Microbial and Bacterial Fibre Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433557 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Microbial and Bacterial Fibre Market Size

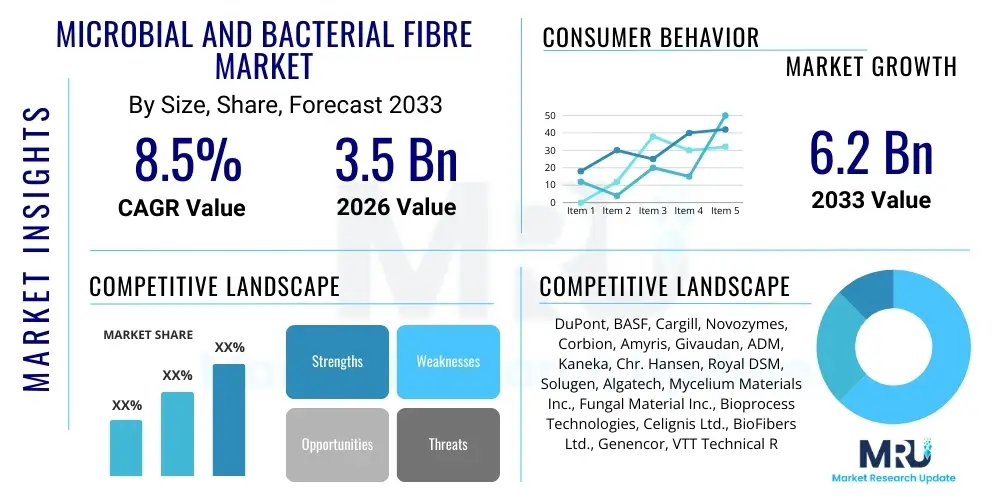

The Microbial and Bacterial Fibre Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2033.

Microbial and Bacterial Fibre Market introduction

The Microbial and Bacterial Fibre Market encompasses the production and utilization of structural and functional fibers synthesized through microbial fermentation processes, primarily utilizing bacteria, fungi, or algae. These biologically derived materials offer superior properties compared to traditional plant-based or synthetic fibers, including high purity, biodegradability, exceptional mechanical strength, and unique surface area characteristics. Key products within this sphere include bacterial cellulose, microbial polysaccharides (such as chitin and chitosan derivatives), and various biocompatible polymers, driven by advancements in synthetic biology and precision fermentation techniques. This market stands at the intersection of biotechnology, materials science, and sustainability, positioning these fibres as critical components in next-generation industrial applications.

Major applications for microbial and bacterial fibres span critical high-value industries, notably in advanced wound care and medical implants due to their high biocompatibility and ability to facilitate tissue regeneration. In the food and beverage sector, they are utilized as texturizing agents, stabilizers, and functional dietary supplements. Furthermore, the textile and consumer goods industries are increasingly adopting these fibres for sustainable and performance-enhancing fabrics, capitalizing on their strength-to-weight ratio and eco-friendly production methods. The versatility and customization potential inherent in microbial fermentation allow manufacturers to tailor fibre characteristics, opening doors to highly specialized applications.

The market is primarily driven by the escalating global demand for sustainable, circular economy solutions, where microbial fibres offer a renewable and low-carbon alternative to petrochemical-derived materials. Increased research investment in bio-based material development, coupled with supportive regulatory frameworks encouraging biodegradable product adoption, further propels market expansion. The functional benefits, such as superior moisture retention, inherent antimicrobial properties, and controllable morphology, are significant driving factors ensuring steady adoption across sophisticated end-user domains like biomedical engineering and high-performance filtration systems. These materials address core industry challenges related to environmental impact and product performance simultaneously.

Microbial and Bacterial Fibre Market Executive Summary

The Microbial and Bacterial Fibre Market is undergoing rapid transformation, characterized by significant investment in bioreactor technology and scale-up infrastructure, driven by the need to achieve cost parity with traditional materials. Current business trends indicate a strong move towards strategic partnerships between biotechnology firms and large industrial manufacturers, particularly in the textile and medical device sectors, aiming to streamline production and commercialization pathways. Innovation is centered around enhancing microbial strains for higher yield and purity, focusing on developing fibers with tailored functionalities, such as enhanced flexibility or specialized drug-delivery capabilities, reflecting a shift from commodity production to high-value specialty materials.

Regionally, North America and Europe maintain dominance, fueled by robust biotech research ecosystems, high consumer awareness regarding sustainable products, and favorable governmental funding for bio-based material innovation. However, the Asia Pacific region is emerging as the fastest-growing market, primarily due to expanding industrial applications in China, Japan, and South Korea, coupled with significant governmental initiatives promoting local production of high-performance biomaterials. This regional growth is supported by increasing investments in advanced manufacturing capabilities capable of handling large-scale fermentation processes required for microbial fibre production.

Segment-wise, bacterial cellulose dominates the market due to its proven efficacy in medical applications and growing use in premium acoustic membranes and electronics. The application segment is heavily tilted toward the medical and healthcare domain, benefiting from the superior biocompatibility and ease of sterilization these fibres offer. Looking forward, the food and beverage segment is projected to experience accelerated growth, driven by consumer demand for natural, functional ingredients and the utility of microbial polysaccharides as high-quality, plant-based alternatives to animal-derived stabilizers and thickeners. Furthermore, sustainability requirements are driving the strong integration of microbial fibres into the textile supply chain.

AI Impact Analysis on Microbial and Bacterial Fibre Market

User inquiries regarding AI's impact on the Microbial and Bacterial Fibre Market primarily focus on optimization, discovery, and quality control. Common questions center on how Artificial Intelligence (AI) and Machine Learning (ML) can accelerate the discovery of novel microbial strains capable of producing superior fibres, how production yields can be maximized through real-time bioreactor monitoring, and the role of computational models in predicting the physical and chemical properties of new biopolymers before costly lab synthesis. Users expect AI to significantly reduce the time-to-market for novel bacterial fibre types and ensure rigorous quality consistency at commercial scale, minimizing batch variations inherent in biological processes. The key themes revolve around efficiency gains, predictive analytics for strain engineering, and automated process management.

- AI-driven optimization of fermentation parameters (temperature, pH, nutrient feed) in bioreactors to maximize fibre yield and purity.

- Machine learning models for rapid screening and selection of high-performance microbial strains (e.g., bacteria or fungi) capable of superior fibre synthesis.

- Computational chemistry and materials informatics used to predict the mechanical, thermal, and surface properties of newly synthesized microbial polymers.

- Automation of quality control processes using computer vision and sensor technology to ensure structural uniformity and detect impurities in fibre batches.

- Predictive maintenance analytics applied to large-scale fermentation equipment, minimizing downtime and optimizing operational efficiency.

- Accelerated discovery of novel enzyme pathways and synthetic biology circuits that can enhance or modify the structural characteristics of bacterial fibres.

DRO & Impact Forces Of Microbial and Bacterial Fibre Market

The dynamics of the Microbial and Bacterial Fibre Market are governed by powerful opposing forces, summarized by Drivers, Restraints, and Opportunities (DRO). The primary drivers stem from critical global needs: the push for sustainable, circular materials and the demanding specifications of advanced biomedical and textile applications where performance outweighs cost. However, market adoption faces significant restraints, chiefly the high initial capital expenditure required for fermentation facilities and the persistent challenge of achieving cost-effective production scaling compared to mature petrochemical processes. These high production costs remain a critical barrier to widespread adoption in low-margin sectors.

Opportunities in this sector are vast, particularly in exploring next-generation functional textiles, personalized medicine (such as bio-scaffolds tailored to patient needs), and novel applications in high-density energy storage membranes. Furthermore, the ability to utilize low-cost or waste feedstocks (like industrial byproducts) for microbial fermentation presents a significant opportunity to drastically reduce raw material costs and enhance the overall sustainability profile of the resulting fibres. Addressing the complexity of regulatory approval, particularly for food-contact and medical applications, also represents a key area of strategic focus for market players.

Impact forces acting on this market include intensifying regulatory pressure favoring biodegradable materials, which acts as a positive externality boosting demand. Conversely, fierce competition from established synthetic polymer manufacturers who are continually improving their sustainability credentials puts downward pressure on price points for bio-based alternatives. Technological breakthroughs in synthetic biology—specifically gene editing tools like CRISPR—are dramatically increasing the speed and efficiency of optimizing microbial strains, acting as a major internal force driving innovation and potential cost reduction over the long term. Investor confidence in green technology further sustains the high level of R&D funding essential for commercialization.

Segmentation Analysis

The Microbial and Bacterial Fibre Market is meticulously segmented based on the nature of the fibre produced, the source microorganism, and the ultimate industrial application, allowing for targeted product development and market penetration strategies. Analyzing these segments is essential as the performance metrics and regulatory requirements vary drastically—for instance, medical-grade bacterial cellulose requires ultra-high purity, while textile-grade fibres prioritize tensile strength and scalability. This segmentation reflects the varied technological maturity and commercial viability across different product types and application fields, with distinct growth trajectories observed between commodity and specialty applications.

Microbial fibres are broadly classified by Type, focusing on core structural components derived from the microorganism, such as cellulose, chitin derivatives, and various non-structural polysaccharides. Source segmentation distinguishes between fibres produced by bacteria, fungi (mycelium-based materials), and algae, each offering unique material characteristics and requiring specific fermentation protocols. The comprehensive segmentation by Application provides the clearest indicator of market value, ranging from mature uses in biomedical and filtration to rapidly emerging areas such as sustainable packaging and consumer electronics components, demonstrating the breadth of end-user potential for these bio-based materials.

- Type:

- Bacterial Cellulose (BC)

- Microbial Chitin and Chitosan

- Microbial Polysaccharides (e.g., Hyaluronic Acid, Xanthan Gum derivatives used as stabilizers/fillers)

- Mycelium-based Materials

- Polyhydroxyalkanoates (PHAs) derived Fibres

- Source:

- Bacteria (e.g., Acetobacter, Komagataeibacter)

- Fungi (Yeast, Molds)

- Algae and Microalgae

- Application:

- Medical and Healthcare (Wound Dressings, Tissue Engineering Scaffolds, Implants)

- Textile and Apparel (Sustainable Fabrics, High-Performance Garments)

- Food and Beverage (Thickeners, Stabilizers, Functional Ingredients)

- Cosmetics and Personal Care

- Filtration and Environmental Remediation

- Electronics and Acoustics

Value Chain Analysis For Microbial and Bacterial Fibre Market

The value chain for microbial and bacterial fibres begins with upstream activities focused heavily on research and feedstock management. Upstream analysis involves the selection and genetic optimization of microbial strains (bacteria, fungi) to maximize fibre yield and control morphology, often utilizing sophisticated synthetic biology tools. The primary raw material input is the feedstock, which traditionally includes glucose or other sugar sources, but increasingly utilizes sustainable alternatives like lignocellulosic biomass or industrial wastewater to improve cost economics and sustainability. Efficient, sterile preparation of growth media and large-scale fermentation protocols define this initial stage, requiring substantial intellectual property protection related to strain technology.

Midstream activities center on the core manufacturing process, which includes large-scale fermentation in specialized bioreactors, followed by complex harvesting, purification, and drying processes to isolate the resulting fibre. The purification stage is critical, especially for medical-grade applications, as it ensures the removal of cellular residues and toxins. Subsequent processing involves converting the raw microbial material into its final form, such as non-woven sheets, hydrogels, or compounded pellets suitable for manufacturing textiles, medical devices, or food additives. Energy efficiency and waste management during fermentation are key determinants of overall production cost and environmental footprint.

Downstream analysis focuses on distribution channels and end-user integration. For high-volume applications like textiles or food stabilizers, distribution often involves bulk sales to intermediate processors or major consumer goods companies. Conversely, highly specialized products, such as bio-scaffolds for regenerative medicine, utilize direct sales models or specialized distributors capable of handling strict regulatory compliance and cold chain requirements. The differentiation between direct sales (common for specialty materials requiring technical support) and indirect sales (common for commodity applications) significantly impacts market reach and profit margins. Successful commercialization hinges on effective technical collaboration with end-users to ensure seamless integration of these novel fibres into existing manufacturing lines.

Microbial and Bacterial Fibre Market Potential Customers

Potential customers for microbial and bacterial fibres represent a diverse spectrum of high-technology and consumer-facing industries, all seeking high-performance, sustainable, or biocompatible raw materials. In the medical sector, primary buyers are pharmaceutical companies, medical device manufacturers, and specialized wound care providers who require materials with high purity, excellent mechanical integration, and minimal immunological response for applications such as tissue engineering, advanced wound dressings, and internal sutures. These customers prioritize regulatory compliance and verified scientific performance over marginal cost differences, driving demand for high-grade bacterial cellulose and engineered microbial chitin.

Within the consumer realm, major target customers include multinational apparel companies and fast-moving consumer goods (FMCG) corporations committed to ambitious sustainability goals. Textile manufacturers seek microbial fibres (like those derived from mycelium or bacterial cellulose) as alternatives to cotton or synthetic polymers to produce eco-friendly, high-performance clothing with enhanced properties such as moisture-wicking or inherent biodegradability. Furthermore, large food processors and functional ingredient suppliers are key buyers, utilizing microbial polysaccharides as stabilizers, fat replacements, or texturizers in dairy alternatives, sauces, and baked goods, catering to the clean label and plant-based trends.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 6.2 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont, BASF, Cargill, Novozymes, Corbion, Amyris, Givaudan, ADM, Kaneka, Chr. Hansen, Royal DSM, Solugen, Algatech, Mycelium Materials Inc., Fungal Material Inc., Bioprocess Technologies, Celignis Ltd., BioFibers Ltd., Genencor, VTT Technical Research Centre of Finland. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Microbial and Bacterial Fibre Market Key Technology Landscape

The technological landscape of the Microbial and Bacterial Fibre Market is dominated by advancements in large-scale precision fermentation and genetic engineering, which are crucial for commercial viability. Precision fermentation involves using highly controlled bioreactor systems to ensure optimal growth conditions for specialized microorganisms, thereby maximizing the yield and uniformity of the secreted fibres. Key innovations in this area include continuous fermentation processes and enhanced downstream processing techniques, such as membrane filtration and supercritical fluid extraction, designed to achieve the high purity levels required for sensitive applications like bio-scaffolds and pharmaceuticals. Continuous improvements in reactor design, including air-lift and stirred-tank bioreactors optimized for high-viscosity media, are central to scaling production.

Synthetic biology and metabolic engineering represent another critical technological pillar. Researchers utilize advanced genetic modification tools (like CRISPR/Cas9) to optimize microbial strains—such as Acetobacter xylinum for cellulose or specific yeast strains for polysaccharides—by enhancing their biosynthetic pathways or enabling them to utilize cheaper, non-food feedstocks. These genetic modifications aim not only for increased yield but also for the incorporation of novel functionalities directly into the fiber structure, such as drug-loading capabilities or specialized binding sites, enabling smart material creation. This engineering approach is vital for overcoming the biological limitations inherent in wild-type strains.

Furthermore, novel material fabrication and composite integration technologies are expanding the utility of these fibres. Techniques like electrospinning and 3D bioprinting are increasingly used to assemble purified microbial fibers into complex, hierarchical structures, mimicking natural tissues for regenerative medicine applications. The development of hybrid materials—combining bacterial cellulose with synthetic polymers or inorganic nanoparticles—is creating composites with tailored mechanical, electrical, and thermal properties. These advanced fabrication methods are crucial for transitioning microbial fibres from laboratory curiosities into functional components in complex industrial systems.

Regional Highlights

- North America: This region holds a leading position, driven by extensive R&D spending, particularly in the U.S., focusing on biomedical applications and sustainable textiles. Strong governmental support, favorable venture capital investment in synthetic biology startups, and the presence of major biotechnology and pharmaceutical companies ensure rapid adoption of high-value microbial fibres. The stringent regulatory environment for medical devices also guarantees demand for high-purity, well-characterized biomaterials.

- Europe: Characterized by stringent environmental regulations and a strong public push toward circular economy practices, Europe is a major adopter of microbial fibres, particularly in the food & beverage sector (as natural stabilizers) and sustainable fashion. Germany, the UK, and the Netherlands lead in industrial-scale fermentation capacity and are pioneering the commercialization of PHAs and mycelium-based materials.

- Asia Pacific (APAC): Expected to exhibit the highest growth rate during the forecast period. This growth is fueled by increasing industrialization, particularly in China and India, rising middle-class disposable income driving demand for high-quality cosmetics and textiles, and significant government investments in bio-based manufacturing technologies. Japan and South Korea are key hubs for advanced research in bacterial cellulose for electronics and acoustic components.

- Latin America (LATAM): Growth in this region is primarily driven by the utilization of readily available agricultural byproducts as inexpensive fermentation feedstocks. Brazil, in particular, shows promise in leveraging its bio-economy to produce microbial fibres for internal consumption, focusing initially on low-cost, high-volume applications like packaging and functional food ingredients.

- Middle East and Africa (MEA): This region is currently a smaller contributor, but nascent growth is emerging, driven by diversification efforts away from petrochemicals. Focus areas include using microbial fibres for water purification and environmental remediation projects, supported by investments in sustainable infrastructure and biotechnology research in nations like Saudi Arabia and the UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Microbial and Bacterial Fibre Market.- DuPont de Nemours, Inc.

- BASF SE

- Cargill, Incorporated

- Novozymes A/S (part of Novonesis)

- Corbion N.V.

- Amyris, Inc.

- Givaudan SA

- Archer Daniels Midland (ADM) Company

- Kaneka Corporation

- Chr. Hansen Holding A/S

- Royal DSM (now part of DSM-Firmenich)

- Solugen, Inc.

- Algatech (now part of Solabia Group)

- Mycelium Materials Inc.

- BioFibers Ltd.

- Fungal Material Inc.

- Celignis Ltd.

- VTT Technical Research Centre of Finland

- Bioprocess Technologies

- Genencor (a segment of IFF)

Frequently Asked Questions

Analyze common user questions about the Microbial and Bacterial Fibre market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of bacterial cellulose in the medical field?

Bacterial cellulose is highly valued in medicine for advanced wound dressings, temporary skin substitutes, burn treatments, and as biocompatible scaffolds in tissue engineering due to its high purity, exceptional water retention capacity, and favorable mechanical properties for promoting cellular adhesion and regeneration.

How do microbial fibres contribute to sustainability in the textile industry?

Microbial fibres offer significant sustainability advantages by being inherently biodegradable, relying on non-petrochemical feedstocks (often waste streams), and requiring less water and land than traditional crops like cotton. They enable the creation of high-performance, circular textiles.

What key challenges restrict the wider adoption of microbial fibres?

The primary restriction is the high cost of production, driven by the substantial capital investment required for large-scale, sterile fermentation facilities (bioreactors) and complex downstream purification processes needed to achieve industrial volumes and regulatory compliance.

Which microbial fibre segment is anticipated to exhibit the fastest growth?

The Microbial Chitin and Chitosan derivatives segment is expected to show accelerated growth, particularly driven by their use in functional food ingredients, pharmaceuticals, and advanced water filtration/environmental remediation applications, capitalizing on their natural antimicrobial and binding capabilities.

How does synthetic biology enhance microbial fibre production?

Synthetic biology is crucial for market growth as it allows researchers to genetically engineer microbial strains for superior performance—achieving higher fibre yields, enabling the utilization of cheaper raw materials (waste feedstocks), and modifying the structural properties of the fibre for specific end-user requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager