volatility and supply instability of key raw materials, particularly the natural fatty acids and specialty alcohols required for the esterification process, which directly impacts production costs and profit margins.

Are MICA Esters used in Electric Vehicles (EVs)?

Yes, MICA Esters are increasingly being developed for specialized applications in Electric Vehicles, particularly as components in dielectric fluids for battery thermal management systems and high-efficiency e-transmission fluids, leveraging their excellent thermal and electrical properties.

The MICA Esters market is highly influenced by global trends toward energy efficiency and clean chemical formulation. Manufacturers are continuously investing in proprietary catalytic technologies to enhance product purity and yield. The shift toward natural and sustainable sourcing of raw materials, such as utilizing non-GMO or sustainably certified plant-derived fatty acids, is a critical competitive necessity, particularly in the European and North American markets where regulatory scrutiny and consumer awareness are highest. Furthermore, the convergence of specialty ester chemistry with advanced material science is paving the way for applications in cutting-edge fields like 3D printing binders and specialized encapsulation techniques for pharmaceuticals, promising long-term revenue diversification.

The complexity of synthesizing specific MICA ester structures with precise chain lengths and branching patterns necessitates a high degree of technical expertise and specialized manufacturing infrastructure. This technical barrier to entry contributes to the market's moderate consolidation. Leading players often possess integrated value chains, from raw material procurement (e.g., access to oleochemical processing facilities) through to final application testing and certification. This integration provides a significant cost advantage and ensures consistent quality control, which is paramount for sensitive end-use sectors like aerospace and personal care. Smaller, specialized firms often thrive by focusing on niche, ultra-high-purity grades or offering custom synthesis services tailored to specific client formulation needs.

Looking ahead, the market is poised for disruption from bio-engineering techniques. Advances in synthetic biology could potentially lead to the use of engineered microbes or algae to produce specific fatty acid precursors more efficiently and sustainably than conventional agricultural methods. While still in nascent stages, this bio-route represents a significant long-term opportunity to decouple MICA ester production from volatile commodity markets and enhance their overall environmental profile, thereby securing future growth in highly regulated and environmentally conscious markets globally.

The demand for MICA Esters in functional fluids, specifically hydraulic and heat transfer fluids, is accelerating due to the push for lighter and more robust machinery across industrial sectors. In aviation, for example, MICA esters are valued for their resistance to high shear stress and compatibility with seals and elastomeric components, which extends the service life of critical systems. Industrial maintenance managers are increasingly recognizing the total cost of ownership benefits associated with synthetic fluids, driving a gradual but sustained shift away from cheaper, less durable mineral oil-based alternatives, thereby ensuring a stable demand base for high-quality MICA ester products.

In the cosmetics segment, the shift towards multifunctional ingredients is favoring MICA esters. They provide not only emollience and moisturizing benefits but also act as efficient solubilizers for UV filters and active pharmaceutical ingredients (APIs) in skincare formulations. This versatility allows formulators to reduce the total number of ingredients, aligning with the clean label movement preferred by consumers. Marketing strategies of key cosmetic raw material suppliers now emphasize the natural origin and sensory advantages of MICA esters, positioning them as premium substitutes for synthetic silicones and traditional petroleum jelly.

The competitive landscape is characterized by intense R&D investment focused on product diversification. Companies are not only refining established MICA ester types but also creating hybrid structures—such as polyol esters or complex esters derived from renewable sources—to meet evolving regulatory standards and specialized performance demands, particularly in extreme temperature environments. Patent activity related to novel ester compositions and sustainable synthesis routes serves as a key indicator of market direction and future competitive advantage, highlighting the strategic importance of intellectual property in maintaining market leadership.

Geopolitical stability and trade policies also exert a notable impact on the MICA Esters market, particularly concerning the movement of raw materials (like palm oil derivatives) and finished specialty chemicals across borders. Disruptions in major shipping routes or the implementation of protective tariffs can significantly inflate costs and extend lead times, forcing regional market players to focus on local or localized supply chains. Manufacturers with geographically diversified production facilities are better positioned to mitigate these macro-economic risks and maintain consistent global pricing and supply stability.

The rigorous process requirements for MICA ester manufacturing, especially the need for high-vacuum and controlled-atmosphere conditions during distillation, limit the number of global participants capable of producing high-specification products reliably. Quality certifications, such as ISO 9001, specific automotive certifications (e.g., IATF 16949), and cosmetic Good Manufacturing Practice (GMP) standards, act as essential gatekeepers. Compliance with these high standards ensures product consistency and traceability, reinforcing the dominance of established multinational chemical conglomerates in the specialty ester space.

Furthermore, digital transformation, as touched upon in the AI analysis, is enhancing market agility. The use of Internet of Things (IoT) sensors within production facilities enables continuous monitoring of reaction vessels, leading to data-driven process adjustments. This capability is vital for managing the complex interplay between reaction time, catalyst loading, and final product specifications, which are highly sensitive in MICA ester synthesis. The adoption of digital twins for simulating new plant designs and optimization scenarios is expected to further compress the time-to-market for novel MICA ester grades.

The application of MICA esters in metalworking fluids (MWFs) is another critical segment showing strong growth. As modern machining processes become faster and more precise, the demand for MWFs that offer superior lubricity, corrosion inhibition, and cooling capabilities increases. MICA esters are utilized as base fluids in synthetic and semi-synthetic MWFs, providing low-foaming properties and excellent health and safety profiles compared to traditional chlorinated paraffins or sulfurized oils. This shift is particularly pronounced in aerospace and precision engineering industries requiring zero-defect components.

Finally, the long-term outlook for the MICA Esters Market remains positive, underpinned by their fundamental role as high-performance building blocks in formulations across diverse sectors undergoing technological evolution. While cost pressures from raw material sources will persist, the increasing value proposition of MICA esters—driven by their superior functional characteristics and alignment with sustainability mandates—ensures their continued preference over cheaper, less effective alternatives in critical applications globally.

The specialty nature of MICA Esters means they often replace traditional mineral oil components in high-stress environments where performance failure is costly or catastrophic. This includes applications in wind turbine gearbox lubrication, where fluid stability over a 20-year lifespan is expected, and in deep-sea drilling operations requiring fluids that can withstand extreme pressure and temperature variations without degrading. The engineering precision required for these uses dictates that only high-quality synthetic esters, often derived using advanced MICA ester chemistry, are suitable, thus maintaining the market’s premium valuation for specialized grades.

The regulatory framework governing chemical use worldwide continues to evolve, compelling manufacturers to continually update their safety and toxicological data. Compliance with regulations like the Toxic Substances Control Act (TSCA) in the US and the requirements set by the European Chemicals Agency (ECHA) significantly influences product development cycles. Companies that proactively invest in toxicology testing and achieve rapid registration for new MICA ester molecules gain a crucial competitive edge, particularly when launching innovative, bio-derived products into sensitive markets like personal care and food packaging lubricants.

Furthermore, consumer perception, particularly in the personal care segment, is acting as a potent driver for MICA esters. The clean beauty movement demands ingredients that are transparently sourced, derived from renewable resources, and free from perceived harmful chemicals. MICA esters derived from natural vegetable oils align well with these demands, allowing brands to formulate high-performance products that meet sensory expectations while adhering to strict ethical and environmental sourcing policies, differentiating them from synthetic petrochemical derivatives.

Investment in production capacity remains skewed towards Asia Pacific, particularly in countries with favorable government policies supporting chemical manufacturing and access to abundant oleochemical feedstocks. However, leading Western manufacturers maintain R&D dominance, focusing their high-cost production facilities on developing proprietary, high-margin specialty esters and formulating blends that solve highly complex technical challenges for specific clients in the aerospace and advanced industrial sectors. This dual geographical focus—volume growth in APAC and innovation leadership in Europe/North America—defines the current market strategy for multinational MICA ester producers.

The technological adoption of MICA esters in the burgeoning electric vehicle market is accelerating rapidly. As EVs require fluids that can simultaneously cool high-voltage batteries and lubricate sensitive gearboxes without conducting electricity, MICA esters with optimal dielectric strength and thermal properties are becoming indispensable. This application area represents a significant future growth trajectory, requiring manufacturers to rapidly adjust their product specifications and undergo extensive testing to secure approval from major EV original equipment manufacturers (OEMs).

Finally, the growth of the overall industrial economy is a fundamental determinant of MICA ester demand. As global manufacturing output, construction activity, and maritime transportation recover and expand, the requirement for high-quality industrial lubricants and functional fluids will inevitably rise. This macroscopic economic linkage ensures that while the market is susceptible to global downturns, its inherent connection to core industrial processes provides long-term stability and resilience, positioning MICA esters as a vital component of modern industrial chemistry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager