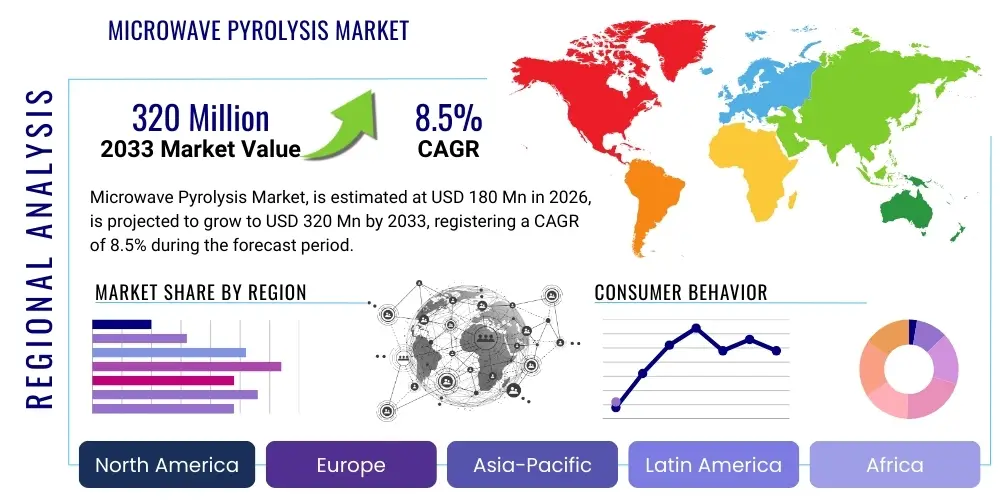

Microwave Pyrolysis Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435372 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Microwave Pyrolysis Market Size

The Microwave Pyrolysis Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 180 Million in 2026 and is projected to reach USD 320 Million by the end of the forecast period in 2033.

Microwave Pyrolysis Market introduction

Microwave pyrolysis represents a cutting-edge thermal decomposition technology utilized for processing organic feedstocks, such as biomass, plastic waste, and sewage sludge, in an oxygen-free or inert environment. Unlike conventional pyrolysis methods that rely on external heating systems, microwave pyrolysis uses electromagnetic energy to directly heat the feedstock volume, leading to rapid, uniform heating and highly efficient energy transfer. This targeted heating capability results in superior reaction kinetics, often yielding higher quality products, including bio-oil, biochar, and non-condensable gases like syngas, which are valuable for energy generation or chemical synthesis. The primary advantage lies in its energy efficiency and ability to handle diverse waste streams, contributing significantly to circular economy initiatives and sustainable resource management.

The core product outputs of this technology—bio-oil, biochar, and syngas—are increasingly sought after across industrial sectors. Bio-oil serves as a potential substitute for petroleum-derived fuels or as a chemical intermediate, while biochar finds extensive use in soil amendment, carbon sequestration, and material science applications due to its high surface area and stability. Syngas, composed mainly of hydrogen, carbon monoxide, and methane, is a reliable source for heat, power generation, or subsequent synthesis processes like Fischer-Tropsch. The technology’s scalability and modular design further enhance its attractiveness for localized waste processing centers and industrial facilities aiming to reduce carbon footprints and monetize waste streams effectively.

Major applications driving market growth include waste-to-energy conversion, waste tire recycling, and the valorization of agricultural and forestry residues. Key benefits encompass enhanced energy efficiency, reduced processing time, better control over product distribution, and significantly lower emissions compared to incineration or traditional thermal processing. The market is driven by stringent environmental regulations mandating waste diversion from landfills, increasing demand for sustainable energy sources, and technological advancements that improve the reliability and throughput capacity of microwave pyrolysis reactors.

- Product Description: Thermal decomposition of organic materials using electromagnetic energy in an inert atmosphere to produce bio-oil, biochar, and syngas.

- Major Applications: Sustainable waste management (plastics, tires, sludge), renewable energy production, and chemical feedstock generation.

- Benefits: High energy efficiency, rapid heating rates, superior product quality control, and environmental compliance.

- Driving Factors: Growing global waste generation, government mandates favoring renewable fuels, and increasing investment in sustainable waste valorization technologies.

Microwave Pyrolysis Market Executive Summary

The Microwave Pyrolysis Market is experiencing robust expansion, fundamentally driven by pervasive global sustainability mandates and the critical need for efficient, decentralized waste processing solutions. Key business trends indicate a significant shift towards modular and containerized microwave pyrolysis systems, making the technology accessible for small to medium-scale enterprises and remote locations. Strategic partnerships between technology developers and waste management companies are accelerating commercialization, focusing particularly on high-value waste streams such as medical plastic waste and high-density polyethylene. Furthermore, increased venture capital funding is being directed toward optimizing catalyst usage within the microwave pyrolysis process to improve the yield and selectivity of specific chemical components in the bio-oil fraction, thereby enhancing the overall economic viability of the operations.

Regional trends reveal that Asia Pacific (APAC) is poised to lead market growth, spurred by rapid industrialization, high rates of waste generation, and proactive government policies, particularly in China and India, aiming to integrate waste-to-energy projects. North America and Europe maintain technological leadership, focusing on regulatory frameworks that standardize bio-product quality and incentivize the use of biochar for carbon sequestration credits. Investment in R&D across these regions is concentrated on scaling up reactor capacity and developing hybrid systems that combine microwave heating with traditional conductive heating to maximize energy utilization efficiency and reduce operational costs associated with electricity consumption.

Segmentation analysis highlights that the plastic waste feedstock segment is expected to exhibit the fastest growth, primarily due to the global plastic pollution crisis and emerging extended producer responsibility (EPR) schemes that necessitate advanced recycling technologies. The bio-oil product segment dominates in terms of revenue, driven by its potential use in marine and heavy transportation sectors seeking low-sulfur fuel alternatives. Conversely, the biochar segment is gaining traction in the agricultural sector, where its application as a soil amendment enhances crop yield and drought resistance, simultaneously offering significant ecological benefits through carbon drawdown. These trends collectively underscore the transition of microwave pyrolysis from a niche research focus to a mainstream industrial solution for sustainable resource recovery.

AI Impact Analysis on Microwave Pyrolysis Market

Common user questions regarding AI's influence on the Microwave Pyrolysis Market center on optimizing complex reactor conditions, predicting product yields based on feedstock variability, and enhancing process safety and automation. Users frequently inquire about how machine learning algorithms can manage the rapid temperature changes inherent in microwave heating and how predictive analytics can forecast equipment failure in high-stress thermal environments. The primary user expectation is that AI will transform microwave pyrolysis from a batch process with variable outcomes into a highly automated, continuous system characterized by maximum efficiency and consistency. The integration of advanced sensor technology combined with neural networks promises to stabilize product output quality, dynamically adjust microwave power input based on real-time feedstock composition analysis, and significantly reduce human intervention in monitoring and operational adjustments, leading to substantial reductions in operating expenditures and enhancing throughput reliability.

- AI facilitates real-time monitoring and dynamic control of microwave power delivery, optimizing energy efficiency.

- Machine learning models predict optimal reaction temperatures and residence times based on heterogeneous feedstock properties.

- Predictive maintenance algorithms minimize downtime by forecasting potential failures in high-temperature reactor components.

- AI enhances product quality control by correlating input conditions with real-time analysis of bio-oil and syngas composition.

- Automated optimization leads to higher yields of desired end-products (e.g., specific hydrocarbon chains from plastic pyrolysis).

DRO & Impact Forces Of Microwave Pyrolysis Market

The market is profoundly influenced by a confluence of accelerating drivers, structural restraints, and emerging opportunities, collectively shaping the direction and pace of market evolution. Key drivers include the overwhelming global volume of challenging waste streams, such as end-of-life tires and mixed plastic residues, coupled with governmental mandates that prioritize waste diversion and the adoption of circular economy principles across industrialized nations. The energy density and quality of the output products, particularly high-grade bio-oil suitable for advanced refining, also serve as a strong commercial impetus, attracting significant investment from the chemical and energy industries seeking renewable alternatives. Furthermore, the inherent advantages of microwave technology, such as faster heating and the capability for localized, decentralized processing, align perfectly with modern sustainability goals requiring distributed energy generation.

However, the market faces notable restraints that challenge widespread adoption. The substantial initial capital investment required for installing microwave pyrolysis reactors and the necessity for specialized operational expertise remain critical barriers, particularly for smaller enterprises. Moreover, the high operational cost attributed to electricity consumption for generating microwave energy can sometimes diminish the economic competitiveness against mature, conventional pyrolysis and gasification technologies. Consistency in feedstock quality, which is vital for maintaining steady reactor performance and predictable product yields, also presents a logistical challenge, especially when dealing with highly variable municipal solid waste streams. Addressing these cost and operational hurdles through technological scaling and improved energy recovery systems is essential for sustained growth.

Opportunities for market expansion are abundant, centered primarily on the application of microwave pyrolysis to specific, high-value waste streams previously deemed uneconomical, such as electronic waste and certain types of medical waste. The growing carbon credit market provides a compelling economic incentive, as biochar derived from the process offers verifiable carbon sequestration benefits, creating an additional revenue stream beyond standard product sales. Furthermore, technological innovation focusing on continuous processing systems, rather than traditional batch reactors, and the integration of novel microwave-absorbing catalysts are expected to drastically improve throughput and overall economic efficiency, solidifying the technology's role in the future landscape of sustainable resource recovery and advanced waste management solutions.

- Drivers: Increasing plastic and tire waste volumes, strict environmental regulations on landfilling, and rising demand for sustainable biofuels and biochar products.

- Restraints: High initial capital expenditure, high operational energy costs, and challenges in maintaining consistent feedstock quality for continuous operation.

- Opportunities: Integration into carbon credit markets via biochar production, development of modular, decentralized processing units, and valorization of specialty industrial wastes.

- Impact Forces: Technological advancements in reactor design, evolving regulatory standards for bio-product utilization, and fluctuating fossil fuel prices influencing demand for bio-oil.

Segmentation Analysis

The Microwave Pyrolysis Market is comprehensively segmented based on the type of feedstock processed, the nature of the end-product generated, the capacity of the reactor deployed, and the specific application areas utilizing the technology. This granular segmentation provides critical insights into market dynamics, highlighting areas of high growth potential and technological focus. Analyzing feedstock segmentation reveals the market's dependence on sustainable raw materials, with biomass (including agricultural and forestry residues) historically dominating due to its abundance and carbon neutrality, though plastic waste is rapidly gaining prominence driven by recycling mandates.

Product segmentation underscores the varying revenue streams, where the demand for bio-oil, driven by the transportation and chemical sectors, significantly influences pricing and investment strategies. Meanwhile, the growing interest in circular economy metrics boosts the biochar segment, which provides long-term environmental benefits. Application segmentation further distinguishes between end-use industries, showing robust adoption in waste management infrastructure and emerging opportunities in the production of specialized chemicals derived from bio-oil upgrading processes.

- By Feedstock Type:

- Biomass (Agricultural Residues, Forestry Waste, Energy Crops)

- Plastic Waste (PE, PP, PS, PVC, Mixed Plastics)

- Sewage Sludge

- Rubber Waste (End-of-Life Tires)

- Industrial and Food Processing Waste

- By Product Type:

- Bio-Oil / Pyrolysis Oil

- Biochar

- Syngas

- By Reactor Capacity:

- Small-Scale (Below 1 Ton/Day)

- Medium-Scale (1–10 Tons/Day)

- Large-Scale (Above 10 Tons/Day)

- By Application:

- Energy Generation (Heat and Power)

- Chemical Production (Platform Chemicals, Fuel Additives)

- Waste Management and Remediation

- Agriculture and Soil Amendment

Value Chain Analysis For Microwave Pyrolysis Market

The value chain for the Microwave Pyrolysis Market begins with the upstream sourcing and preparation of diverse feedstocks. This stage involves sophisticated logistics for collecting, sorting, and pre-treating materials like agricultural waste, industrial plastics, or sludge. Effective pre-treatment, often involving shredding, drying, and homogenization, is crucial as the efficiency of microwave heating is highly sensitive to the moisture content and particle size distribution of the feedstock. Key upstream participants include specialized feedstock aggregators, waste collection companies, and equipment manufacturers providing dryers and shredders designed for resilient, high-volume operation. The complexity of managing heterogeneous waste streams necessitates robust sorting technologies, often leveraging AI and sensor-based systems to ensure optimal material flow into the reactor.

The central stage of the value chain involves the technology providers who design, manufacture, and install the specialized microwave pyrolysis reactors. These companies hold proprietary knowledge regarding reactor design (e.g., fixed-bed, fluidized-bed, or rotary kilns adapted for microwave frequency), magnetron systems, and heat recovery mechanisms. Following the pyrolysis process, the downstream segment focuses on the separation, refinement, and monetization of the three primary products: bio-oil, biochar, and syngas. Bio-oil often requires extensive upgrading (e.g., hydrotreating or catalytic cracking) to meet fuel or chemical specifications, involving specialized chemical refineries. Syngas is typically consumed on-site for internal energy needs or sold to nearby industrial consumers.

Distribution channels for the final products are bifurcated into direct and indirect routes. Bio-oil and syngas are frequently sold directly to large industrial off-takers, such as power utilities, petrochemical producers, or specialized chemical companies through long-term supply agreements. Biochar, conversely, typically relies on indirect distribution channels, utilizing agricultural product suppliers, wholesale fertilizer distributors, and specialized environmental remediation firms. Direct distribution requires high volume and consistent quality assurance, while indirect channels necessitate careful packaging, certification, and robust marketing efforts to educate end-users on the specific benefits of the biochar product, including its carbon sequestration properties and soil health advantages.

Microwave Pyrolysis Market Potential Customers

The potential customer base for the Microwave Pyrolysis Market is highly diversified, spanning multiple industrial sectors focused on sustainable waste management, renewable energy, and chemical production. Primary end-users include municipal solid waste (MSW) management facilities and environmental services companies seeking advanced, high-efficiency technologies to divert organic and plastic waste from landfills and comply with increasingly strict disposal regulations. These entities are drawn to microwave pyrolysis for its ability to handle difficult or mixed waste streams and generate valuable co-products, turning a disposal cost center into a potential revenue source. The modular nature of the technology appeals to decentralized urban planning strategies requiring localized waste processing capabilities.

Another significant customer segment comprises the energy and power generation sectors, including independent power producers and industrial sites requiring reliable, localized heat and power. These customers primarily purchase the syngas and high-calorific value bio-oil produced by the pyrolysis process, utilizing them as direct fuel sources or blending components to reduce reliance on fossil fuels. Furthermore, the agricultural and construction industries represent a growing market, particularly for biochar. Farmers, agricultural cooperatives, and soil remediation companies purchase biochar for its soil conditioning, water retention, and carbon sequestration properties, linking the microwave pyrolysis industry directly to sustainable food production and environmental restoration projects.

Finally, the chemical and petrochemical industries constitute a premium customer segment, purchasing upgraded bio-oil for use as sustainable chemical intermediates. Companies focused on specialty chemicals, polymers, and advanced materials are increasingly interested in the specific hydrocarbon composition derived from plastic pyrolysis, viewing these fractions as drop-in sustainable alternatives to crude oil derivatives. These commercial end-users often require high purity and consistent product specification, driving technology providers to focus heavily on catalytic upgrading processes integrated into the microwave pyrolysis system, thereby cementing the technology’s position as a crucial component of future sustainable chemical manufacturing chains.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 180 Million |

| Market Forecast in 2033 | USD 320 Million |

| Growth Rate | CAGR 8.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pyrochem, Clean Pyrolysis Solutions, Pyreg GmbH, BTG Biomass Technology Group, Ensyn Corporation, Diacarbon Energy Inc., Agilyx Corporation, Cynar Plc, Beston Machinery, New Energy Systems, Advanced Biofuels USA, Green Waste Energy, RadMax Technologies, Inc., EESI Group, Renewable Algal Energy, Karrabing Environmental Solutions, OMNI Conversion Technologies, Inc., Genesis Energy, Inc., Brightmark Energy, Alternative Petroleum Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Microwave Pyrolysis Market Key Technology Landscape

The technological landscape of the Microwave Pyrolysis Market is defined by continuous innovation focused primarily on optimizing heating uniformity, improving product selectivity, and enhancing system energy recovery. The core technology involves the use of specialized microwave generators (magnetrons or solid-state sources) operating typically in the ISM frequency bands (2.45 GHz or 915 MHz) to induce rapid dielectric heating within the feedstock. A critical technological distinction lies in the reactor design, which must effectively couple the microwave energy into the material. Fixed-bed, moving-bed, and continuous screw reactors are commonly employed, with continuous systems gaining prominence for industrial-scale operations due to their consistent throughput capabilities and enhanced automation potential.

A significant area of technological advancement involves the incorporation of microwave-absorbing catalysts or additives, such as activated carbon, silicon carbide, or specific metal oxides, mixed directly with the feedstock. These additives act as susceptors, rapidly heating up and transferring thermal energy conductively and radiatively to the surrounding organic matter, thereby improving the efficiency of the decomposition reaction and mitigating the poor dielectric properties of certain feedstocks, particularly plastics. Furthermore, these catalysts can be tailored to specifically cleave hydrocarbon chains into desired shorter fractions, optimizing the quality and market value of the resulting bio-oil for specific chemical applications rather than just fuel use. The development of robust, cost-effective susceptor materials remains a cornerstone of current R&D efforts in the field.

In addition to core reactor optimization, the technological landscape includes sophisticated downstream processing and energy integration techniques. Modern microwave pyrolysis systems are increasingly incorporating integrated heat exchangers to recover residual heat from the syngas and biochar streams, significantly improving the overall thermal efficiency of the plant and offsetting operational electricity demand. Condensation and fractional distillation systems are also undergoing refinement to efficiently separate the water and acidic components from the crude bio-oil, reducing the need for extensive external upgrading. The shift towards solid-state microwave power sources, replacing traditional magnetrons, offers better control, longer lifespan, and superior energy conversion efficiency, albeit at a higher initial cost, positioning solid-state technology as a key enabler for future high-throughput industrial facilities.

Regional Highlights

The global Microwave Pyrolysis Market exhibits distinct growth patterns influenced by regional regulatory environments, waste infrastructure maturity, and energy security priorities. North America, particularly the United States and Canada, holds a substantial market share, driven by strong governmental support for waste-to-energy projects and significant private sector investment into advanced plastics recycling solutions. The region benefits from established technology providers and an environment conducive to early commercial adoption of novel thermal technologies. Emphasis in North America is placed on developing high-quality biofuels and utilizing biochar for large-scale carbon offsets in agricultural and forestry contexts.

Europe demonstrates high penetration rates, primarily spurred by the stringent European Union directives targeting waste reduction, circular economy mandates, and ambitious renewable energy targets. Countries like Germany, the Netherlands, and Scandinavia are leaders in developing integrated waste management parks where microwave pyrolysis systems are seamlessly incorporated alongside conventional recycling and thermal processes. European market growth is highly focused on utilizing sewage sludge and specific industrial byproducts, aiming for detoxification and resource recovery while adhering to rigorous environmental standards regarding air emissions.

Asia Pacific (APAC) is projected to be the fastest-growing region throughout the forecast period. This rapid expansion is fundamentally linked to the region's escalating urbanization rates, massive generation of municipal and industrial waste, and increasing government recognition of pyrolysis as a viable solution for managing land scarcity for landfills. China, India, and Southeast Asian nations are investing heavily in new waste processing infrastructure. While cost sensitivity remains a factor, the massive scale of feedstock availability, particularly agricultural biomass and post-consumer plastics, provides unparalleled opportunities for large-scale deployment, often supported by public-private partnerships focused on solving critical local pollution issues.

Latin America, the Middle East, and Africa (MEA) represent emerging markets where market penetration is currently lower but exhibits significant potential. Growth in these regions is driven by specific energy needs and the necessity to manage challenging resources like oil sludge or vast quantities of agricultural residue that often go unused. Investment here is typically catalyzed by foreign direct investment or international aid focused on developing sustainable energy infrastructure and local capacity building for waste processing. The modularity of microwave pyrolysis is particularly attractive in remote or rapidly developing areas lacking centralized waste handling facilities.

- North America: High technological maturity, strong regulatory support for recycling, and focus on high-value biofuel production and carbon sequestration via biochar.

- Europe: Driven by strict circular economy mandates, high utilization rates for sewage sludge and industrial waste, and emphasis on low-emission process standards.

- Asia Pacific (APAC): Fastest-growing region, fueled by massive waste generation, urbanization challenges, and government investment in large-scale decentralized waste-to-energy solutions.

- Latin America & MEA: Emerging markets with potential growth driven by localized energy demands, increasing need for proper municipal waste disposal, and targeted applications for specific local waste streams.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Microwave Pyrolysis Market.- Pyrochem

- Clean Pyrolysis Solutions

- Pyreg GmbH

- BTG Biomass Technology Group

- Ensyn Corporation

- Diacarbon Energy Inc.

- Agilyx Corporation

- Cynar Plc

- Beston Machinery

- New Energy Systems

- Advanced Biofuels USA

- Green Waste Energy

- RadMax Technologies, Inc.

- EESI Group

- Renewable Algal Energy

- Karrabing Environmental Solutions

- OMNI Conversion Technologies, Inc.

- Genesis Energy, Inc.

- Brightmark Energy

- Alternative Petroleum Technologies

Frequently Asked Questions

Analyze common user questions about the Microwave Pyrolysis market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of microwave pyrolysis over conventional thermal methods?

The primary advantage of microwave pyrolysis is its ability to achieve rapid and volumetric heating of the feedstock, leading to significantly higher energy efficiency and superior control over reaction kinetics. This targeted heating often results in higher yields of specific products, such as high-grade bio-oil, compared to slow, externally heated conventional systems.

How does biochar produced by microwave pyrolysis contribute to the circular economy?

Biochar generated via microwave pyrolysis is a stable, carbon-rich solid that serves multiple roles in the circular economy. It sequesters carbon permanently when applied to soil, enhances soil fertility and water retention, and reduces the need for synthetic fertilizers, effectively closing the loop on organic waste streams and providing verifiable carbon offset credits.

What are the key feedstocks driving commercial adoption in the microwave pyrolysis market?

The key feedstocks driving commercial adoption include various forms of challenging waste, specifically mixed plastic waste (due to global recycling mandates), end-of-life tires (due to high energy content), and abundant agricultural and forestry biomass residues. Processing these difficult materials efficiently provides immediate environmental and economic benefits.

What major challenges constrain the large-scale implementation of microwave pyrolysis technology?

Major challenges include the high upfront capital investment required for specialized microwave reactor infrastructure, the substantial operational cost associated with high electricity consumption, and the critical need to ensure consistent, homogenized feedstock quality to maintain stable and continuous reactor performance.

In which geographical region is the Microwave Pyrolysis Market expected to see the fastest growth rate?

The Asia Pacific (APAC) region is forecasted to exhibit the fastest growth rate, driven by enormous volumes of waste generation resulting from rapid industrialization and urbanization, combined with strong governmental initiatives in countries like China and India to develop new, decentralized waste-to-energy infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager