Microfluidic Syringe Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434183 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Microfluidic Syringe Pump Market Size

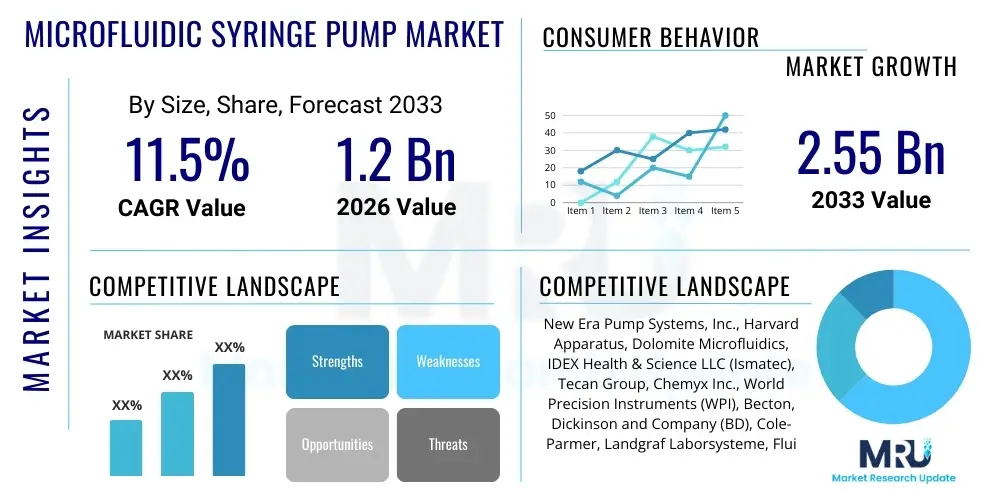

The Microfluidic Syringe Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $2.55 Billion by the end of the forecast period in 2033.

Microfluidic Syringe Pump Market introduction

The Microfluidic Syringe Pump Market encompasses specialized fluidic handling systems designed to deliver highly accurate and precise amounts of liquid reagents, samples, or solutions at exceptionally low flow rates, typically ranging from picoliters to milliliters per minute. These pumps are instrumental in microfluidic applications where control over laminar flow, mixing, and reaction kinetics is paramount. The fundamental mechanism involves a motor-driven lead screw that controls the movement of a syringe plunger, ensuring non-pulsatile, volumetric dispensing necessary for sensitive biological and chemical assays. Their importance is magnified by the rapid trend toward miniaturization in analytical chemistry and life sciences, replacing bulkier, less precise traditional pumps.

Microfluidic syringe pumps are crucial tools across major application fields, including drug discovery, clinical diagnostics (Point-of-Care Testing), genomics, proteomics, and advanced materials synthesis. In drug discovery, these pumps enable the precise handling of expensive reagents in high-throughput screening, significantly reducing material consumption and assay costs. For clinical diagnostics, they facilitate controlled sample delivery into micro-channels, forming the backbone of lab-on-a-chip devices that require minimal sample volumes and rapid analysis times. The product range includes standalone pumps, integrated flow control modules, and specialized high-pressure systems tailored for viscous fluids or challenging microchannel architectures.

The principal benefits driving market expansion include unparalleled precision in flow control, enhanced experimental reproducibility, and the ability to handle extremely small sample volumes, thereby conserving rare or costly biological materials. Key driving factors involve the exponential growth of microfluidics research globally, increasing demand for portable and automated diagnostic devices, and substantial investment in personalized medicine and genomic sequencing technologies, all of which rely heavily on ultra-precise fluid handling capabilities. Furthermore, regulatory support for advanced diagnostic tools and growing collaborations between academic research institutions and commercial manufacturers are accelerating the adoption of these sophisticated pumps.

Microfluidic Syringe Pump Market Executive Summary

The Microfluidic Syringe Pump Market is experiencing robust business trends characterized by intense focus on automation, connectivity (IoT integration), and system modularity. Manufacturers are strategically moving toward developing multi-channel pump systems that allow parallel experimentation and complex fluidic routing, catering to the needs of high-throughput applications in pharmaceutical research and academic laboratories. A significant trend involves the integration of advanced control software that offers real-time monitoring, feedback mechanisms, and sophisticated programming capabilities, enhancing the user experience and ensuring compliance with stringent laboratory standards. Furthermore, strategic partnerships and mergers among hardware manufacturers and software providers are common, aimed at offering complete, end-to-end microfluidic solutions rather than just individual components.

Regionally, North America maintains market dominance, primarily due to the presence of leading pharmaceutical and biotechnology companies, extensive R&D spending, and well-established academic infrastructure heavily involved in cutting-edge microfluidics research. However, the Asia Pacific (APAC) region is projected to register the fastest growth rate, fueled by substantial government initiatives supporting biomedical research, increasing establishment of clinical diagnostic centers, and expanding manufacturing capacities in countries like China, India, and South Korea. Europe remains a strong market, driven by advancements in personalized medicine and the adoption of microfluidic technologies in clinical trials and point-of-care applications, particularly in Germany and the UK, which prioritize innovation in laboratory automation.

Segment trends indicate a strong preference for high-pressure syringe pumps designed for complex fluid handling, particularly in materials science and applications involving high viscosity fluids or demanding shear environments. By application, drug discovery and development account for the largest market share, driven by continuous demand for optimizing screening processes. The academic and research institutes segment is projected to grow significantly as microfluidics technology becomes a standard tool in university laboratories worldwide. Segmentation based on control mechanism shows that computerized or software-controlled pumps are replacing manual systems, reflecting the overarching industry trend toward digitization and integration into automated laboratory workflows (Lab 4.0). The shift toward miniaturization and portability further favors specialized, compact syringe pump modules for integration into portable diagnostic kits.

AI Impact Analysis on Microfluidic Syringe Pump Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can enhance the precision, autonomy, and throughput of microfluidic systems utilizing syringe pumps. Key concerns revolve around integrating AI for real-time flow rate optimization, predictive maintenance of pump components, and autonomous experimental design within complex microfluidic circuits. Expectations center on AI enabling pumps to dynamically adjust dispensing parameters (such as flow rate and pressure) based on real-time sensor feedback regarding fluid properties or reaction states, minimizing errors caused by viscosity variations or bubble formation. This shift from static programming to dynamic, feedback-driven control represents the primary transformative potential of AI in this domain, aiming to improve reproducibility and speed up experimental cycles significantly, especially in optimization processes like droplet generation or nanoparticle synthesis.

The immediate impact of AI is visible in advanced calibration and error correction protocols. ML algorithms are being used to analyze historical data generated by syringe pumps regarding performance drift, mechanical hysteresis, and flow anomalies. This predictive capability allows for proactive recalibration or replacement, minimizing downtime and ensuring high fidelity in sensitive experiments. Furthermore, integrating computer vision and AI with microfluidic systems allows automated analysis of downstream results (e.g., droplet size distribution, cell sorting efficiency) and feeds that information back to the pump control unit, enabling closed-loop optimization without human intervention. This capability is pivotal for automating complex, multi-step chemical synthesis or biological assays conducted on a chip, fundamentally altering the operating paradigm.

In the future, AI will drive the development of "smart" microfluidic platforms where the syringe pump acts as an intelligent agent. Users expect AI to autonomously manage multi-pump synchronization in complex gradient generation or perfusion systems, learning the optimal flow profiles to achieve desired outcomes. This integration reduces the skill required to operate sophisticated microfluidic setups, democratizing access to complex experimental techniques. The adoption of AI tools within the control software also helps manage the massive data streams generated by high-throughput microfluidic experiments, providing actionable insights into fluid dynamics and biological responses that would be impossible to deduce manually, thereby enhancing the scientific yield of experiments conducted using these precision tools.

- AI-driven real-time flow control optimization based on sensor feedback.

- Predictive maintenance and anomaly detection in pump mechanics using machine learning.

- Autonomous experimental design and parameter adjustment in closed-loop microfluidic systems.

- Enhanced calibration routines utilizing historical performance data for higher dispensing accuracy.

- Integration of AI for complex multi-pump synchronization and gradient generation management.

DRO & Impact Forces Of Microfluidic Syringe Pump Market

The Microfluidic Syringe Pump Market is primarily driven by the escalating demand for high-precision, low-volume fluid handling across life sciences and chemical research, catalyzed by the rapid adoption of microfluidic chip technology. The restraints center predominantly on the high initial cost of these precision instruments and the necessity for specialized technical expertise to operate and maintain the complex, highly sensitive systems. Significant opportunities lie in developing highly portable, battery-operated units for Point-of-Care (POC) diagnostics and integrating pumps with next-generation sequencing platforms. The impact forces acting on the market include the swift advancement of lab-on-a-chip technologies (pushing for miniaturization), stringent regulatory frameworks mandating high fidelity in diagnostic assays, and strong funding streams directed towards personalized medicine research worldwide.

Key drivers underpinning market growth include the inherent advantages of microfluidics, such as reduced reagent consumption, faster analysis times, and improved thermal control, all of which are directly facilitated by the reliable operation of syringe pumps. The increasing incidence of chronic diseases necessitates rapid and accurate diagnostics, creating a robust demand for automated microfluidic systems in clinical settings. Furthermore, ongoing research breakthroughs in areas like single-cell analysis and organ-on-a-chip modeling require non-pulsatile, highly controllable fluid delivery, making microfluidic syringe pumps indispensable components. The commercialization of integrated microfluidic platforms by large analytical instrument manufacturers also serves as a significant driver, standardizing adoption across various research and industrial sectors.

However, market growth is tempered by certain restraints, particularly the high barrier to entry for smaller laboratories due to the significant capital investment required for high-end microfluidic setups, including multi-channel pumps and associated control hardware. Technical complexity related to minimizing pulsation, managing bubble formation at extremely low flow rates, and ensuring compatibility with various fluid chemistries also presents operational challenges. Opportunities for future growth are vast, particularly in customization—designing pumps specifically optimized for high-viscosity bio-inks for 3D bioprinting or high-pressure systems for supercritical fluid applications. Moreover, developing open-source hardware and standardized communication protocols for pump control offers pathways to broader market penetration by improving interoperability and reducing complexity for new users.

Segmentation Analysis

The Microfluidic Syringe Pump Market is comprehensively segmented based on its technical specifications, application areas, and end-user profiles, reflecting the diverse requirements across research, clinical, and industrial environments. Key segmentation variables include the type of flow rate (nanoliter, microliter, milliliter), the number of channels (single-channel vs. multi-channel), and the operational pressure capabilities (low pressure vs. high pressure). Analyzing these segments allows market participants to tailor their product development and marketing strategies to specific high-growth niches, such as the increasing demand for multi-channel pumps in high-throughput screening or specialized high-pressure systems required for dense polymer solutions in materials science.

The segmentation by application highlights the dominant role of drug discovery and academic research, where precise fluid control is fundamental to assay success and experimental reproducibility. Conversely, the diagnostic and clinical segments are emerging rapidly, driven by the need for miniaturized, portable diagnostic devices that integrate these pumps. End-user segmentation reveals that pharmaceutical and biotechnology companies represent the largest revenue generators due to their substantial R&D budgets and large-scale automation requirements, while contract research organizations (CROs) and clinical laboratories are demonstrating high adoption rates as they seek to streamline processes and reduce sample volume requirements in complex bioassays.

- By Type:

- Single-Channel Syringe Pumps

- Multi-Channel Syringe Pumps

- High-Pressure Syringe Pumps

- OEM/Integrated Syringe Pump Modules

- By Flow Rate:

- Nanoliter/Picoliter Pumps

- Microliter Pumps

- Milliliter Pumps

- By Application:

- Drug Discovery and Development (HTS, Screening)

- Diagnostics and Clinical Testing (POC devices)

- Genomics and Proteomics

- Cell Biology and Tissue Engineering (Organ-on-a-Chip)

- Chemical Synthesis and Materials Science

- By End User:

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutes

- Contract Research Organizations (CROs)

- Hospitals and Diagnostic Laboratories

Value Chain Analysis For Microfluidic Syringe Pump Market

The value chain for the Microfluidic Syringe Pump Market begins with upstream activities focused on the sourcing and precision manufacturing of critical components, including stepper motors, lead screws, high-precision mechanical linkages, and sophisticated electronic control boards. Key suppliers in this segment are specialized manufacturers of motion control systems and high-reliability electronic components. Quality control at this stage is crucial, as the accuracy and non-pulsatile performance of the final pump depend directly on the mechanical tolerances of these input materials. Component standardization and supply chain resilience are primary concerns, particularly given the global nature of electronic component sourcing.

Midstream activities involve the design, assembly, and integration of the final syringe pump unit. This phase is characterized by intense intellectual property development, focusing on proprietary motor control algorithms, fluidics programming interfaces, and specialized pump head designs tailored for microfluidic compatibility. Manufacturers invest heavily in software development to ensure user-friendly interfaces, connectivity options (e.g., Ethernet, USB, IoT integration), and compatibility with third-party microfluidic chips and systems. After assembly, rigorous calibration and testing, particularly validation of sub-microliter dispensing accuracy, are mandatory before the product moves to distribution.

Downstream activities include distribution, sales, and post-sales support. Distribution channels are typically segmented into direct sales (for large pharmaceutical accounts requiring highly customized solutions) and indirect sales through specialized scientific instrument distributors and regional resellers, particularly in emerging markets. Post-sales support, including application training, maintenance, and repair, is a critical value differentiator, given the technical nature and high cost of these instruments. The end-user often integrates the syringe pump into a larger workflow involving microfluidic chips, optical detection systems, and automated robotics, requiring comprehensive technical assistance from the pump provider to ensure seamless integration and optimized experimental outcomes.

Microfluidic Syringe Pump Market Potential Customers

The primary cohort of potential customers for Microfluidic Syringe Pumps comprises research scientists and engineers operating within academic laboratories, pharmaceutical R&D departments, and biotechnology startups. These users are typically engaged in fundamental research requiring precise, controlled dosing of minimal reagent volumes, such as generating complex concentration gradients for cell migration studies or synthesizing uniform nanoparticles for materials applications. Their purchasing decisions are heavily influenced by performance metrics like flow rate accuracy, non-pulsatile delivery, and ease of software programmability, often prioritizing high-end, multi-channel models that offer maximal experimental flexibility and reproducibility, ensuring data integrity for publication or regulatory submission.

Another rapidly expanding customer segment includes clinical diagnostic manufacturers and hospital laboratories adopting Point-of-Care (POC) testing platforms. For this segment, the focus shifts slightly from absolute R&D flexibility to reliability, compact form factor, and low maintenance requirements, as the pumps are often permanently integrated into commercial diagnostic devices. These buyers seek OEM (Original Equipment Manufacturer) modules that offer high durability and cost-effectiveness when procured in large volumes. The shift toward decentralized testing and rapid pathogen identification further solidifies clinical labs and specialized diagnostic centers as high-potential buyers demanding robustness and minimal complexity.

Furthermore, Contract Research Organizations (CROs) and Contract Development and Manufacturing Organizations (CDMOs) represent significant potential customers, driven by the increasing outsourcing trend in drug development. CROs require flexible, high-throughput microfluidic systems to manage multiple client projects simultaneously, necessitating multi-channel, automated pump systems capable of continuous operation. Their purchasing criteria often emphasize scalability and integration compatibility with existing liquid handling robotics, viewing the syringe pump as a critical component in maintaining efficiency and reducing labor costs across large-scale screening and assay development programs commissioned by pharmaceutical clients.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $2.55 Billion |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | New Era Pump Systems, Inc., Harvard Apparatus, Dolomite Microfluidics, IDEX Health & Science LLC (Ismatec), Tecan Group, Chemyx Inc., World Precision Instruments (WPI), Becton, Dickinson and Company (BD), Cole-Parmer, Landgraf Laborsysteme, Fluigent, KDS Legato, F. Hoffmann-La Roche Ltd., Kloehn, Inc., Takasago Fluidic Systems, Shenzhen Longer Precision Pump Co., Ltd., Elveflow, Fusion Pump, Mirus Bio, Gilson, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Microfluidic Syringe Pump Market Key Technology Landscape

The core technology landscape for microfluidic syringe pumps revolves around highly precise mechanical engineering coupled with sophisticated electronic control systems to achieve unparalleled accuracy in volumetric delivery. Stepper motors or servo motors, coupled with high-resolution lead screws and anti-backlash nuts, form the foundation of the movement mechanism, ensuring smooth, non-pulsatile linear motion of the syringe plunger. Recent technological advancements focus on minimizing the effects of mechanical hysteresis and thermal expansion, which are critical sources of flow error at picoliter per minute flow rates. This involves integrating high-resolution encoders and closed-loop feedback systems that constantly monitor the plunger position, making instantaneous adjustments to maintain the programmed flow profile, drastically improving reproducibility in long-duration experiments.

A significant trend is the development of microfluidic specific pumps characterized by exceptionally low dead volume and chemical compatibility across a broad spectrum of aggressive solvents and biological buffers. Manufacturers are leveraging advanced materials, such as PEEK (Polyether ether ketone) and high-grade ceramics, for fluid-contact parts to enhance inertness and reduce carry-over contamination, crucial in sensitive analytical chemistry and drug formulation. Furthermore, the integration of specialized pressure sensors directly into the pump system allows for real-time pressure monitoring, providing crucial diagnostic information regarding potential blockages or leaks within the microfluidic chip, thus preventing system damage and experimental failure.

Software and connectivity technologies are rapidly evolving, positioning the syringe pump within the broader framework of Laboratory Automation Systems (LAS). Modern pumps feature Ethernet and Wi-Fi capabilities, enabling remote control and monitoring, essential for handling hazardous or time-sensitive experiments conducted in incubators or specialized enclosures. The accompanying software often includes graphical programming environments, allowing users to define complex flow profiles, sequences, and synchronization schedules across multiple pumps and valves. Furthermore, the adoption of standardized communication protocols facilitates seamless integration with robotic liquid handlers, analytical instruments (like mass spectrometers), and automated data acquisition systems, driving the transition towards fully integrated, automated microfluidic workstations and aligning the technology with the principles of Lab 4.0.

Regional Highlights

Regional dynamics heavily influence the Microfluidic Syringe Pump Market, with concentration patterns reflecting R&D investment and established industrial bases. North America, particularly the United States, represents the largest market share holder. This dominance is attributable to massive spending by pharmaceutical giants on drug discovery infrastructure, the presence of numerous leading biotechnology firms, and extensive government funding for advanced biomedical research, including initiatives focused on precision medicine and advanced diagnostics. The high adoption rate is also supported by a mature ecosystem of highly specialized component suppliers and system integrators. The focus in this region is often on high-end, multi-channel automated systems required for high-throughput screening (HTS) and complex biological modeling.

Europe holds a strong second position, driven by stringent quality standards in clinical diagnostics and powerful national R&D programs, particularly in Germany, the UK, and Switzerland. European academic institutions are at the forefront of microfluidic device design and application, leading to a steady demand for high-fidelity syringe pumps used in collaborative industry-academia projects, especially those related to personalized therapeutics and environmental monitoring. Recent European Union directives supporting innovation in medical devices and laboratory automation further stimulate market growth, focusing on integration into regulated clinical environments and quality-controlled research settings across the continent.

The Asia Pacific (APAC) region is poised for the highest growth rate during the forecast period. This rapid expansion is primarily powered by fast-developing economies like China and India, which are significantly increasing their investments in healthcare infrastructure, indigenous pharmaceutical manufacturing, and establishing cutting-edge national research laboratories. Favorable government policies aimed at promoting scientific self-sufficiency and attracting global manufacturing operations contribute to this growth. While historically focused on basic research instruments, the APAC market is increasingly adopting sophisticated, multi-channel pumps for advanced applications in genomics and contract research, often driven by the competitive push to reduce costs and increase throughput in outsourced development services.

- North America: Dominant market due to strong pharmaceutical R&D, high biotech spending, and advanced research facilities.

- Europe: High adoption driven by stringent clinical diagnostic standards, strong academic research, and focus on personalized medicine.

- Asia Pacific (APAC): Fastest-growing region; powered by increasing government investment in science and healthcare, expanding manufacturing, and rising demand for low-cost diagnostics.

- Latin America & MEA: Emerging markets showing gradual uptake, mainly concentrated in academic institutions and select diagnostic centers, driven by modernization of healthcare infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Microfluidic Syringe Pump Market.- New Era Pump Systems, Inc.

- Harvard Apparatus

- Dolomite Microfluidics

- IDEX Health & Science LLC (Ismatec)

- Tecan Group

- Chemyx Inc.

- World Precision Instruments (WPI)

- Becton, Dickinson and Company (BD)

- Cole-Parmer

- Landgraf Laborsysteme

- Fluigent

- KDS Legato

- F. Hoffmann-La Roche Ltd.

- Kloehn, Inc.

- Takasago Fluidic Systems

- Shenzhen Longer Precision Pump Co., Ltd.

- Elveflow

- Fusion Pump

- Mirus Bio

- Gilson, Inc.

Frequently Asked Questions

Analyze common user questions about the Microfluidic Syringe Pump market and generate a concise list of summarized FAQs reflecting key topics and concerns.What defines a microfluidic syringe pump, and how does it achieve high accuracy?

A microfluidic syringe pump is a specialized volumetric device designed for non-pulsatile fluid delivery at exceptionally low flow rates (pL/min to mL/min). High accuracy is achieved through the integration of high-resolution stepper motors, precision-ground lead screws, and closed-loop electronic feedback systems that precisely control and monitor the linear movement of the syringe plunger, minimizing mechanical error and ensuring reliable flow profiles required for microscale experiments.

In which applications are high-pressure microfluidic syringe pumps necessary?

High-pressure microfluidic syringe pumps are necessary in applications involving fluids with high viscosity (such as polymer solutions or bio-inks for 3D bioprinting) or when working with microfluidic chips that have extremely high flow resistance, often due to very long, narrow channels or porous media. They are crucial for maintaining consistent flow against significant back pressure without mechanical slippage or system stalling.

What are the primary differences between single-channel and multi-channel syringe pumps?

Single-channel pumps deliver fluid through one outlet, suitable for simple dosing or single-reaction experiments. Multi-channel pumps, however, offer simultaneous and independently controllable fluid delivery through multiple channels, allowing for complex applications like gradient generation, parallel screening, or precise cell media perfusion in organ-on-a-chip models, significantly boosting experimental throughput and complexity.

How does the integration of smart software impact the usability of modern microfluidic pumps?

Smart software integration significantly enhances usability by providing graphical user interfaces for complex programming, enabling remote control and monitoring (IoT capabilities), and facilitating automated synchronization with other laboratory instruments. This software often includes real-time diagnostics and data logging, simplifying validation, improving experimental reproducibility, and allowing for dynamic, feedback-driven flow adjustments based on external sensor data.

Which regional market is anticipated to show the fastest growth rate for these pumps?

The Asia Pacific (APAC) region is anticipated to show the fastest growth rate. This acceleration is driven by substantial government investments in establishing advanced biomedical research infrastructure, rapid expansion of the domestic pharmaceutical and biotechnology industries, and increasing adoption of microfluidic technology for cost-effective clinical diagnostics and manufacturing applications across countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager