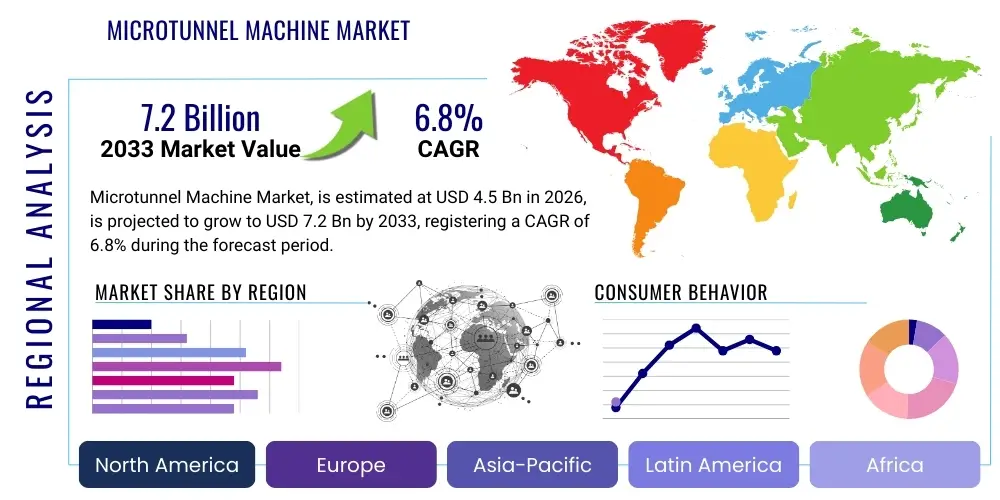

Microtunnel Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436949 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Microtunnel Machine Market Size

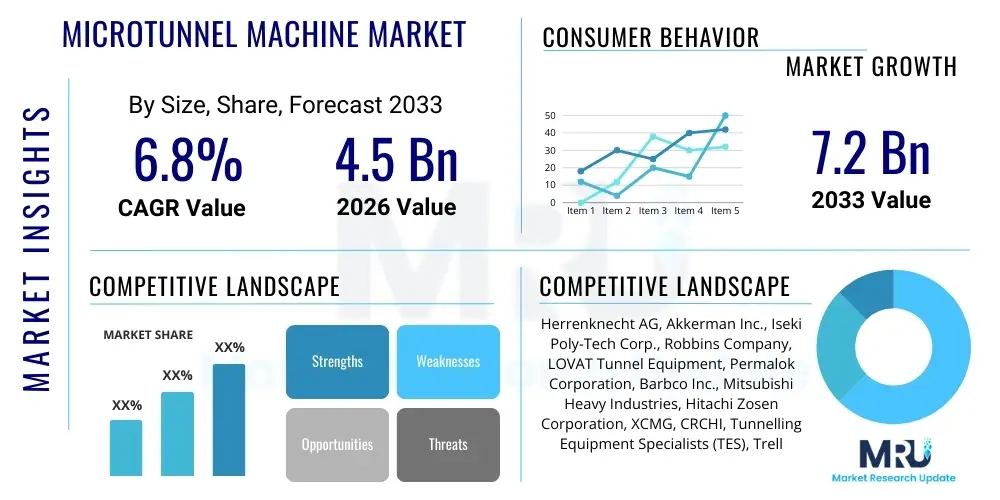

The Microtunnel Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033.

Microtunnel Machine Market introduction

The Microtunnel Machine Market encompasses the manufacturing, sales, and service of trenchless construction equipment specifically designed for installing pipelines, conduits, and utility crossings with minimal surface disruption. Microtunneling, often referred to as pipe jacking, utilizes remote-controlled, guided boring machines (MTBMs) to excavate underground tunnels while simultaneously pushing pipe segments behind the cutterhead. This technology is critical for modern urban infrastructure development where conventional trenching methods are impractical due to dense urbanization, deep installations, or environmental restrictions. Key applications span across sanitary sewer systems, storm drainage, potable water transmission lines, and utility corridors for electricity and telecommunications.

Product descriptions within this market generally classify MTBMs based on excavation technique, such as slurry systems, which manage spoil by mixing it with fluid for transport, and earth pressure balance (EPB) machines, which maintain face stability in cohesive soils by balancing earth pressure. The primary driving factors for market expansion include the global imperative for upgrading aging water and sewage infrastructure, particularly in mature economies, and the rapid pace of urbanization in developing regions, which necessitates efficient, non-disruptive installation methods. Furthermore, stringent environmental regulations discouraging open-cut trenching in sensitive areas significantly bolster the adoption of microtunneling technology.

The core benefits offered by microtunneling machines involve enhanced safety compared to traditional manned tunneling, precision guidance systems ensuring high accuracy over long distances, and substantial cost savings associated with reduced traffic disruption and reinstatement costs. The sophisticated hydraulic, mechanical, and electronic components ensure these machines can operate effectively across diverse geological conditions, from soft clay and sand to highly consolidated rock formations. Technological advancements focusing on automation, real-time data monitoring, and improved cutterhead designs are continuously enhancing the efficiency and versatility of microtunneling operations globally.

Microtunnel Machine Market Executive Summary

The global Microtunnel Machine Market is poised for robust growth, driven primarily by favorable long-term business trends focused on infrastructural resilience and sustainable construction practices. Key business trends include increased investment by municipal governments in water and wastewater infrastructure projects globally, coupled with a shift towards high-diameter microtunneling capabilities to accommodate larger utility transmission networks. Manufacturers are focusing on developing hybrid machines capable of handling varying ground conditions and integrating advanced teleoperation features, enhancing operational efficiency and reducing on-site personnel requirements. Mergers and acquisitions focused on securing specialized geotechnical expertise and expanding service network coverage are also defining the competitive landscape.

Regionally, the Asia Pacific (APAC) region is projected to maintain the highest growth trajectory due to massive government spending on urban development, exemplified by extensive railway and pipeline projects in China, India, and Southeast Asian nations. North America and Europe, while representing mature markets, exhibit steady growth driven by the replacement of deteriorating, decades-old sewer and storm drain infrastructure. Segment trends indicate a rising demand for slurry-based MTBMs, particularly for tunneling beneath water tables or in unstable, sandy soils. Additionally, the increasing complexity of urban projects is fueling the requirement for highly accurate laser and gyroscope guidance systems, bolstering the associated ancillary equipment market.

In terms of segment performance, machines designed for medium-to-large diameter pipes (1500 mm to 3000 mm) are expected to capture a substantial market share, reflecting the scale of modern infrastructure upgrades. The competitive environment is moderately consolidated, dominated by a few established global players offering comprehensive product portfolios and sophisticated technical support. Successful market penetration increasingly relies on manufacturers providing holistic project support, including machine customization, maintenance agreements, and operator training, ensuring efficient utilization of high-capital equipment. Overall, the market outlook remains highly positive, underpinned by urbanization and environmental policy mandates.

AI Impact Analysis on Microtunnel Machine Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Microtunnel Machine Market typically center on how AI can enhance operational safety, improve construction accuracy, and optimize maintenance schedules. Users are concerned about the practicality of integrating complex machine learning algorithms into rugged construction environments and the necessary skill shift required for machine operators. Key expectations revolve around using AI for predictive modeling of geotechnical conditions, automating the cutterhead steering process, and minimizing human intervention in hazardous environments. The demand is high for systems that can process real-time sensor data from the excavation face to instantaneously adjust tunneling parameters, thereby mitigating risks such as face instability, ground settlement, or unplanned stoppages.

The immediate and tangible impact of AI is observed in predictive maintenance systems. By analyzing vibration, temperature, pressure, and operational cycle data collected from hydraulic pumps, gearboxes, and cutter drives, AI algorithms can accurately forecast component failure with high precision. This transition from scheduled maintenance to condition-based monitoring drastically reduces unexpected downtime, a critical factor given the immense capital cost and logistical complexity of microtunneling projects. Furthermore, AI-driven diagnostics are streamlining troubleshooting processes, allowing remote technical support teams to analyze operational anomalies rapidly and propose solutions without extensive physical inspection, significantly enhancing machine availability.

In terms of operational efficiency, AI is beginning to revolutionize guidance and steering. Traditional microtunneling relies heavily on experienced operators making manual adjustments based on laser guidance readings and pressure sensors. AI-powered control systems can process multi-sensor inputs—including seismic data, ground radar, and pressure readings—to create a dynamic model of the ground ahead. This allows the system to autonomously adjust thrust, torque, and slurry flow rates in real-time to maintain line and grade with sub-millimeter precision, especially crucial during long-distance drives or navigating complex curves. This integration of smart systems not only improves accuracy but also substantially lowers the risk associated with human error.

- AI-driven Predictive Maintenance: Utilizing machine learning on sensor data to forecast equipment failure, minimizing unplanned downtime and optimizing component lifespan.

- Automated Guidance Systems: Implementing AI algorithms for real-time analysis of geotechnical parameters, enabling autonomous micro-adjustments to thrust and steering for enhanced precision (AEO focus: Sub-millimeter accuracy).

- Geotechnical Risk Modeling: Employing neural networks to analyze historical drilling data and current face pressure to predict potential ground instability (e.g., sinkholes or large boulders) before the MTBM encounters them.

- Optimized Slurry Management: AI systems fine-tuning the composition and flow rate of slurry based on real-time spoil characteristics, ensuring optimal face support and efficient material removal.

- Enhanced Operator Assistance: Providing augmented reality overlays and intelligent decision support systems to operators, simplifying complex responses to dynamic ground conditions.

- Safety Monitoring: Using computer vision and machine learning models to monitor site conditions and adherence to safety protocols, reducing human-related accidents during pipe jacking operations.

DRO & Impact Forces Of Microtunnel Machine Market

The Microtunnel Machine Market is shaped by a strong interplay of positive and negative external forces. The primary Drivers include global urban densification and the consequent need for trenchless technology, coupled with massive investments in resilient water and sanitation infrastructure across developed and developing economies. Opportunities largely stem from the adoption of larger diameter machines for major utility arteries and the expansion into niche applications, such as geothermal heat exchange installations. Conversely, Restraints primarily involve the high initial capital expenditure associated with purchasing and deploying MTBMs, the scarcity of highly trained operational personnel, and significant geopolitical instability affecting raw material supply chains for steel and specialized components. The collective impact forces drive innovation towards lower operating costs and higher automation levels.

Key drivers center on regulatory mandates that favor non-disruptive installation methods. Many municipalities now prioritize trenchless solutions like microtunneling over open-cut methods due to reduced traffic congestion, minimized environmental impact, and lower social costs. Furthermore, the deteriorating condition of infrastructure installed post-World War II necessitates replacement, often in deep or restricted urban environments where microtunneling is the only viable option. The technological advancements, particularly in automated guidance and monitoring, have also lowered the perceived technical risk associated with microtunneling, thereby boosting its acceptance among engineering consultants and construction firms globally.

Restraints impose significant challenges, primarily the economic barrier to entry. A single, large-diameter MTBM represents a multi-million dollar investment, limiting ownership primarily to large construction conglomerates or specialized rental firms. This high capital cost impacts overall project budgets, often requiring extensive financing. Furthermore, operational hurdles include the specialized geotechnical expertise needed to accurately assess ground conditions and the specialized labor required to operate and maintain these complex machines, creating bottlenecks in rapid market expansion. Opportunities, however, present themselves in emerging markets adopting stringent environmental standards and in the development of modular, multi-purpose machines that can be adapted for varying pipe diameters and soil types, increasing return on investment for contractors.

Segmentation Analysis

The Microtunnel Machine Market is systematically segmented based on various technical and application parameters, providing clarity on operational trends and investment hotspots. Key segmentation categories include the Type of Machine (differentiated by excavation method, primarily Slurry MTBM and Earth Pressure Balance MTBM), the Diameter of Pipe (ranging from small to large bore), and the End-Use Application (focusing on wastewater, storm water, and utilities). Understanding these segments is crucial as project requirements—such as soil permeability, water table depth, and required pipe size—dictate the specific machine configuration chosen, thereby influencing market demand for specialized components and machine types.

- By Type of Machine:

- Slurry Microtunneling Machines (Best suited for granular soils and high water tables, utilizing fluid transport for spoil removal)

- Earth Pressure Balance (EPB) Microtunneling Machines (Ideal for cohesive and mixed soils, maintaining face stability through controlled earth pressure)

- Auger Boring Machines (Used primarily for smaller, shorter tunnels in stable soil conditions)

- Rock Microtunneling Machines (Specialized cutterheads for hard rock formations)

- By Pipe Diameter:

- Small Diameter (Up to 1000 mm)

- Medium Diameter (1000 mm to 2000 mm)

- Large Diameter (Above 2000 mm)

- By End-Use Application:

- Water and Wastewater (Sanitary sewers, force mains, storm drains – dominant segment)

- Oil and Gas Pipelines (Installation of major crossings under infrastructure)

- Telecommunications and Power Cables (Installation of utility conduits)

- Transportation Infrastructure (Under road, rail, and airport crossings)

- By Sales Channel:

- Direct Sales (From manufacturer to large contractor)

- Rental and Leasing (Popular among smaller or regional contractors)

Value Chain Analysis For Microtunnel Machine Market

The value chain for the Microtunnel Machine Market begins with the Upstream Analysis, which involves the sourcing and procurement of critical raw materials, specifically high-grade steel alloys for the cutterhead and shield, advanced hydraulic components, specialized sealing systems, and complex electronics for guidance and control systems. Key suppliers in the upstream segment include specialized steel manufacturers, precision engineering firms for bearings and seals, and global electronics providers. Efficiency in this stage is crucial, as the quality of materials directly impacts the MTBM’s durability and performance under high pressure and abrasive environments. Price volatility in global commodity markets, particularly steel, significantly influences the overall manufacturing cost structure.

The Midstream segment encompasses the core activities of research and development, machine design, precision manufacturing, assembly, and rigorous testing. Leading MTBM manufacturers differentiate themselves through R&D investment in cutterhead design optimization, advanced robotics integration, and the proprietary development of guidance software. The manufacturing process requires highly specialized facilities capable of handling large-scale precision fabrication. Distribution channels are typically Direct, involving manufacturers selling or leasing high-value machinery directly to major infrastructure contractors globally. However, for smaller regional markets or specific projects, indirect channels utilize specialized equipment distributors or rental houses that also provide localized maintenance and support services.

The Downstream Analysis involves the application, maintenance, and end-of-life management of the machines. Once deployed on a project, the MTBM requires specialized on-site operational support, often provided under contract by the manufacturer. Maintenance services, including repair, component replacement (e.g., cutterhead teeth, seals), and machine refurbishment, constitute a significant post-sales revenue stream. End-users (contractors) prioritize reliability and rapid service turnaround to minimize expensive project delays. The effectiveness of the overall value chain relies on seamless integration between manufacturers and geotechnical experts to ensure the selected machinery is optimally suited for the specific geological challenges of the project site, maximizing operational success and equipment longevity.

Microtunnel Machine Market Potential Customers

The primary customers for Microtunnel Machine technology are large civil engineering and infrastructure construction firms specializing in underground utility installation and trenchless technology. These customers typically operate regionally or globally and possess the significant capital required to invest in or lease advanced MTBMs. Their projects are often commissioned by public sector entities, making municipal and governmental agencies the ultimate beneficiaries and drivers of demand, particularly concerning water, wastewater, and urban transit infrastructure. The decision-makers within these construction firms prioritize machine reliability, technical support, project case studies demonstrating success in challenging ground conditions, and the ability to achieve precise line and grade specifications over long distances.

A second major customer base includes specialized utility companies, particularly those involved in installing major transmission pipelines for oil, gas, or large-diameter water delivery systems across environmentally sensitive or heavily developed corridors. For these customers, the non-disruptive nature of microtunneling is paramount, as regulatory compliance dictates methods that minimize disturbance to existing ecosystems or surrounding infrastructure. They often look for customized solutions tailored to specific pipe materials (e.g., concrete cylinder pipe, steel casing pipe) and geological constraints, seeking partnerships with manufacturers who offer comprehensive project planning and risk assessment services alongside the machinery itself.

Finally, equipment rental and leasing companies represent a growing segment of potential customers, especially those serving smaller or mid-sized contractors who cannot justify the outright purchase of an MTBM for infrequent project usage. These companies serve as crucial intermediaries, enabling broader access to microtunneling technology. Their purchasing decisions are driven by factors such as machine versatility (ability to handle different diameters and soils), ease of transport and assembly, and high resale value. Manufacturers focusing on modular designs and robust maintenance plans are best positioned to capture this segment, ensuring their machines remain viable assets through multiple project cycles and different end-users.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Herrenknecht AG, Akkerman Inc., Iseki Poly-Tech Corp., Robbins Company, LOVAT Tunnel Equipment, Permalok Corporation, Barbco Inc., Mitsubishi Heavy Industries, Hitachi Zosen Corporation, XCMG, CRCHI, Tunnelling Equipment Specialists (TES), Trelleborg AB, Normet Group, Komatsu Ltd., Kawasaki Heavy Industries, Boretec Inc., Sunward Equipment Group, Wirth Group, Vermeer Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Microtunnel Machine Market Key Technology Landscape

The technological landscape of the Microtunnel Machine Market is characterized by continuous refinement aimed at increasing operational speed, improving accuracy, and enhancing safety. Core technological components include sophisticated Guidance Systems, which have evolved from basic laser and optical systems to highly precise inertial navigation systems (INS) utilizing gyroscopes and inclinometers. This advancement allows for tunneling with superior accuracy over greater lengths and navigating complex, non-linear alignments required beneath dense urban infrastructure. Furthermore, real-time data acquisition systems (DAS) integrate hundreds of sensors on the MTBM, monitoring cutterhead torque, thrust pressure, slurry density, and ground stability metrics, transmitting data instantaneously to surface control cabins for immediate operational decision-making.

Another crucial area of innovation is Cutterhead Technology. Manufacturers are developing highly specialized and versatile cutterheads that can rapidly adapt to mixed-face conditions, such as transitioning from soft soil to fractured rock within a single drive. Hybrid cutterheads and interchangeable tool systems minimize the need for costly and time-consuming mid-drive maintenance interventions. Alongside this, the efficiency of Slurry and Spoil Removal Systems is being maximized. Advanced separation plants on the surface utilize hydrocyclones and specialized polymer injection techniques to process excavated material more efficiently, reducing environmental impact and minimizing disposal costs associated with spoil management, particularly for projects handling contaminated soil.

Automation and remote control are rapidly becoming standard technologies. Modern MTBMs are increasingly operated from sophisticated surface control rooms, reducing personnel exposure to potentially hazardous underground conditions. This trend is supported by robust communication technologies, often utilizing fiber optics and secure wireless protocols, ensuring uninterrupted control and data flow over long tunneling distances. The integration of Building Information Modeling (BIM) software with MTBM guidance systems allows for precise virtual simulation and clash detection prior to excavation, leading to better project planning and risk mitigation, defining the forefront of current technological adoption in the microtunneling sector.

Regional Highlights

The performance and growth drivers of the Microtunnel Machine Market vary significantly across geographical regions, reflecting differences in infrastructure age, urbanization rates, and regulatory environments.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market globally, driven by massive infrastructure expansion across China, India, and Southeast Asia. The demand is particularly high in megacities undertaking large-scale sewer, subway, and utility network extensions. Government initiatives focusing on smart city development and rapid urbanization fuel the need for high-efficiency trenchless methods to minimize disruption. Investments here often favor large-diameter machines due to the scale of new projects.

- North America (NA): The North American market is characterized by robust, ongoing infrastructure replacement cycles. The focus is primarily on rehabilitating aging water, sewer, and gas distribution networks installed decades ago, particularly in urban cores of the US and Canada. The region demands highly reliable machines capable of navigating complex, pre-existing underground utilities. High labor costs also drive the adoption of more automated and efficient MTBM systems.

- Europe: Europe is a mature market exhibiting stable growth, highly concentrated on environmental compliance and strict regulations governing groundwater protection and surface disruption. Countries like Germany, the UK, and the Netherlands lead in adopting sophisticated microtunneling techniques for water management and sensitive river crossings. The emphasis is on precision, safety, and specialized slurry separation technologies to meet stringent environmental discharge standards.

- Latin America (LATAM): Growth in LATAM is emerging, concentrated mainly in economic hubs like Brazil, Mexico, and Chile. Market expansion is closely tied to municipal funding for sanitation and water access projects. While capital constraints can favor localized or older equipment, the necessity for modern infrastructure is creating long-term opportunities, particularly for manufacturers offering flexible financing and robust technical training programs.

- Middle East and Africa (MEA): The MEA region shows strong potential, particularly in the Gulf Cooperation Council (GCC) states, driven by mega-construction projects, rapid desalination plant connections, and the expansion of oil and gas pipelines. Projects often involve challenging high-temperature, highly abrasive desert sands, requiring MTBMs with specialized sealing technology and robust cooling systems. Africa's market remains nascent but is poised for growth as urbanization accelerates in key economic centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Microtunnel Machine Market.- Herrenknecht AG

- Akkerman Inc.

- Iseki Poly-Tech Corp.

- Robbins Company

- LOVAT Tunnel Equipment

- Permalok Corporation

- Barbco Inc.

- Mitsubishi Heavy Industries

- Hitachi Zosen Corporation

- XCMG

- CRCHI

- Tunnelling Equipment Specialists (TES)

- Trelleborg AB

- Normet Group

- Komatsu Ltd.

- Kawasaki Heavy Industries

- Boretec Inc.

- Sunward Equipment Group

- Wirth Group

- Vermeer Corporation

Frequently Asked Questions

Analyze common user questions about the Microtunnel Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is microtunneling and how does it differ from traditional tunneling?

Microtunneling is a trenchless construction method utilizing a remote-controlled Microtunnel Boring Machine (MTBM) to install pipes (pipe jacking) precisely to a specified line and grade. Unlike traditional tunneling, MTBMs are typically un-manned, significantly smaller, and designed specifically for utility installation (sewer, water lines) with minimal surface disruption and high positional accuracy.

Which factors are driving the current growth of the Microtunnel Machine Market?

The market is primarily driven by three factors: increasing global urbanization, necessitating non-disruptive construction methods; the massive need to replace or upgrade aging water and sanitation infrastructure, particularly in North America and Europe; and the implementation of stricter environmental regulations favoring trenchless technologies over open-cut excavation.

What is the technological difference between Slurry MTBMs and Earth Pressure Balance (EPB) MTBMs?

Slurry MTBMs are optimized for granular soils and high water tables, using fluid pressure at the face to balance earth pressure and transport excavated material (spoil) back to the surface via a slurry line. EPB MTBMs are designed for cohesive or mixed soils, using the excavated material itself to create a plug that maintains face stability by balancing applied pressure against surrounding ground pressure.

How is Artificial Intelligence (AI) impacting the efficiency of microtunneling operations?

AI primarily impacts efficiency through two pathways: predictive maintenance, which reduces unplanned downtime by forecasting equipment failure based on sensor data analysis, and advanced guidance systems, which use AI algorithms to automatically adjust machine steering and operational parameters in real-time for improved line and grade accuracy.

What are the main constraints limiting the widespread adoption of microtunneling technology?

The primary constraints are the exceptionally high initial capital investment required for purchasing and mobilizing Microtunnel Boring Machines and the critical shortage of specialized geotechnical engineers and skilled operators needed to manage and execute complex microtunneling projects successfully.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager