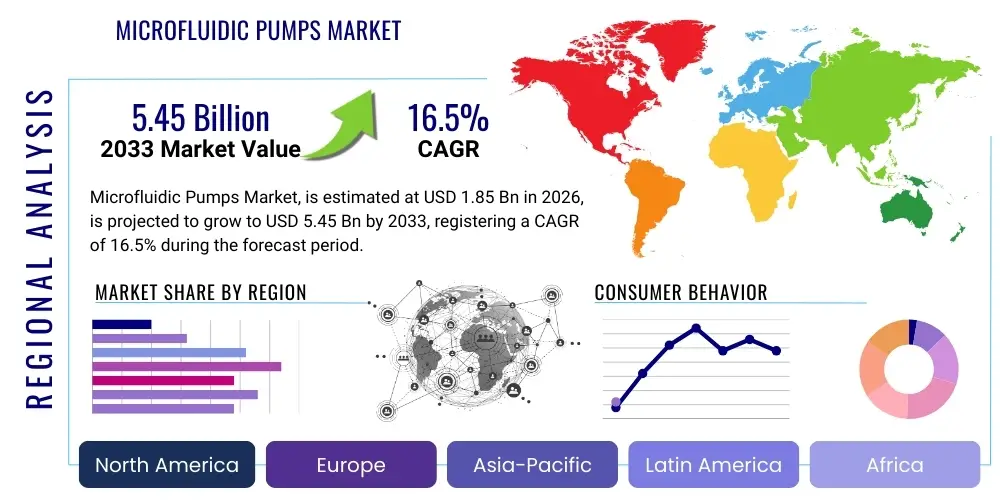

Microfluidic Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436843 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Microfluidic Pumps Market Size

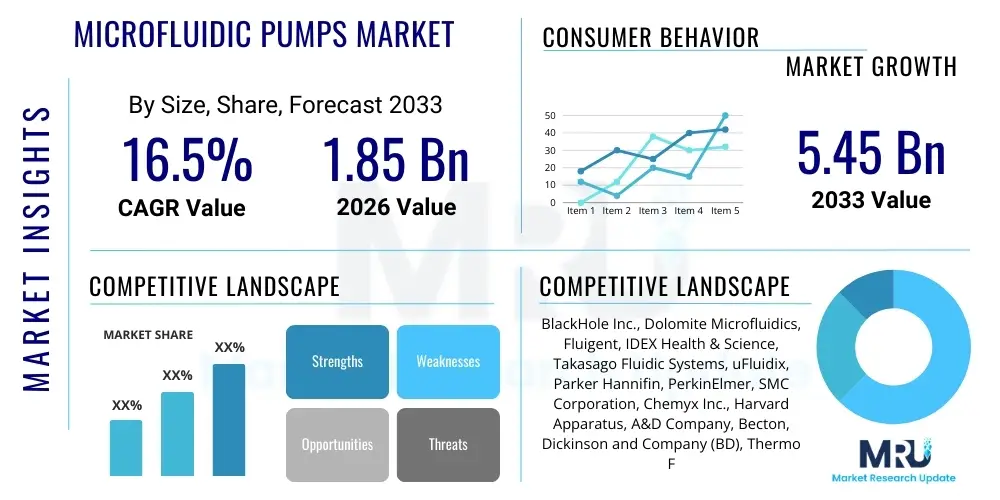

The Microfluidic Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 16.5% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $5.45 Billion by the end of the forecast period in 2033.

Microfluidic Pumps Market introduction

The Microfluidic Pumps Market encompasses devices engineered for the precise control and manipulation of minute volumes of fluids, typically in the range of nanoliters to microliters, within microchannels. These systems are foundational components in Micro-Total-Analysis Systems (µTAS) and lab-on-a-chip devices, enabling sophisticated chemical and biological experiments on a miniature scale. The technology offers unparalleled precision, reduced reagent consumption, and faster analysis times compared to traditional laboratory methodologies. The versatility of microfluidic pumps—ranging from mechanical displacement pumps (syringe and peristaltic) to non-mechanical pumps (electrokinetic and acoustic)—allows for their integration across diverse scientific and industrial platforms, particularly in areas requiring high throughput and miniaturization.

Microfluidic pumps are essential for achieving laminar flow control, precise droplet generation, and efficient mixing in microscale environments. Major applications span clinical diagnostics, drug discovery, genomics, proteomics, and environmental monitoring. In diagnostics, they enable Point-of-Care (PoC) testing devices by automating complex sample handling and assay steps in a portable format. In drug discovery, these pumps are critical for high-throughput screening, compound delivery, and mimicking physiological conditions for organ-on-a-chip models. The ability to precisely meter and mix viscous or sensitive biological fluids without contamination or shear stress is a significant benefit driving their adoption.

Driving factors for this market include the increasing demand for advanced diagnostic tools, particularly in infectious disease detection and personalized medicine, which necessitate rapid, low-volume testing. Furthermore, the relentless pursuit of miniaturization in laboratory equipment and automation, coupled with significant investments in biomedical research and development, particularly concerning microfluidic chip fabrication and integration, are major catalysts. The operational benefits—such as cost-effectiveness due to reduced sample volume and enhanced portability—further solidify the market's robust growth trajectory globally.

Microfluidic Pumps Market Executive Summary

The Microfluidic Pumps Market is characterized by rapid technological evolution, driven by the shift from external benchtop pumps to integrated, chip-level pumping solutions, enhancing system portability and automation capabilities. Business trends indicate strong merger and acquisition activity focused on consolidating expertise in fabrication technologies (like 3D printing for microchannels) and expanding application portfolios, especially into high-growth areas such as single-cell analysis and rapid molecular diagnostics. Key market players are concentrating on developing software-controlled, closed-loop systems that offer real-time feedback and high precision, addressing the stringent requirements of pharmaceutical R&D and clinical settings. The push towards low-power, disposable microfluidic cartridges is defining the competitive landscape, prioritizing ease of use and reduced cross-contamination risk.

Regional trends highlight North America and Europe as dominant markets, primarily due to established healthcare infrastructures, substantial government funding for life sciences research, and the presence of major biotechnology and pharmaceutical companies that are early adopters of advanced automation. However, the Asia Pacific (APAC) region is forecasted to exhibit the highest growth rate, fueled by improving healthcare access, increasing governmental focus on domestic pharmaceutical manufacturing, and the rising prevalence of chronic diseases necessitating rapid diagnostic penetration. Countries like China and India are becoming pivotal manufacturing and consumption hubs, fostering local innovation in cost-effective microfluidic solutions tailored for resource-limited settings. The demand surge in APAC is particularly notable in applied diagnostics and agriculture technology (AgriTech) where rapid, field-deployable testing is essential.

Segment trends demonstrate the dominance of the mechanical pump segment, particularly syringe pumps, due to their robust control, high pressure generation, and historical reliability in laboratory settings, though non-mechanical pumps are rapidly gaining traction due to superior integration potential within disposable chips. By application, the In Vitro Diagnostics (IVD) segment holds the largest market share, driven by the global expansion of decentralized testing and the development of sophisticated companion diagnostics. The pharmaceutical and biotechnology segment is expected to show the highest growth rate, propelled by the increasing complexity of drug screening processes and the adoption of advanced cell culture techniques, such as microfluidic bioreactors and organ-on-a-chip platforms, which mandate highly accurate fluid control for long-term viability studies.

AI Impact Analysis on Microfluidic Pumps Market

User inquiries regarding AI's influence on the Microfluidic Pumps Market primarily center on how artificial intelligence and machine learning (ML) algorithms can enhance the functional reliability, precision, and automation level of these systems. Common themes include the potential for AI to optimize pump performance parameters (such as flow rate consistency under varying conditions), predict and compensate for fluidic anomalies (like bubble formation or clogging), and accelerate experimental design in microfluidic applications. Users are concerned with the complexity of integrating sophisticated AI models into compact, low-power systems and seek clarity on how AI might streamline high-throughput screening workflows by automating data interpretation and decision- making regarding fluid handling sequences. Expectations revolve around AI transforming current open-loop manual systems into closed-loop, self-regulating microfluidic ecosystems.

The convergence of AI with microfluidic technologies is pivotal for realizing the full potential of complex lab-on-a-chip devices, moving them beyond simple automation towards intelligent, adaptive experimentation platforms. AI algorithms, particularly deep learning networks, are being deployed to process real-time sensor data—including pressure, temperature, and optical feedback—from the microfluidic system. This data is used to continuously refine pump actuation protocols, ensuring absolute flow stability and compensating for environmental fluctuations or component wear over time. This capability is critical for sensitive applications like single-cell encapsulation or time-lapse microscopy, where even minute flow variations can compromise experiment integrity.

Furthermore, AI is instrumental in the design and manufacturing phases. ML models are being utilized to optimize the geometric design of microchannels and integrated valves, predicting fluid behavior before physical prototyping, thus significantly reducing R&D cycles and material costs. In operational use, AI facilitates complex liquid handling protocols in multi-step assays, learning the optimal sequence and timing for reagent addition, mixing, and washing steps based on desired outcomes. This transition from pre-programmed fixed protocols to intelligent, adaptive protocols is redefining the capabilities and scope of microfluidic instruments, making complex biochemical assays accessible to non-expert users in decentralized settings.

- AI-driven flow stabilization and anomaly detection, minimizing experimental errors.

- Machine learning optimization of pump parameters (pressure, pulse frequency) for various fluidic properties.

- Accelerated microchannel and device design through predictive simulation and optimization algorithms.

- Automated assay protocol development and execution using closed-loop control systems.

- Enhanced data interpretation from high-throughput screening via embedded AI analytics.

- Predictive maintenance schedules for mechanical pump components based on usage patterns.

DRO & Impact Forces Of Microfluidic Pumps Market

The Microfluidic Pumps Market is influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces shaping its trajectory. Key drivers include the overwhelming global trend toward Point-of-Care (PoC) diagnostics, demanding portable, accurate, and rapid testing solutions that rely fundamentally on precision fluidic control. Furthermore, the necessity for high-throughput screening in pharmaceutical development and the increasing adoption of personalized medicine approaches, which require handling minimal sample volumes, consistently push the demand for advanced microfluidic pumping technology. The inherent benefits of miniaturization, such such as reduced reagent consumption and faster reaction times, solidify the market's expansive growth.

Conversely, significant restraints impede faster adoption. The primary restraint is the high initial cost associated with complex microfluidic system integration and fabrication, particularly when dealing with specialized materials like glass or silicon, rather than low-cost polymers. Technical hurdles related to fluid interface issues, such as bubble generation, leakage, and effective long-term sealing within microchannels, remain ongoing challenges. Furthermore, the lack of standardized regulatory guidelines for microfluidic devices, especially integrated diagnostic platforms, creates uncertainty and delays in market entry for innovative products, particularly in highly regulated clinical fields.

Opportunities for market expansion are abundant, centered on the development of highly integrated, disposable pump solutions that minimize system cost and complexity. The emergence of novel non-mechanical pumping mechanisms, such as those based on magnetohydrodynamics or acoustofluidics, promises greater control and scalability without moving parts. Furthermore, the expansive potential within non-medical fields, including environmental monitoring (water quality testing), chemical synthesis (continuous flow chemistry), and industrial sensing, represents substantial untapped growth avenues. Strategic partnerships between chip fabricators, instrument manufacturers, and biotechnology companies will be crucial to fully capitalize on these technological and application opportunities.

Segmentation Analysis

The Microfluidic Pumps Market is systematically segmented based on Product Type, Mechanism, Application, and End-User, providing granular insights into the diverse technological offerings and consumption patterns across the industry. This structural breakdown helps stakeholders identify high-growth segments and tailor their product development and market strategies. The segmentation highlights the intrinsic trade-offs between pump complexity, precision, integration potential, and cost, which dictate adoption rates across different end-user verticals, from highly regulated clinical laboratories to decentralized research settings. The ongoing evolution in materials science and fabrication techniques continues to refine these segments, blurring the lines between traditional benchtop systems and modern, fully integrated chip components.

Segmentation by Mechanism is critical, distinguishing between mechanical pumps, which rely on moving physical components (like pistons or rotors), and non-mechanical pumps, which leverage external energy fields (like electrical or acoustic forces) to drive fluid movement. While mechanical pumps offer high reliability and throughput, non-mechanical pumps offer unparalleled integration capabilities and precise, non-pulsatile flow often required for sensitive biological samples. Application segmentation clarifies the end use, with In Vitro Diagnostics (IVD) being the dominant segment, driven by global demand for portable and rapid testing platforms, while the life sciences research segment, encompassing drug discovery and genomics, demands the highest level of flow stability and accuracy for complex experimental protocols.

The End-User segment reflects the varied adoption levels, with Academic and Research Institutes focusing on fundamental research and novel applications, often favoring flexible, high-precision benchtop systems. Conversely, Diagnostic Laboratories and Hospitals prioritize standardized, reliable, and often disposable cartridge-based systems, emphasizing low cost per test and ease of operation. The pharmaceutical and biotechnology companies segment requires highly automated, scalable systems for high-throughput screening. Analyzing these segments reveals that future growth will be concentrated in developing highly integrated, polymer-based disposable non-mechanical pump systems tailored for the PoC diagnostics market.

- Product Type:

- Integrated Microfluidic Pumps (On-chip)

- Non-Integrated Microfluidic Pumps (External/Benchtop)

- Mechanism:

- Mechanical Pumps

- Syringe Pumps

- Peristaltic Pumps

- Diaphragm Pumps

- Piston Pumps

- Non-Mechanical Pumps

- Electrokinetic Pumps (Electroosmotic, Electrophoretic)

- Acoustic/Ultrasonic Pumps

- Magnetic Pumps

- Centrifugal Pumps

- Mechanical Pumps

- Application:

- In Vitro Diagnostics (IVD)

- Pharmaceutical and Biotechnology Research

- Drug Delivery

- Clinical and Forensic Analysis

- Environmental Monitoring

- Chemical Synthesis

- End-User:

- Academic and Research Institutes

- Hospitals and Diagnostic Centers

- Pharmaceutical and Biotechnology Companies

- Contract Research Organizations (CROs)

Value Chain Analysis For Microfluidic Pumps Market

The Microfluidic Pumps market value chain begins with upstream analysis involving raw material suppliers and component manufacturers. This stage is dominated by specialized suppliers of precision plastics (polymers like PDMS and COC), glass, silicon wafers, and micro-actuators (piezoelectric and electromagnetic). The quality and consistency of these materials are paramount, particularly for manufacturing microchannels with feature sizes often less than 100 micrometers. Strong reliance on specialized fabrication techniques, such as photolithography, soft lithography, and advanced 3D printing, necessitates high investment in specialized equipment and expertise at this initial stage. The procurement of high-performance components, especially micro-sensors and micro-valves, directly impacts the final performance characteristics of the pump system.

The midstream focuses on the assembly and integration of the pump systems and microfluidic chips. This stage involves complex engineering tasks: integrating the fluidic control mechanism (the pump itself) with the analytical or diagnostic chip, ensuring robust sealing, and developing sophisticated control electronics and software interfaces. Key players in this stage often specialize in providing integrated fluidic solutions, moving beyond standalone pumps to complete module systems. The value addition here lies in miniaturization, automation, and validation of the entire fluidic pathway. Effective quality control and calibration procedures are essential to maintain the high accuracy demanded by clinical and research applications.

Downstream analysis highlights the distribution channels and end-user engagement. Distribution primarily occurs through specialized scientific instrument distributors and direct sales teams targeting large pharmaceutical and diagnostic companies. The market exhibits a mixture of direct and indirect channels; direct sales are preferred for complex, high-value benchtop systems requiring intensive technical support and customization (common in research institutes), while indirect channels, relying on regional distributors, are utilized for high-volume, standardized, or disposable diagnostic cartridges (common in PoC and hospital settings). Customer support, training, and ongoing technical service constitute a significant portion of the downstream value, particularly due to the specialized nature of microfluidic assays. Potential customers range from dedicated core labs to decentralized clinical diagnostic units seeking streamlined, automated workflows.

Microfluidic Pumps Market Potential Customers

Potential customers for microfluidic pump technologies are highly diverse, spanning the entire spectrum of life sciences, clinical healthcare, and advanced materials engineering. The largest and most influential customer segment comprises pharmaceutical and biotechnology companies. These entities utilize microfluidic pumps extensively for automating drug screening processes, developing organ-on-a-chip models for toxicology testing, and performing high-throughput compound validation. Their purchasing decisions are driven by the need for high precision, scalability, and integration with robotic liquid handling systems to accelerate discovery pipelines and reduce reliance on expensive manual processes. They often procure high-end, multi-channel benchtop pumps and integrated microfluidic systems tailored for complex cell culture and assay environments.

Hospitals and Diagnostic Laboratories constitute another massive end-user base, driven primarily by the shift towards rapid, decentralized, and cost-effective In Vitro Diagnostics (IVD). These customers seek fully automated, user-friendly PoC devices utilizing integrated, often disposable microfluidic cartridges. The pumps used here must prioritize low manufacturing cost, high reliability in non-laboratory settings, and seamless integration for automated sample processing from collection to result reporting. The rising demand for molecular diagnostics (e.g., PCR testing) in clinical settings globally mandates precise microfluidic control, making this segment a key growth area for integrated pump solutions.

Furthermore, Academic and Government Research Institutes represent a constant demand base, particularly for novel, flexible microfluidic systems used in fundamental research areas like genomics, proteomics, and advanced materials science. These users typically require robust, customizable pumps that can handle a wide variety of fluids and experimental conditions for proof-of-concept studies and tool development. Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs) are also increasing their adoption, integrating microfluidic platforms into their service offerings to provide automated, specialized testing and manufacturing capabilities to their pharmaceutical and biotech clients, seeking efficiency gains through precise volumetric control and automation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $5.45 Billion |

| Growth Rate | 16.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BlackHole Inc., Dolomite Microfluidics, Fluigent, IDEX Health & Science, Takasago Fluidic Systems, uFluidix, Parker Hannifin, PerkinElmer, SMC Corporation, Chemyx Inc., Harvard Apparatus, A&D Company, Becton, Dickinson and Company (BD), Thermo Fisher Scientific, Danaher Corporation, Micropump Inc., Elveflow, Bio-Rad Laboratories, World Precision Instruments, QIAgen N.V. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Microfluidic Pumps Market Key Technology Landscape

The technological landscape of the Microfluidic Pumps Market is rapidly advancing, focusing on enhancing precision, reducing footprint, and improving integration capabilities within complex lab-on-a-chip systems. A central theme is the move toward non-mechanical, actuation-based technologies that eliminate moving parts, thereby minimizing pulsation, reducing shear stress on biological samples, and enabling highly compact device architectures. Key non-mechanical technologies include electroosmotic pumps (EOPs), which use electric fields to drive fluid through charged microchannels, offering pulsation-free flow highly suitable for electrophoresis and chromatography. Similarly, magnetohydrodynamic (MHD) pumps use magnetic fields to propel electrically conductive fluids, proving valuable in applications requiring external, non-contact control.

Despite the rise of non-mechanical systems, mechanical pumps, especially syringe and peristaltic pumps, remain critical technologies, particularly in benchtop applications requiring high pressure or handling viscous fluids. Technological improvements in these traditional systems focus on enhanced stepper motor control, optimized gear ratios, and advanced materials to increase resolution and longevity. Furthermore, integrated mechanical pumps, such as micro-diaphragm pumps fabricated using MEMS (Micro-Electro-Mechanical Systems) techniques, are emerging, offering pneumatic or piezoelectric actuation for on-chip flow control, which bridges the gap between traditional mechanical strength and modern miniaturization needs.

The integration of advanced sensing and control technologies is defining the next generation of microfluidic pumps. This includes incorporating micro-sensors (pressure, flow, optical) directly adjacent to the pumping elements to create true closed-loop feedback systems. Such systems utilize sophisticated microcontrollers and embedded software to instantaneously adjust pump output based on real-time fluid dynamic measurements, ensuring unprecedented flow stability and consistency. Furthermore, the adoption of 3D printing and advanced polymer manufacturing (such as injection molding of cyclic olefin copolymer - COC) is facilitating the mass production of complex, disposable pump-integrated microfluidic cartridges, thereby lowering per-test costs and driving market accessibility in PoC diagnostics.

Regional Highlights

North America maintains its dominant position in the Microfluidic Pumps Market, driven primarily by the United States. This leadership is attributed to robust expenditure on research and development across pharmaceutical, biotechnology, and academic sectors. The region hosts a significant number of major global players in life sciences instrumentation and microfluidic component manufacturing. High adoption rates are sustained by favorable government policies supporting personalized medicine and genomics research, which inherently rely on high-precision fluidic control for complex molecular assays. Furthermore, the strong presence of diagnostic developers necessitates continuous innovation in rapid, automated, microfluidic-based testing platforms for clinical use and emerging infectious disease surveillance.

Europe represents the second-largest market, characterized by stringent quality standards and substantial funding from organizations like the European Commission for developing advanced medical technologies (e.g., Horizon Europe programs). Countries such as Germany, the UK, and Switzerland are pivotal, possessing strong academic research ecosystems and established industrial manufacturing capabilities for precision engineering and medical devices. European demand is driven by the mature clinical diagnostics market and a concerted effort to integrate microfluidic systems into point-of-care testing and continuous flow chemical synthesis applications, particularly leveraging MEMS-based pump technologies.

The Asia Pacific (APAC) region is projected to register the fastest growth rate during the forecast period. This rapid expansion is primarily fueled by improving healthcare infrastructure, massive population bases driving demand for diagnostics, and increasing government investment in local R&D and manufacturing capabilities, particularly in China, Japan, and South Korea. These nations are becoming crucial manufacturing hubs for low-cost, high-volume microfluidic devices. The increasing prevalence of chronic diseases and infectious disease outbreaks further accelerates the necessity for decentralized, rapid diagnostic solutions, making integrated microfluidic pump systems highly attractive for widespread clinical deployment across the region.

- North America: Market leader due to high R&D spending, strong pharmaceutical presence, and early adoption of integrated diagnostic platforms.

- Europe: Second largest market, focused on quality, supported by EU funding, and strong integration of MEMS technology in established healthcare systems.

- Asia Pacific (APAC): Highest CAGR, driven by infrastructural development, increasing access to healthcare, and localized manufacturing of cost-effective microfluidic PoC devices.

- Latin America: Emerging market focusing on infectious disease control and basic research, characterized by increasing import dependence on established technologies.

- Middle East and Africa (MEA): Limited adoption, concentrated in high-income Gulf Cooperation Council (GCC) countries for specialized biomedical research and advanced hospital diagnostics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Microfluidic Pumps Market.- BlackHole Inc.

- Dolomite Microfluidics

- Fluigent

- IDEX Health & Science

- Takasago Fluidic Systems

- uFluidix

- Parker Hannifin

- PerkinElmer

- SMC Corporation

- Chemyx Inc.

- Harvard Apparatus

- A&D Company

- Becton, Dickinson and Company (BD)

- Thermo Fisher Scientific

- Danaher Corporation

- Micropump Inc.

- Elveflow

- Bio-Rad Laboratories

- World Precision Instruments

- QIAgen N.V.

- Bürkert Fluid Control Systems

- Cole-Parmer Instrument Company

- Tecan Group

Frequently Asked Questions

Analyze common user questions about the Microfluidic Pumps market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Microfluidic Pumps Market?

The primary growth driver is the escalating global demand for Point-of-Care (PoC) diagnostic devices. These applications require highly precise, automated, and portable fluid handling capabilities at the microscale, which microfluidic pumps efficiently provide, reducing analysis time and sample consumption.

How do mechanical microfluidic pumps compare to non-mechanical pumps?

Mechanical pumps (e.g., syringe and peristaltic) offer high flow rates, robust pressure generation, and established reliability, making them suitable for benchtop systems. Non-mechanical pumps (e.g., electrokinetic, acoustic) are favored for their ability to achieve pulsation-free flow and high integration density, crucial for disposable, chip-based applications and sensitive biological experiments.

Which geographical region is expected to demonstrate the highest growth rate?

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This acceleration is driven by significant investments in healthcare infrastructure, increasing adoption of advanced diagnostics, and local manufacturing scaling in countries such as China and India.

What are the main technical challenges restraining market adoption?

Key restraints include the complexity and high cost associated with manufacturing and integrating microfluidic systems, especially concerning chip fabrication and robust fluidic interconnects. Technical issues like bubble formation and precise long-term flow stability under varying environmental conditions also pose significant hurdles.

What role does Artificial Intelligence (AI) play in advancing microfluidic pump technology?

AI is increasingly used to develop closed-loop fluidic control systems, utilizing real-time sensor data to optimize pump performance, compensate for flow disturbances, and automate complex experimental protocols. This integration enhances precision and reliability, particularly in high-throughput and critical diagnostic applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager